clutch HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 358 of 1681

Clutch

Speciaf Tools ........ .'--"" 12-2

lflustrated Index ........ ".' 12-3

Clutch Pedal

Adjustment "..".""'...' 12-4

Clutch Master Cylinder

Removal/lnstallation -'.' 12-5

Slave Cylinder

Removal/lnstallation '..' 12-6

Pressure Plate

Removal/lnspection .'-.' 12-7

Clutch Disc

Removal/lnspection '...' 12-a

Flywheel, Flywheel Bearing

fnspection ' 12-9

Replacement .................'............. 1 2-9

Clutch Disc, Pressure Plate

lnstallation ................. 12-10

Release Bearing

Removal/lnspection "'.' 12-11

fnstaffation ".""".-'."'. 12-12

Page 359 of 1681

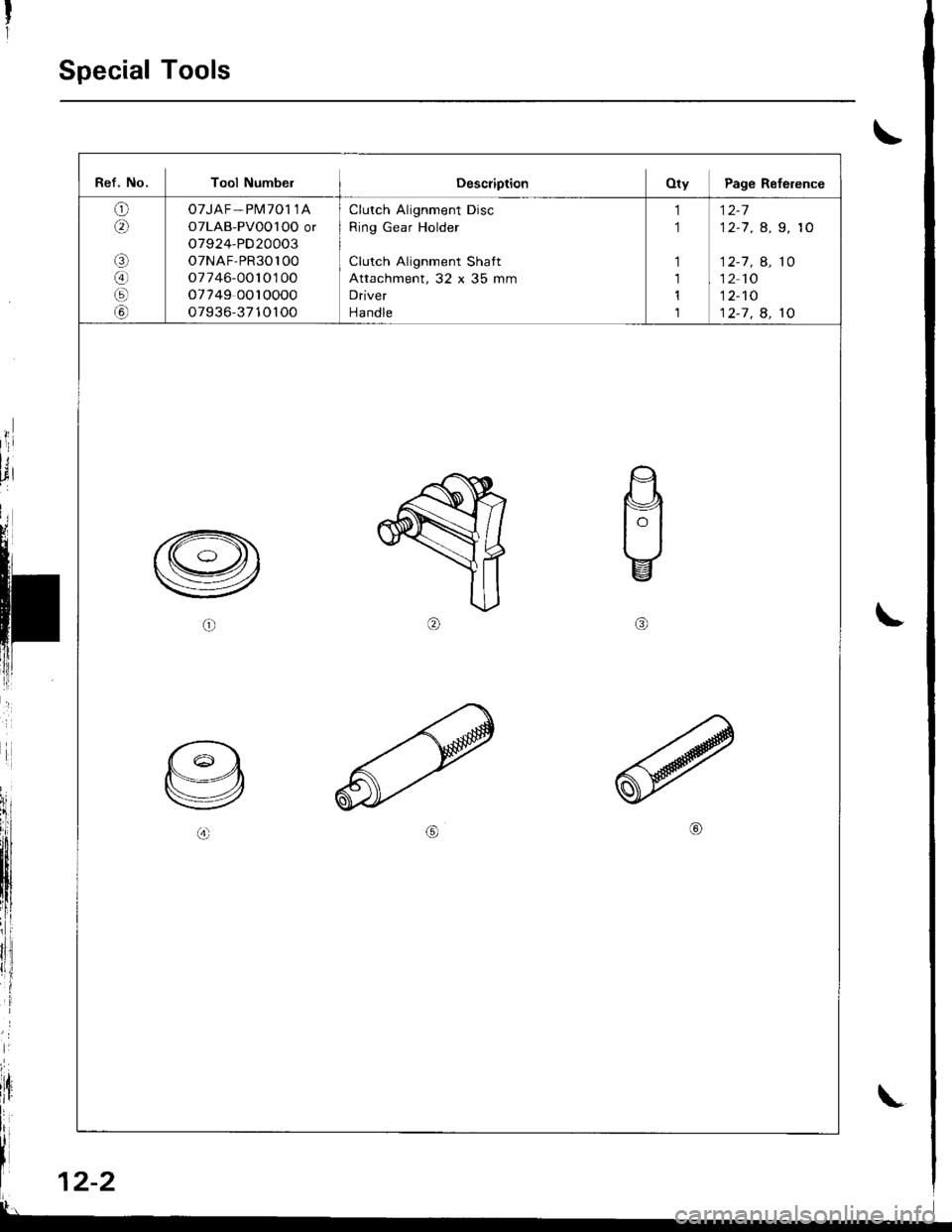

Special Tools

\

t

rl

;

lt, 12-2

Ref. No. Tool NumbelDescriptionOty Page Reference

o6\

aa

G)

07JAF - Pl\il701 1A

OTLAB-PVoO l OO or

o7924-PD20003

o7NAF,PR30100

o7746-0010100

o7749 0010000

o7936-3710100

Clutch Alignment Disc

Ring Gear Holder

Clutch Alignment Shatt

Attachment, 32 x 35 mm

Driver

Handle

1

1

1

1,l

1

12-7

12-7 , a, 9, 10

12-1 , A, 10

12 10

12-'tO

12-7 . 8. 10

\

Page 360 of 1681

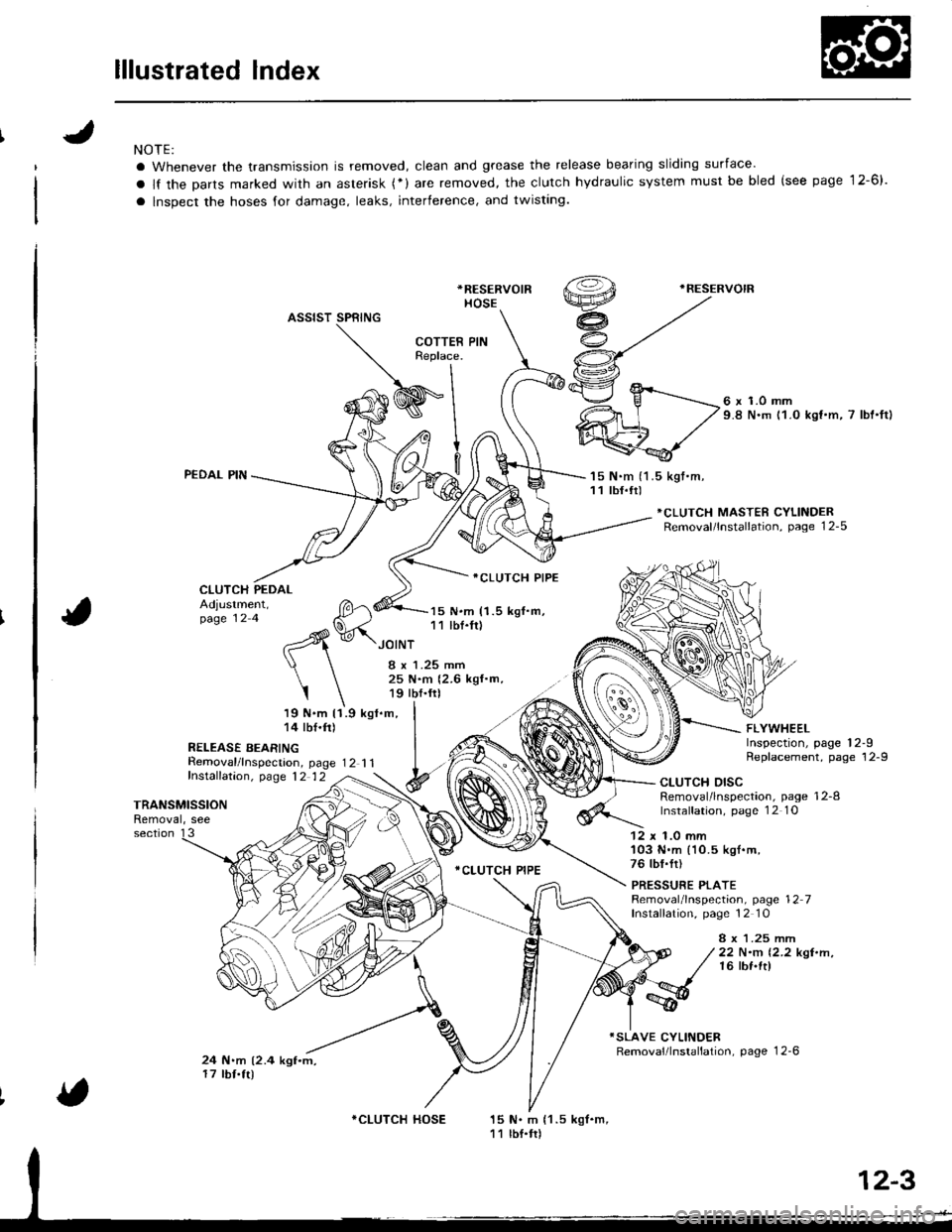

lllustrated Index

NOTE:

a Whenever the transmission is removed, clean and grease the release bearing sliding surface'

a lf the Darts marked with an asterisk (*) are removed, the clutch hydraulic system must be bled (see page 12-6).

a lnspect the hoses for damage, leaks, interference, and twisting.

*RESERVOIR

HOSE

.RESERVOIR

ASSIST SPRING

PEDAL PIN

CLUTCH PEDAL

Removal/lnspecrion, page 12 1 1fnstalfation, p,age 12 12

6 x 1.0 mm9.8 N.m 11.0 kst.m, 7 lbt'ftl

'15 N.m (1 .5 kgt.m,11 tbf.tr)

*CLUTCH MASTER CYLINDERRemoval/lnstallation, page 12-5

Adjustment,page 12 4

19 N.m 11.9 kgl.m,14 tbf.ft)

R€LEASE BEARING

15 N.m (1.5 kgf.m,11 lbf.fr)

ICLUTCH PIPE

.CLUTCH PIPE

FLYWHEELInspection, page 12-9Replacement, page 12-9

JOINT

I x 1.25 mm25 N.m {2.6 kgf.m,19 tbf.frl

I

TRANSMISSIONRemoval, see

CLUTCH DISCRemoval/lnspection, page 12-8lnstalfation, page 1 2 1O

section 1312 x 1.0 mm'103 N.m (10.5 kgl.m,76 tbf.fr)

PRESSURE PLATERemoval/lnspection, page 12 7Installation, page 12 10

8 x 1.25 mrr|22 N.m 12.2 kgt.n,16 lbf.ft)

24 N.m (2.4 kgf.m,17 tbf.tr)

15 N. m {1 .5 kgf.m,11 lbf.tr)

COTTERReplace.

I

WInl

9l

v.^- fl

*CLUTCH HOSE

Page 361 of 1681

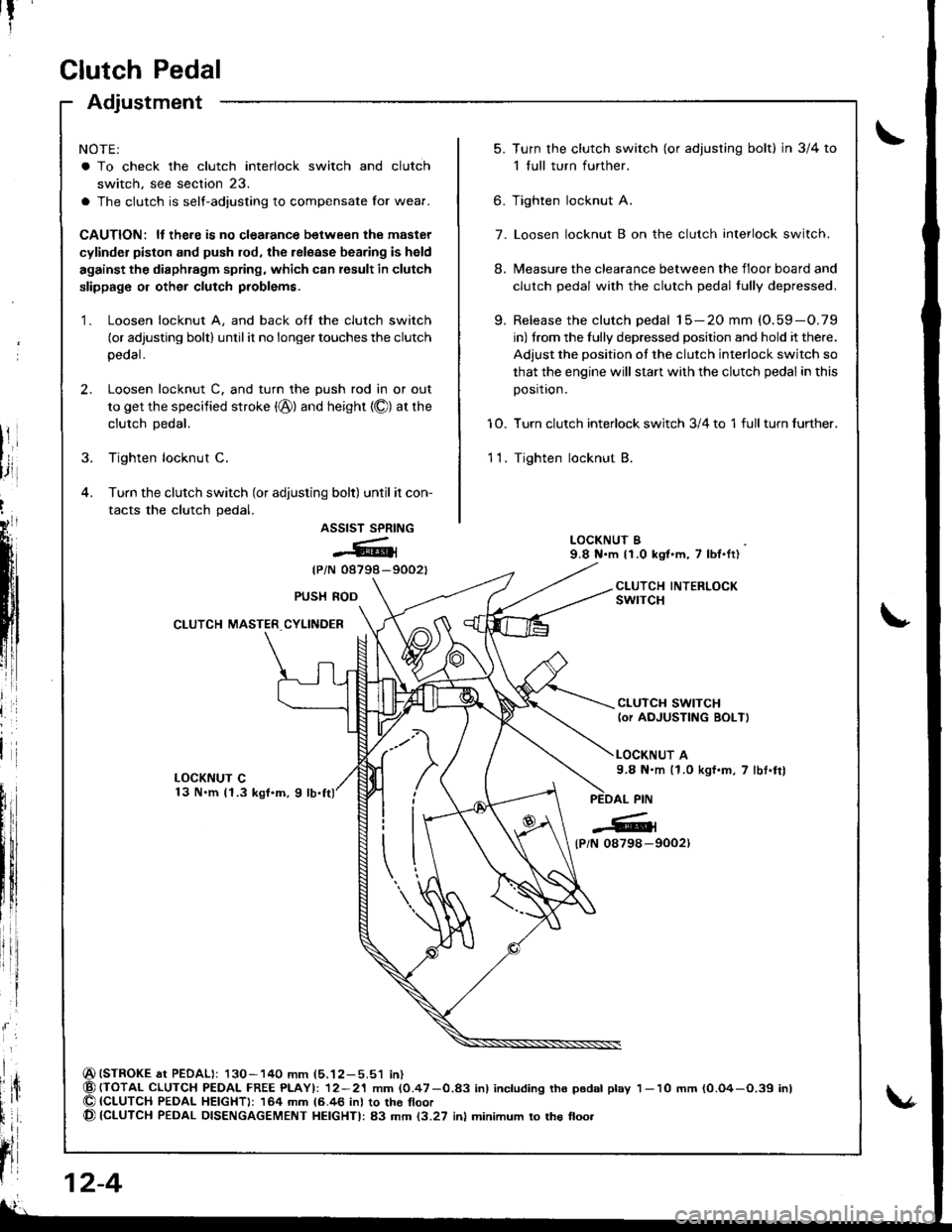

Clutch Pedal

Adjustment

NOTE:

a To check the clutch interlock switch and clutch

switch, see section 23.

a The clutch is self-adjusting to compensate Ior wear.

CAUTION: ll there is no clealance between the master

cylinder piston and push rod, the release bearing is held

against the diaphragm spring, which can result in clutch

slippage or other clutch problems.

1. Loosen locknut A, and back off the clutch switch

(or adjusting bolt) until it no longer touches the clutch

peoal.

2. Loosen locknut C. and turn the push rod in or out

to get the specified stroke (@) and height {O) at the

clutch Dedal.

3. Tighten locknut C.

4. Turn the clutch switch (or adjusting bolt) until it con-

tacts the clutch pedal.

ASSIST SPRING

@{

{PiN 08798-9002t

(STROKE at PEDAL): 130-140 mm (5.12-5.51 in){TOTAL CLUTCH PEDAI- FREE PLAYI: 12-21 mm (0.47-0.83 inl including tho p6dal play{CLUTCH PEDAL HEIGHT): 164 mm 16.46 inl to the tloor(CLUTCH PEDAL DISENGAGEMENT HEIGHTI: 83 mm {3.27 inl minimum to the floo.

t?

5.Turn the clutch switch (or adjusring bolt) in 3/4 to

1 full turn further.

Tighten locknut A.

Loosen locknut B on the clutch interlock switch.

Measure the clearance between the floor board and

clutch pedal with the clutch pedal tully depressed.

Release the clutch pedal 15-20 mm (O.59-O.79

in) from the fully depressed position and hold it there.

Adjust the position of the clutch interlock switch so

that the engine will stan with the clutch pedal in this

position.

Turn clutch interlock switch 3/4 to 1 full turn further.

Tighten locknut B.

9.

6.

7.

8.

10.

11.

LOCKNUT B9.8 N.m 11.0 kgt.m, 7 lbl.ft)

CLUTCH INTERLOCKswrTcHPUSH ROD

CLUTCH MASTER CYLINDER

CLUTCH SWITCH(or AOJUSTING BOLT)

LOCKNUT A9.8 N.m (1.0 kgf.m, 7 lbt.frl

l

{P/N 0879a-9002)

12-4

1- 10 mm (0.O4-O.39 inl

Page 362 of 1681

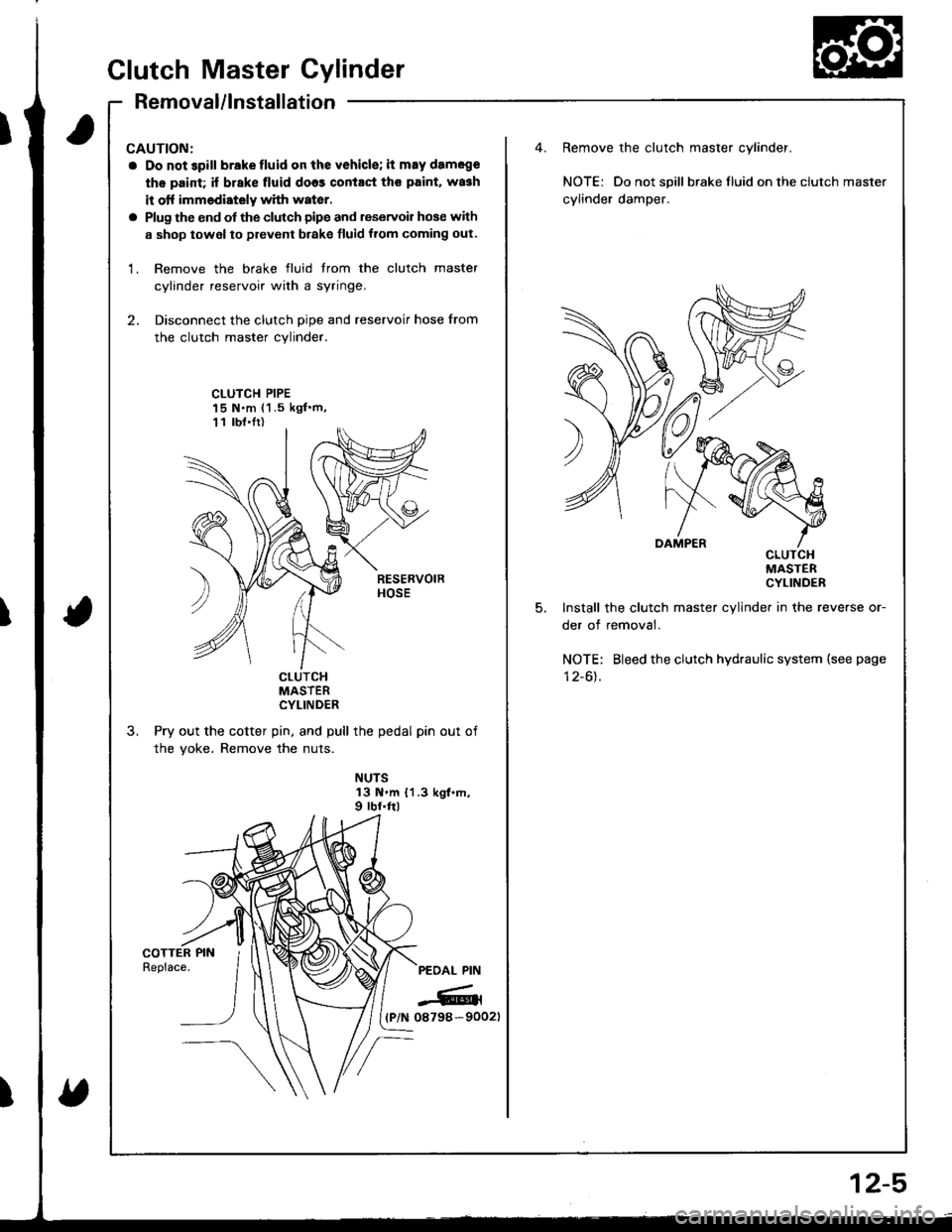

CAUTION:

a Do not 3pill brakefluid on the vehicle; it may damege

th€ paid; if brake fluid do63 contact th€ paint. wa3h

it otf immediately with water.

a Plug the end of the clutch pipe and reservoir hose with

a shop towel to prevent brake fluid from coming out.

1. Remove the brake fluid trom the clutch master

cylinder reservoir with a syringe,

2. Disconnect the clutch pipe and reservoir hose from

the clutch master cylinder.

Remove the clutch master cylinder.

NOTE: Do not spill braketluid ontheclutch master

cylinder damper.

CLUTCH PIPE15 N.m {1 .5 kgf'm,11 lbt.Ir)

5.

cLulcHMASTERCYLINDER

Install the clutch master cylinder in the reverse or-

der of removal.

NOTE: Bleed the clutch hydraulic system {see page

I z-ol.cturcHMASTERCYLINDER

Pry out the cotter pin, and pull the pedal pin out of

the yoke. Remove the nuts.

NUTS13 N.m {1.3 kgt.m,9 rbf.ftl

PEOAL PIN

-6rl(P/N 08798-90021

Clutch Master Cylinder

Removal/lnstallation

2-5

Page 363 of 1681

T

fi

;ill

Slave Cylinder

Removal/lnstallation

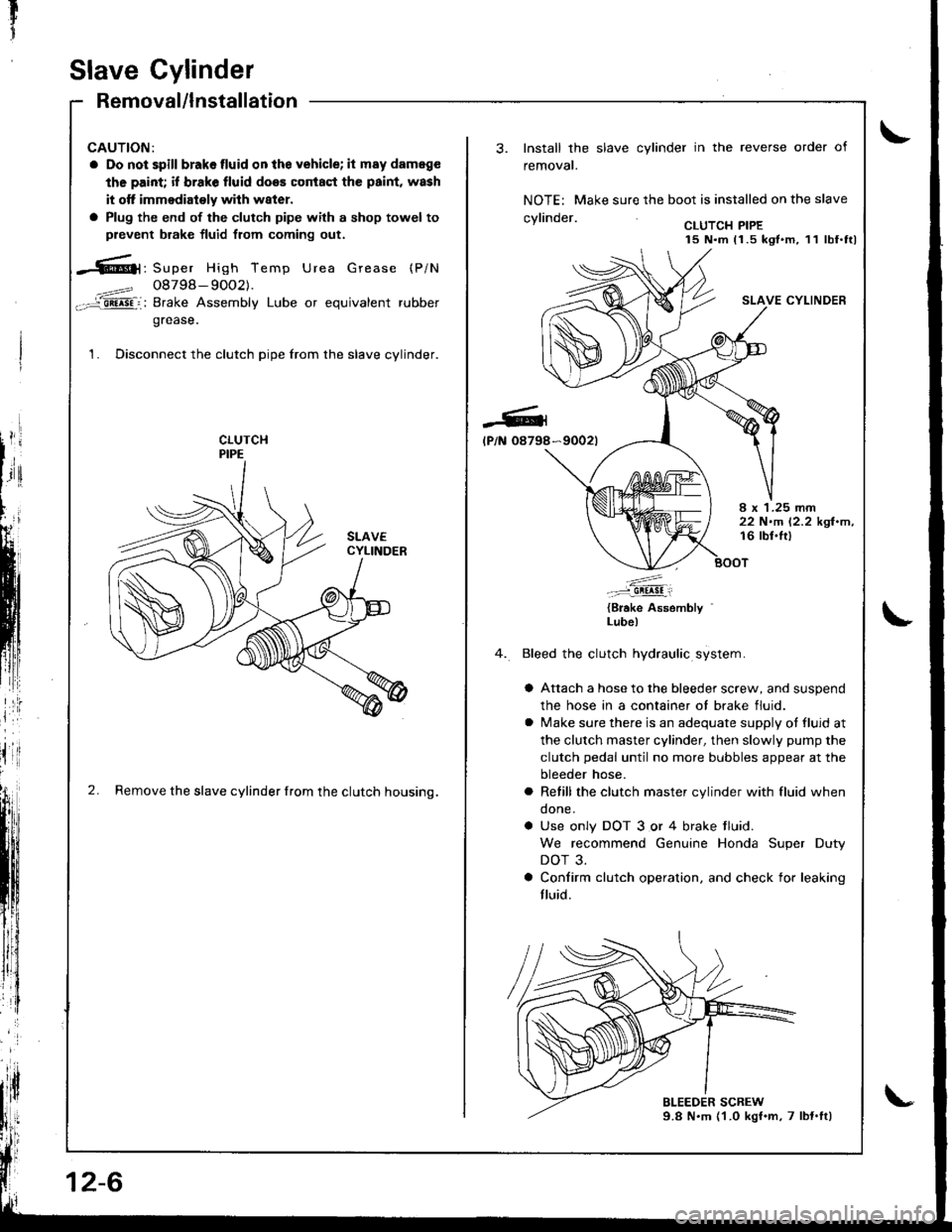

CAUTION:

a Do not spill brakelluid onthe vehicle; it may dameg€

the paint; if brake fluid does coniaqt the paint, wash

it otf immodiaioly wilh w8ter.

a Plug the end of the clutch pipe with a shop towel to

prevent brake fluid from coming out.

-6|1, Super High Temp Urea Grease (P/N

4==? 08798- 9OO2).-='aii^5Fi: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch pipe from the slave cylinder.

2. Remove the slave cylinder from the clutch housing.

12-6

-Gl

lP/N 08798

Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

.wlin.larCLUTCH PIPE15 N.m 11.5 kgt.m, 11 lbf.ttl

SLAVE CYLINDER

*9002t

I x 1.25 rnm22 N.m 12.2 kgl.m,16 lbl.lt)

.'....-..-:::-9!!!!!i

{Brake Assembly '

Lube)

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container ot brake fluid.

a lvlake sure there is an adequate supply ot fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

a Refill the clutch master cylinder with fluid when

done.

a Use only DOT 3 or 4 brake tluid.

We recommend Genuine Honda Super Duty

DOT 3.

a Confirm clutch operation. and check for leaking

fluid.

Page 364 of 1681

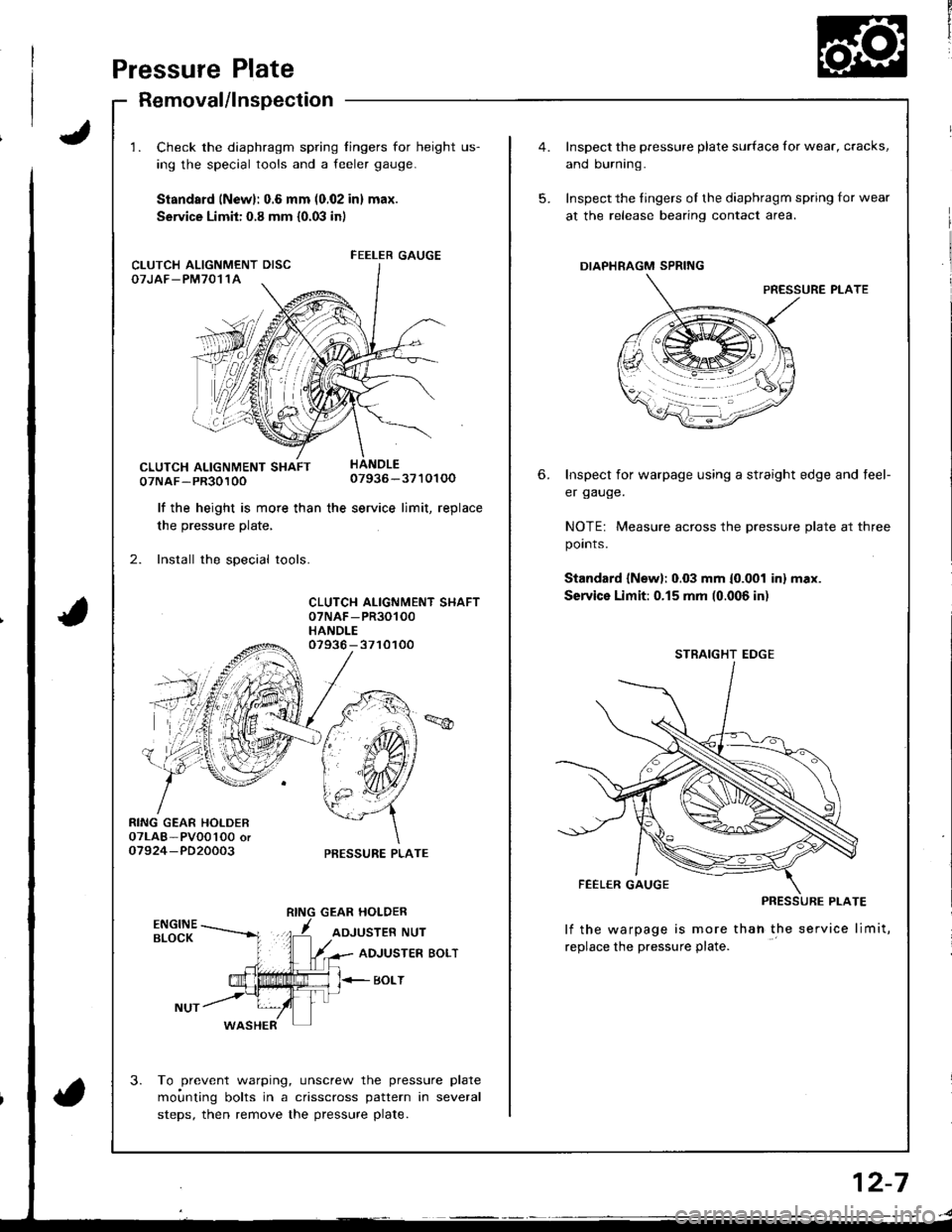

Pressure Plate

Removal/lnspectaon

1. Check the diaphragm spring fingers for height us-

ing the special tools and a feeler gauge.

Standsrd (New): 0.6 mm (0.02 in) max.

Service Limit: 0.8 mm {0.03 in)

07NAF-PR3010007936-3710100

lf the height is more than the service limit, replacethe hro..rr.a nlefe

2. Install the special tools.

CLUTCH ALIGNMENT SHAFT07NAF -PR30100

HANDLE

RING GEAR HOLDER07LAB- PVOo'l0O oro7924-PD20003

07936 - 3710100

PRESSURE PLATE

GEAR HOLDER

ADJUSTER NUT

3.

ADJUSTER BOLT

BOLT

WASHER

To prevent warping, unscrew the pressure plate

moi.rnting bolts in a crisscross pattern in several

steps, then remove the pressure plate.

FEELER GAUGECLUTCH ALIGNMENT DISCOTJAF_PM7011A

5.

6.

Inspect the pressure plate surface for wear, cracks,

and burning.

Inspect the fingers of the diaphragm spring for wear

at the release bearing contact area.

DIAPHRAGM SPRING

PRESSURE PLATE

Inspect for warpage using a straight edge and teel-

er gauge.

NOTE: Measure across the pressure plate at three

points.

Standard {New}: 0.03 mm {0.001 inl max.

Service Limit:0.15 mm (0.006 in)

lf the warpage is more thah the service limit,

replace the pressure plate.

STRAIGHT EDGE

2-7

Page 365 of 1681

rtr

1

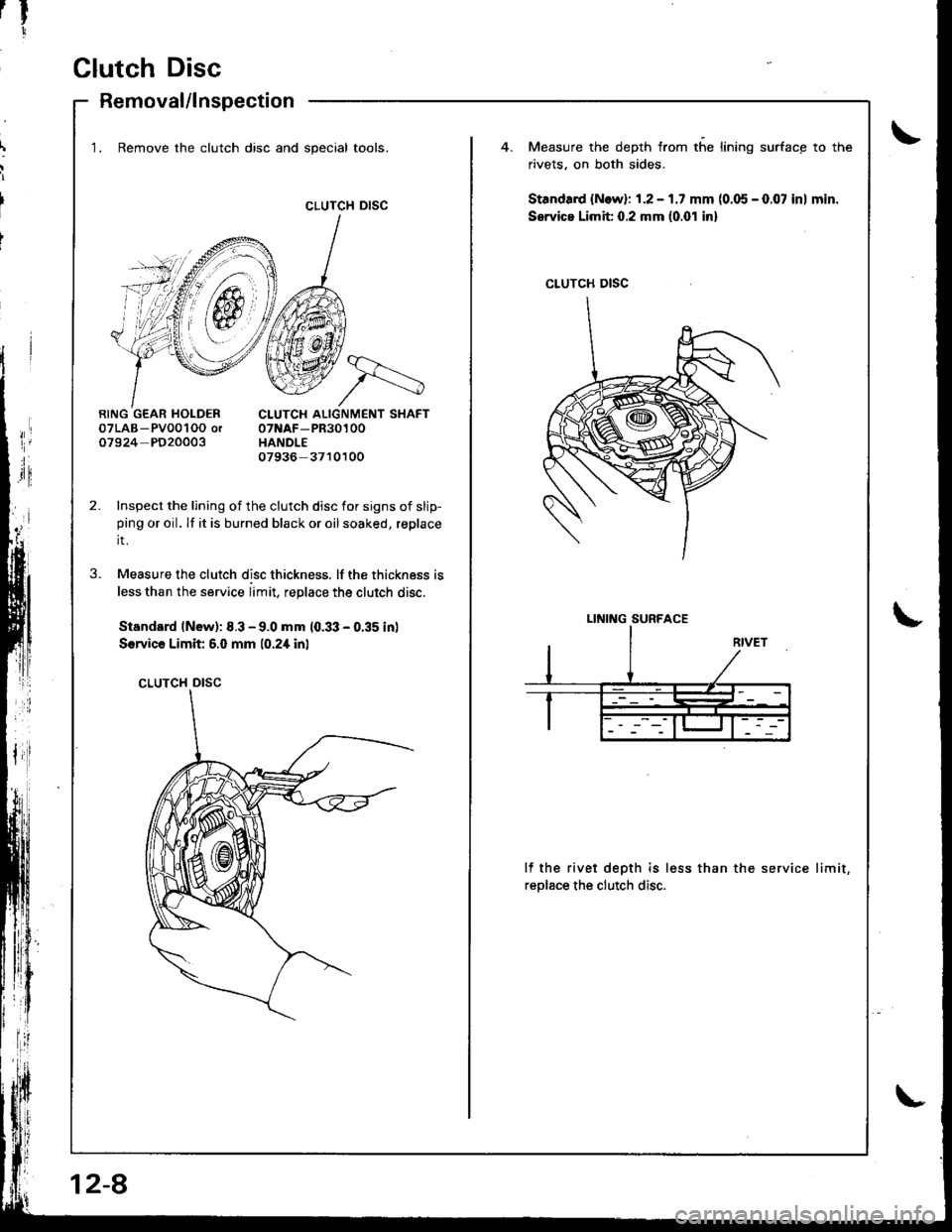

Clutch Disc

Removal/lnspection

CLUTCH DISC

1. Remove the clutch disc and special tools.Measure the depth from the lining surface to the

rivets. on both sides.

Standa.d {N.w}: 1.2 - 1.7 mm (0.05 - 0.07 in} min.

Service Limit 0.2 mm (0.01 inl

07LAB- Pv001OO or07924 PD20003

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936- 3710100

Inspect the lining of the clutch disc for signs of slip-ping or oil. lf it is burned black or oil soaked, replace

it.

Measure the clutch disc thickness. lf the thickness is

less than the service limit, replace the clutch disc.

Standard lNew): 8.3 - 9.0 mm 10.33 - 0.35 in)

Sorvica Limit 6.0 mm 10.2i[ inl

CLUTCH DISC

3.

lf the rivet depth is less than the service limit,

reolace the clutch disc.

CLUTCH DISC

LINING SURFACE

12-8

Page 366 of 1681

Flywheel, Flywheel Bearing

Inspection

t

',4

i

Replacement

1. Install the special tool.

MOUNTING BOLTS

Remove the flywheel mounting bolts in a crisscrosspattern in several steps as shown, then.emove the

Jlvwheel.

Bemove the flywheel bearing from the flywheel.

(cont'd)

FLYWHEEL

I

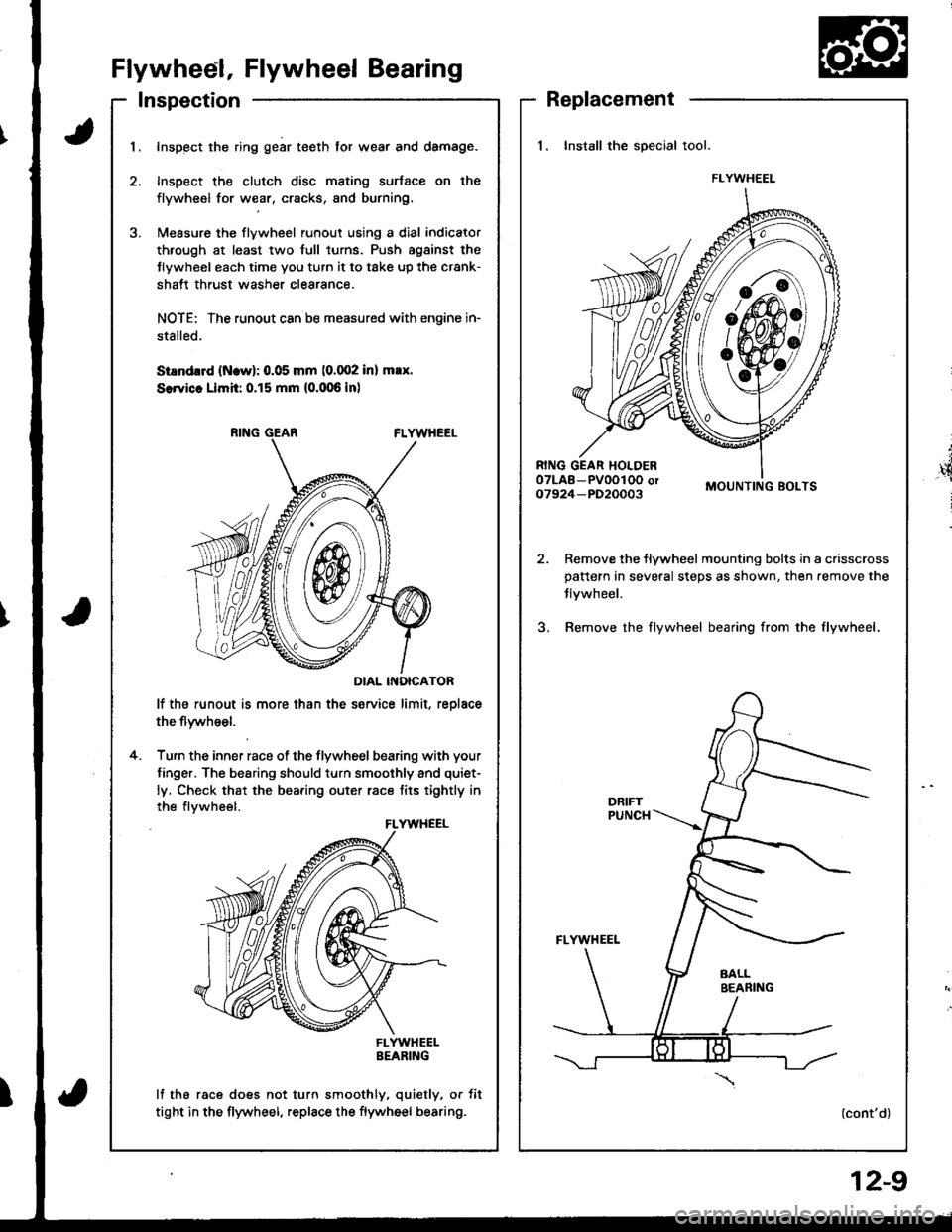

1.Inspect the ring gear teeth tor wear and damage.

Inspect the clutch disc mating surtace on the

flywheel for wear, cracks, and burning.

l\,reasure the flywheel runout using a dial indicator

through at least two full turns. Push agsinst the

Jlywheel each time you turn it to take up the crank-

shatt thrust washer clearance.

NOTE: The runout can ba measured with engine in-

stalled.

SiEndrrd (Ncw): 0.05 mm (0.002 inl max.

SerYicc Llmh: 0.15 mm (0.006 inl

DIAL INOICATOR

lf the runout is more than the service limit, reolace

the flywheel.

Turn the inner race of the flywheel bearing with your

tinger. The bearing should turn smoothly and quiet-

ly. Check that the bearing outer race tits tightly in

the flvwheel.

FLYWHEELBEARING

lf the race does not turn smoothly, quietly, or tit

tight in the flywheel, replace the flywheel bearing.

4.

FLYWHEEL

12-9

Page 367 of 1681

Clutch Disc,

Flywheel, Flywheel BearingPressure Plate

Replacement (cont'd)Installation

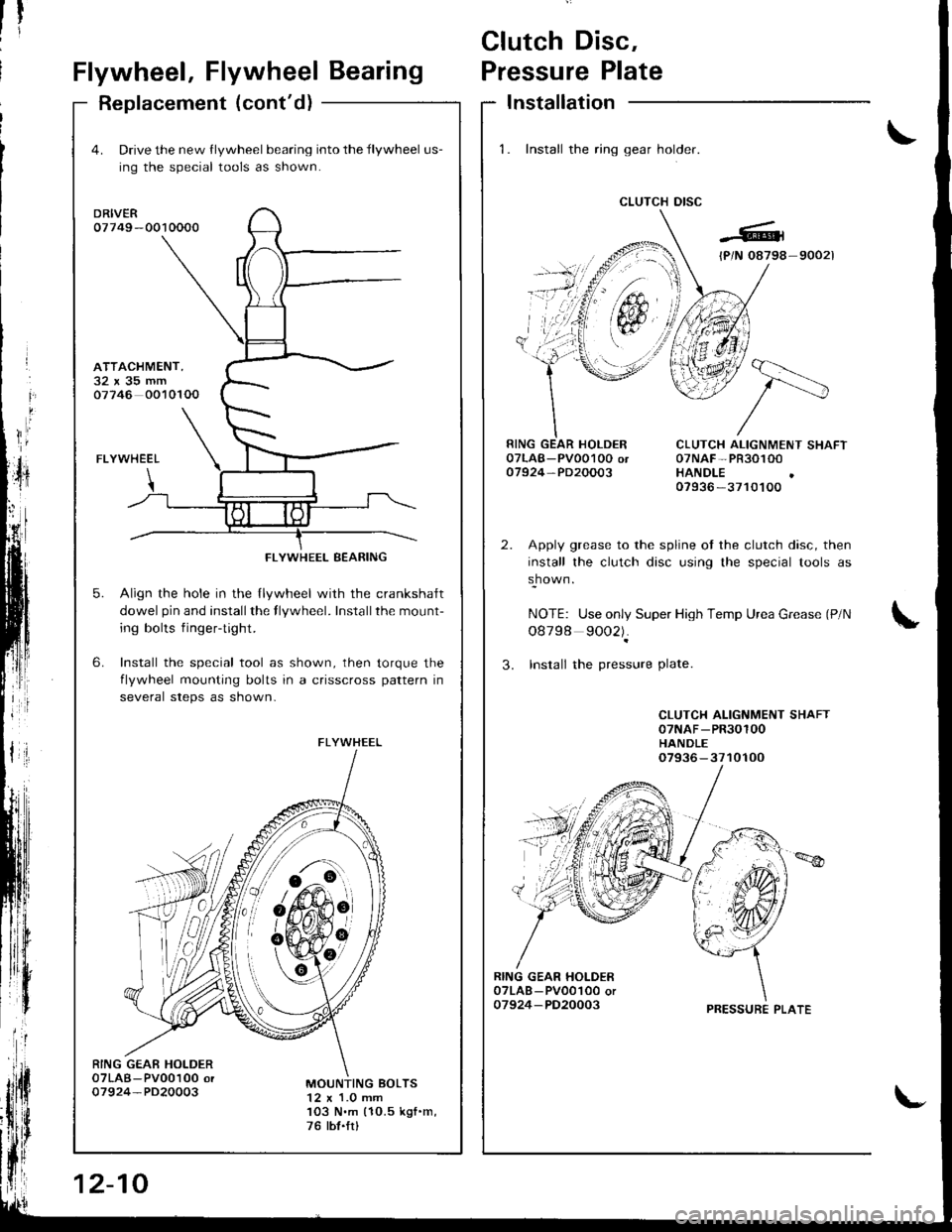

1. Install the ring gear holder.

CLUTCH DISC

1tti

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936 -3710100

Apply grease to the spline ot the clutch disc, then

install the clutch disc using the special tools as

shown.

NOTE: Use only Super High Temp Urea Grease (P/N

o8798 9002).

3. Insrall the pressure Plate.

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710100

RING GEAR HOI-DER07LAB - PV001O0 or07924-PD20003

4. Drive the new flywheel bearing into the flywheel us-

ing the special tools as shown.

DRIVER07749 -0010000

FLYWHEEL

Align the hole in the llywheel with the crankshalt

dowel pin and installthe flywheel. Installthe mount-

ing bolts fingertight.

Install the special tool as shown, then torque the

flvwheel mounting bolts in a crisscross pattern in

several steps as shown-

6.

ATTACHMENT,32x35mm07746 0010100

5.

RING GEAE HOLDER07LAB-Pv00100 or07924-PD20003MOUNTING BOLTS12 x 1.0 mm103 N.m (10.5 kgf .m,

76 tbt.frl

FLYWHEEL BEARING

FLYWHEEL

6!-o

&#,oit

12-10

PRESSURE PLATE