check engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1187 of 1681

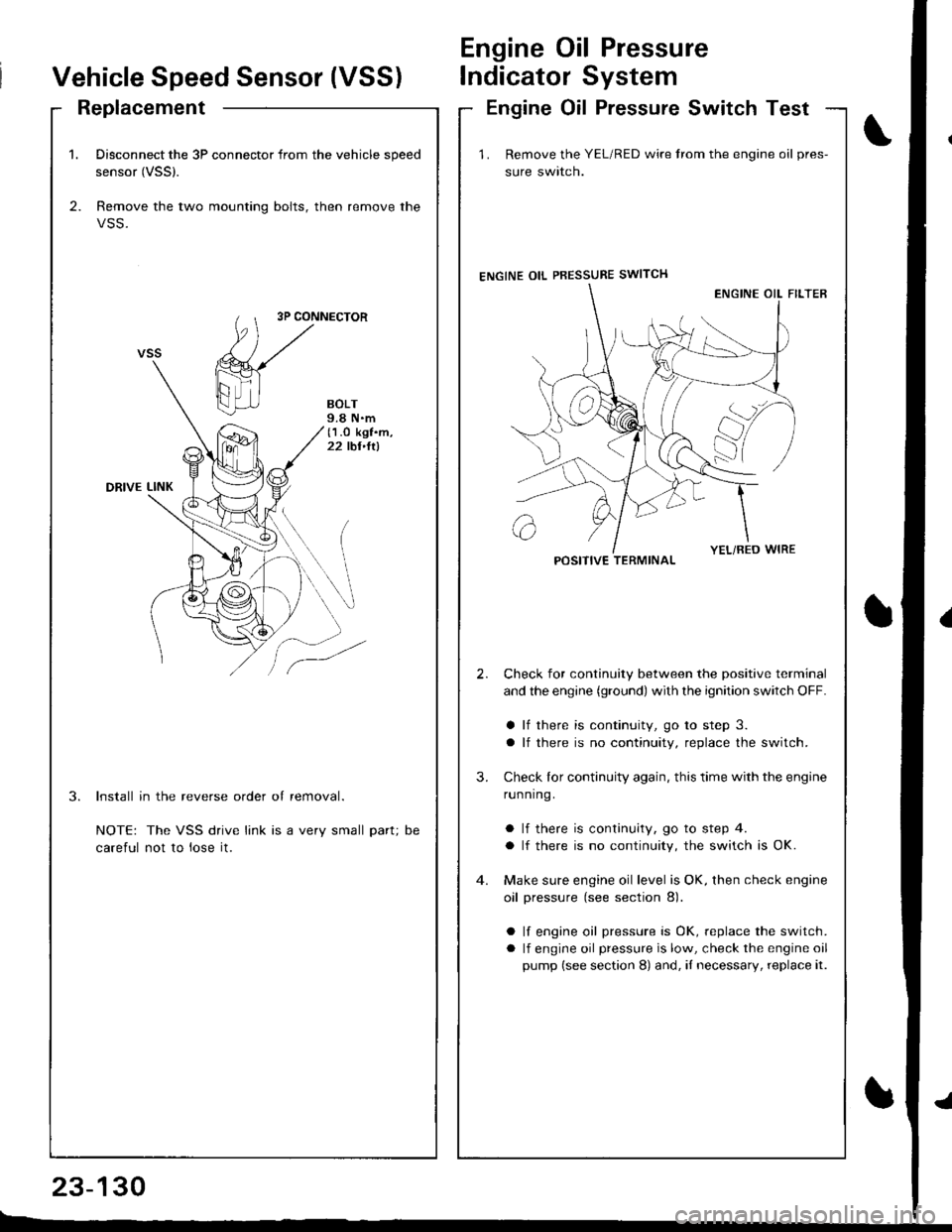

1. Disconnect the 3P connector from the vehicle speed

sensor (VSSl.

2. Remove the two mounting bolts, then remove the

VSS.

3P CONNECTOR

BOLT9.8 N.m(1.O kgf.m,22 tbt,ltl

DRIVE LINK

3.Install in the reverse order of removal.

NOTE: The VSS drive link is a very small part;

careful not to lose it.

DC

Vehicle Speed Sensor (VSS)

Engine Oil Pressure

lndicator System

ReplacementEngine Oil Pressure Switch Test

23-130

E-_

1 . Remove the YEL/RED wire trom the engine oil pres-

sure swlrcn.

ENGINE OIL PBESSURE SWITCH

Check for continuity between the positive terminal

and the engine (ground) with the ignition switch OFF.

a lf there is continuity, go to step 3.

a lf there is no continuity, replace the switch.

Check lor continuity again, this time with the engine

running.

a lf there is continuity, go to step 4.

a lf there is no continuity, the switch is OK.

Make sure engine oil level is OK, then check engine

oil pressure (see section 8).

a lf engine oil pressure is OK, replace the switch.

a lf engine oil pressure is low, check the engine oil

pump (see section 8) and, iI necessary, replace it.

2.

3.

POSITIVE TERMINAL

Page 1191 of 1681

Engine Coolant Temperature (ECT) Gauge

Gauge Test

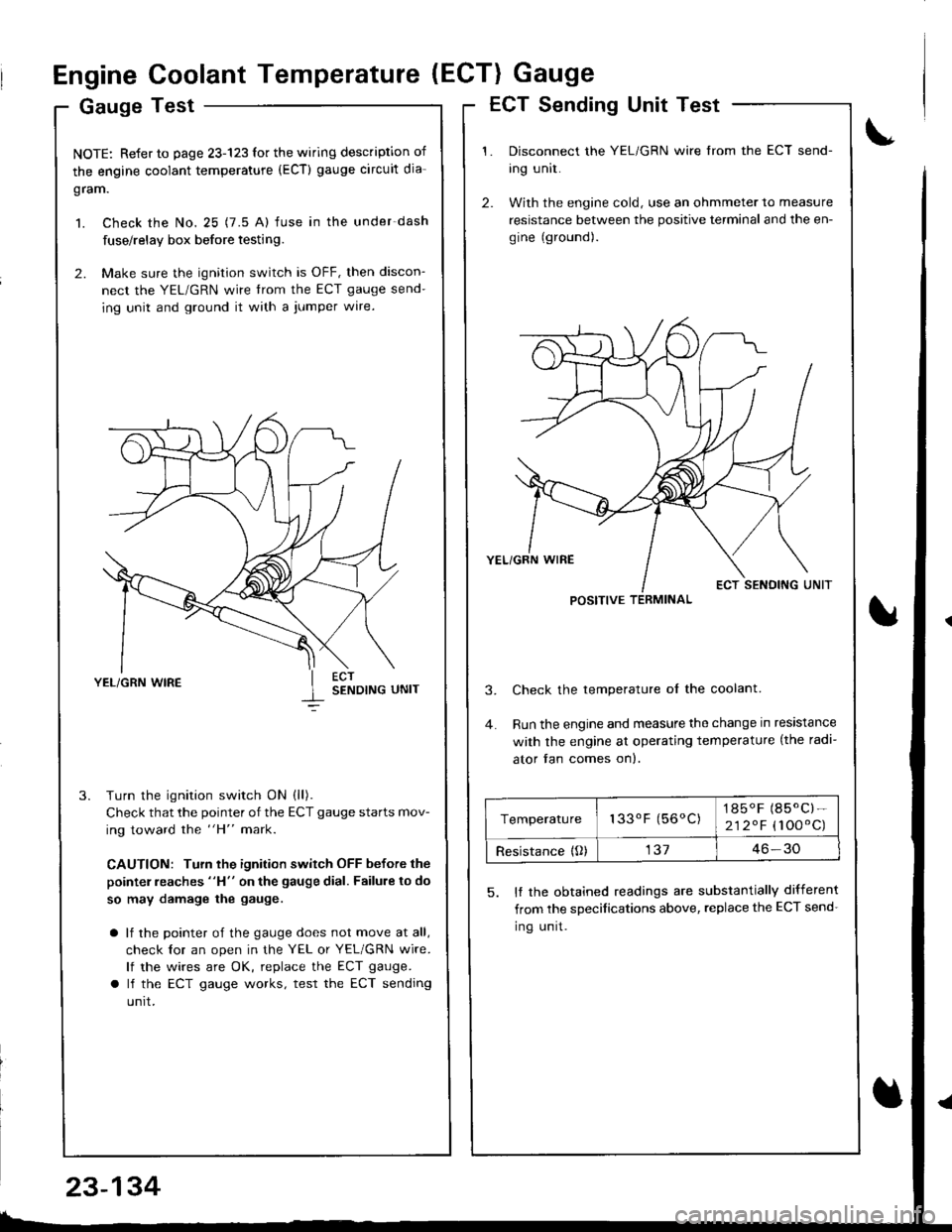

NOTE: Refer to page 23-123 for the wiring description of

the engine coolant temperature (ECT) gauge circuit dia-

gram.

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2. Make sure the ignition switch is OFF, then discon-

nect the YEL/GRN wire trom the ECT gauge send-

ing unit and ground it with a jumper wire.

YEL/GRN WIRESENDING UNIT

Turn the ignition switch ON (ll).

Check that the pointer of the ECT gauge starts mov-

ing toward the "H" mark.

CAUTION: Turn the ignition switch OFF before the

pointer reaches "H" on the gauge dial. Failure to do

so may damage the gauge.

a lf the pointer of the gauge does not move at all,

check lor an open in the YEL or YEL/GRN wire.

lf the wires are OK, replace the ECT gauge.

a lf the ECT gauge works, test the ECT sending

unrt.

ECT Sending Unit Test

Disconnect the YEL/GRN wire from the ECT send-

ing unit.

With the engine cold, use an ohmmeter to measure

resistance between the positive terminal and the en-

gine (ground).

Check the temperature ol the coolant.

Run the engine and measure the change in resistance

with the engine at operating temperature (the radi-

ator fan comes on).

5. It the obtained readings are substantially different

from the sDecifications above, replace the ECT send-

Ing unrt.

POSITIVE TERMINAL

Temperature133oF (56oC)1850F (85.C)-

212.F (100'C)

Resistance {O)13746-30

23-134

Page 1202 of 1681

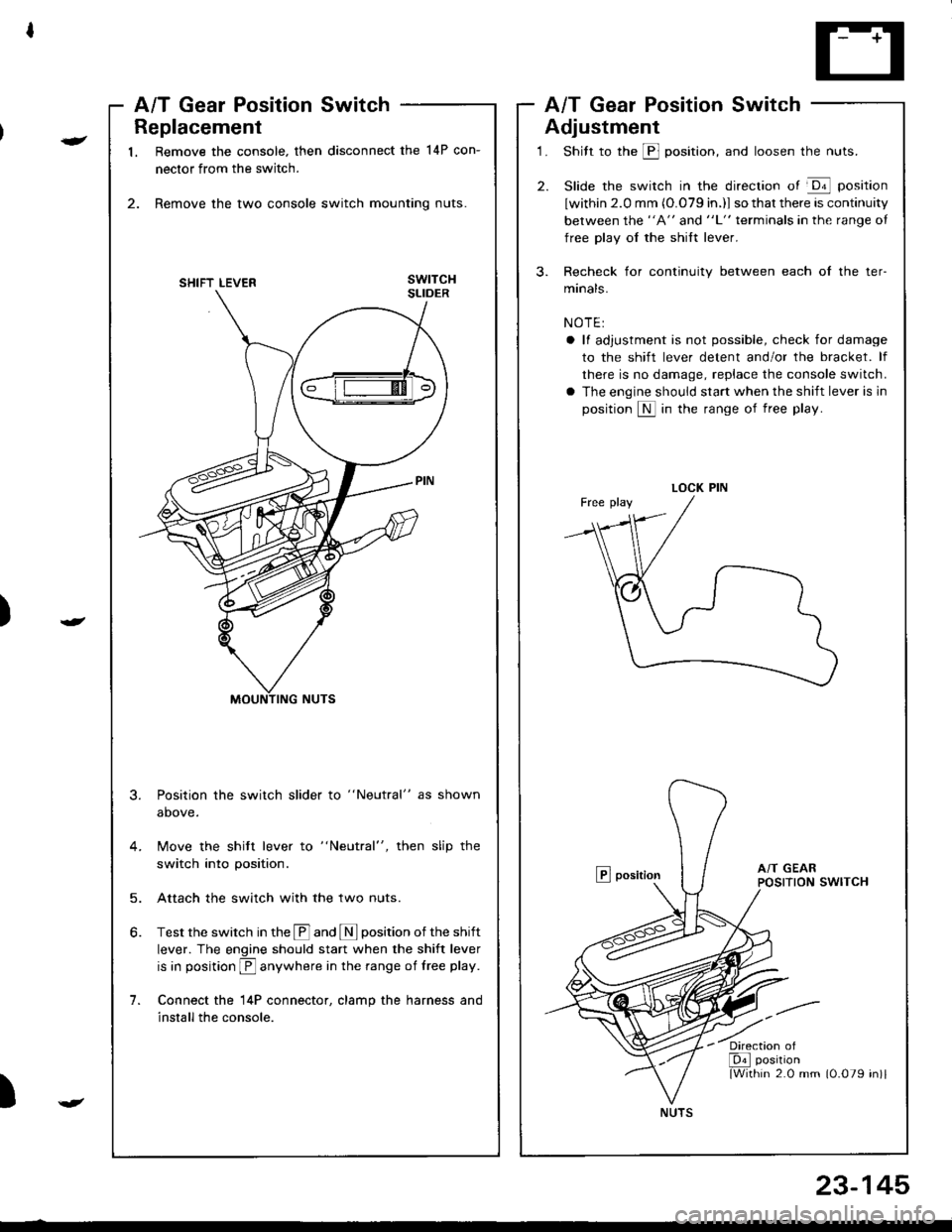

Replacement

1. Remove the console. then disconnect the 14P con-

nector from the switch.

2. Remove the two console switch mounting nuts.

3.

1.

Position the switch slider to "Neutral" as shown

above.

Move the shitt lever to "Neutral", then slip the

switch into position.

Attach the switch with the two nuts.

Test the switch in the @ and I position of the shift

lever. The engine should start when the shift lever

is in position E anywhere in the range of free play.

Connect the l4P connector, clamp the harness and

install the console.

5.

)

-

A/T Gear Position SwitchA/T Gear Position Switch

Adjustment

1. Shitt to the @ position, and loosen the nuts.

2. Slide the switch in the direction of @ position

lwithin 2.0 mm (O.079 in.)l so that there is continuity

between the "A" and "L" terminals in the range oI

free play oI the shift lever.

3. Recheck for continuity between each of the ter-

manals.

NOTE:

a ll adjustment is not possible, check for damage

to the shift lever detent and/or the bracket. lf

there is no damage, replace the console switch.

a The engine should start when the shift lever is in

position S in the range of free play.

E position

)

LOCK PIN

'/ia

NUTS

23-145

Page 1209 of 1681

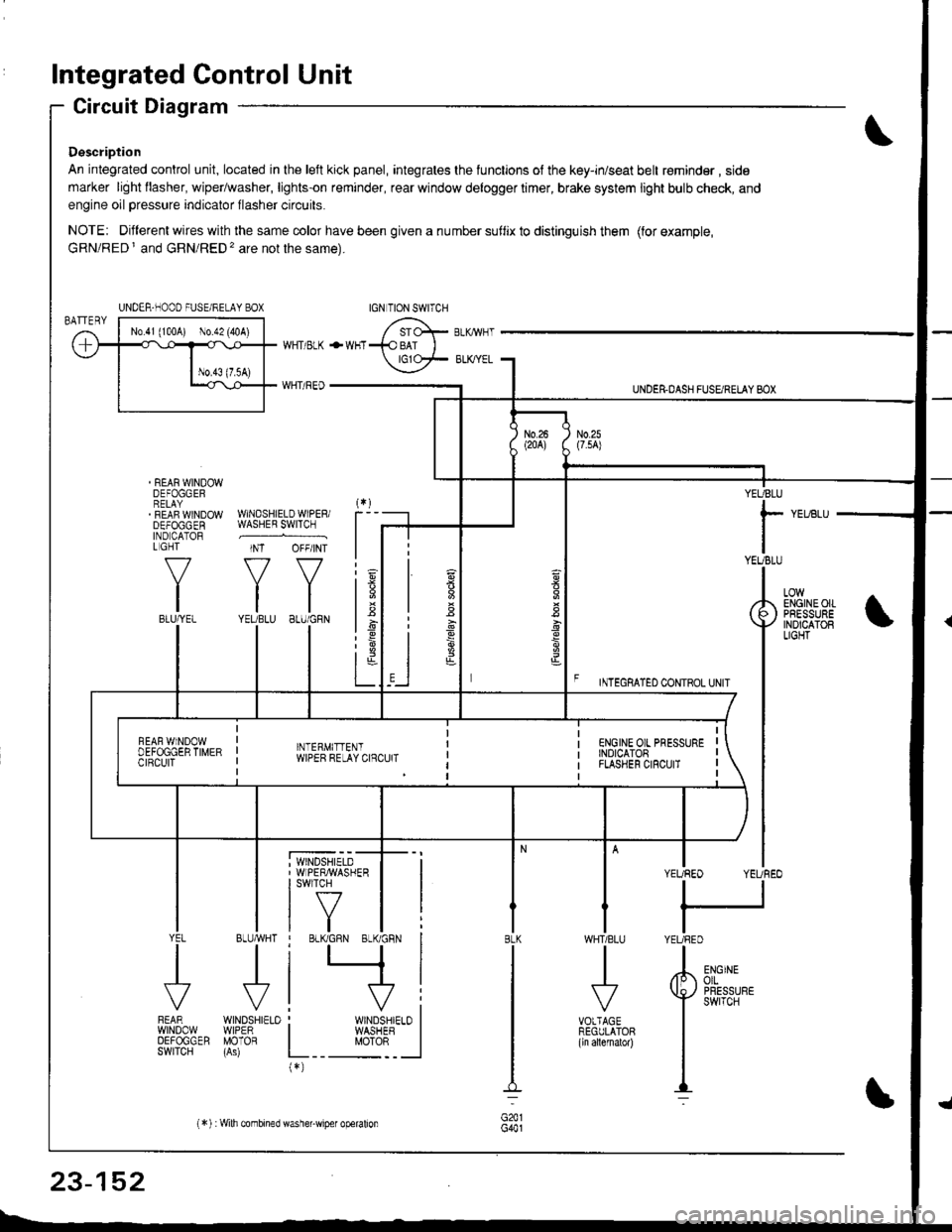

Integrated Control Unit

Circuit Diagram

Description

An integrated control unit, located in lhe left kick panel, integrates the lunctions of the key-in/seat belt r€minder , side

marker light llasher, wiper/washer, lights-on reminder, rear window delogger timer, brake system light bulb check, and

engine oil pressure indicator flasher circuits.

NOTE: Different wires with the same color have been given a nu mber suflix to distinguish them (for example,

GRN/RED I and GRN/RED'� are not the same).

REAR WINDOWDEFOGGERRELAYREAF WINDOWDEFOGGENIND CATORL GHT

f-7

IIBLU/YEL

WHT/ BLK

WHT/ REO

+WHT

WNDSHIELDWIPERiWASHER SWITCH

INT OFF/INT

f7 f7

tltlYEUBLU 8LU/GRN

BLUMHT

J

wtN0sHr€10WIPERMOTOR

UNDER.DASH FUSARETAY BOX

F rmecnlleo counoL ultr

YEUBLU

rYEUBLU

YEUREO YEUREO

tl

IYEURED

LOWENGINEOIIPRESSUREINOICATOBLIGHT

; WINDSHIELD' WIPERMASHERI swlTcH

tf7IVtlYEL

J

FEARwtN00wOEFOGGERSWITCH

WHTIBLU

J

VOTTAGEREGULATOR(ln allernatol)

BLK

G441

ENGINEolLPRESSUREswrTcH

UNDER-NOOO FUSE/RELAY BOX

1.6

:6

t;t-L

i

"'i'- 'i*-

|

I Il

I vi: WINDSHIELO II WASHEB I

L__ "oto: _ __l(*)

n

s

s

,]

23-152

(*) :Wilh combined washer-wiper operalion

Page 1213 of 1681

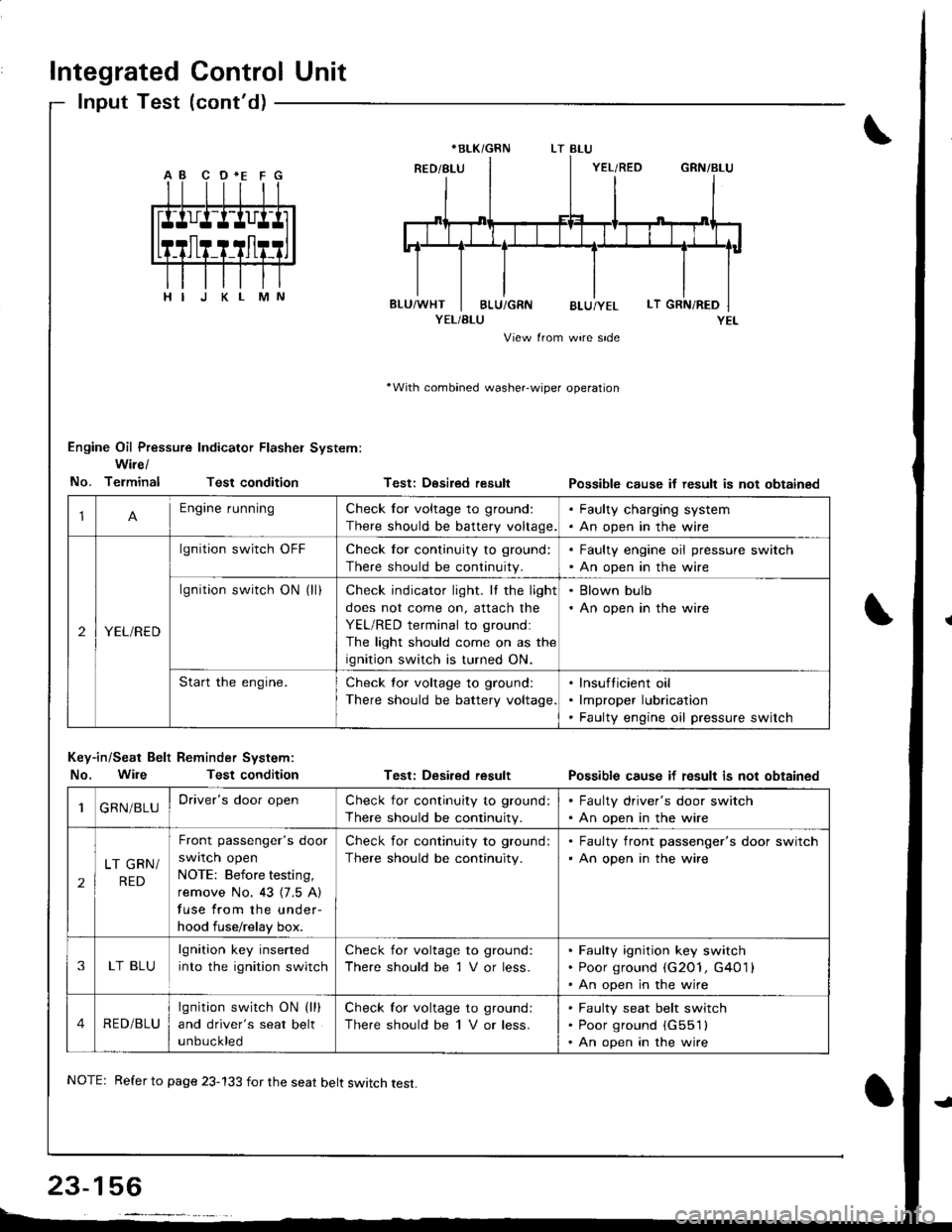

Integrated Control Unit

lnput Test (cont'd)

YEL/BLU

View from wire side

'With combined washer-wiper operation

Engine Oil Pressure Indicator Flasher System:

Wire/

No. TerminalTest condition

Key-in/Seat Belt Reminder System:

No. WileTest condition

Testi Desired result

Test: Desired result

Possible cause if result is not obtainsd

Possible cause if fesult is not obtained

*BLK/GRN

1Engine runningCheck for voltage to ground:

There should be battery voltage.

. Faulty charging system. An open in the wire

2YEL/RED

lgnition switch OFFCheck for continuity to ground:

There should be continuity.

. Faulty engine oil pressure switch. An open in the wire

lgnition switch ON (ll)Check indicator light. It the light

does not come on, attach the

YEL/RED terminal to groundl

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the wire

Start the engine.Check tor voltage to ground:

There should be battery voltage

lnsufticient oil

lmproper lubrication

Faulty engine oil pressure switch

1GRN/BLUDriver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An open in the wire

2

LT GRN/

RED

Front passenger's door

swrlcn open

NOTE: Before testing,

remove No. 43 {7.5 A)

fuse from the under-

hood fuse/relay box.

Check for continuity to ground:

There should be continuity.

. Faulty front passenger's door switch'An open in the wire

3LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G2O1, G401 l

An open in the wire

4RED/BLU

lgnition switch ON (lll

and driver's seat belt

unbuckled

Check for voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground (G551l

An open in the wire

NOTE: Refer to page 23-133 for the seat belt switch test.

Page 1313 of 1681

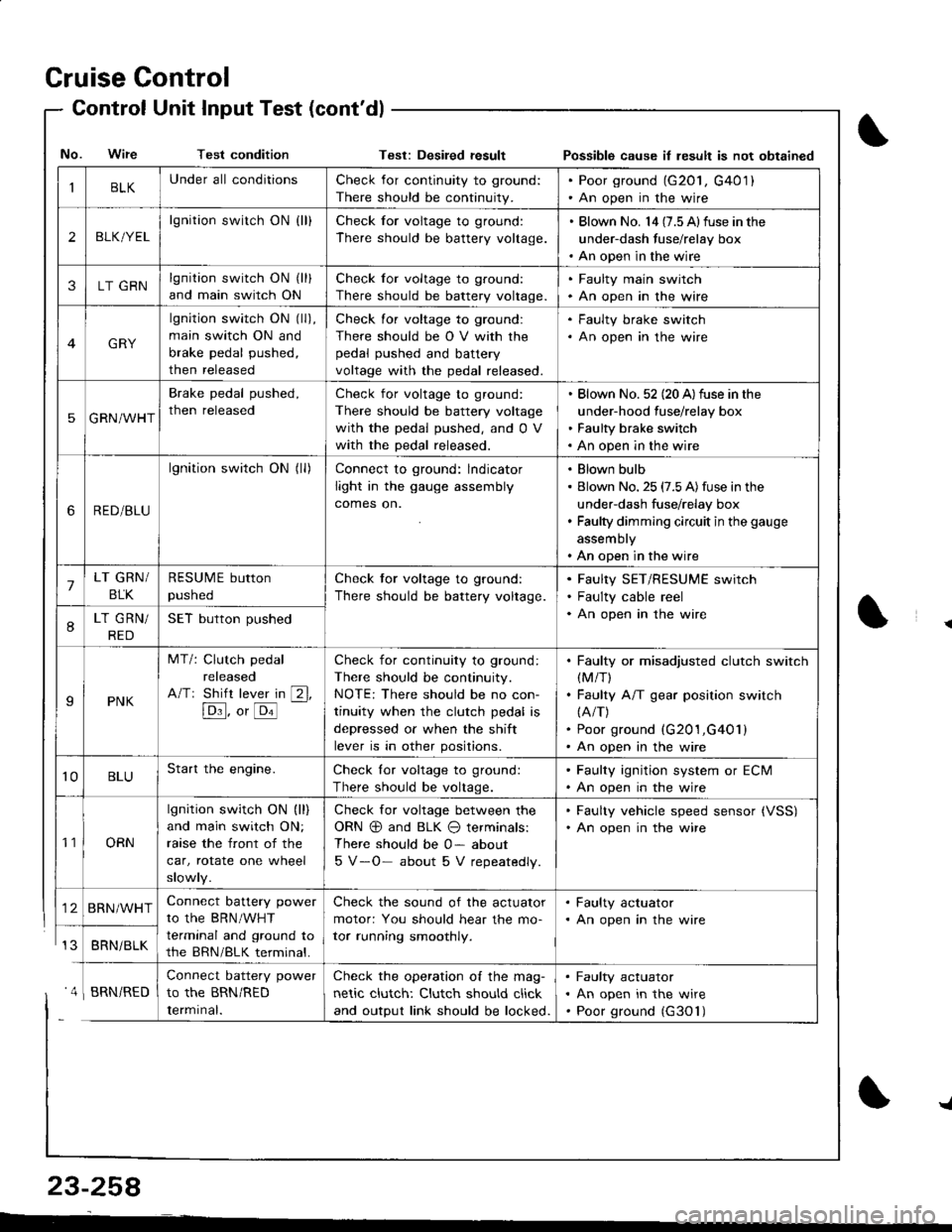

Cruise Control

- Control Unit InputTest(cont'dl

IBLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G20l, G401). An open in the wire

2BLK/YEL

lgnition switch ON {ll}Check for voltage to ground:

There should be battery voltage.

. Blown No. l4 (7.5 Alfuse in the

under-dash fuse/relay box. An open in the wire

3LT GRNlgnition switch ON (ll)

and main switch ON

Check for voltage to ground:

There should be battery voltage.

. Faulty main swjtch. An open in the wire

GRY

lgnition switch ON (ll),

main switch ON and

brake pedal pushed,

then released

Check for voltage to ground:

There should be O V with the

pedal pushed and battery

voltage with the pedal released.

. Faulty brake switch. An open in the wire

5GRN/WHT

Brake pedal pushed,

then released

Check for voltage to ground:

There should be battery voltage

with the pedal pushed, and 0 V

with the pedal released.

Blown No. 52 (20 A)fuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

6RED/BLU

lgnition switch ON (ll)Connect to ground: lndicator

light in the gauge assembly

comes on.

Blown bulb

Blown No. 25 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

7LT GRN/

BLK

RESUME button

pushed

Check tor voltage to ground:

There should be battery voltage.

Faulty SET/RESUME switch

Faulty cable reel

An open in the wire8LT GRN/

RED

SET button pushed

IPNK

MT/: Clutch pedal

released

A/Tr Shift lever in [2l,

[Dl]. o, [o'l

-

Check for continuity to ground:

There should be continuity.

NOTE: There should be no con-

tinuity when the clutch pedal is

depressed or when the shift

lever is in other positions.

Faulty or misadjusted clutch switch(M/T)

Faulty A/T gear position switch(A/T)

Poor ground (G201,G401)

An open in the wire

't0BLUStart the engine.Check lor voltage to ground:

There should be voltage.

. Faulty ignition system or ECM. An open in the wire

't1ORN

lgnition switch ON (ll)

and main switch ON;

raase the front of the

car, rotate one wheel

slowly.

Check for voltage between the

ORN @ and BLK O terminals:

There should be 0- about

5 V-O- about 5 V repeatedly.

. Faulty vehicle speed sensor {VSS). An open in the wire

BRN/WHTConnect battery power

to the BRN/WHT

terminal and ground to

the BRN/BLK terminal.

Check the sound of the actuator

motor: You should hear the mo-

tor running smoothly.

. Faulty actuator. An open in the wire

BRNi BLK

Connect battery power

to the BRN/RED

Iermrnal.

Check the operation of the mag-

netic clutch: Clutch should click

and output link should be locked.

Faulty actuator

An open in the wire

Poor ground (G30'l)

No. Wire Test conditionTest: Desiled result Possible cause il lesult is not obtained

' 4 I BRN/RED

{

{

23-258

-L

Page 1319 of 1681

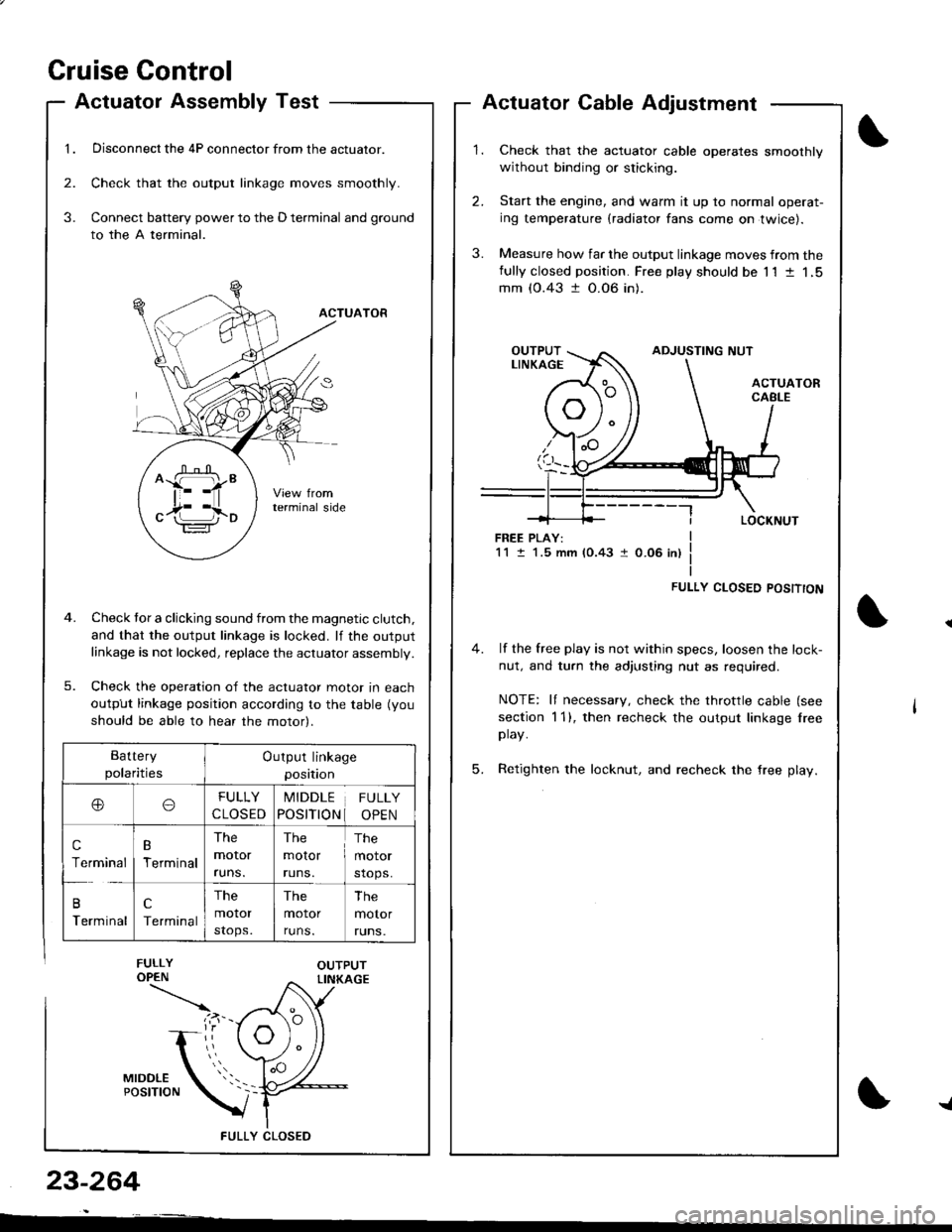

Cruise Gontrol

1.

Actuatol Assembly Test

Disconnect the 4P connector from the actuator.

Check that the output linkage moves smoothly.

Connect battery power to the D terminal and ground

to the A terminal.

ACTUATOR

Check tor a clicking sound from the magnetic clutch.

and that the output linkage is locked. lf the outputlinkage is not locked, replace the actuator assembly.

Check the operation of the actuator moror In eacn

output linkage position according to the table (you

should be able to hear the motor).

FULLY CLOS€D

2.

3.

3.

23-264

Actuator Cable Adjustment

Check that the actuator cable operates smoothly

without binding or sticking.

Start the engine, and warm it up to normal operat-

ing temperature (radiator fans come on twice).

Measure how far the output linkage moves from thefully closed position. Free play should be 11 t 1,5mm (0.43 t 0.06 in).

FREE PLAY:1M.5 mm (0.43 1 0.06 in)

FULLY CLOSED POSITTON

4. lf the free play is not within specs, loosen the lock-

nut, and turn the adjusting nut as required.

NOTE: It necessary, check the throttle cable (see

section 1 1), then recheck the output linkage lreeplay.

5. Retighten the locknut, and recheck the free play.

^ffi"

c17i l,io

Battery

polaritiesOutput linkage

position

ooFULLY

CLOSED

MIDDLE

POSITION

FULLY

OPEN

c

Terminal

B

Terminal

The

moror

runs.

The

molor

runs.

The

motor

stops.

B

Terminal

c

Terminal

The

motor

stops.

The

motor

runs.

The

motor

runs.

{

Page 1390 of 1681

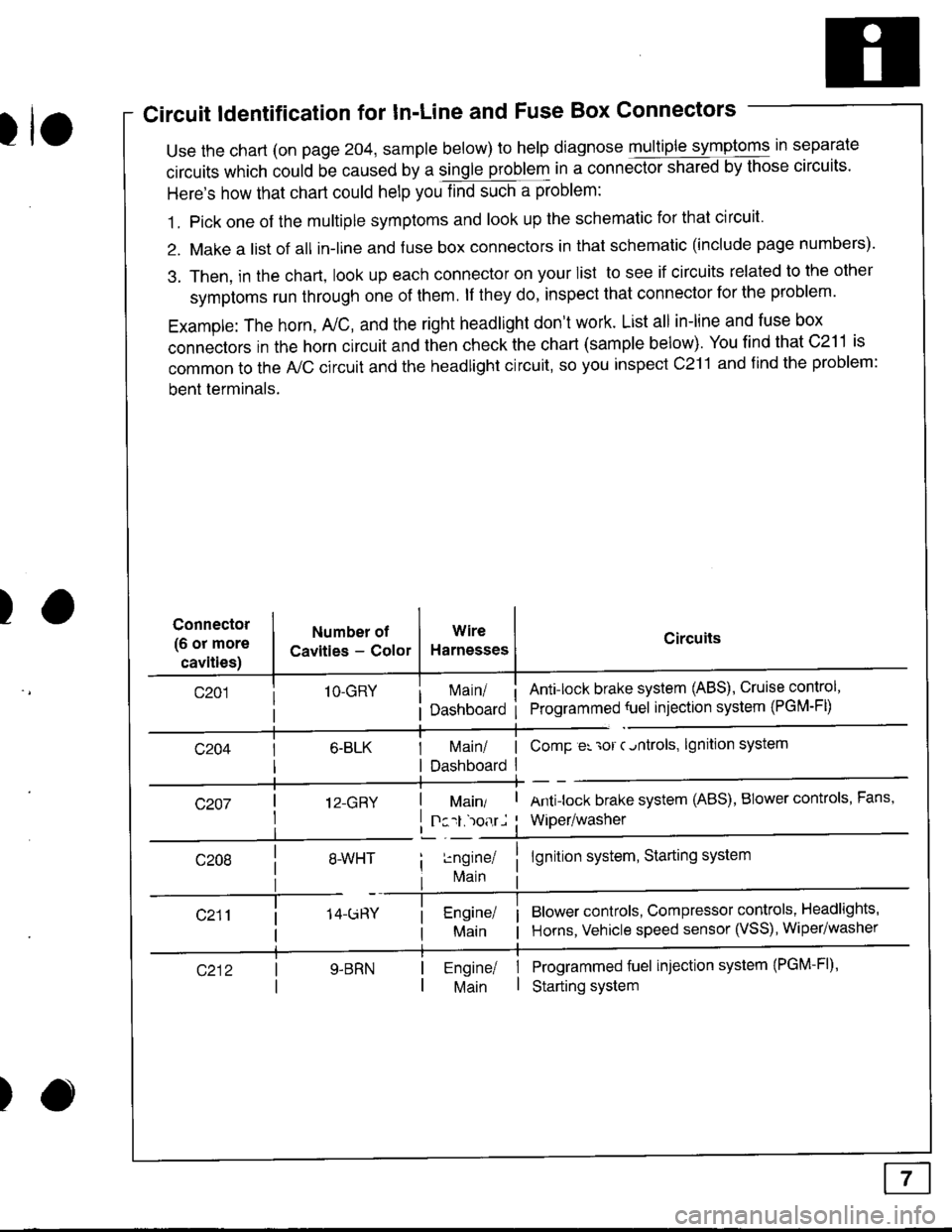

Circuit ldentification for In'Line and Fuse Box Connectors

tuse the chart (on page 204, sample below) to help diagnose multiple symptoms in separate

circuits which could be caused by a single problem in a connect,oishared by those circuits'

Here's how that chart could help you find such a problem:

1. Pick one of the multiple symptoms and look up the schematic for that circuit'

2. Make a list of all in-lrne and fuse box connectors in that schematic (include page numbers).

3. Then, in the chart, look up each connector on your list to see if circuits related to the other

symptoms run through one of them. lf they do, inspect that connector for the problem.

Example: The horn, A,/C, and the right headlight don't work. List all in-line and fuse box

connectors in the horn circuit and then check the chart (sample below). You find that C211 is

common to the A,/C circuit and the headlight circuit, so you inspect c211 and find the problem:

bent terminals.

)Connector

(6 or more

cavities)

Numbel of

Cavities - Color

1O-GRY

I 12-GRY

I

Wire

Harnesses

I Main/ | ComP er 'ror c.ntrols,

I Dashboard I

Circuits

Ant!lock brake system (ABS), Cruise control,

Programmed {uel injection system (PGM-FD

!ngrnei

lvlain

lgnition system

Antilock brake system (ABS), BIower controls, Fans,

Wiper/washer

lgnition system, Starting system

Blower controls, Compressor controls, Headlights'

Horns, Vehicle speed sensor (VSS), Wiper/washer

Programmed fuel injection system (PGM-Fl)'

Starting system

Engine/ |Main I

)

Page 1395 of 1681

How To Use This Manual

Test Equipment

lf, in addition, you need to know exactly how

much resistance there is between two ooints.

use a digital volVohmmeter (DVOM).

In the "oHMS" range, the DVOM will show

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting the measurement.

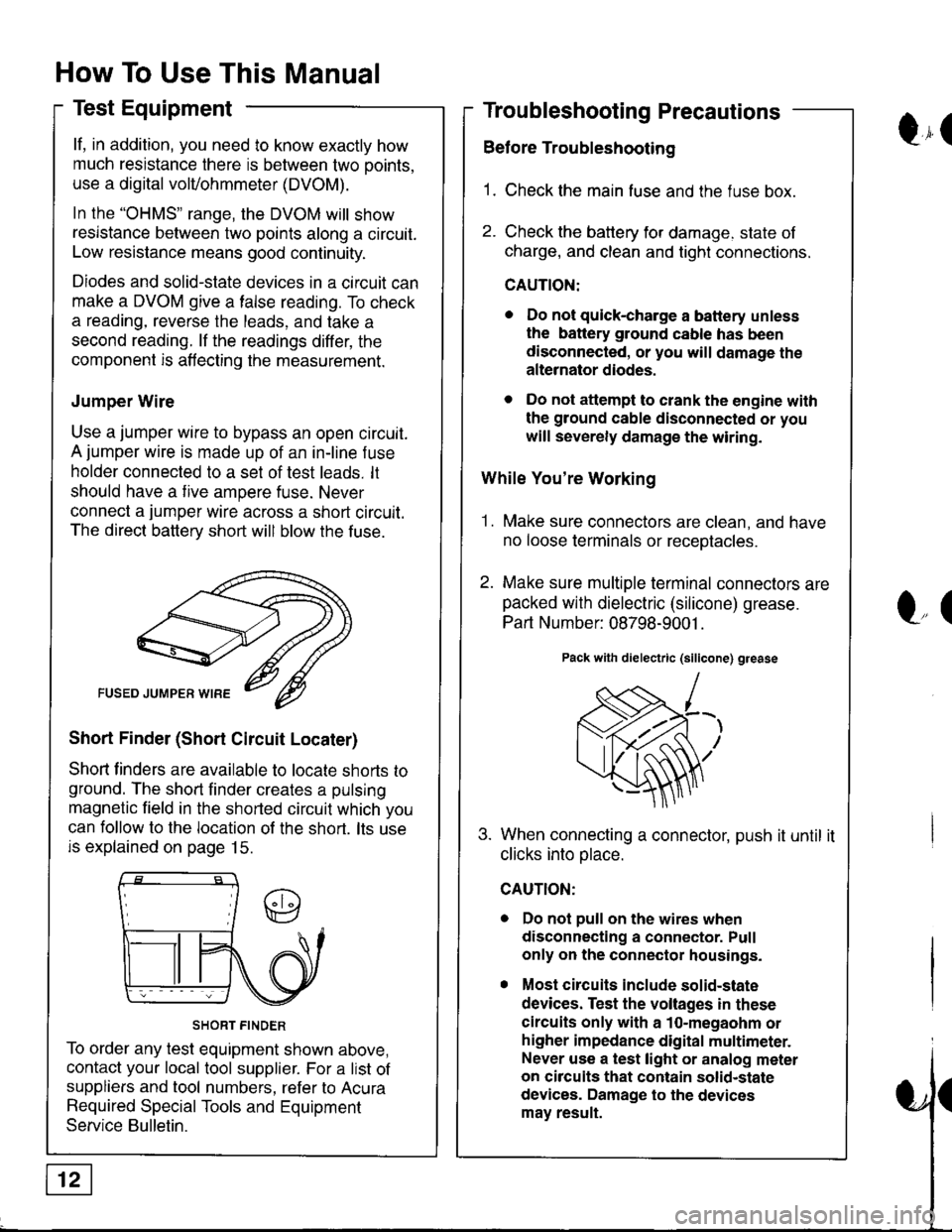

Jumper Wire

Use a jumper wire to bypass an open circuit.

A jumper wire is made up of an in-line f use

holder connected to a set of test leads. lt

should have a tive ampere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Shoft linders are available to locate shorts to

ground. The short finder creates a pulsing

magnetic field in the shorted circuit which you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To order any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Acura

Required Special Tools and Equipment

Service Bulletin.

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage. state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unless

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine with

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receotacles.

2. Make sure multiple terminal connectors are

packed with dielectric (silicone) grease.

Part Number: 08798-9001 .

Pack with dielectric (silicone) grease

When connecting a connector, push it until it

clicks into olace.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector housings.

Most circuits include solid-state

devices. Test the voltages in these

circuits only with a 1o-megaohm or

higher impedance digital multimeter.

Never use a test light or analog meter

on circuits that contain solid-state

devices. Damage to the devices

may result.

Qr(

l"(

Page 1406 of 1681

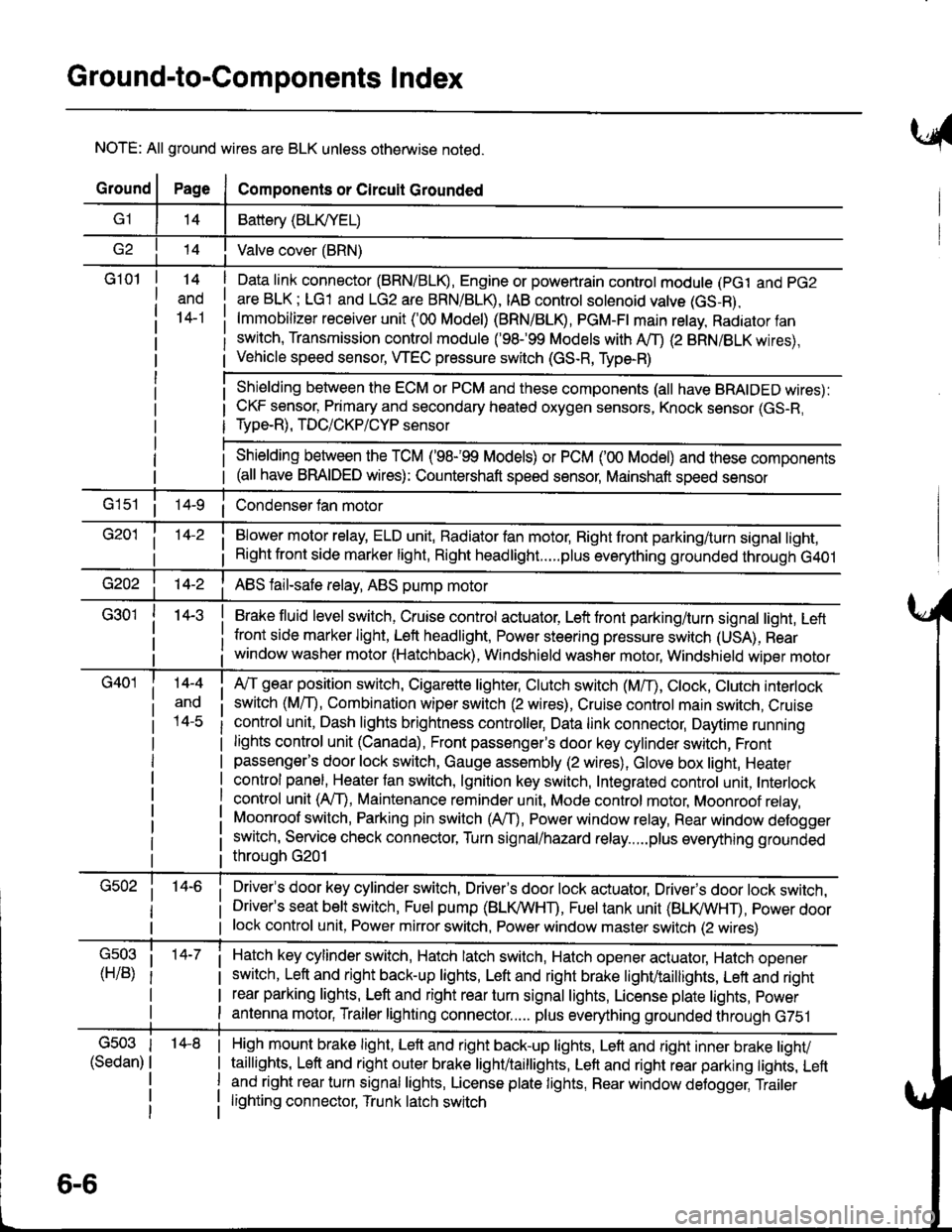

Ground-to-Components I ndex

NOTE: All ground wires are BLK unless otherwise noted.

GroundPageComponents or Circuit Grounded

Battery (BLIVYEL)

--t'I Valve cover (BRN)

G101t.+

and

14-1

Daia link connector (BRN/BLK), Engine or powertrain controt module (pct and pG2

are BLK; LG1 and LG2 are BRN/BLR, IAB controt solenoid valve (GS-B),

lmmobilizer receiver unit ('00 Model) (BRN/BLR, PGM-Ft main retay, Radiator fan

switch, Transmission control module ('98.�99 Models with MD (2 BRN/BLK wires),

Vehicle speed sensor, WEC pressure switch (GS-R, Type-R)

Shielding between the ECM or PCM and these components (all have BRAIDED wires):

CKF sensor, Primary and secondary heated oxygen sensors, Knock sensor (GS-R,

Type-R), TDC/CKP/CYP sensor

Shielding between the TCM ('98-'99 Models) or PCM ('00 Model) and these components(all have BRAIDED wires): Countershaft speed sensor, Mainshaft speed sensor

G1s1 ii Condenser fan motor

Brake fluid level switch, Cruise control actuator, Left front parking/turn signal light, Left

front side marker light, Left headlight, Power steering pressure switch (USA), Rear

window washer motor (Hatchback), Windshield washer motor, Windshield wiper motor

14-3

Blower motor relay, ELD unit, Badiator fan motor, Right front parking/turn signal light,

Right front side marker light, Right headlight.....plus everything grounded through G401

ABS fail-safe relay, ABS pump motor

G40114-4

ano

l4-c

A,/T gear position switch, Cigarette lighter, Clutch switch (M,/T), Ctock, Ctutch interlock

switch (MfD, Combination wiper switch (2 wires), Cruise control main switch, Cruise

control unit, Dash lights brightness controller, Data link connector, Daytime running

lights control unit (Canada), Front passenger's door key cylinder switch, Frontpassenger's door lock switch, Gauge assembly (2 wires), Glove box light, Heater

control panel, Heater tan switch, lgnition key switch, Integrated control unit, Interlock

control unit (AfI), Maintenance reminder unit, Mode control motor, Moonroof relay,

Moonroof switch, Parking pin switch (AfD, Power window relay, Rear window defogger

switch, Service check connector, Turn signal/hazard relay.....plus everything grounded

throuoh G201

Driver's door key cylinder switch, Driver's door lock actuator, Drivels door lock switch,Driver's seat belt switch, Fuel pump (BLI(/WHT), Fuel tank unit (BLI(/WHT), power doorlock control unit, Power mirror switch, Power window master switch (2 wires)

Hatch key cylinder switch, Hatch latch switch, Hatch opener actuator, Hatch ooener

switch, Left and right back-up lights, Left and right brake light/taillights, Lett and right

rear parking lights, Left and right rear turn signal lights, License plate lights, power

antenna motor, Trailer lighting connector..... plus everything grounded through G751

6-6

'14-8G503

(Sedan)

High mount brake light, Left and right back-up lights, Lett and right inner brake tighv

taillights, Left and right outer brake light/taittights, Left and right rear parking tights, Leftand right rear turn signal lights, License plate lights, Rear window detogger, Trailer

lighting connector, Trunk latch switch