Mount HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 332 of 1681

1r

;

J

I

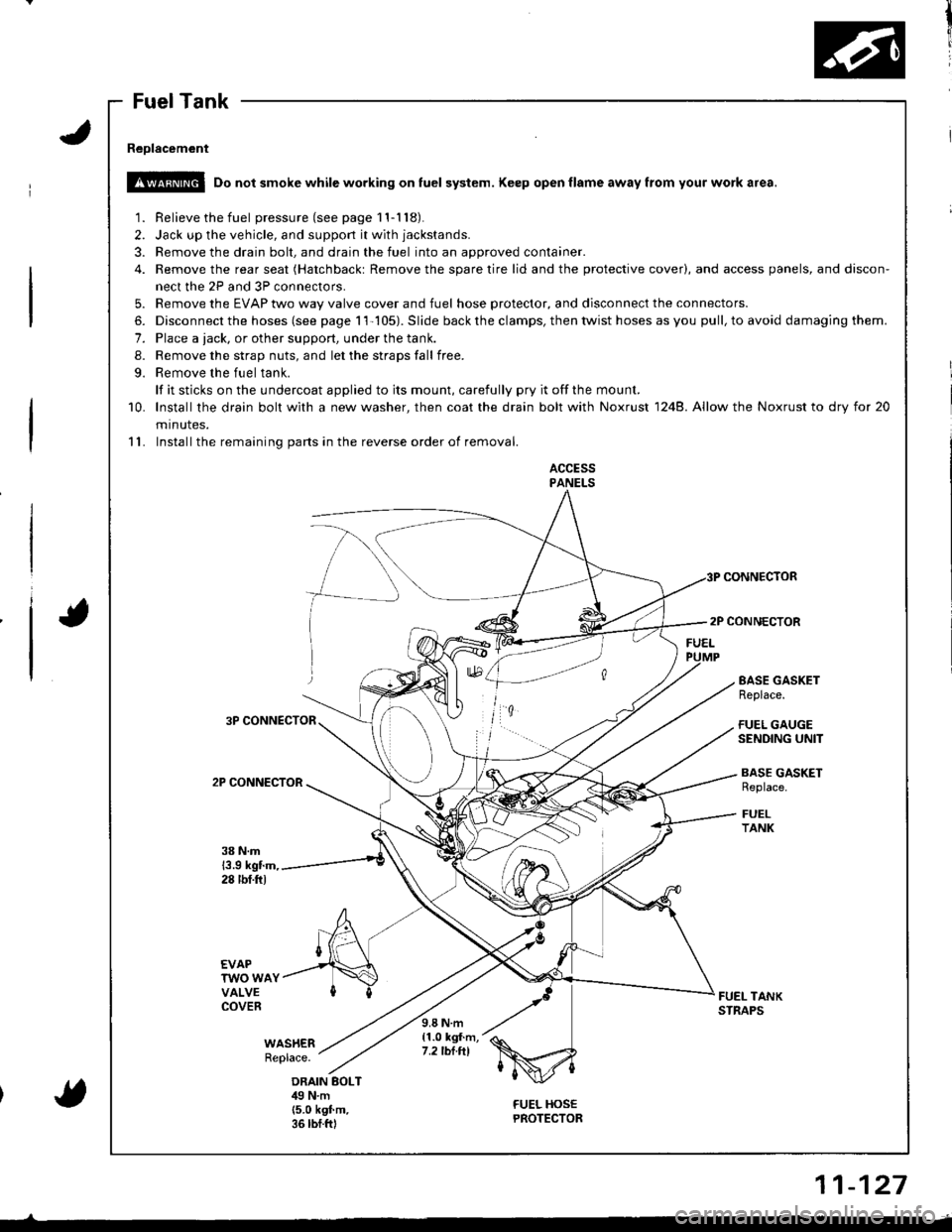

Fuel Tank

Reolacement

!!@ Do not smoke while working on fuel system. Keep open flame away from your work a.ea.

1. Relieve the fuel pressure(seepagell-118).

2. Jack up the vehicle, and support it with jackstands.

3. Remove the drain bolt, and drain the fuel into an approved container.

4. Remove the rear seat (Hatchbackt Remove the spare tire lid and the protective cover), and access panels, and discon-

nect the 2P and 3P connectors.

5. Remove the EVAP two way valve cover and fuel hose protector, and disconnect the connectors.

6. Disconnect the hoses (see page 11-105). Slide back the clamps, then twist hoses as you pull, to avoid damaging them.

7. Place a tack, or other support, under the tank.

8. Remove the strap nuts, and let the straps fall free.

9. Remove the fuel tank.

lf it sticks on the undercoat applied to its mount, carefully pry it offthe mount.

10. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248. Allow the Noxrust to dry tor 20

minutes.

11. Installthe remaining parts in the reverse order of removal.

ACCESSPANELS

CONNECTOR

2P CONNECTOR

3P CONNECTOR

2P CONNECTOR

EASE GASKETReplace.

FUEL GAUGESENDING UNIT

BASE GASKETReplace.

FUELTANK

38 N.m13.9 kgtm,28 tbf.ftl

EVAPTWO WAYVALVECOVERFUEL TANKSTNAPS

WAS}IERReplace.

9.8 N.m{1.0 kgf.m,7.2 tbt.tll

ORAIN BOLTilg N.m(5.0 k9f.m.36 rbf.ftl

FUEL HOSEPROTECTOR{

11-127

Page 346 of 1681

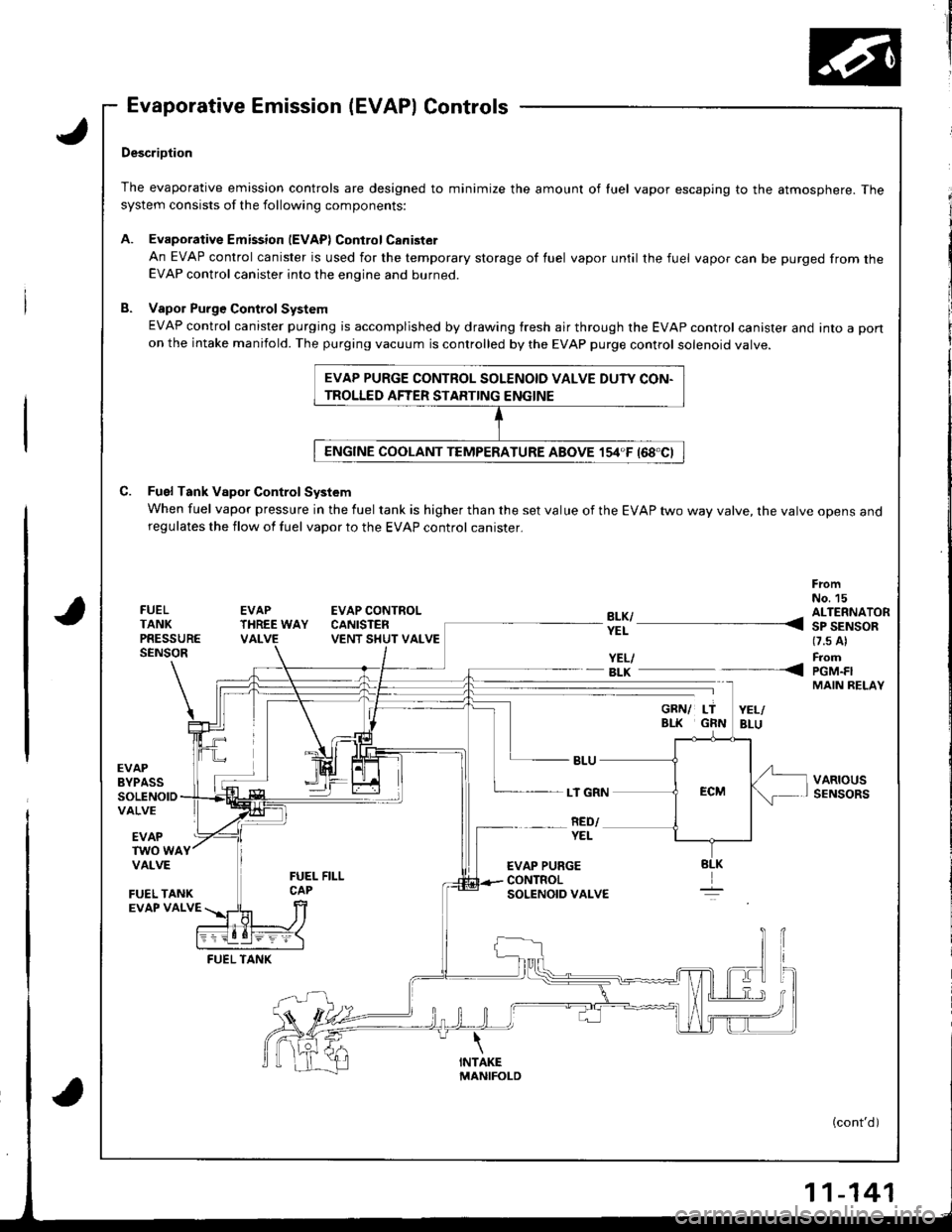

Evaporative Emission (EVAP) Controls

,J

a

DescriDtion

The evaporative emission controls are designed to minimize the amount of luel vapor escaping to the atmosphere. Thesystem consists of the following components:

A. EvaporativeEmission lEVAPlControlCanister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from theEVAP control canister into the engine and burned.

B. Vapol Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the varve opens anoregulates the flow of fuel vapor to the EVAP control canister.

FrcmNo. 15FUELTANKPRESSURESENSOR

EVAPTHREE WAYVALVE

EVAP CONTROLCANISTENVENT SHUT VALVE

YEL/- BLK

EVAPBYPASSSOLENOIDVALVE

LT GRN

RED/EVAPTWO WAYVALVE

FUEL TANKEVAP VALVE

FUEL TANK

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

?!l ---- 311'AiS-*(7.s Al

FromPGM.FIMAIN RELAY

VARIOUSSENSORS

----<

YEL

EVAP PURGECONTROLSOLENOID VALVE

(cont'd)

-141

Page 366 of 1681

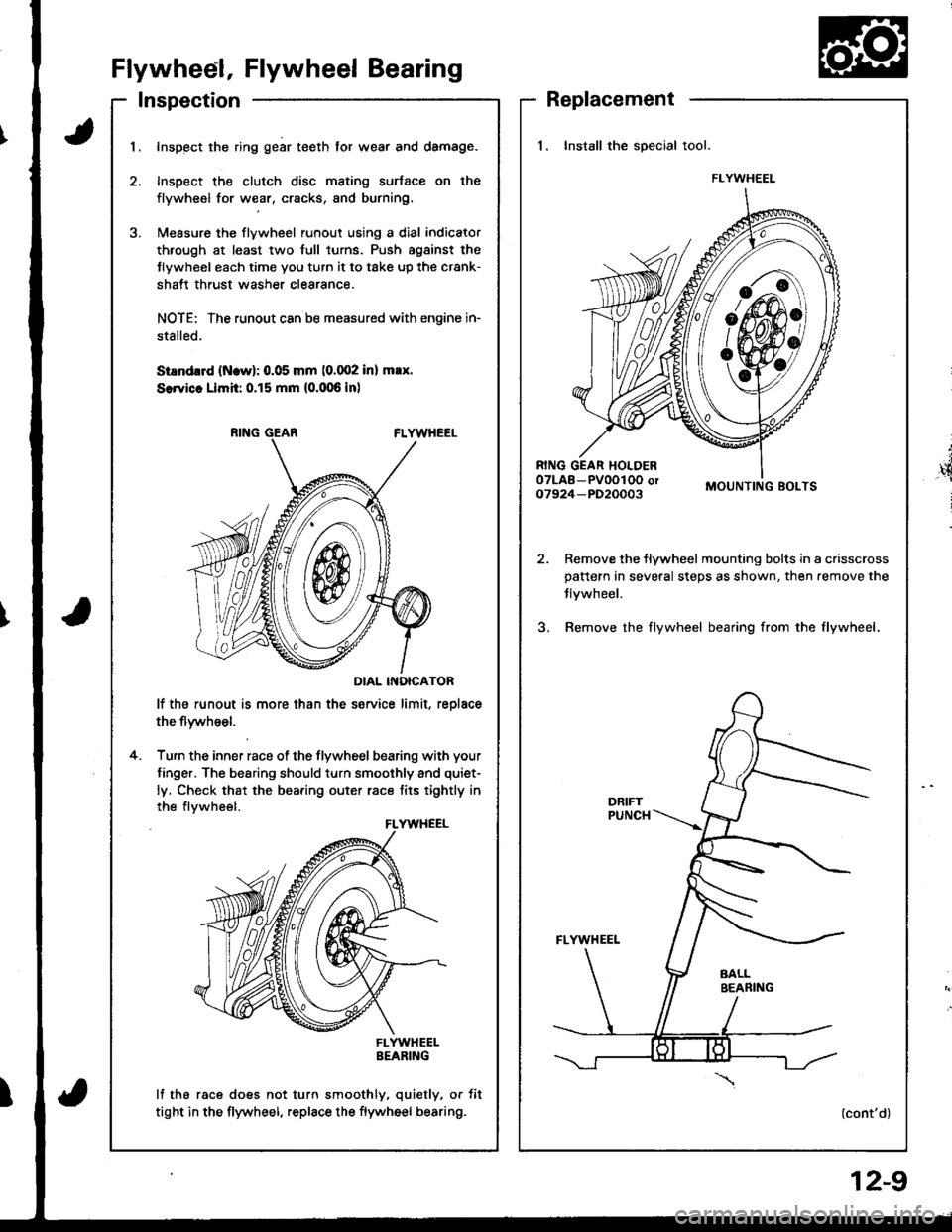

Flywheel, Flywheel Bearing

Inspection

t

',4

i

Replacement

1. Install the special tool.

MOUNTING BOLTS

Remove the flywheel mounting bolts in a crisscrosspattern in several steps as shown, then.emove the

Jlvwheel.

Bemove the flywheel bearing from the flywheel.

(cont'd)

FLYWHEEL

I

1.Inspect the ring gear teeth tor wear and damage.

Inspect the clutch disc mating surtace on the

flywheel for wear, cracks, and burning.

l\,reasure the flywheel runout using a dial indicator

through at least two full turns. Push agsinst the

Jlywheel each time you turn it to take up the crank-

shatt thrust washer clearance.

NOTE: The runout can ba measured with engine in-

stalled.

SiEndrrd (Ncw): 0.05 mm (0.002 inl max.

SerYicc Llmh: 0.15 mm (0.006 inl

DIAL INOICATOR

lf the runout is more than the service limit, reolace

the flywheel.

Turn the inner race of the flywheel bearing with your

tinger. The bearing should turn smoothly and quiet-

ly. Check that the bearing outer race tits tightly in

the flvwheel.

FLYWHEELBEARING

lf the race does not turn smoothly, quietly, or tit

tight in the flywheel, replace the flywheel bearing.

4.

FLYWHEEL

12-9

Page 367 of 1681

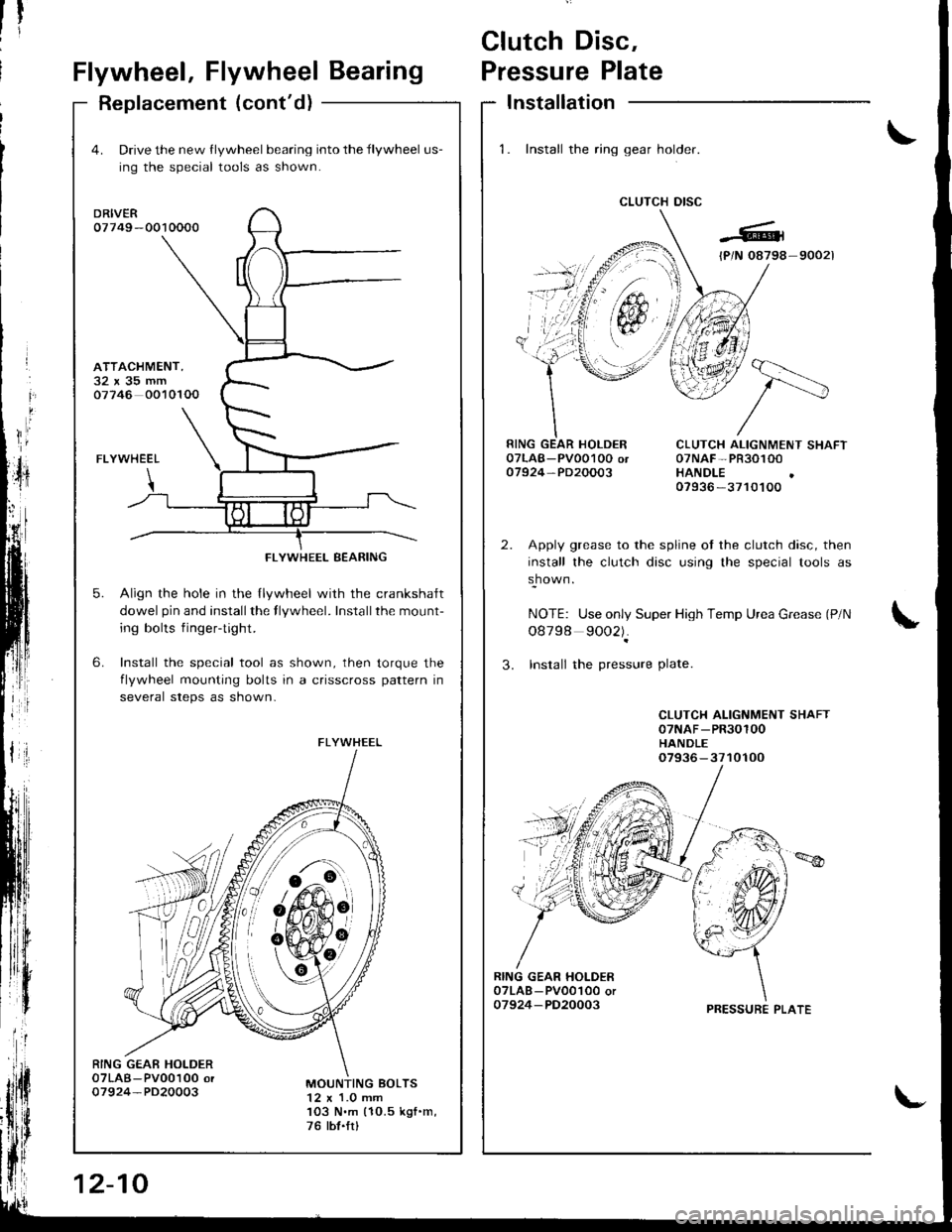

Clutch Disc,

Flywheel, Flywheel BearingPressure Plate

Replacement (cont'd)Installation

1. Install the ring gear holder.

CLUTCH DISC

1tti

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936 -3710100

Apply grease to the spline ot the clutch disc, then

install the clutch disc using the special tools as

shown.

NOTE: Use only Super High Temp Urea Grease (P/N

o8798 9002).

3. Insrall the pressure Plate.

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710100

RING GEAR HOI-DER07LAB - PV001O0 or07924-PD20003

4. Drive the new flywheel bearing into the flywheel us-

ing the special tools as shown.

DRIVER07749 -0010000

FLYWHEEL

Align the hole in the llywheel with the crankshalt

dowel pin and installthe flywheel. Installthe mount-

ing bolts fingertight.

Install the special tool as shown, then torque the

flvwheel mounting bolts in a crisscross pattern in

several steps as shown-

6.

ATTACHMENT,32x35mm07746 0010100

5.

RING GEAE HOLDER07LAB-Pv00100 or07924-PD20003MOUNTING BOLTS12 x 1.0 mm103 N.m (10.5 kgf .m,

76 tbt.frl

FLYWHEEL BEARING

FLYWHEEL

6!-o

&#,oit

12-10

PRESSURE PLATE

Page 368 of 1681

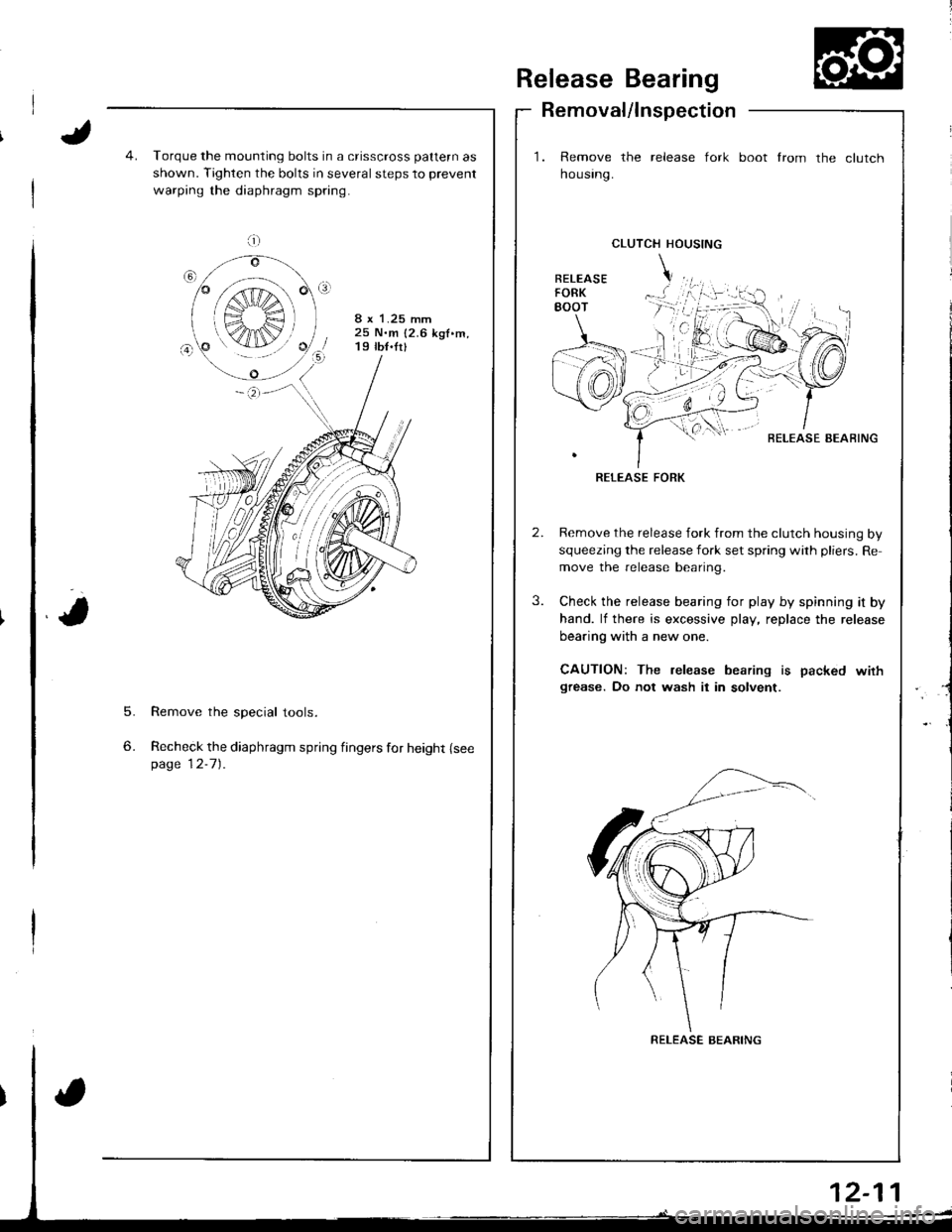

Release Bearing

Removal/lnspection

1. Remove the release fork

housrng.

boot from the clutch

5.

6.

Torque the mounting bolts in a crisscross pattern as

shown. Tighten the bolts in several steps to prevent

warping the diaphragm spring.

8 x 1.25 mm25 N.m {2.6 kgf.m,19 tb{.fr}

Remove the special tools.

Recheck the diaphragm spring fingers for height {seepage 12-7).

CLUTCH HOUSING

BELEASE AEAFING

RELEASE FORK

Remove the release fork from the clutch housing by

squeezing the release fork set spring with pliers. Re

move the release bearing.

Check the release bearing for play by spinning it by

hand. lf there is excessive play, replace the release

bearing with a new one.

CAUTION: The release bearing is packed wirhgrease. Do not wash it in solvent.

a;;;:

S",€ r

K4IN/

RELEASE BEARING

Page 374 of 1681

I

T

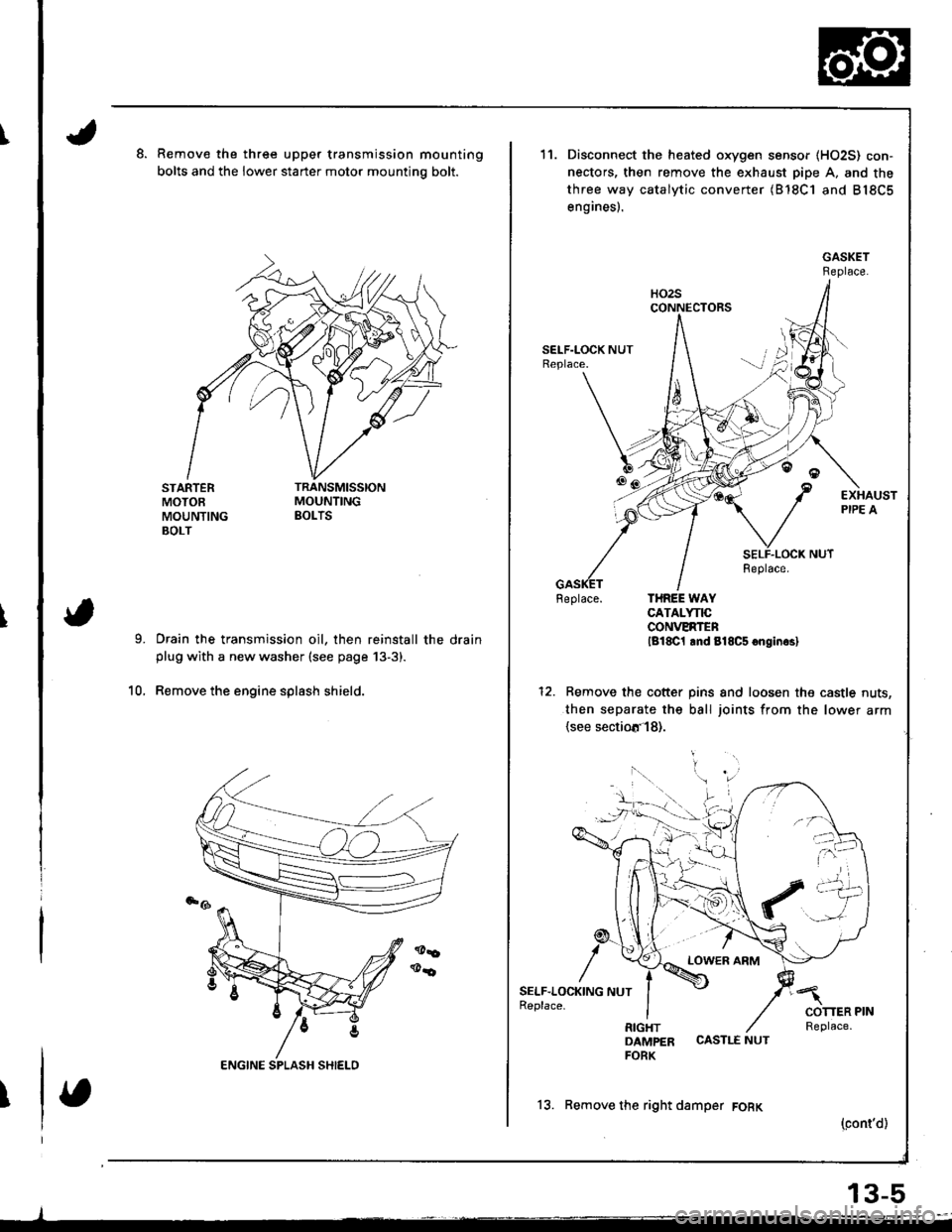

Remove the three upper transmission mounting

bolts and the lower starter motor mountino bolt.

STARTERMOTOEMOUNTINGBOLT

Drain the transmission oil, then reinstall the drainplug with a new washer (see page 13-3).

Remove the engine splash shield.10.

11.

6tr!

/

SELF.LOC1(ING NUTReplace.

Disconnect the heated oxygen sensor (HO2S) con-

nectors, then remove the exhaust pipe A. and the

three way catalytic converter (B'18C1 and B18C5

engines).

Feplace. THREE WAYCATALYNCCONVERTENlg18C1 lnd 818C5 onginrsl

Remove the cotter pins and loosen the castle nuts,

then separate the ball joints from the lower arm(see sectiotr'l8).

LOWER ARM

DAMPER CASTLE NUTFORK

13. Remove the right damper FORK

(cont'd)

13-5

Page 406 of 1681

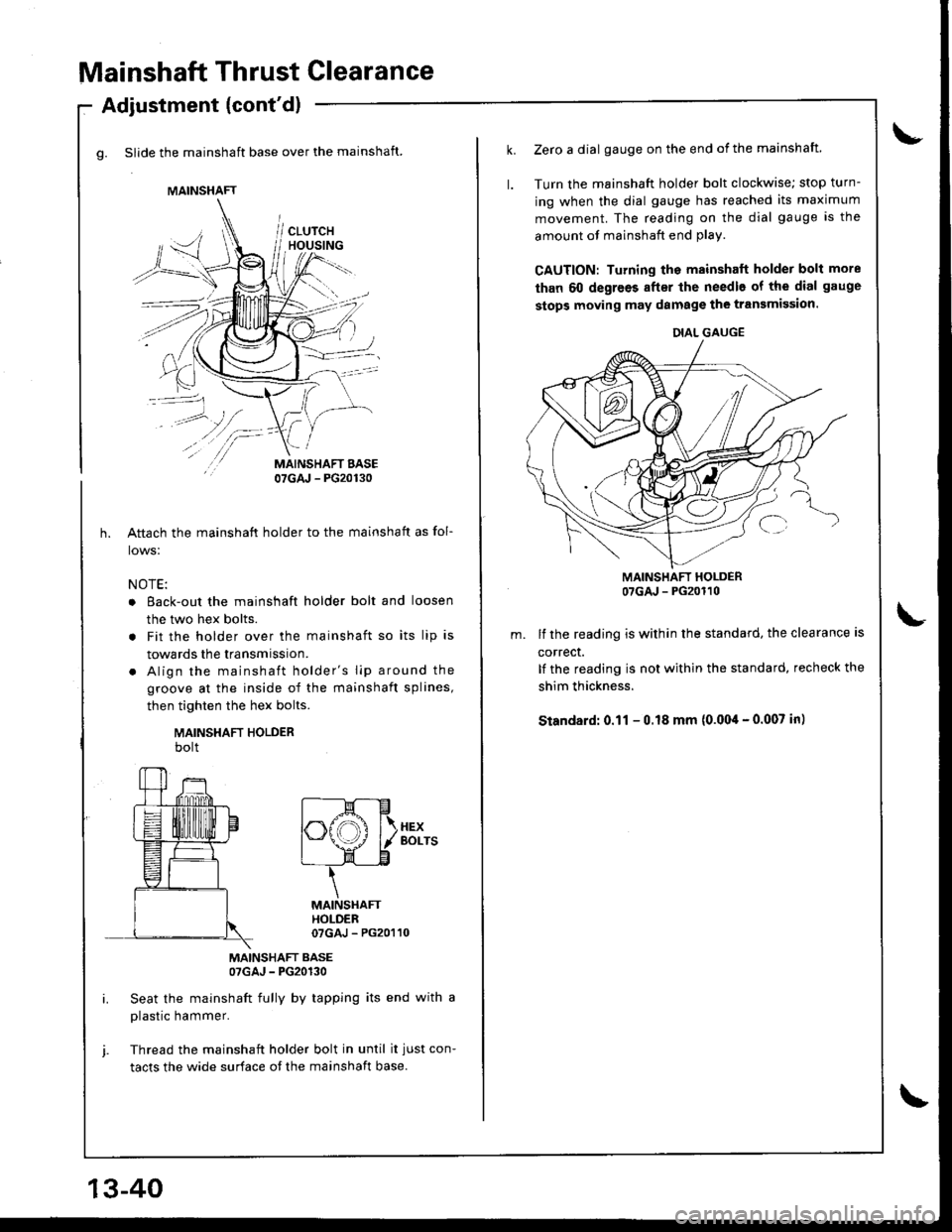

Mainshaft Thrust Clearance

g. Slide the mainshaft base over the mainshaft.

Adjustment (cont'dl

/\

/-

MAINSHAFT BASE07GAJ - PG20130

Aftach the mainshaft holder to the mainshaft as fol-

lows:

NOTE:

o Eack-out the mainshaft holder bolt and loosen

the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft splines,

then tighten the hex bolts.

MAINSHAFT HOLDERbolt

MAINSHAFT BASE07GAJ - PG20130

Seat the mainshaft fully by tapping its end with a

plastic hammer.

Thread the mainshaft holder bolt in until it just con-

tacts the wide surface of the mainshaft base.

MAINSHAFT

f----M---E

|".ffi f\.xex

I \J \--l./ l/ Borrs

L- LE

\

MAINSHAfiHOLDER07GAJ - PG20110

13-40

Zerc a dial gauge on the end of the mainshaft.

Turn the mainshaft holder bolt clockwise; stop turn-

ing when the dial gauge has reached its maximum

movement. The reading on the dial gauge is the

amount of mainshaft end plav.

CAUTION: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial gauge

stops moving may damage the transmission.

MAINSHAFT HOLDER07GAJ - PG20110

lf the reading is within the standard, the clearance is

correct.

It the reading is not within the standard, recheck the

shim thickness.

Standard: 0.11 - 0.18 mm (0.004 - 0.007 in)

DIAL GAUGE

Page 408 of 1681

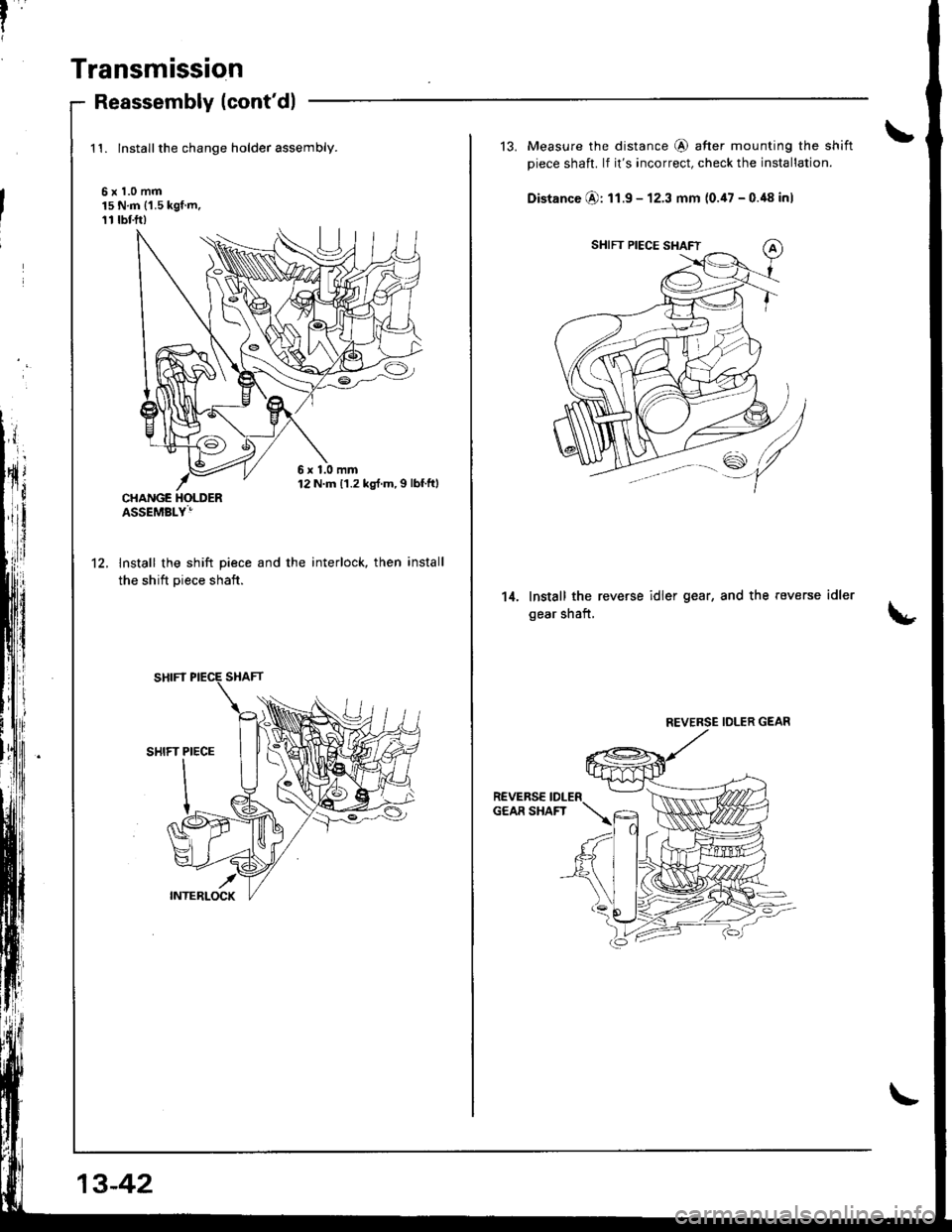

Transmission

Reassembly (cont'dl

1't. lnstallthe change holder assembly.

6x1.0mm15 N.m ('1.5 kgf.m,11 rbf.ft)

lnstall the shift piece and the

the shift piece shaft.

interlock, then install't2.

6x1.0mm12 N.m 11.2 kg{.m,I lbf.ftl

13-42

13. Measure the distance @ after mounting the shift

piece shaft. lf it's incorrect, check the installation.

Distance @: 11.9 - 12.3 mm (0.47 - 0.48 inl

Install the reverse idler gear, and the reverse

gear shaft,

idler14.

REVERSE IDLER GEAR

Page 412 of 1681

I

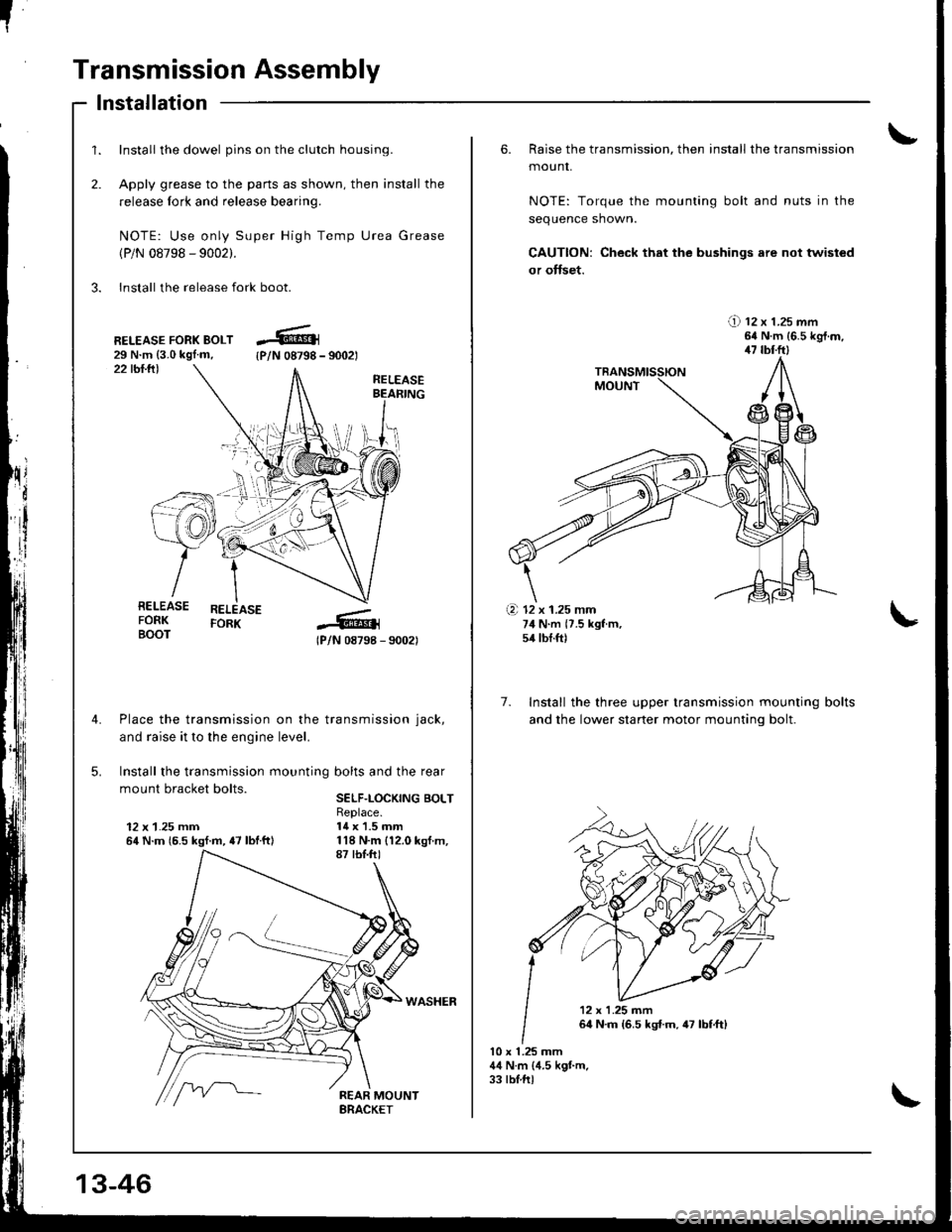

Transmission Assembly

1.

2.

Install the dowel pins on the clutch housing.

Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbl.lll

RELEASE FORK BOLT29 N.m {3.0 kgl.m,{P/N 08798 - 9002t

RELEASEBEAFING

RELEASEFORK

lPlN 08798 - 90021

Place the transmission on the transmission jack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts.SELF.LOCKING BOLT

12 x 1.25 mm64 N.m {6.5 kgf.m, {7 lbtftl

Replace.14 x 1.5 mm

RELEASEFORKBOOT

\i'l-r )i-

.+.i

13-46

6. Raise the transmission, then install the transmission

mounr,

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twisted

or offset.

!) tz x t.zs mm64 N.m {6.5 kgt.m,47 tbl.ftl

7. Install the three upper transmission mounting

and the lower staner motor mountinq bolt.

bolts

10 x 1.25 mm44 N.m (4.5 kgt m.33 tblftl

(a 12 x 1.25 mm74 N.m {7.5 kgf m,54 tbf.ft)

'12x1.25m�n

64 N.m {6.5 kst.m,47 lbf,ft)

Page 413 of 1681

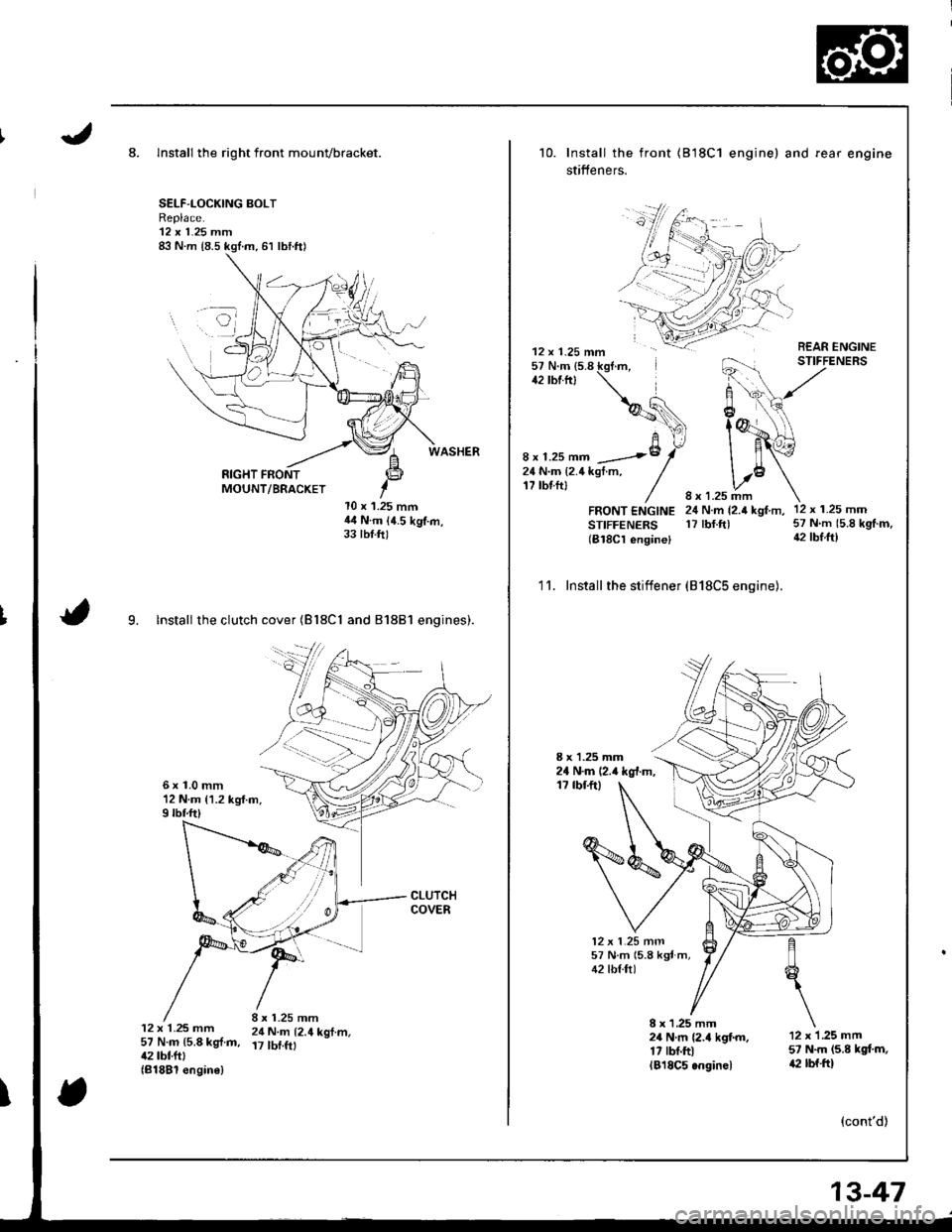

8. Install the right front mounvbracket.

SELF-LOCKING BOLTReplace.'12 x 1.25 mm

RIGHT FRONTMOUNT/BRACKET

l0 x 1.25 mmil4 N.m (4.5 kg'f.m,33 tbt.ft)

9. lnstall the clutch cover (Bl8Cl and 81881 engines).

6x1.0mm12 N.m {1.2 kg{.m,9 rbf.ft)

12 x 1.25 mm 24 N.m t2.4 kof.m.57 N.m {5.8 kg{.m, 17 tbf.ftt42 tbt.ftl(81881 engin€)

10. Install the front

stifteners.

(818C1 engine) and fear engine

REAR ENGINESTIFFENERS

12 x 1.25 mm57 N'm 15.8 kg{.m.42 tbr.ltl

H!\,

f @^\

I B'�{o| \-

1.25 mmN.m {2.4 kgf m,rbf.ftl

12 x 1.25 mm57 N.m (5.8

{2 tbtft}

8 x 1.25 mm -8

24 N.m {2.4 kgt m,17 tbtftl

FRONT ENGINESTIFFENERS(B18Cl engine)

12 x 1.25 mn157 N m (5.8 kgt m,42 tbl.ftl

2111

'11. Install the stiffener (818C5 engine).

8 x 1.25 mm24 N.m (2.4 kg{.m,1? tbf.ftl

8 x 1 ,25 mm24Nm{2.4kgtm.17 rbr.ftllBl8C5.nginel

12 x 1 .25 mm57 N.m (5.8 kgl.m,a2 rbf.ftl

(cont'd)

13-47