Head HONDA INTEGRA 1998 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 343 of 1681

t"iI

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

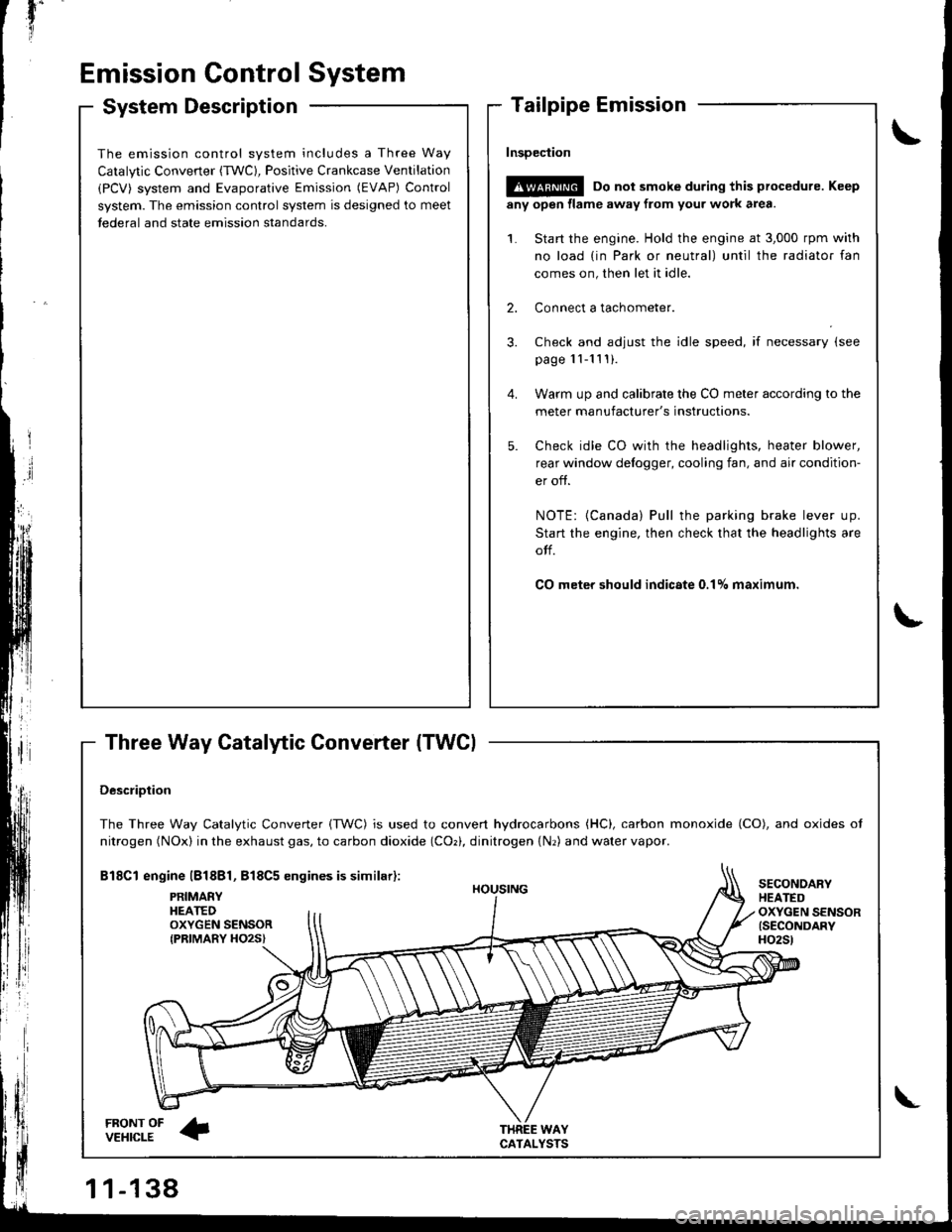

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 403 of 1681

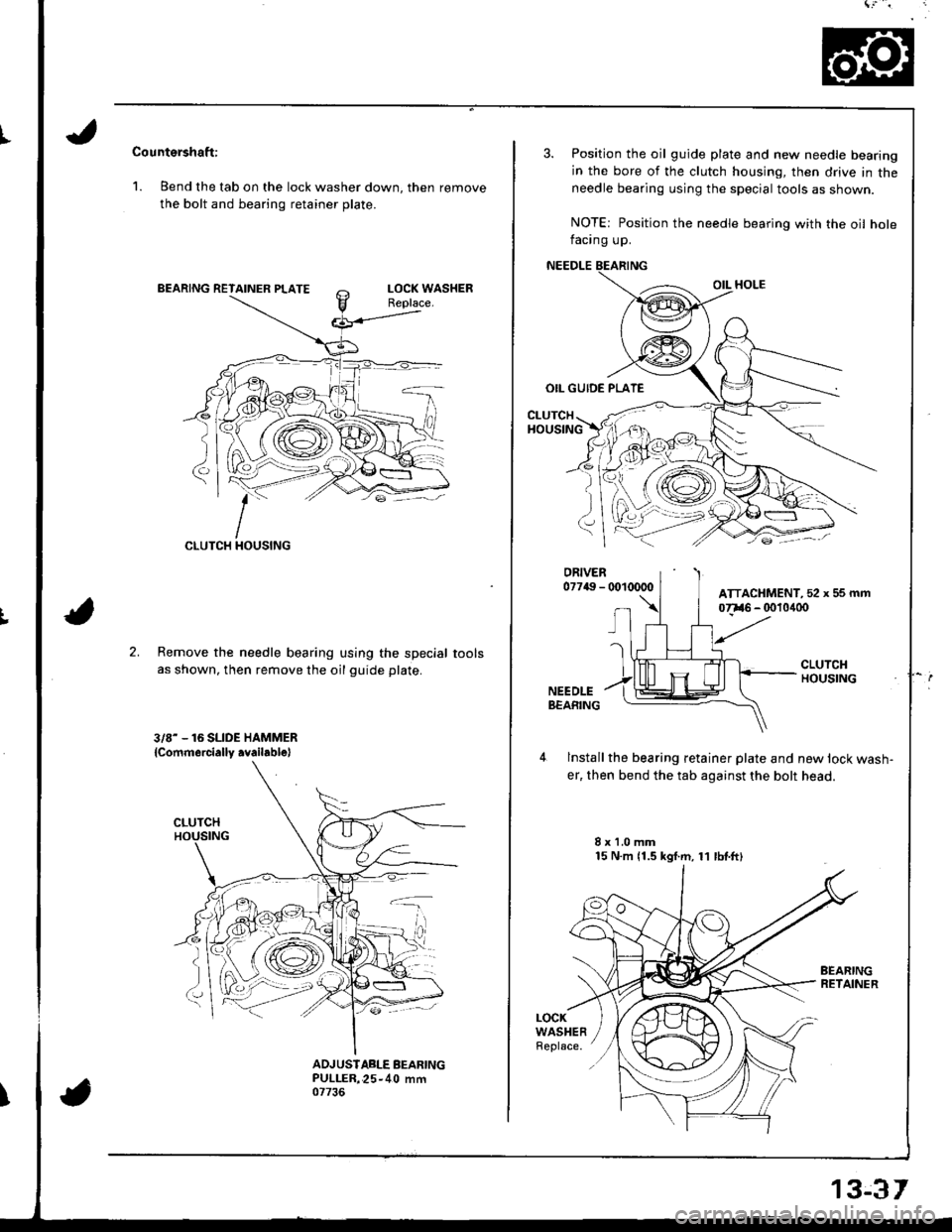

Countershaft:

1. Bend the tab on the lock washer down, then remove

the bolt and bearing retainer plate.

CLUTCH

;:-

2.Remove the needle bearing using the special

as shown, then remove the oil guide plate.

3/8- - 16 SLIDE HAMMER

lcommercially .vailablel

tools

ADJUSIABLE BEARINGPULLER,25-40 mm07736

3. Position the oil guide plate and new needle bearing

in the bore of the clutch housing, then drive in theneedle bearing using the special tools as shown.

NOTE: Position the needle bearing with the oil holefacing up.

NEEDLE

OIL HOLE

OIL GUIDE PLATE

CLUTCHHOUSING

lnstall the bearing retainer plate and new lock wash-

er, then bend the tab against the bolt head.

8x1.0mm15 N.m 11.5 kgf.m, 11 lbtftl

LOCKWASHERReplace.

ATTACHMENT, 52 x 5s mm

13€r

Page 579 of 1681

![HONDA INTEGRA 1998 4.G Owners Guide 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in HONDA INTEGRA 1998 4.G Owners Guide 18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in](/img/13/6069/w960_6069-578.png)

18. Install the sub-shaft assembly in the transmission

housing {see page 14-142],.

'19. Install the reverse idler gear and gear shaft holder(see page 14-158).

20. Install the differential assembly in the torque con

verter housrng.

21. Assemble the mainshaft and countershaft sub-

assembly, then install them together in the torque

converler noustng.

22. Turn the shilt fork so the large chamlered hole is fac-

ing the fork bolt hole, then installthe shift tork with

the reverse selector and torque the lock bolt. Bend

the lock tab against the bolt head.

SHIFT FORK

23. Install the reverse gear with the collar and needte

bearing on the countershaft.

24. Align the spring pin of the control shaft with the

transmission housing groove by turning the control

shaft.

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins.

CONTROL

TRANSMISSION HOUSING

lnstall the transmission housing mounting bolts along

with the transmission hanger and the connector

bracket, then torque the bolts in two or more steps

in the sequence shown.

TOROUE: rt4 N'm (4.5 kgt.m, 33 lbt.lt)

TRANSMISSION

26.

LOCK WASHERReplace.

6 x 1.0 mm4 t{.m(1.4 kgf.m, 10

e

Large chamfered hole

/ -'K\,,

a

14-163

Page 658 of 1681

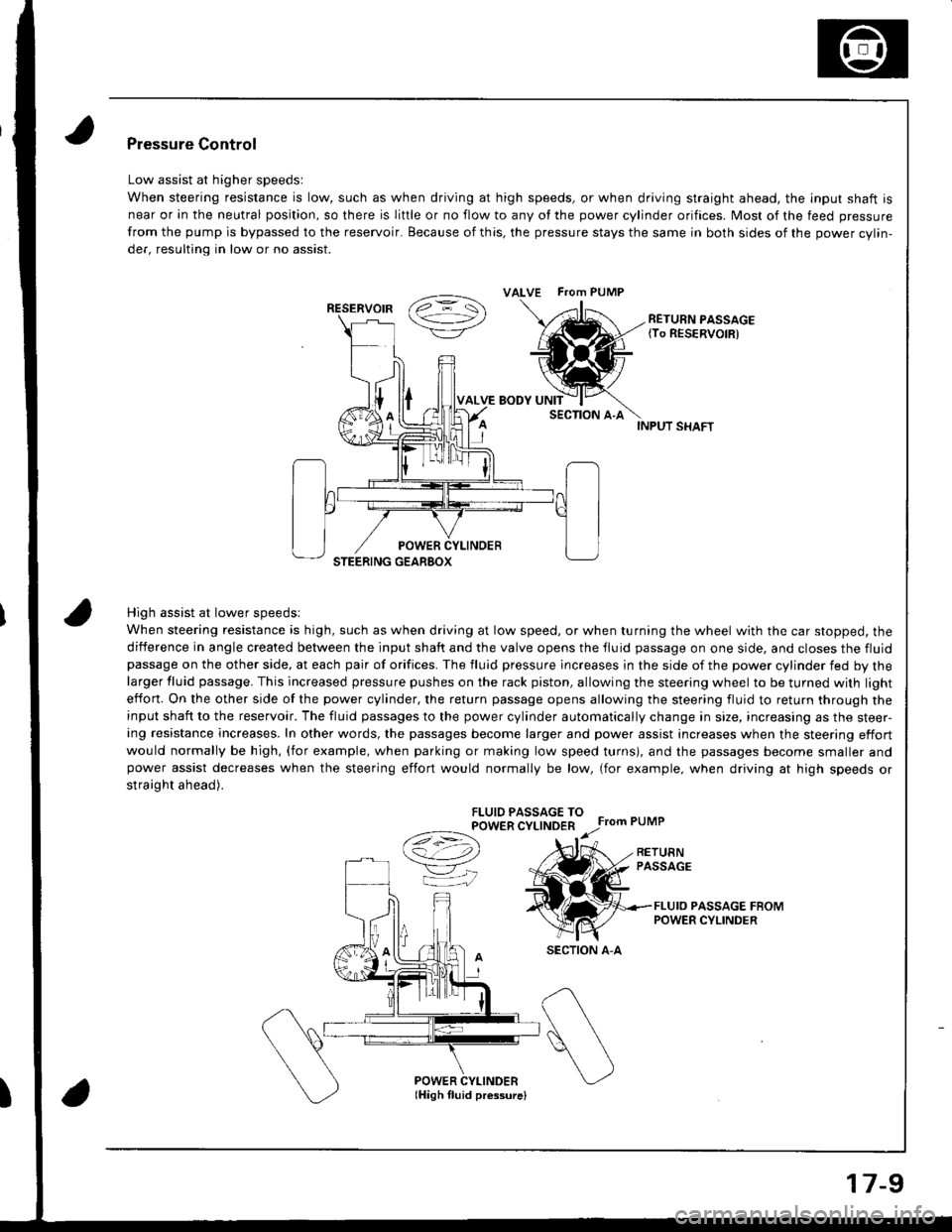

INPUT SHAFT

High assist at lower speedsl

When steering resistance is high, such as when driving at low speed, or when turning the wheel with the car stopped, the

diiference in angle created between the input shaft and the valve opens the tluid passage on one side, and closes the fluidpassage on the other side, at each pair of orifices. The fluid pressure lncreases in the side of the power cylinder fed by thelarger fluid passage. This increased pressure pushes on the rack piston, allowing the steering wheel to be turned with light

effon. On the other side of the power cylinder, the return passage opens allowing the steering fluid to return through theinput shaft to the reservoir. The fluid passages to the power cylinder automatically change in size, increasing as the steer-ing resistance increases. In other words, the passages become larger and power assist increases when the steering effort

would normally be high, (for example, when parking or making low speed turns), and the passages become smaller andpower assist decreases when the steering effort would normally be low, (for example, when driving at high speeds or

straight ahead).

FLUIO PASSAGE TOPOWER CYLINDER

Ce) r.r;

VK

Pressure Control

Low assist at higher speedsl

When steering resistance is low, such as when driving at high speeds, or when driving straight ahead. the lnput shaft is

near or in the neutral position, so there is liftle or no flow to any of the power cylinder orifices. Most of the feed pressure

from the pump is bypassed to the reservoir. Because of this, the pressure stays the same in both sides of the power cvlin-

der, resulting in low or no assist.

RETURN PASSAGE{To RESERVOIR)

POWER CYLINDERlHigh fluid pressurelI

ALVE FTom PUMP

RESERVOIR

SECTION A-A

17-9

Page 667 of 1681

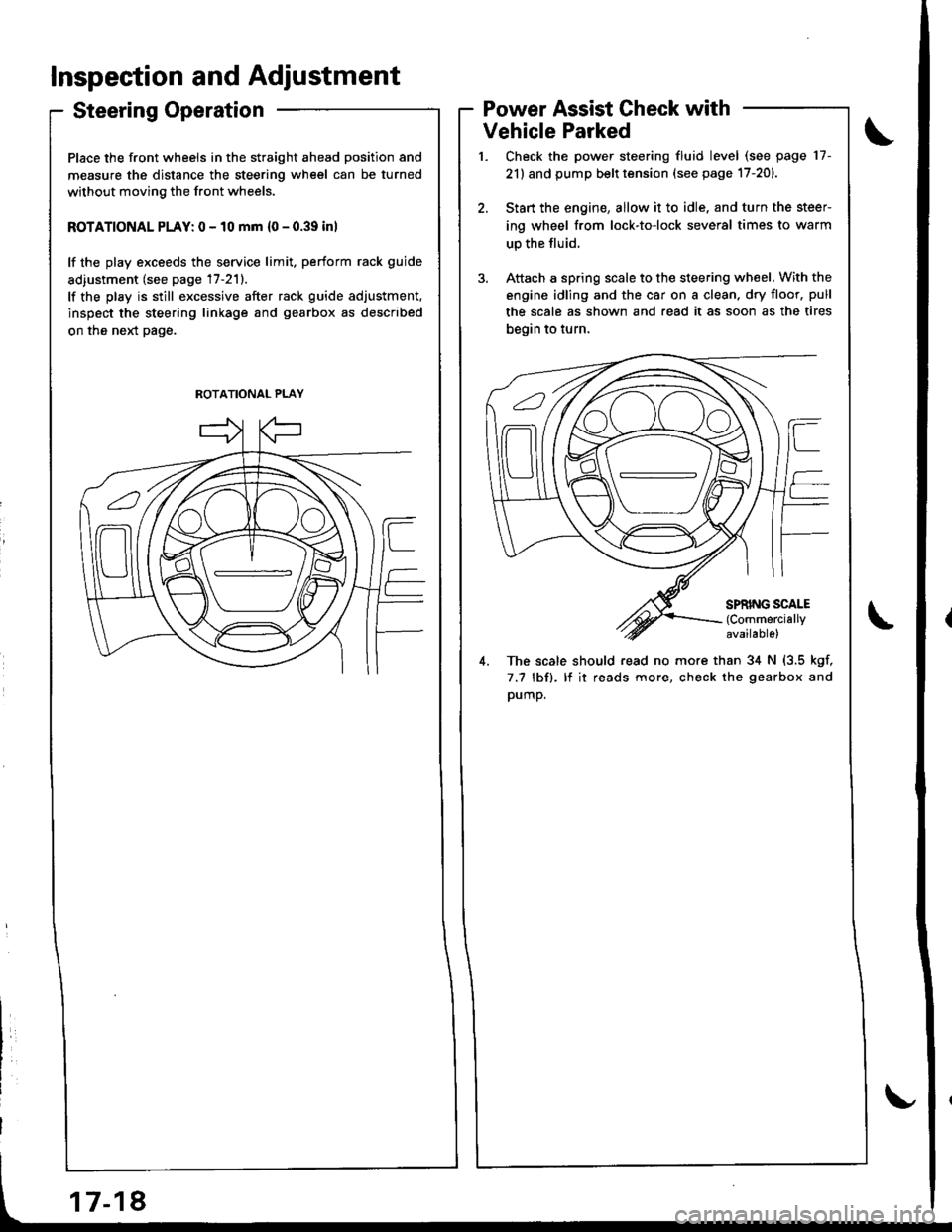

Inspection and Adjustment

Steering Operation

Place the front wheels in the straight ahead position and

measure the distance the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm {0 - 0.39 inl

lf the play exceeds the service limit. perform rack guide

adiustment (see page 17-211.

lf the play is still excessive after rack guide adjustment.

inspect the steering linkage and gearbox as described

on the neld page.

Power Assist Check with

Vehicle Parked

Check the power steering fluid level (see page 17-

21) and pump belt tension (see page 17-201.

Start the engine, allow it to idle. and turn the steer

ing wheel from lock-to-lock several times to warm

up the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean. dry floor. pull

the scale as shown and read it as soon as the tires

begin to turn,

4. The scale should read no more than 34 N (3.5 kgf,

7.7 lbf). lf it reads more, check the gearbox and

pump.

ROTATIONAL PLAY

Page 670 of 1681

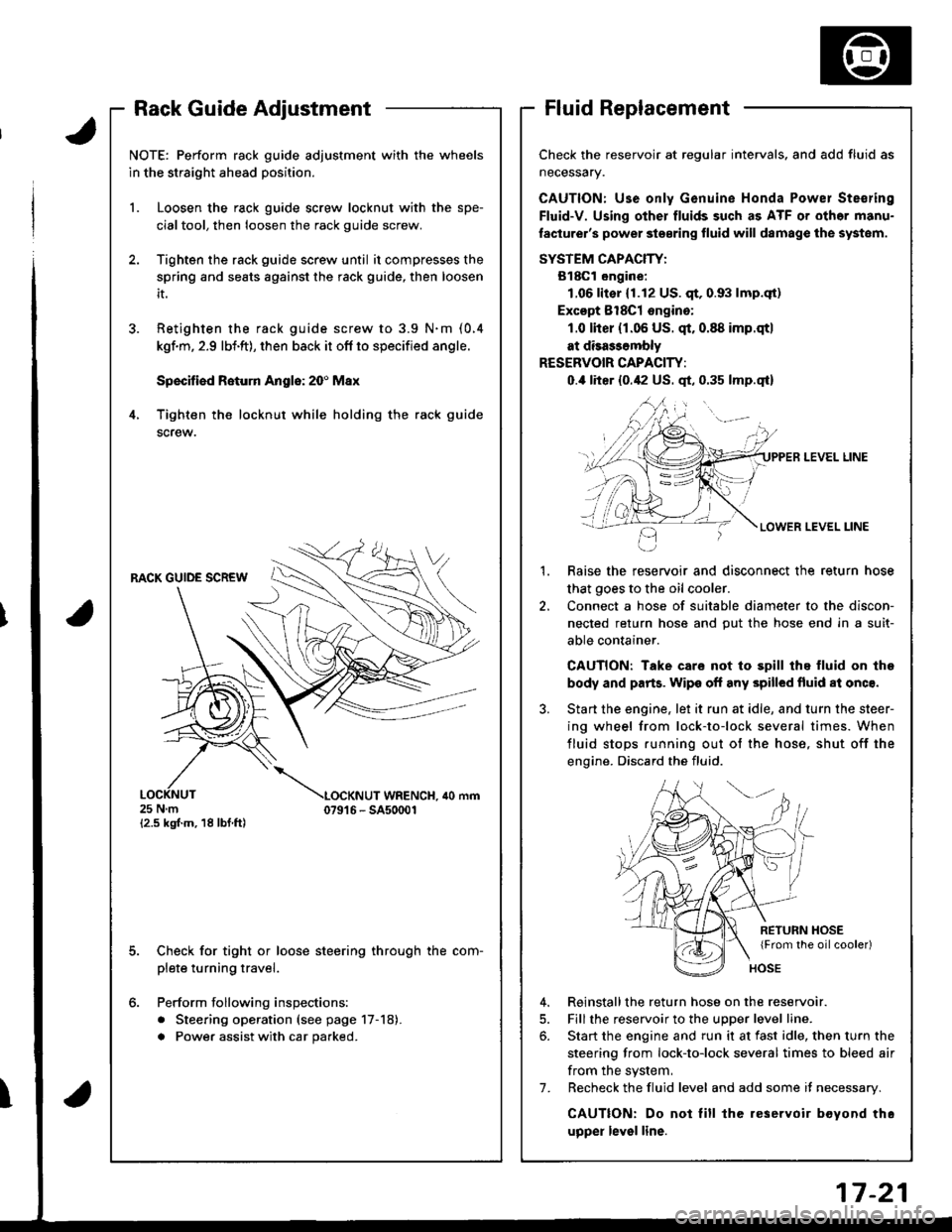

Rack Guide AdjustmentFluid Replacement

Check the reservoir at regular intervals, and add fluid as

neceSsary.

CAUTION: Use only Genuine Honda Powel Ste€ring

Fluid-V. Using other fluids such as ATF or othor manu-

laclurer's power ste€ring fluid will damag€ the systom.

SYSTEM CAPACIW:

B18Gl ongine:

1.06lit€r (1.12 US. qt,0.93 lmp.qt)

Excopt 8l8Cl ongino:

1.0 lher (r.06 US. qt.0.88 imp.qtl

at disa$ombly

RESERVOIR CAPACITY:

0.,0 liter {0.42 US. qt, 0.35 lmp.qt}

LEVEL LINE

LEVEL LINE

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Take care not to spill thq fluid on lhe

body and parts. Wipe off any spilled fluid al onc€.

Start the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

2.

RETURN HOSE{From the oilcooler)

4. Reinstallthe return hose on the reservoir.

5. Fill the reservoir to the uDDer level line.

6. Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

from the system,

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not lill the reservoir boyond thc

upper level line.

J.

4.

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

it.

Retighten ihe rack guide screw to 3.9 N.m (0.4

kgf.m, 2.9 lbi.ft), then back it ofl to specified angle.

Speciliad Roturn Anglo: 20' Max

Tighten th€ locknut while holding the rack guide

screw.

RACK GUIDE SCREW

25Nm{2.5 kgf.m, 18 lbf ft)

LOCKNUT WRENCH. ilo mm079't 6 - SA50001

E

6.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

a Power assist with car parked.

I

Page 675 of 1681

Steering Wheel

lnstallation

Airbag installation

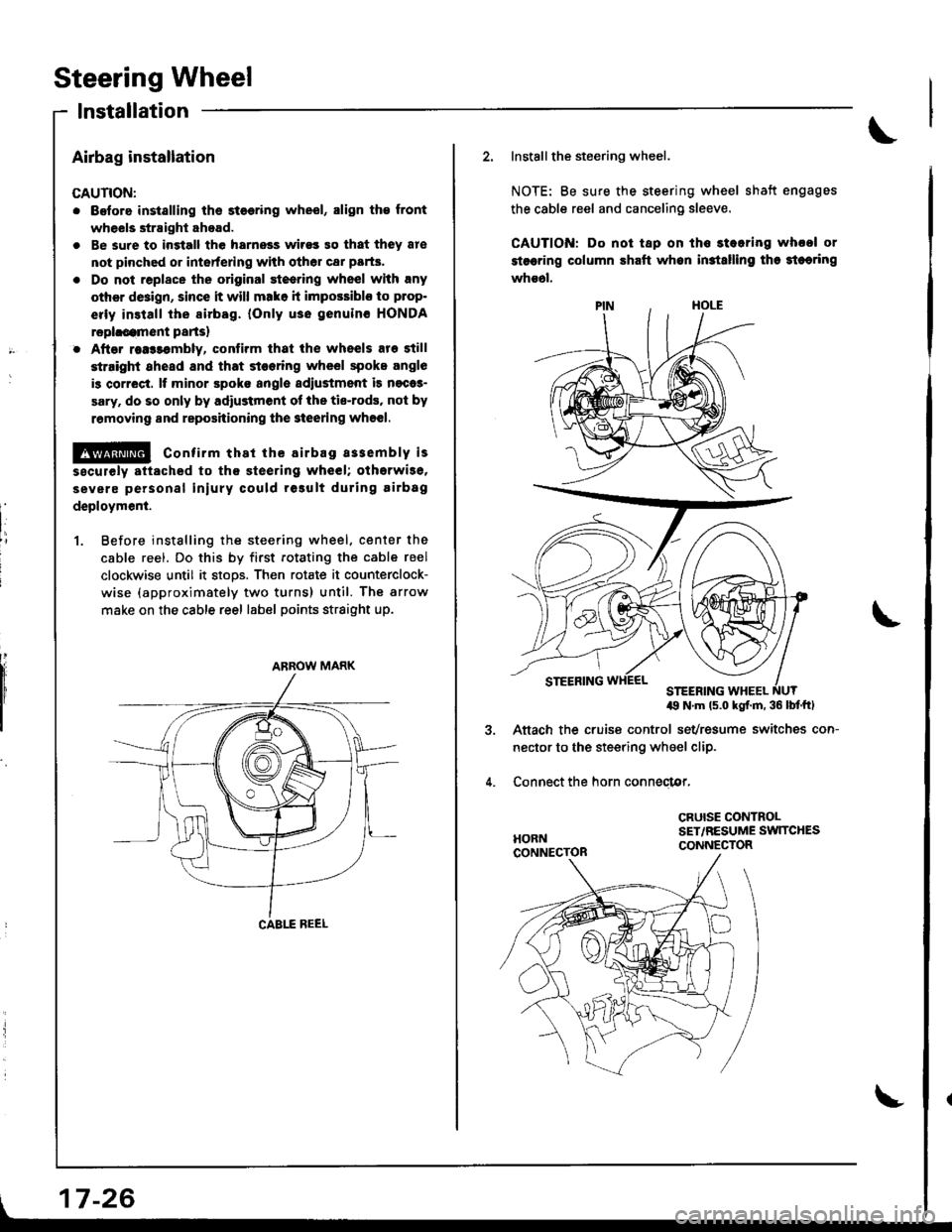

CAUTION:

. Before installing ths st€€ring wheel, align th€ front

wheels straight ahead.

. Be sure to ingtall the harnoss wirss 90 that they 8re

not pinched or intorfering with other car parts.

. Do not replace the original st€ering wheel with rny

other d8ign, since it will mako h impossiblo to p.op-

erly install the sirbag. {Only use genuinc HONDA

rephcamont parts)

. After rea$embly, contirm that ih€ wheels are still

st.ight 8head and that stooring wheel spoke angle

is correct. It minor spoko aogle sdiustment is n€cas-

sary. do so only by adiustment ol the tis-rods, not by

removing and reposhioning the 3teering who€|.

!@ confirm thst the airbag a33embly is

sscurely attached to th€ steering wheel; otherwi3e,

severe personal iniury could result during airbag

deploymenl.

1. Before instslling the steering wheel. center the

cable reel. Do this by first rotating the cable reel

clockwise until it stoos. Then rotate it counterclock-

wise (approximately two turns) until. The arrow

make on the cable reel label points straight up.

ARROW MARK

| 17-26

\

2. Installthe steering wheel.

NOTE: Be sure the steering wheel shatt engages

the cable reel and canceling sleeve.

CAUTION: Do not tap on ths stearing whool or

stsering column shaft whon in3tslling tha 3teoring

whs6l.

49 N'm ls.o kgf.m. 36 lbf'ftl

Aftach the cruise control sevresume switches con-

nector to the steering wheel clip.

Connect the horn conneclor,

CRUISE CONTROLSET,/RESUME SW]TCHESCONNECTOR

Page 692 of 1681

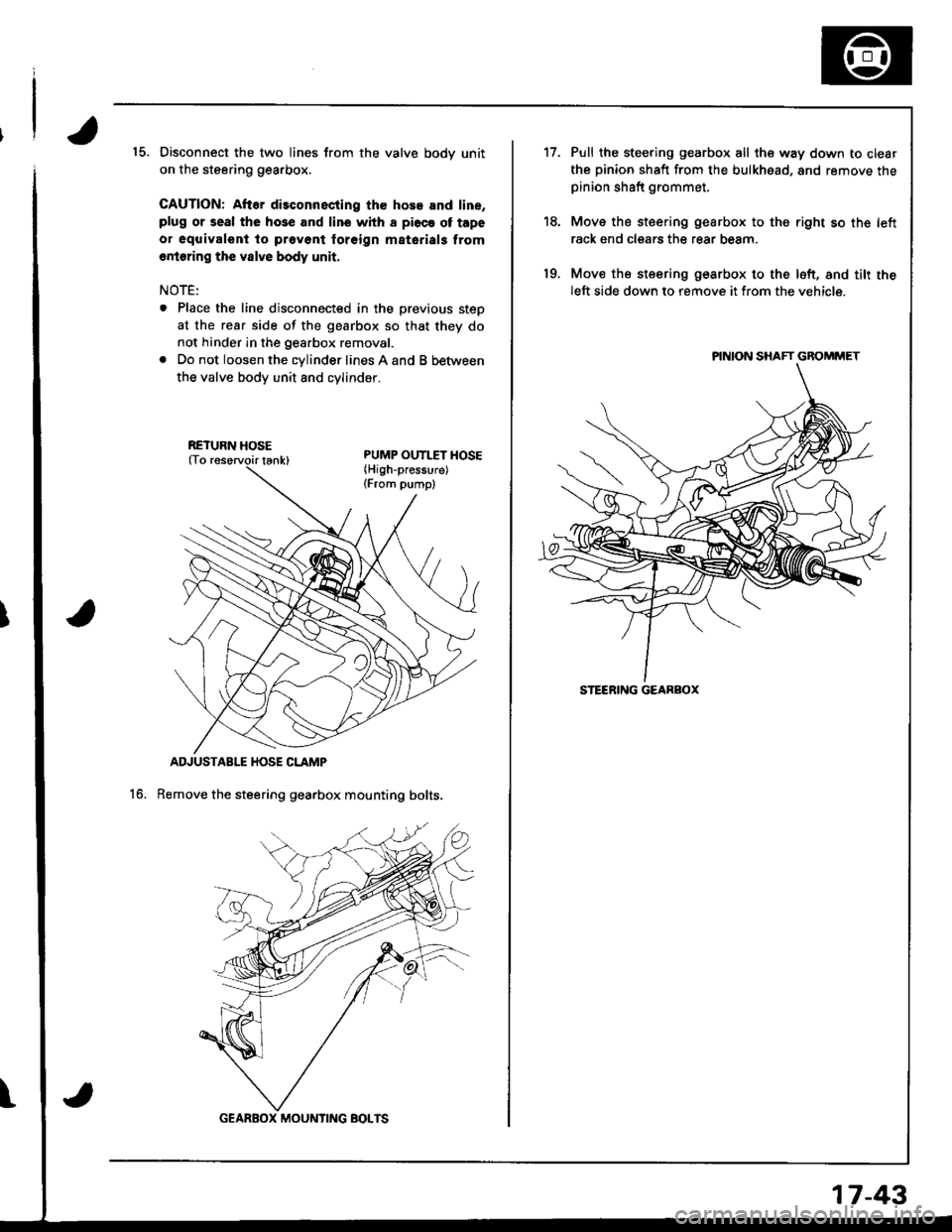

15. Disconnect the two lines from the valve bodv unit

on the steering gearbox.

CAUTION: After disconnscting the hose and line,plug or seal the hose and lino whh I pi6ce ot tape

o. oquivalent to prevont foreign matarials from

6rioring the vslve body unit,

NOTE:

. Place the line disconnected in the previous steD

at the rear side of the gearbox so that they do

not hinder in the gearbox removal.

. Do not loosen the cylinder lines A and B between

the valve body unit 8nd cvlinoer.

ADJUSTABLE HOSE CLAMP

Remove the steering gearbox mounting bolts.16.

\

RETURN HOSE

GEARBOX MOUNTING BOTTS

17-43

't7.

19.

Pull the steering gearbox all the way down to clear

the pinion shaft from the bulkhead, and remove thepinion shaft grommet.

Move the steering gearbox to the right so th€ left

rack end clears the rear beam.

Mov€ the steering gearbox to the loft, and tilt theleft side down to remove it from the vehicle.

PINION SHAFT GBOMMET

STEERING GEARBOX

Page 706 of 1681

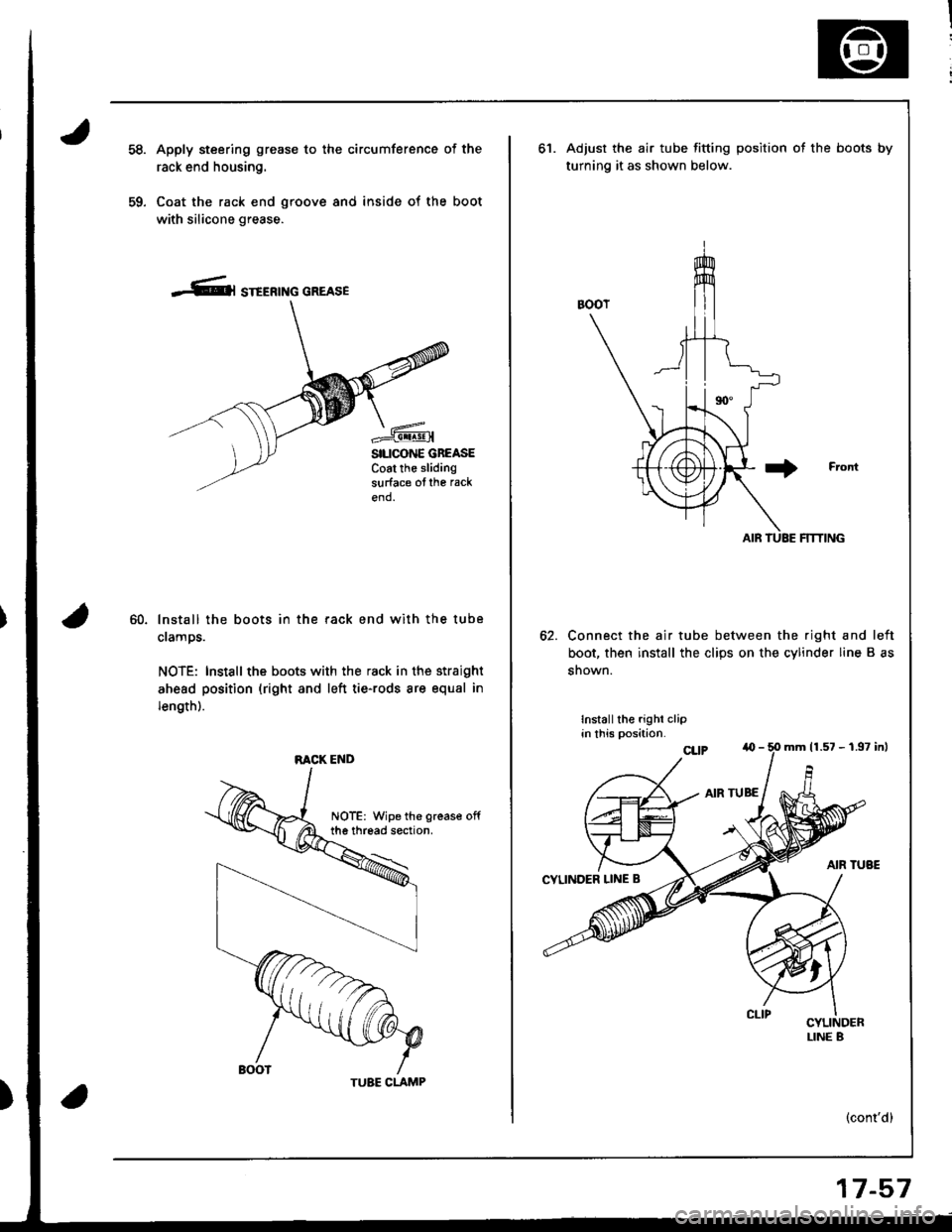

59.

Apply steering grease to the circumference of the

rack end housing.

Coat the rack end groove and inside of the boot

with silicone grease.

-Cl STEERTNG GREASE

SILICONE GBEASECoat the slidingsurface ofthe rack

end.

60.lnstall the boots in the rack end with the tube

clamps.

NOTE: Install the boots with the rack in the straight

ahead position (right and left tie-rods are equal in

length).

RACK END

TUBE CLAMP

17-57

ot.Adjust the air tube fitting position ot the boots by

turning it as shown below.

Connect the air tube between the right and left

boot, then install the clips on the cylinder line B as

snown.

Installthe righi clipin this position.

(cont'd)

mrn 11.57 - 1.97 inl

Page 715 of 1681

\

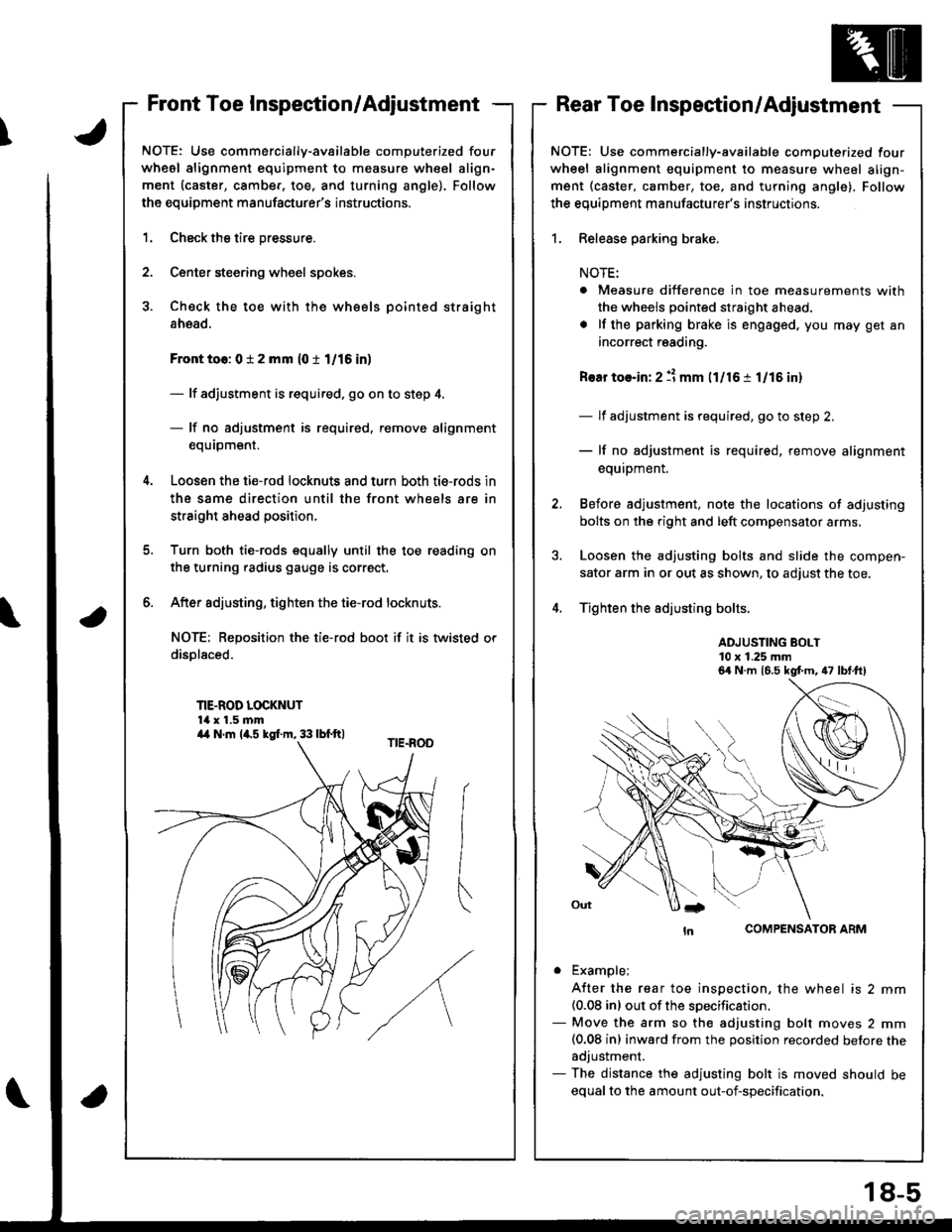

Front Toe Inspection/AdjustmentRear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

whesl alignment equipment to measure wheel align-

ment (caster, camber, toe. and turning angle). Follow

the equipment manufacturer's instructions.

1.

2.

Check the tire pressure.

C€nter steering wheel spokes.

Check the toe with the wh€els pointed straight

ahead.

Front to6: 0 i 2 mm (0 t 1/16 in)

- lf adjustment is required. go on to step 4.

- lf no adjustment is required, remove alignment

equrpm€nr,

Loosen the ti€-rod locknuts and turn both tie-rods in

the same direction until the front wheels are in

straight ahead position.

Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

After sdjusting, tighten the tie-rod locknuts.

NOT€: Reposition the tie-rod boot if it is twisted or

displaced.

TIE-ROD LOCKNUT14 x 1.5 mm

6.

a

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle), Follow

the equiDment manufacturer's instructions.

1. Release parking brake.

NOTE:

. Measure difference in toe measurements with

the wheels pointed straight ahead.

. lf the parking brake is engaged. you may get an

incorrect reading.

Rear toe-in: 2 11 mm l1l16 i 1/15 in)

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts and slide the compen-

sator arm in or out as shown, to adjust the toe.

Tighten the adjusting bolts.

ADJUSTING BOLT10 x 1.25 mm

COMPENSATOR ARM

. Example;

A{ter the rear toe inspection, the wheel is 2 mm(0.08 inl out of the soecification.- Move the arm so the adjusting bolt moves 2 mm(0.08 inl inward from the position recorded betore theadjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

6a N.m 16.5 kgt m, 47 lbt.ft)

a4 N.m la.s kgI.m, 33 lbf.ft)

18-5