bulb HONDA INTEGRA 1998 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1270 of 1681

J

)

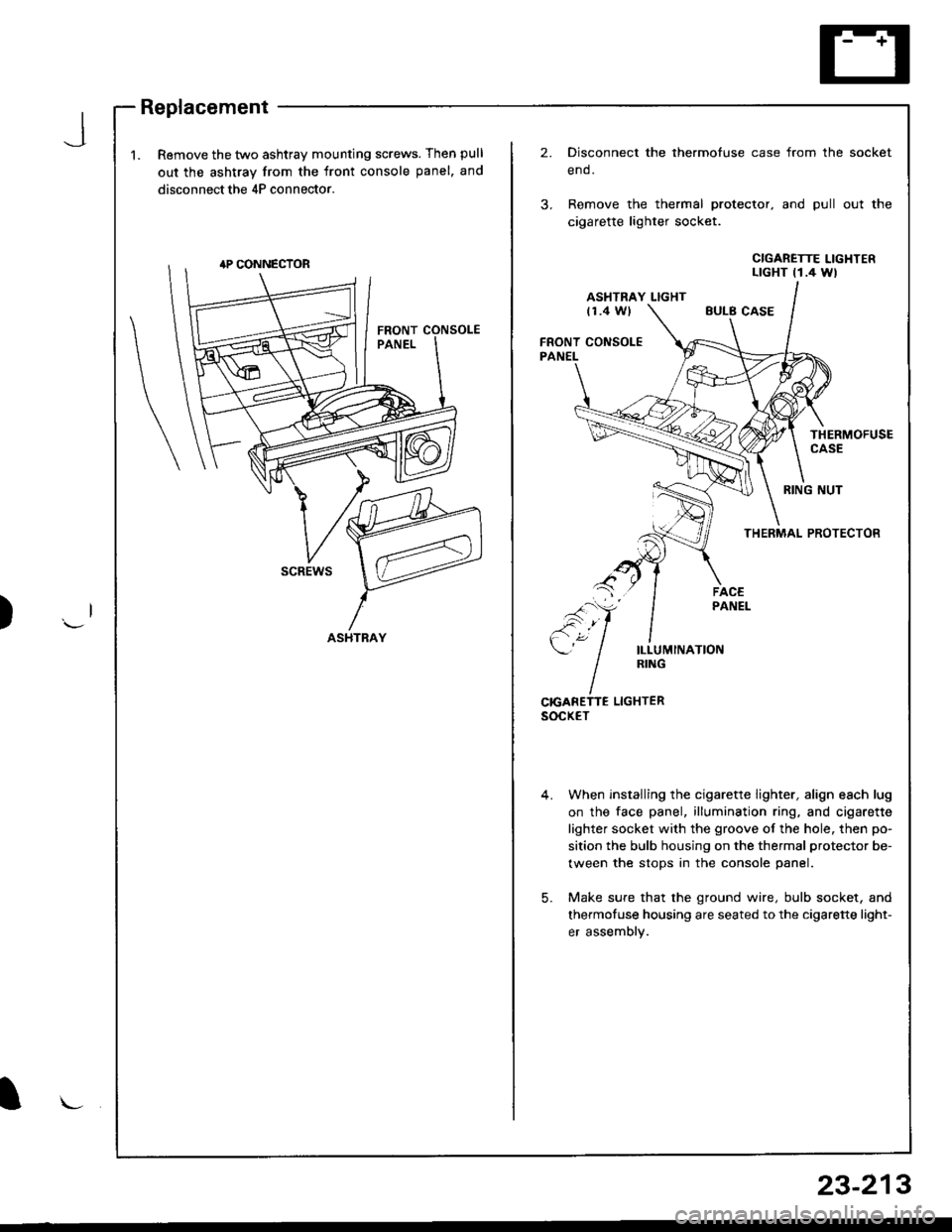

1.Remove the two ashtray mounting screws. Then pull

out the ashtray from the front console panel. and

disconnect the 4P connector.

2.Disconnect the thermofuse case from the

end.

Remove the thermal protector, and pull

cigarette lighter socket.

socket

out the

CIGARETTE LIGHTERLTGHT t1.4 Wl

ASHTRAY LIGHTt1.4 WlEULB CASE

FRONT CONSOLEPANEL

THERMOFUSECASE

RING NUT

THERMAL PROTECTOR

scREws

ILLUMINATIONRING

CrcANETTE LIGHTERsocxET

When installing the cigarette lighter, align each lug

on the face panel, illumination ring, and cigarette

lighter socket with the groove of the hole. then po-

sition the bulb housing on the thermal protector be-

tween the stops in the console panel.

Make sure that the ground wire, bulb socket, and

thermofuse housing are seated to the cigarette light-

er assembly.

5.

ASHTRAY

l\-

23-213

Page 1274 of 1681

)

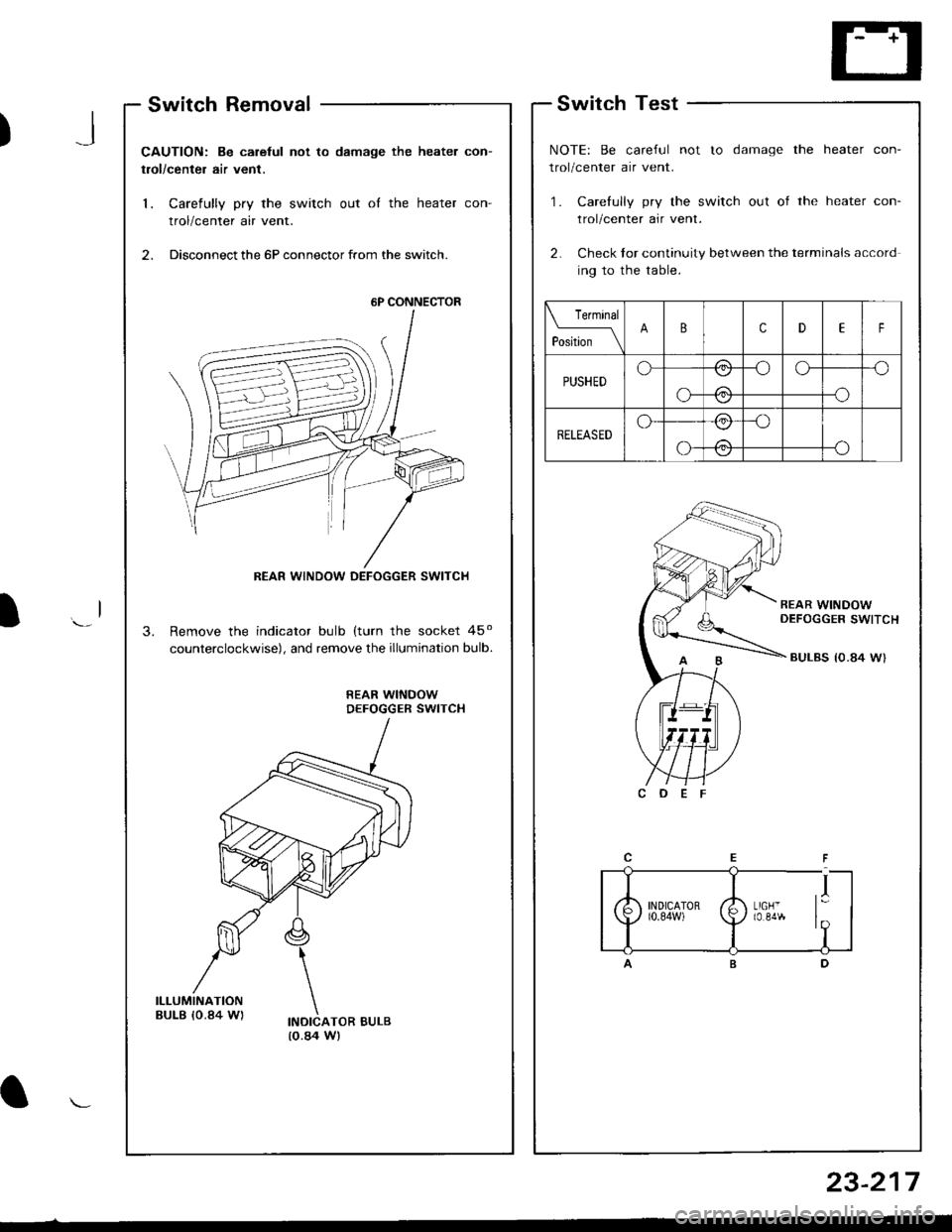

Switch Removal

CAUTION: Be carelul not to damage the heater con-

trol/center air vent.

1. Carefully pry the switch out oI the heater con-

trol/center air vent.

2. Disconnect the 6P connector from the switch.

Remove the indicator bulb (turn the socket 45o

counterclockwise), and remove the illumination bulb.

REAR WINDOWDEFOGGER SWITCH

INDICATOR BULB(o.84 W)

.l

Switch Test

NOTE: Be careful not to damage the heater con-

trol/center air vent.

'1. Carefully pry the switch out of the heater con-

trol/center air vent.

2. Check tor continuity between the terminals accord

ing to the table.

Terminal

pLN-_\BcDEF

PUSHEDo/:\-oo--o

o-

\:./

-o\:/

RELEASEDo-/:\_o

-oo-

\:,/

/:\\:./

I

6P CONNECTOR

REAR WINDOW DEFOGGER SWITCH

23-217

Page 1308 of 1681

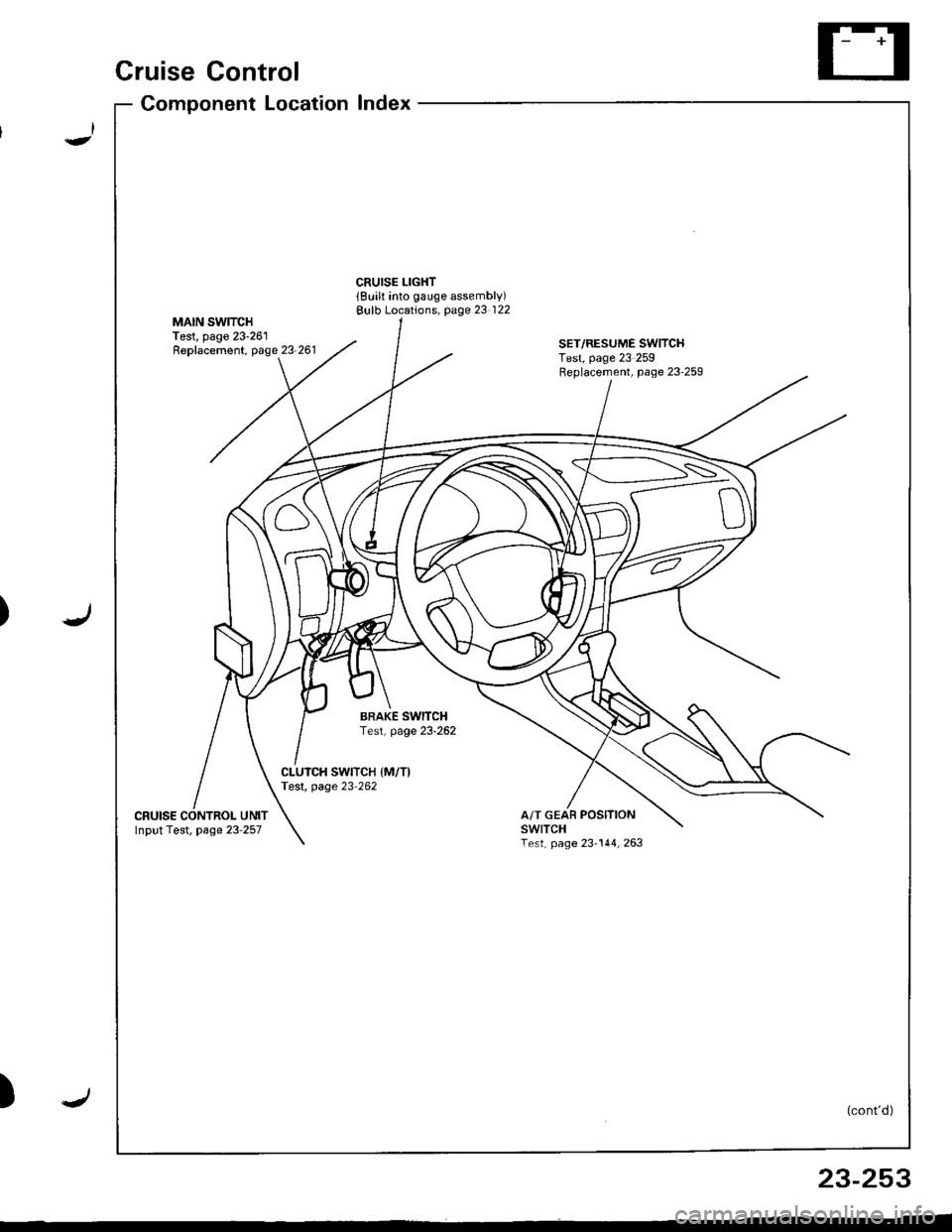

Cruise Control

)

Component LocationIndex

CRUISE LIGHT{Built into gauge assembly)Bulb Locations, page 23 122MAIN SWITCHTest, page 23-261Replacement, page 23-261SET/RESUME SWITCHTest, page 23 259Feplacement, page 23'259

BRAKE SwlTCHTest, page 23-262

CLUICH SWITCH IM/T)Test, page 23 262

cRutsEA/T GEAR POSITIONswtTcHTest, page 23-144,263Input Test, page 23 257

(cont'd)

23-253

Page 1313 of 1681

Cruise Control

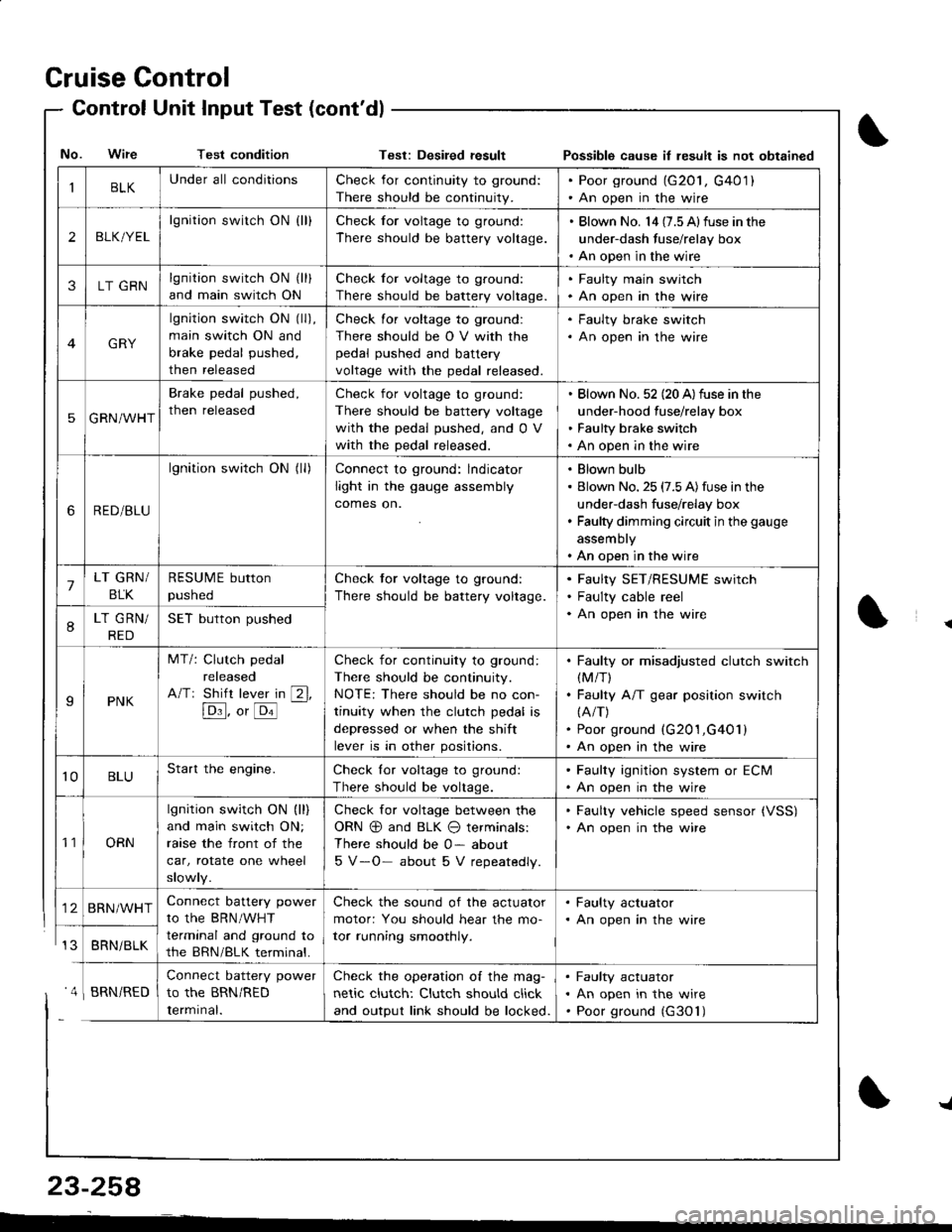

- Control Unit InputTest(cont'dl

IBLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G20l, G401). An open in the wire

2BLK/YEL

lgnition switch ON {ll}Check for voltage to ground:

There should be battery voltage.

. Blown No. l4 (7.5 Alfuse in the

under-dash fuse/relay box. An open in the wire

3LT GRNlgnition switch ON (ll)

and main switch ON

Check for voltage to ground:

There should be battery voltage.

. Faulty main swjtch. An open in the wire

GRY

lgnition switch ON (ll),

main switch ON and

brake pedal pushed,

then released

Check for voltage to ground:

There should be O V with the

pedal pushed and battery

voltage with the pedal released.

. Faulty brake switch. An open in the wire

5GRN/WHT

Brake pedal pushed,

then released

Check for voltage to ground:

There should be battery voltage

with the pedal pushed, and 0 V

with the pedal released.

Blown No. 52 (20 A)fuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

6RED/BLU

lgnition switch ON (ll)Connect to ground: lndicator

light in the gauge assembly

comes on.

Blown bulb

Blown No. 25 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

7LT GRN/

BLK

RESUME button

pushed

Check tor voltage to ground:

There should be battery voltage.

Faulty SET/RESUME switch

Faulty cable reel

An open in the wire8LT GRN/

RED

SET button pushed

IPNK

MT/: Clutch pedal

released

A/Tr Shift lever in [2l,

[Dl]. o, [o'l

-

Check for continuity to ground:

There should be continuity.

NOTE: There should be no con-

tinuity when the clutch pedal is

depressed or when the shift

lever is in other positions.

Faulty or misadjusted clutch switch(M/T)

Faulty A/T gear position switch(A/T)

Poor ground (G201,G401)

An open in the wire

't0BLUStart the engine.Check lor voltage to ground:

There should be voltage.

. Faulty ignition system or ECM. An open in the wire

't1ORN

lgnition switch ON (ll)

and main switch ON;

raase the front of the

car, rotate one wheel

slowly.

Check for voltage between the

ORN @ and BLK O terminals:

There should be 0- about

5 V-O- about 5 V repeatedly.

. Faulty vehicle speed sensor {VSS). An open in the wire

BRN/WHTConnect battery power

to the BRN/WHT

terminal and ground to

the BRN/BLK terminal.

Check the sound of the actuator

motor: You should hear the mo-

tor running smoothly.

. Faulty actuator. An open in the wire

BRNi BLK

Connect battery power

to the BRN/RED

Iermrnal.

Check the operation of the mag-

netic clutch: Clutch should click

and output link should be locked.

Faulty actuator

An open in the wire

Poor ground (G30'l)

No. Wire Test conditionTest: Desiled result Possible cause il lesult is not obtained

' 4 I BRN/RED

{

{

23-258

-L

Page 1347 of 1681

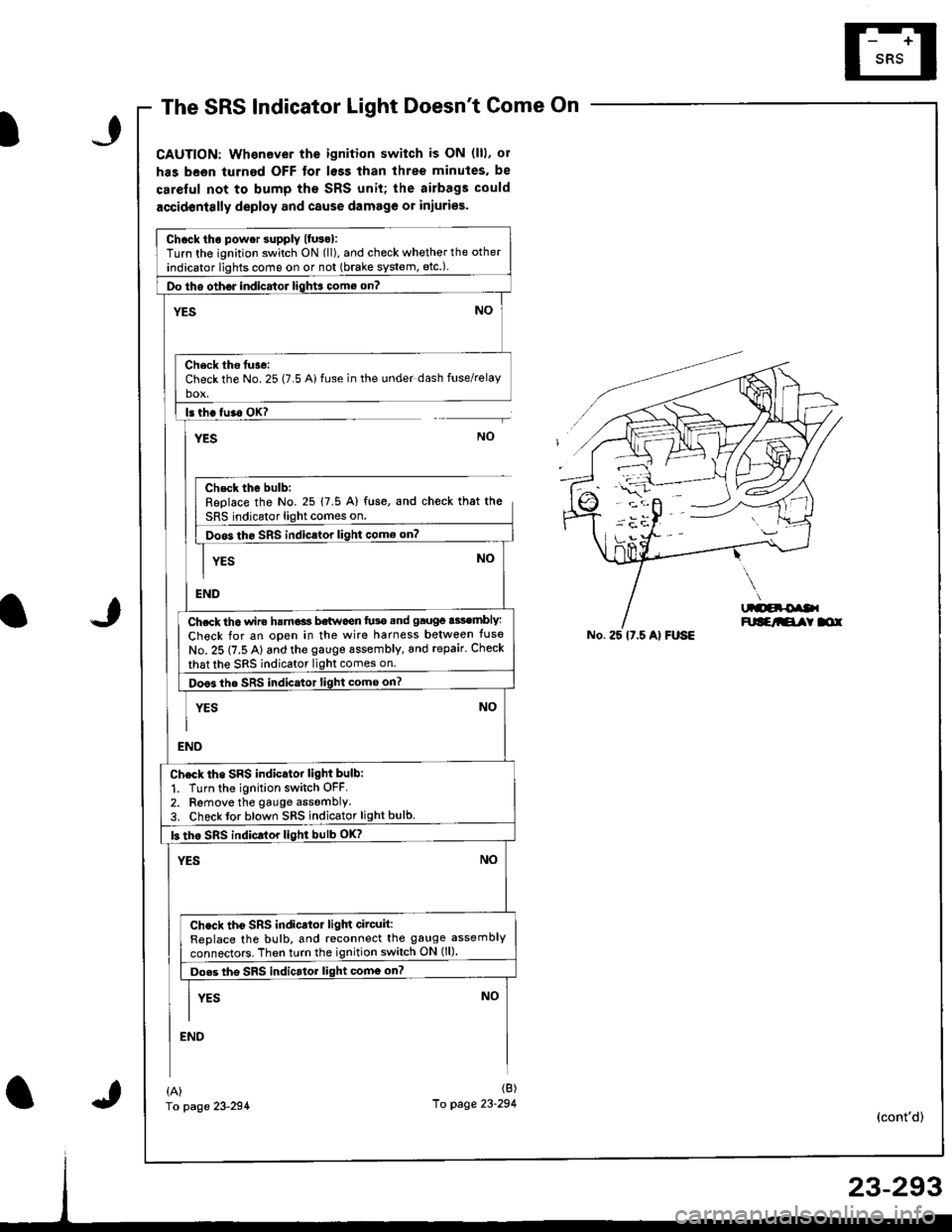

The SRS Indicator Light Doesnt Come On

CAUTION: Whenever the ignition switch is ON (lll, ol

has been turned OFF tor lsss than three minutes. be

careful not to bump the SRS unit; the airbags could

accidentslly deploy and cause damage or iniuries.

Chcck tho power supply lfuso):Turn the ignition switch ON (ll), and check whether the other

indicator lights come on or not (brake system, etc.).

Do tho oth6J indicator ligh$ come on?

NO'ES

Check ths tuse:Check the No. 25 (7.5 Ai fuse in the under dash fuse/relayho!

ls th. tu.o OK?

YESNO

Chsck the bulb:Replace the No. 25 17.5 A) fuse, and check that the

SRS indicator light comes on.

Doos tho SRS indic.lor light como on?

YES

END

Ch.ck th6 wir€ ham€ls b€twoen fu3e snd gauge .3sembly:

Check for an open in the wire harness belween tuse

No. 25 (7.5 A) and the gauge sssembly, and repair. Check

that the sRS indicator light comes on.

Doo3 the SRS indicator light come on?

YES

NO

NO

END

Ch6ck tho SRS indicator light bulb:

1. Turn the ignition switch OFF.2. Remove the gauge assemblY3. Check tor blown SRS indicator light bulb.

b tho sRs indicrlor light bulb oK?

YESNO

Check tho SRS indicator ligln circuit:ReDlace the bulb, and reconnect the gauge assembly

connectors. Then turn the ignition switch ON (ll).

Do.s tho SRS indicrtor light comG on?

I vrs NoII

END

No. 25 lt.5 Al FUSE

{A)fo page 23-294

(B)

10 page 23-294(cont'd)

Page 1394 of 1681

'l'

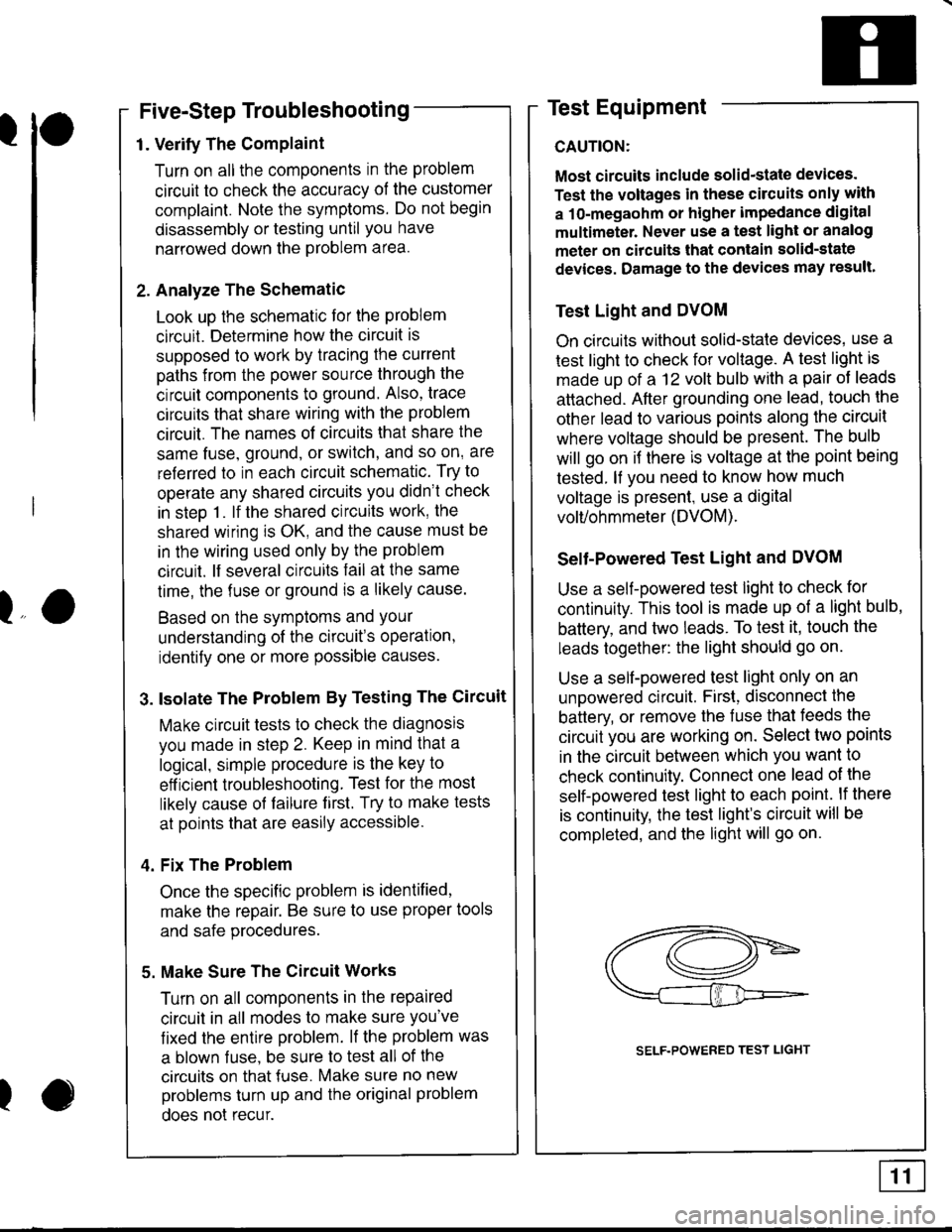

Five-Step Troubleshooting

1. Verify The Complaint

Turn on all the components in the problem

circuit to check the accuracy of the customer

complaint. Note the symptoms. Do not begin

disassembly or testing until you have

narrowed down the Problem area.

2. Analyze The Schematic

Look up the schematlc for the problem

circuit. Determine how the circuit is

supposed to work by tracing the current

paths from the power source through the

circuit components to ground. Also, trace

circuits that share wiring with the problem

circuit. The names of circuits that share the

same fuse, ground, or switch, and so on' are

referred to in each circuit schematic. Try to

operate any shared circuits you didn't check

in steo 1. lf the shared circuits work, the

shared wiring is OK, and the cause must be

in the wiring used only by the problem

circuit. lf several circuits fail at the same

time, the fuse or ground is a likely cause.

Based on the symptoms and Your

understanding of the circuit's operation,

identify one or more possible causes.

3. lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis

you made in step 2. Keep in mind that a

logical, simple procedure is the key to

eff icient troubleshooting. Test for the most

likely cause of failure f irst. Try to make tests

at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified,

make the repair. Be sure to use proper tools

and safe procedures.

5. Make Sure The Circuit Works

Turn on all components in the repaired

circuit in all modes to make sure you've

fixed the entife problem. lf the problem was

a blown f use, be sure to test all of the

circuits on that {use. Make sure no new

problems turn up and the original problem

does not recur.

Test Equipment

CAUTION:

Most circuits include solid-state devices.

Test the voltages in these circuits only with

a 1o-megaohm or higher impedance digital

multimeter. Never use a test light or analog

meter on citcuits that contain solid-state

devices. Damage to the devices may result.

Test Light and DVOM

On circuits without solid-state devices, use a

test light to check for voltage. A test light is

made up of a 12 volt bulb with a pair of leads

attached. After grounding one lead, touch the

other lead to various points along the circuit

where voltage should be present. The bulb

will go on i{ there is voltage at the point being

tested. lf you need to know how much

voltage is present, use a digital

volVohmmeter (DVOM).

Selt-Powered Test Light and DVOM

Use a self-powered test light to check for

continuity. This tool is made up of a light bulb,

battery, and two leads. To test it, touch the

leads together: the light should go on.

Use a self-powered test light only on an

unoowered circuit. First, disconnect the

battery, or remove the fuse that feeds the

circuit you are working on. Select two points

in the circuit between which you want to

check continuity. Connect one lead ol the

self-powered test light to each point. lf there

is continuity, the test light's circuit will be

completed, and the light will go on.

lo

I

SELF.POWERED TEST LIGHT

Page 1489 of 1681

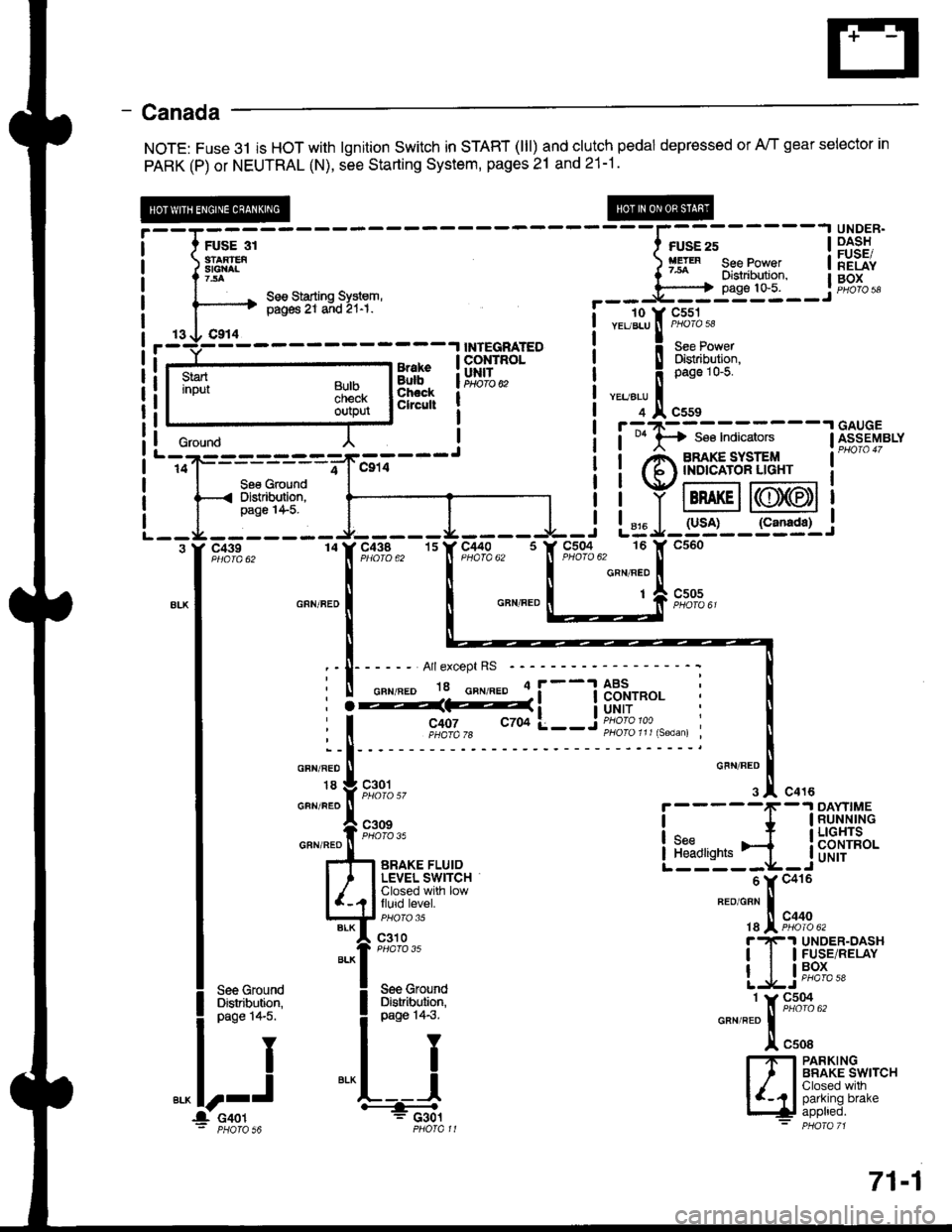

- Canada

NOTE: Fuse 3l is HOT with lgnition Switch in START (lll) and clutch pedal depressed or A/T gear selector in

PARK (P) or NEUTRAL (N), see Starting System, pages 21 and 21-1.

;;;----

----l;";;-----l

iiSF:'

:'eI[^ ) fg'" see Power | lEiiv

^ seesiarrins sysrem, --- j'[ffi-- j #"1""------'+ pig6 Zr a;d 2r-r. !- - To-v cssr

i r- 3li:Tf8l r---r--_l

| | y tBRAKEil((lJ)(EDt I

L - -r4 - - - - - - - r- - - - - J. - - - - -l - i L= J- g'j'- - S3g1-,

.[Hr*. "IF#1s,, ''f,"c,flls. 'It*'t"i_[

^.^.

*- I o^n".' | | o"n".o L___:;[ s;*,,

lri:

tl

I :-I------ Arrexcept Rs -----------: t

I ii%d#i__jflffi: i I

| """;l

'- ll

I * Vg,l.gl,,

o'""'1.!.

"o'u

i-----f

-1Ri-[iil,'"

I

*"ff;i;-.,.,,"

LEb'r.ji_jb'f,{H*

I l#[i.#rsr

"-"fX;;;;.,

| ].1s*" [Tr P.ls.',ePfiv

|

**1

Lljti';-! see Ground ! See Grouno

'-,oij---------=-*"-,,;---J

i i Anmg"#l''3;' i-

-

l--ffi'Pilr"r-l t ' iiYffi@i

--I -i:"-:-- J-----L---I -i L= J-rs'i-- r"=sr.i

i it"!,8li6l i iq,iit"l :'fl"";'#.,

i

**'?

i

**''; *""*i:;;-

l!."1 IrflBAt['JS*,""

l--J

*^L---l

|y', I Shtrl'l-"

itooo, '---& [+! iPPtreo.: PHoTa s6 PHofall - PHora 71

: | - - --'l uauuc

crourd l ! i t *lA se€ Indicators lfr1s-eyerv

BulbcnecKoutpur

71-1

Page 1491 of 1681

- How the Circuit Works

The low engine oil pressure indicator light works in

two ways: il flashes continuously following a

momentary loss of engine oil pressure, or it comes

on and stays on with a complete loss of engine oil

oressure,

When the engine first starts, before its oil pressure

rises above 4.3 psi, voltage is applied to the closed

and grounded engine oil pressure switch and the

light comes on to test the bulb.

With the engine running, voltage is applied at the

WHT/BLU wire of the integrated control unit. With

normal engine oil pressure, the engine oil pressure

switch is open and the low oil pressure indicator

light does not come on. lf the engine oil pressure

switch closes momentarily (more than 0.5 seconds)

but then opens again, the YEURED wire at the

integrated control unit will sense ground through the

switch. The integrated control unit will then provide

and remove ground for the low oil pressure indicator

light through the YEURED wire. The light will flash

on and off until you turn the ignition switch off. The

flashing feature will not work until 30 seconds after

initial voltage is applied to the WHT/BLU wire of the

oil pressure indrcator llasher circuit. This delay

keeps the low oil pressure indicator light from

coming on during engine warm-up.

lf engine oil pressure falls below 4.3 psi and does

not increase, the engine oil pressure switch will stay

closed. The low oil pressure indicator light will then

come on and stay on.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

72-1

Page 1502 of 1681

How the Circuit Works

The maintenance reminder light comes on to

remind the driver that the car is due for

scheduled mainlenance.

The maintenance reminder unit receives a vehicle

speed input from the vehicle speed sensor (VSS)

and uses this inlormation to compute the distance

traveled. For the first 6000 t 1 00 miles (9650 t 160

km) after the maintenance reminder light is reset, it

will come on for two seconds when you turn the

ignition switch to ON (ll) as a bulb check.

Between 6000 1 100 miles (9650 t 160 km) and

7500 t 100 miles (12070 I 160 km) the reminder

light will come on for two seconds when you turn

the ignition switch to ON (ll), and then flash for eight

seconds more.

Beyond 7500 t 100 miles (12070 t l60 km) the

reminder light will stay on when the ignition switch is

in the ON (ll) position until the unit is reset.

To reset the unit, the car must be parked and the

ignition switch in the ON (ll) position. Press the

reset button on the unit and hold it there for more

than three seconds, and the reminder light will

go off.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

83-1

Page 1504 of 1681

- How the Circuit Works

With the ignition switch in ON (ll) or START (lll),

voltage is applied to the A,/T gear position indicator.

The A,/T gear position switch provides a ground for

each position. As an input is grounded, ils indicator

light comes on. lf you se,ecl B, tor example, ground

will be applied to the input of the A,/T gear position

indicator, and the R indicator bulb will come on.

With the headlight switch in PARK or HEAD, voltage

is applied to the RED/BLK wire terminal. this

changes the indicator panel illumination from lixed

to controlled by the dash lights dimmer inpul

through the RED wire.

When the lransmission ('98.�99 models) or

powertrain ('00 model) control module (TCM or

PCM) detects an abnormality in the automatic

transmission control system, or when you request

diagnostic trouble codes through the service

check connector, the TCM or PCM will make lhe D4

indicator light blink.

Refer to the Service Manual (Section 14,

Automatic Transmission) for soecific tests or

troubleshooting procedures.

89-1