Compressor HONDA INTEGRA 1998 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1052 of 1681

Compressor

a

a

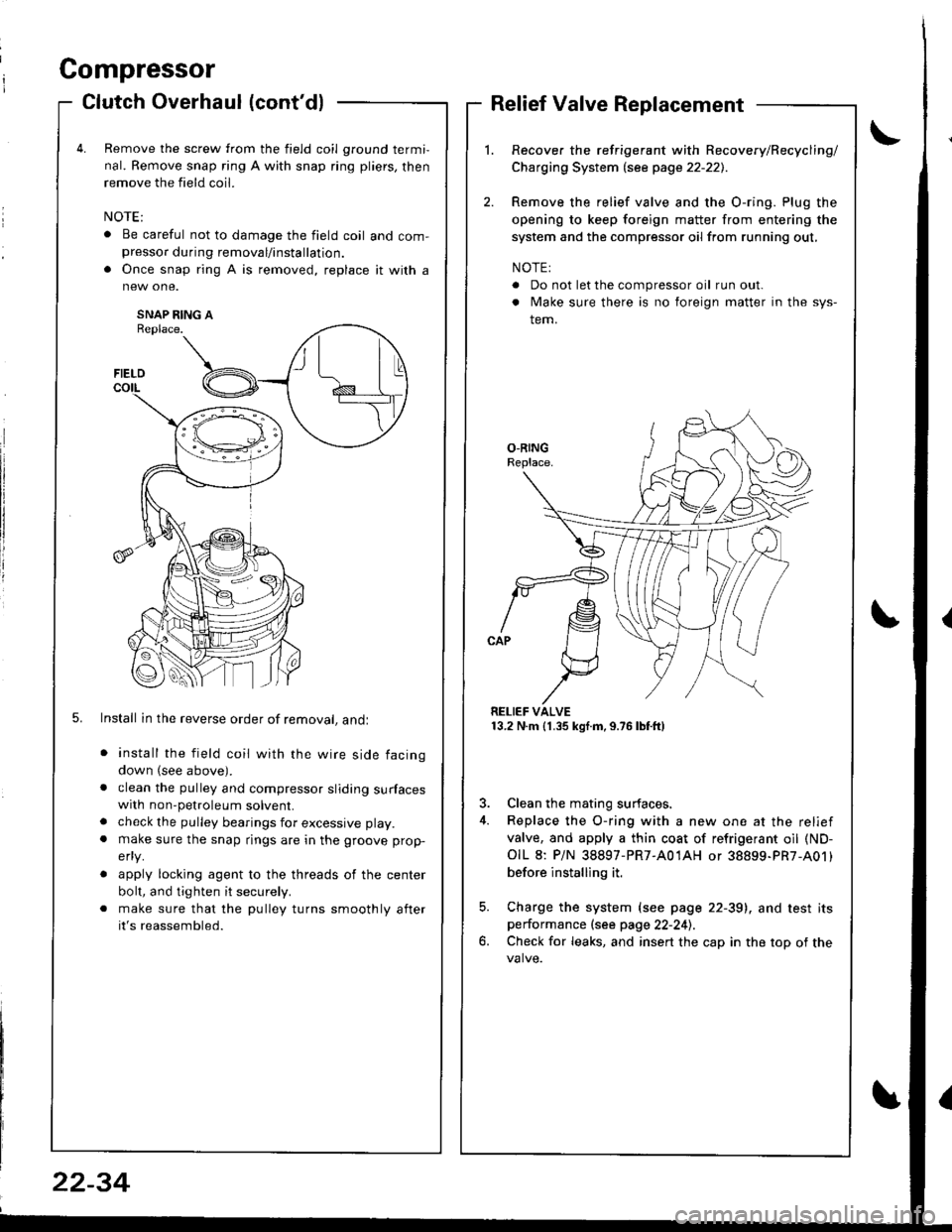

Clutch Overhaul (cont'dl

Remove the screw from the field coil ground termi,

nal. Remove snap ring A with snap ring pliers, then

remove the field coil.

. Be careful not to damage the field coil and com-presso. during removal/installation.

. Once snap ring A is removed, replace it with a

SNAP RING AReplace.

5. Install in the reverse order of removal, andl

install the field coil with the wire side facing

down (see above).

clean the pulley and compressor sliding surfaceswith non-petroleum solvent.

check the pulley bearings for excessive play.

make sure the snap rings are in the groove prop-

efly.

apply locking agent to the threads of the center

bolt, and tighten it securely.

make sure that the pulley turns smoothly after

it's reassembled.

Relief Valve Replacement

Recover the refrigerant with Recovery/Recycling/

Charging System lsee page 22-221.

Remove the relief valve and the O-ring. Plug the

opening to keep foreign matter from entering the

system and the compressor oil from running out,

NOTE:

. Do not let the compressor oil run out.

. Make sure there is no foreign matter in the sys-

tem.

RELIEF VALVE13.2 N.m (1.35 kgf.m,9.76lbtft)

3. Clean the mating surfaces.

4. Replace the O-ring with a new one at the relief

valve, and apply a thin coat of refrigerant oil (ND-

OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01)

before installing it.

5. Charge the system (see page 22-39), and test itsperformance (see page 22-241.

6. Check for leaks, and insert the cap in the top of the

FIELD

t\I lu

B _t_:---\-lr

\,/

22-34

Page 1053 of 1681

J

A/G Compressor Belt

Replacement

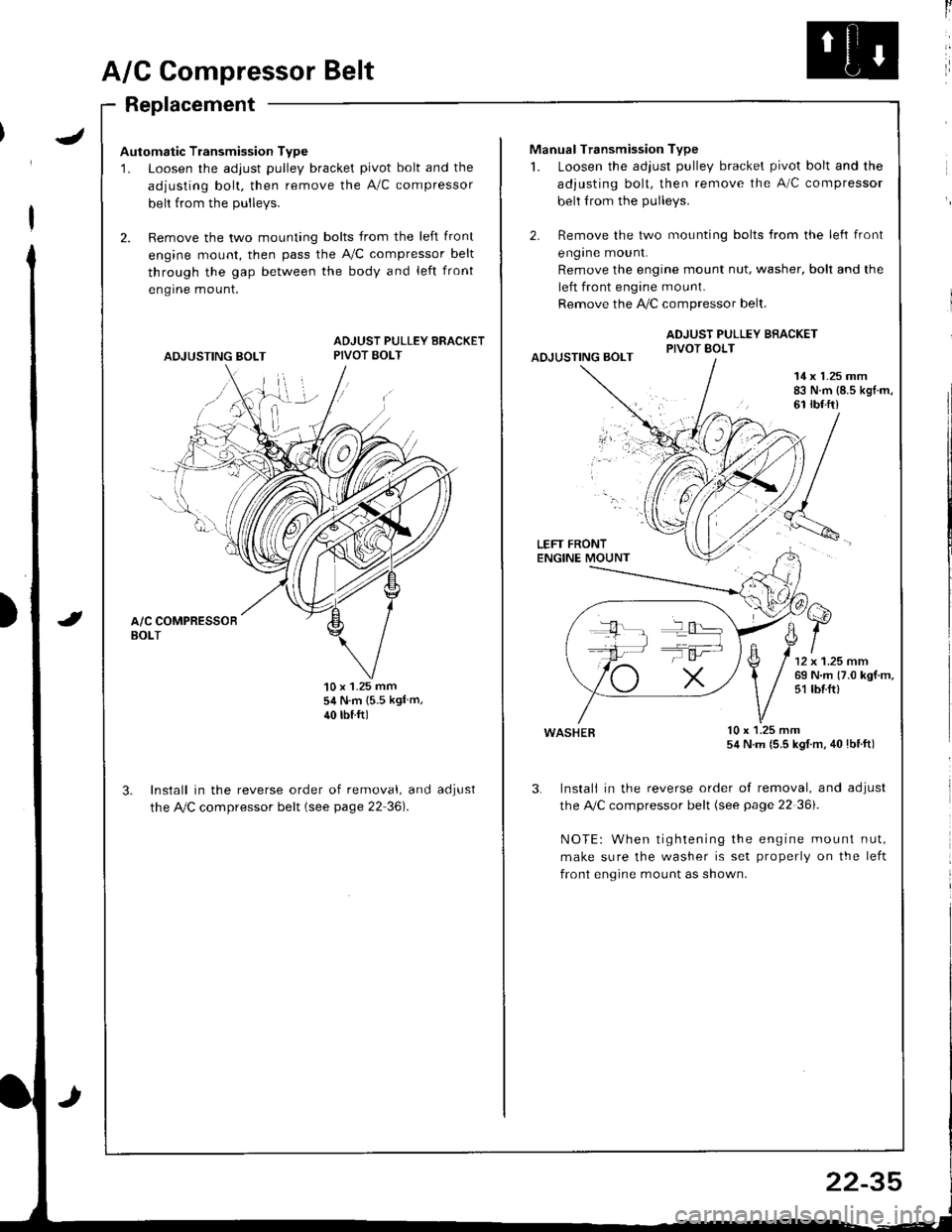

Automatic Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt. then remove the A/C compressor

belt from the Dullevs.

2. Remove the two mounting bolts from the left front

engine mount, then pass the A,/C compressor belt

through the gap between the body and left front

engrne mount.

ADJUSTING BOLT

ADJUST PULLEY BRACKETPIVOT BOLT

'10 x 1.25 mm54 N.m {5.5 kgl m,

40 rbtftl

Install in the reverse order of removal, and

the Ay'C compressor belt (see page 22 36).

aoJUsI

ll

Manual Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the pulleys.

2. Remove the two mounting bolts from the left front

engrne mount.

Remove the engine mount nut, washer, bolt and the

left front engine mount.

Remove the !i/C compressor belt.

ADJUST PULLEY BRACKETPIVOT BOLTAOJUSTING BOLT

14 x 1.25 mm83 N.m {8.5 kgl.m,61 rbf.ft)

LEFT FRONTENGINE MOUNT

wasHEB lu x l.z5 mm54 N.m (5.5 kgl m, 40lbtft)

3. Instali in the reverse order of removal, and adjust

the A,/C compressor belt (see page 22 36i.

NOTE: When tightening the engine mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

T':

22-35

Page 1054 of 1681

A/C Compressor Belt

Adiustment

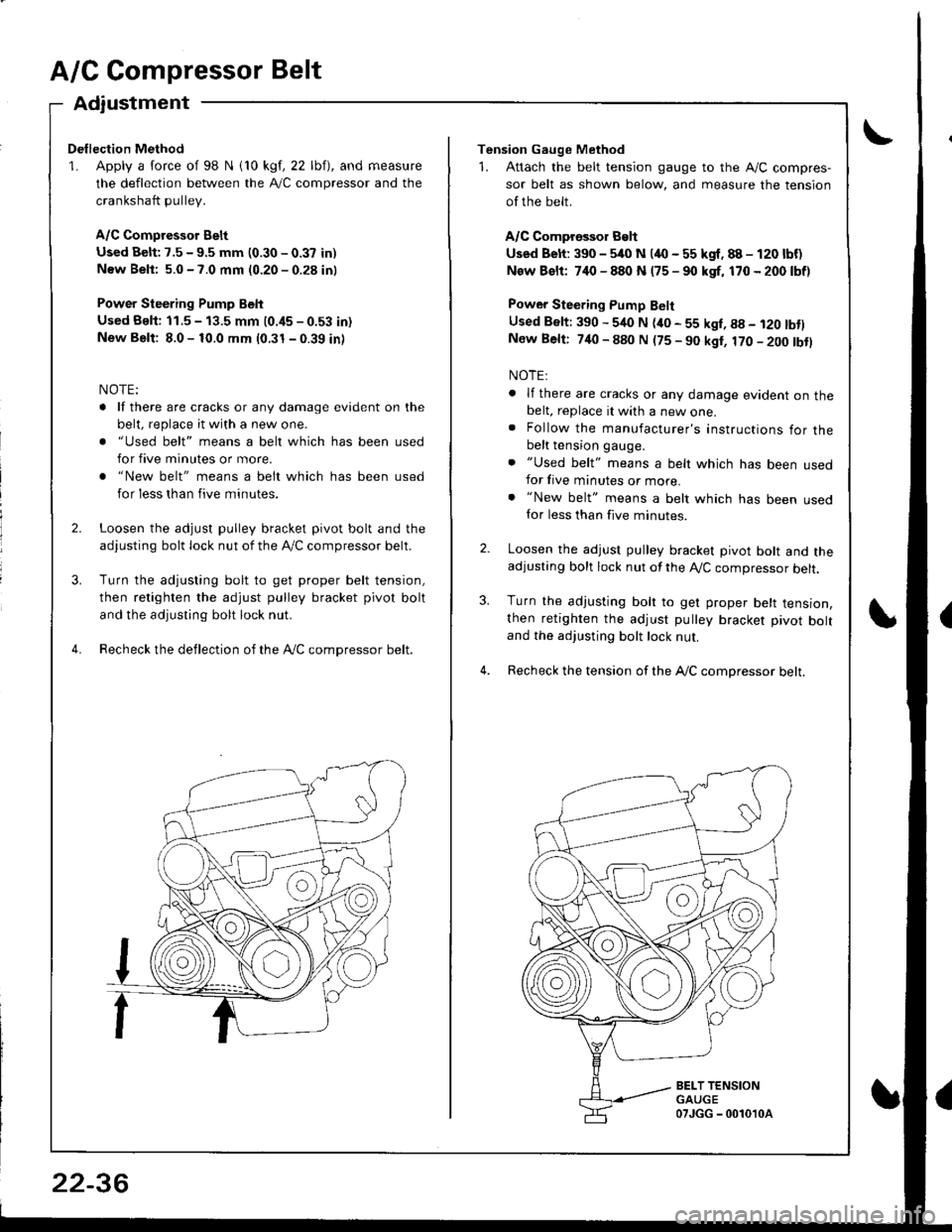

Dellection Method

1. Apply a force of 98 N i10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft pullev.

A/C Compressor Belt

Used Belt: 7.5 - 9.5 mm (0.30 - 0.37 in)

New Beli: 5.0 - 7.0 mm (0.20 - 0.28 in)

Power Steering Pump Belt

Used Bslt: 11.5 - 13.5 mm (0.i15 - 0.53 in)

New Belt: 8.0 - 10.0 mm (0.31 - 0.39 in)

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the lVC compressor belt.

Turn the adjusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

Recheck the deflection of the Ay'C compressor belt.

22-36

Tension Gauge Method

1. Attach the belt tension gauge to the Ay'C compres-

sor belt as shown below, and measure the tension

of the belt.

A/C Comprossor Belt

Used Belt: 390 - 5/rc N (4O - 55 kgf. 88 - 120 lbf)

New Bslt: 7,10 - 880 N (75 - 90 kgf, 170 - 200 lbf)

Power Steering Pump Belt

Used Belt: 390 - 540 N (ito - 55 kgl, g8 - i20 tbtlNew Belt: 740 - 880 N (75 - 90 kgt, 170 - 200 tbtl

NOTE:

. lf there are cracks or any damage evident on thebelt, replace it with a new one.. Follow the manufacturer's instructions for thebelt tension gauge.

. "Used belt" means a belt which has been usedfor five minutes or more.. "New belt" means a belt which has been usedfor less than five minutes.

Loosen the adjust pulley bracket pivot bolt and theadjusting bolt lock nut of the A,/C compressor belt.

Turn the adjusting bolt to get proper belt tension,then retighten the adjust pulley bracket pivot boltand the adjusting bolt lock nut.

Recheck the tension of the A,/C compressor belt.

3.

BELT TENSIONGAUGE07JGG - 0010'l0a

Page 1064 of 1681

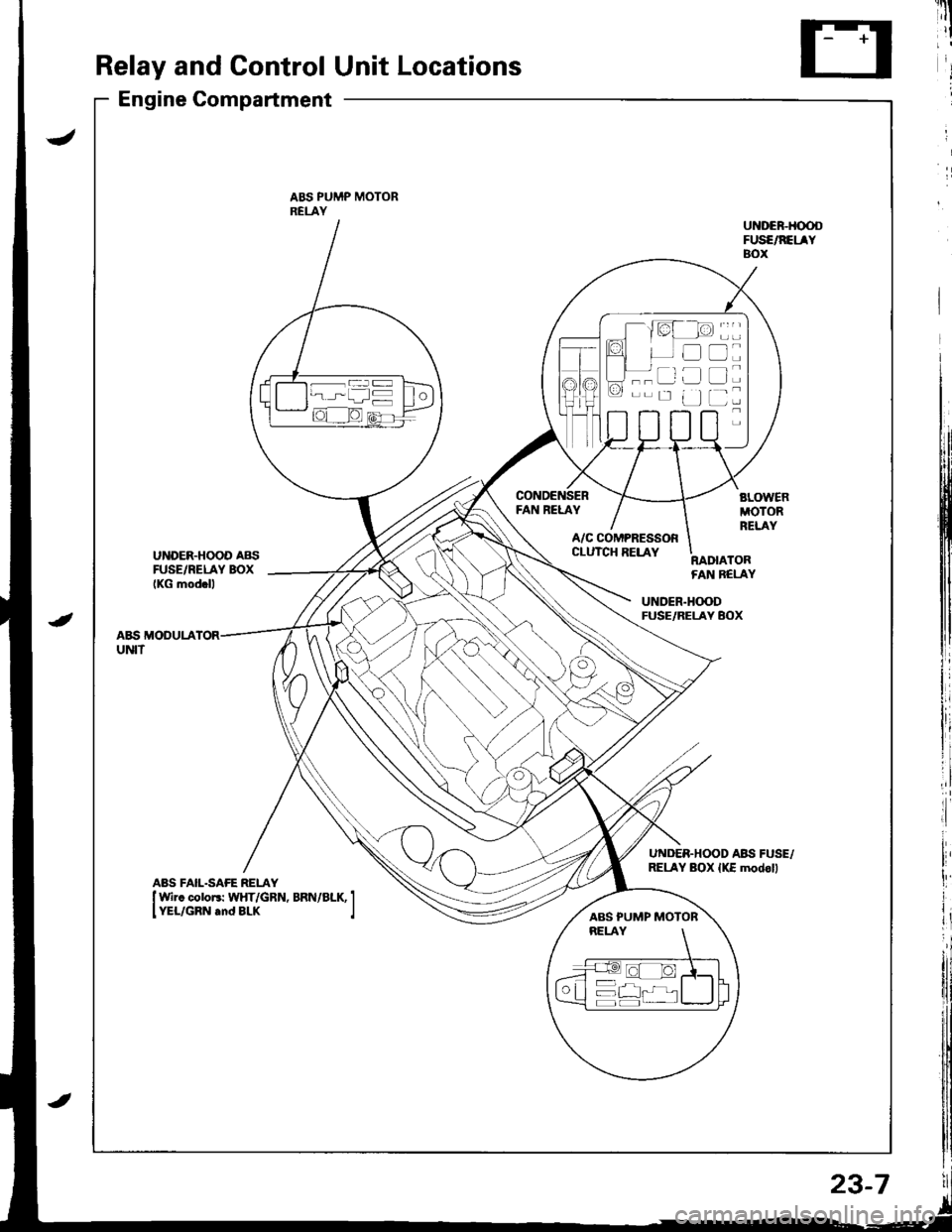

Relay and Control Unit Locations

Engine Compartment

ABS PUMP MOTORRELAY

FAN RELAY

UNDER.HOOD AB{iFUSE/RELAY BOXIKG mod.ll

A/C COMPRESSORCLUTCH RELAYRADIATORFAN BELAY

UNDER.H(X)DFUSE/RELAY BOX

A&S MODULAUNIT

UNDER.HOOD ABII FUSE,/RELAY BOX {KE modoll

----ar:l

--r: u

D

tr

L]

ABS PUMP MOTOR

23-7

Page 1071 of 1681

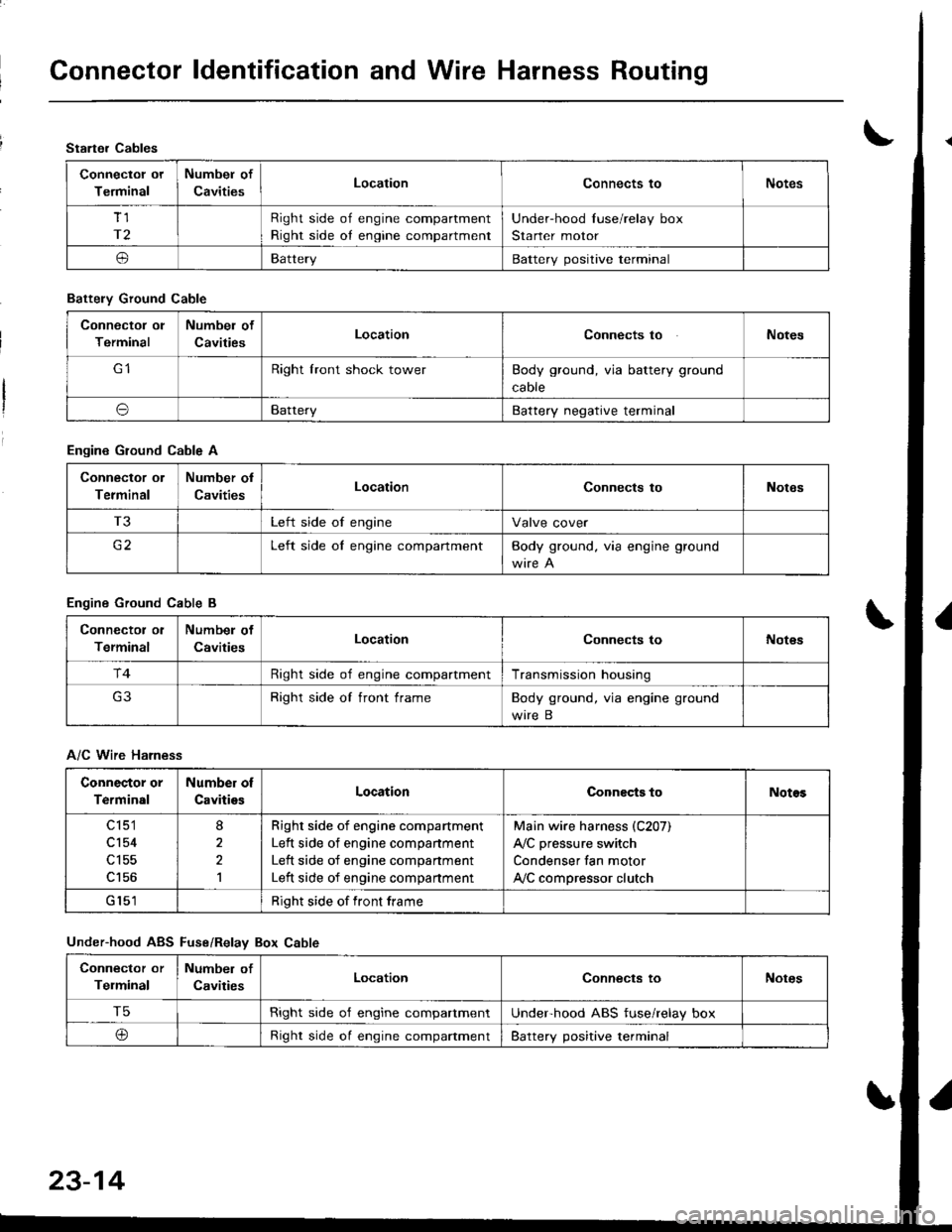

Connector ldentification and Wire Harness Routing

Starter Cables

Connectol ot

Terminal

Numbel of

CavitiesLocationConnects toNotes

Tl

r2

Right side of engine compartment

Right side oI engine compartment

Under-hood Iuse/relay box

Starter motor

oBatteryBattery positive terminal

Battely Ground Cable

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNotes

Right lront shock towerBody ground, via battery ground

caore

oBatteryBattery negative terminal

Engine Ground Cable A

Connector ol

Terminal

Number ol

CavitiesLocationConnects toNotes

T3Left side of engineValve cover

c2Left side oI engine compartmentBody ground. via engine ground

Engine Ground Cable B

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNot€s

r4Right side of engine compartmentTransmission housing

Right side of front frameBody ground, via engine ground

wire B

A/C Wire Harness

Connector or

Terminal

Number of

CavitiesLocationConnects toNotos

c 151

cl54

c156

8

2,l

Righr side of engine compartment

Left side of engine companment

Left side of engine compartment

Left side of engine compartment

Main wire harness (C207)

A,/C pressure switch

Condenser fan motor

ly'C compressor clutch

Right side of front frame

Under-hood ABS Fuse/Relav Box Cable

Connector or

Telminal

Number of

CavitiesLocationConnects toNotes

T5Right side o'f engine compartmentUnderhood ABS fuse/relay box

@Right side oI engine compaftmentBattery positive terminal

23-14

Page 1110 of 1681

J

)1 -

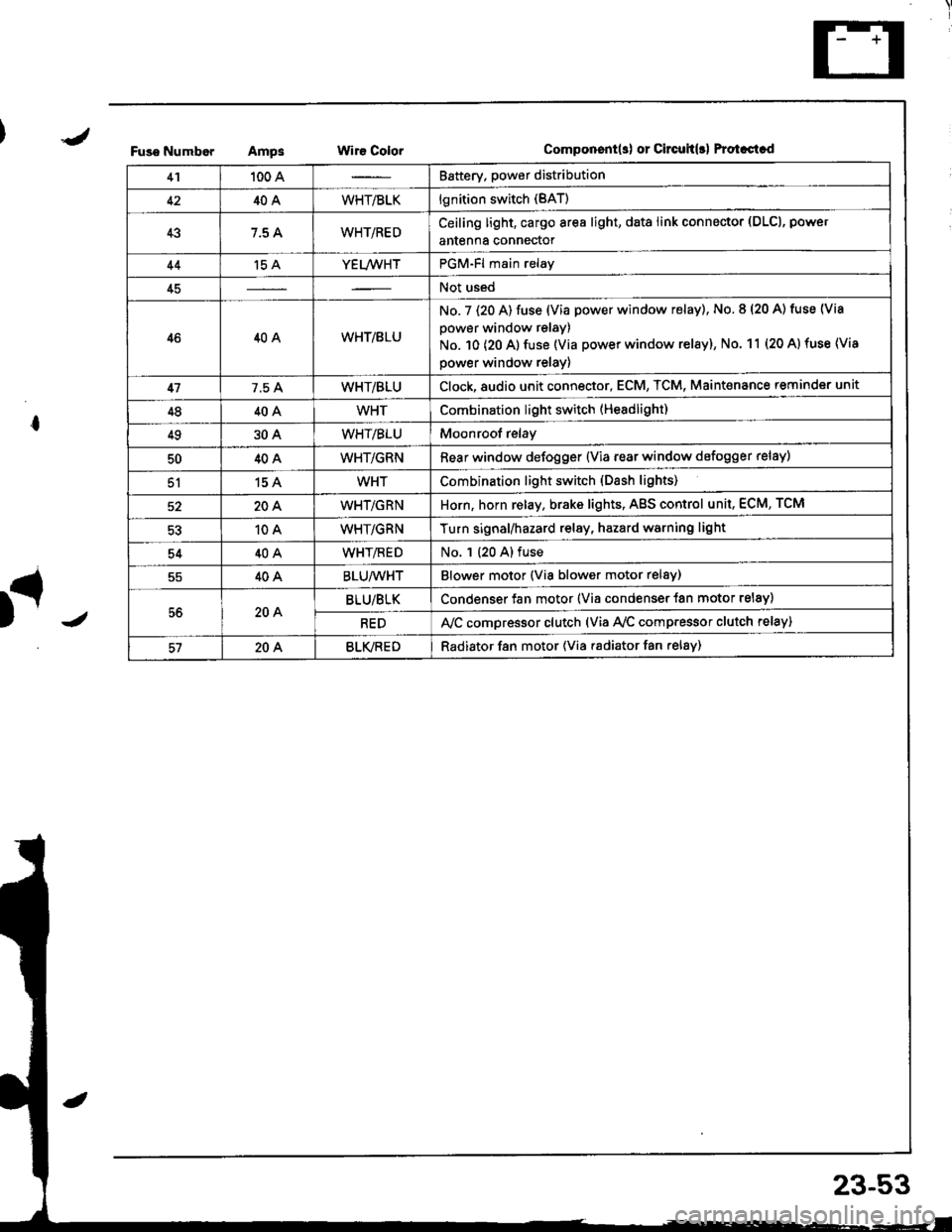

Fuso NumborAmpsWir€ ColorComponent(s) or Circuh(rl Protastcd

41100 ABattery. power distribution

4240AWHT/BLKlgnition switch (BAT)

437.5 AWHT/REDCeiling light, cargo area light, data link connector (DLCl, power

antenna connector

44't5 AYEL/WHTPGM-Fl main relay

45Not used

4640AWHT/8LU

No. 7 (20 A) fuse (Via power window relay), No. 8 (20 A) tuse (Via

power window relay)

No. 10 (20 A) fuse (Via power window relay), No. 11 (20 A) fuse (Via

power window relay)

417.5 AWHT/BLUClock,8udio unit connector, ECM, TCM, Maint€nance reminder unit

4840AWHTCombination light switch (Headlight)

4930AWHT/BLUMoonroof relay

5040AWHT/GRNRear window defogger {Via rear window defogger relay)

51154WHTCombination light switch (Dash lights)

20AWHT/GRNHorn, horn relay, brake lights, AgS control unit, ECM, TCM

10AWHT/GRNTurn signal/hazard relay, hazard warning light

5440AWHT/flEDNo. 1 (20 A) fuse

40ABLU/WHTBlower motor (Via blower motor relsy)

56204BLU/BLKCondenser fan motor (Via condenser {an motor relay)

REDA,/C compressor clutch (via Ay'c comp.essor clutch relay)

57204BLVREDRadiator f8n motor (Via radiator fan relay)

23-53

Page 1112 of 1681

\

I

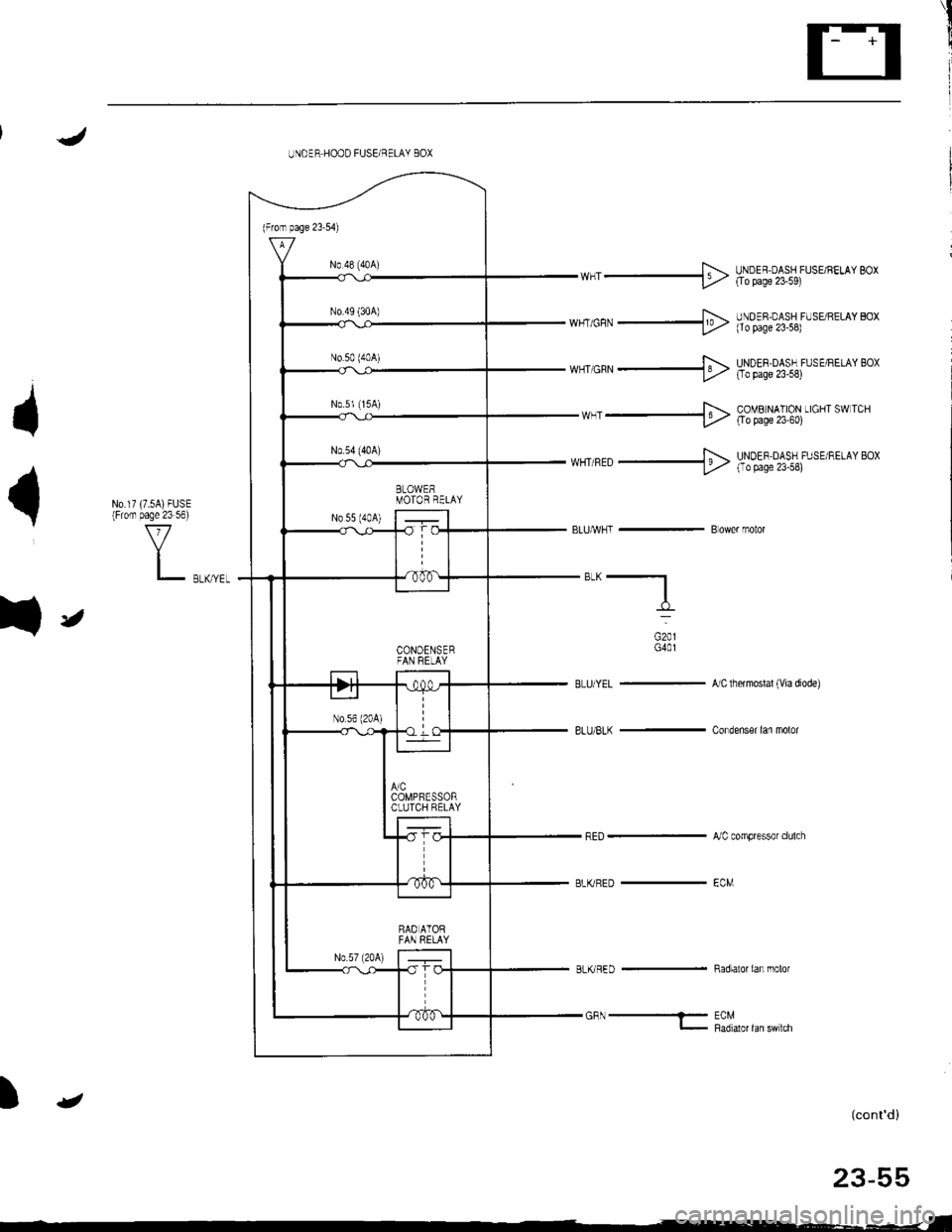

UNOER HOOD FUSE/RELAY BOX

t

{

fr

wHr _+> HtXl!;%,'$1r.,',"' *,

F.-wr cn,r _l9> l,)ooll;%,r$lrr. rr,or ro,

*,,'orn. ---$ H?!!;oA%iu'n"*"o'

wHr -+ &?Tll:11$ uo""* "*

N0.17 (7.5A)FUSE(Fiom page 23 56)

V

L r,*,rr,

**, orn N u-NoEF DASF FlrsE RE'AY Boxt'/' I aaaqe zJ''L

BLUA/VHI - B ower motor

"*-f_

oro,G40l

BLU/YEL -'ncthermoslal(viadiode)

8LU/BLK - Condenser lan molor

,JC compressor clulch

BLKRED _ €CM

BLKRED - Radiatorian molor

GFN- EcMl- P36,r1ot 1"n t'n '"n

(cont'd)

23-55

_-_ _-.-

Page 1126 of 1681

1

I

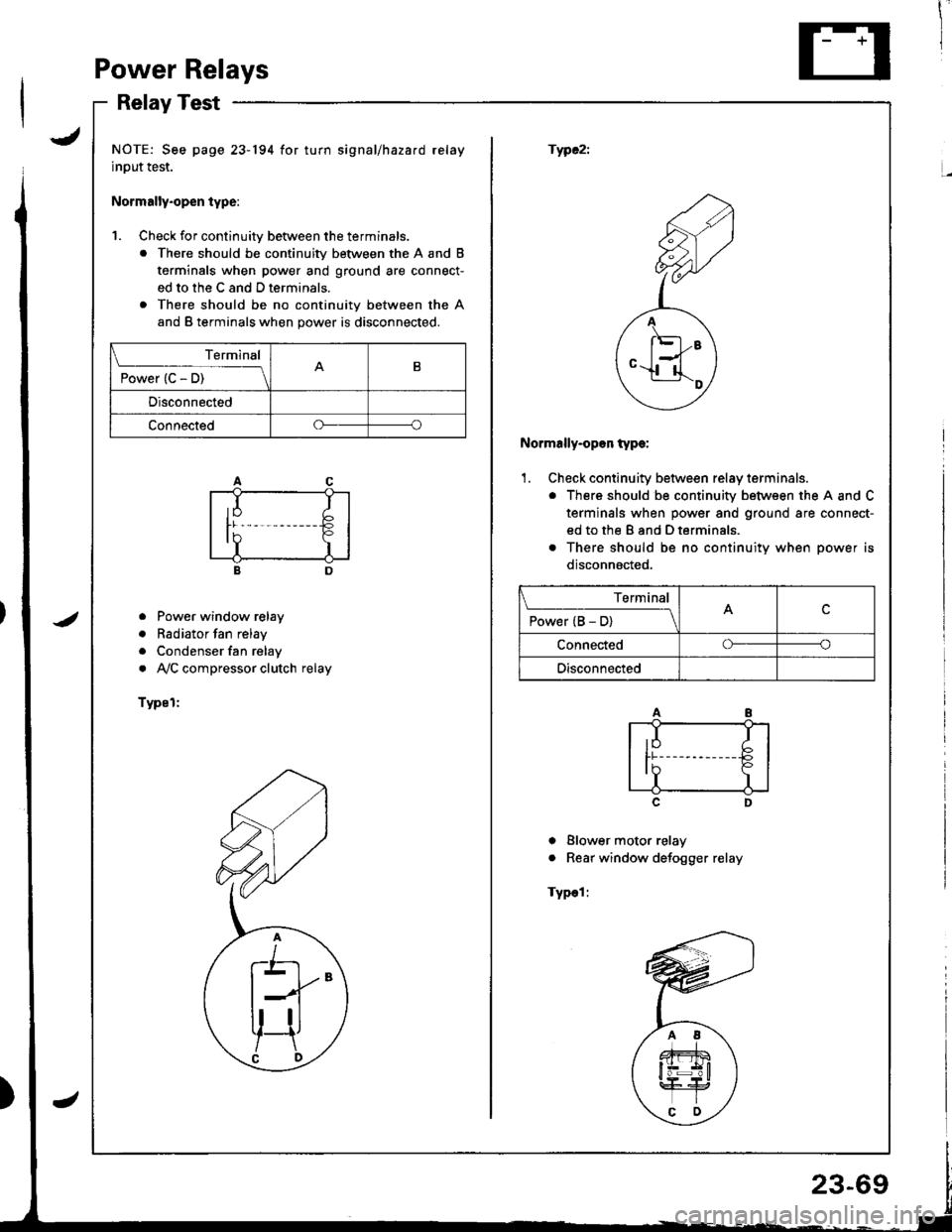

PowerRelays

RelayTest

JNOTE: See page 23-194 for turn signal/hazard relay

input test.

Normally.open type:

fWC2i

1. Check for continuitv between the terminals.

. There should be continuity between the A and B

terminals when power and ground are connect-

ed to the C and D terminals.

. There should be no continuity between the A

and B terminals when power is disconnected.

<2

F;Z

,,A

/ l'El--E \

ey

Normally-opon type:

'1. Check continuity between relay terminals.

. There should be continuity between the A and C

terminals when power and ground are connect-

ed to the B and D terminals.

o There should be no continuitv when oower is

disconnacted,

o Power window relay

. Radiator fan relay

. Condenser fan relay

. AVC compressor clutch relay

Typel:

c

I Blower motor relay

. Rear window defogger relay

Typel:

Terminal

P";(c5t--__\B

Disconnected

Connectedoo

Terminal

P"*"r(B5-lc

Connectedoo

Disconnected

Page 1172 of 1681

)

t

J

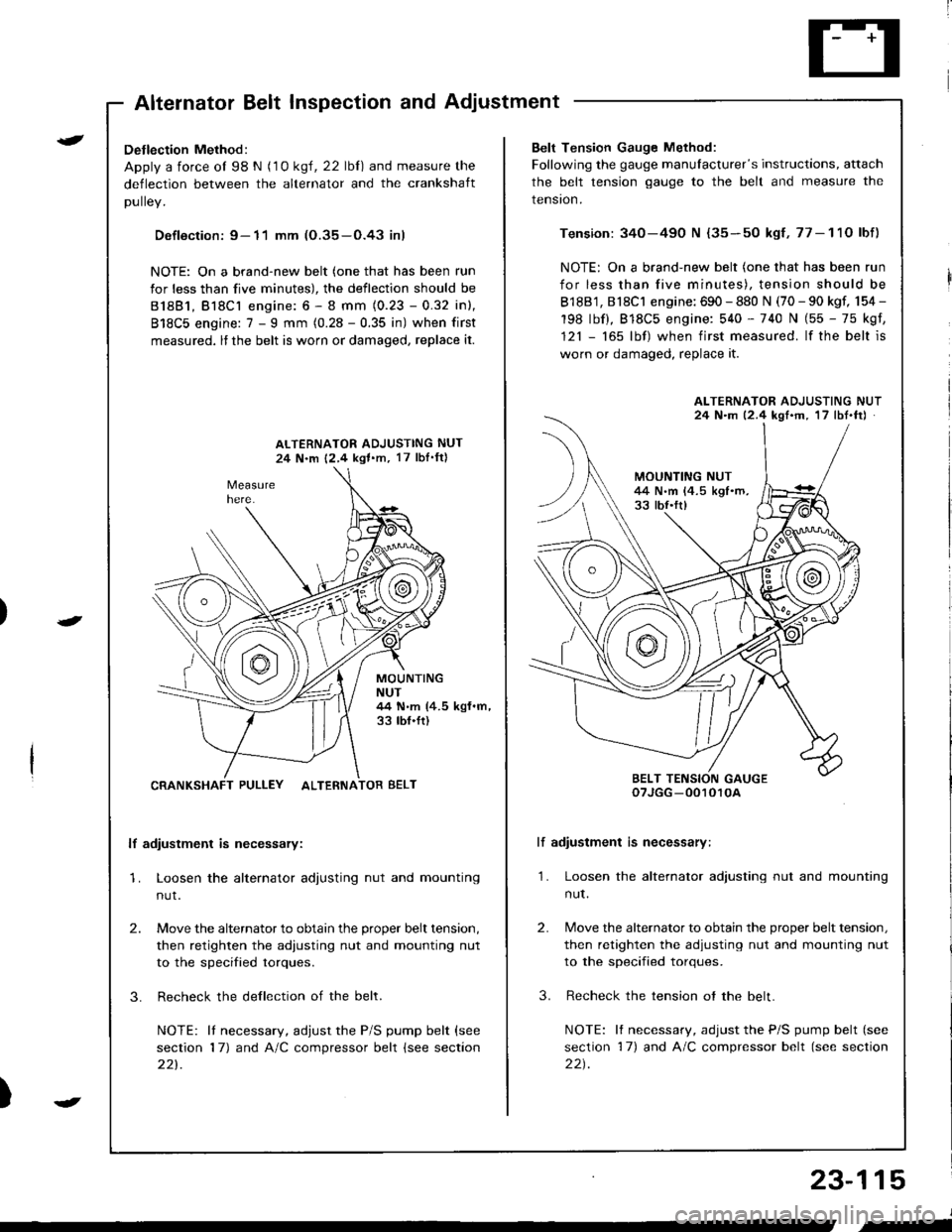

Altelnator ttelr Inspecuon ano Aol

Detlection Method:

Apply a force ol 98 N (1 0 ksl, 22 lbl) and measure the

deflection between the alternator and the crankshaft

DUllev,

Defloction: 9- 11 mm (O.35-O.43 inl

NOTE: On a brand-new belt (one that has been run

for less than five minutes), the deflection should be

81881, Bl8Cl engine: 6 - 8 mm (0.23 - 0.32 inl,

818C5 engine: 7 - I mm (0.28 - 0.35 in) when first

measured, lf the belt is worn or damaged, replace it.

ALTERNATOR ADJUSTING NUT

24 N.m 12,4 kgl.m, 17 lbI'ftl

MOUNTINGNUT44 N.m (4.5 kgf.m,33 tbf.ft)

CRANKSHAFT PULLEY ALTERNATOR BELT

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adiusting nut and mounting nut

to the specified torques.

Recheck the dellection of the belt.

NOTE: lI necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

221.

Belt Tension Gauge Method:

Following the gauge manulacturer's instructions, attach

the belt tension gauge to the belt and measure the

tension.

Tension: 340-490 N {35-50 kgf,77-11O lbf)

NOTE: On a brand-new belt (one that has been run

for less than five minutes), tension should be

818B1, 818C1 engine: 690 - 880 N (70 - 90 kgf, 154 -

198 lbf), 818C5 engine: 540 - 740 N (55 - 75 kgf,

121 - 165 lbf) when first measured. lf the belt is

worn or damaged, replace it.

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

Recheck the tension ot the belt.

NOTE: It necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

22t.

ALTERNATOR ADJUSTING NUT24 N.m 12.4 kgf'm, 17 lbt.ftJ

BELT TENSION GAUGEoTJGG -0010r0A

23-115

J

,-

Page 1383 of 1681

).1

Contents

How to Use This l\.4anual 1Circuit Schematics (see Circuit Index)Fuse/Relaylnformation 6ComponentLocation Photographs 201

Connector Cavity Numbers 202Connectorldentification 203

Ground-to-Components Index 6-6Wire Harness Routing 203Circuit ldentification lor ln-Line and Fuse Box Connectors

Circuit Index

Air conditionerAir delivery 61Blower controls 60Compressor controls 62Fans 63Anti-lock brake system (ABS) 44A/T gear position indicator 89Automatic transmission controls'98199 models 39'00 models 39-4Back-up lightsHatchback 110Sedan 110- 1Brake system indicator light

USA 71Canada 71-1Brake lightsHatchback 110-6Sedan 110-7Cargo area light (Hatchback) 114-3Ceiling light 114-2Charging system 22Cigarette lighter 155

Clock 154Condenser fan 63Console lights 114Cruise control 34Dash lights 1 14Daytime running lights 110-8Door open indicator 114-2Engine coolant temperature gauge 81Engine oil pressure indicator light 72Fog lights 110-14Front parking lights 110-11Front side marker lights 110-11Fuel gauge 81Fuse/relay boxUnder-dash 6Under-hood 6-3Under-hood ABS 6-5Gauges 81Glove box light 114Ground distribution 14Ground-to-Componentsindex 6-6Hatch open indicator '114-3

Hatch opener '134

Hazard warning lightsHatchback 'l l0-2Sedan 110-4Headlights 1'10-8Headlight switch 100HeaterAir delivery 61Blower controls 60Fanswith A,/C 63without A,/C 63-2Horns 40lgnilion key reminder 73lgnition system 20

204

lmmobilizer system ('00 model) 132lndicators 80Integrated control unit 70Interlock system'98199 models 138'00 models 138-1License plate lightsHatchback 110-12Sedan 110-13Lights-on reminder 73Low fuel indicator light 74l\,4aintenance reminder light 83l\iloonroof 122Odometer 81-1Power antenna 151Power distributionBattery to ignilion switch, fuses, and relays

Fuses to relays and components 10-2Power door locksHatchback '130

Sedan 130-2Power mirrorsHatchback 141Sedan 141-1Power windowsHatchback 120Sedan 120-2Programmed fuel injection system (PGM-Fl)'98199 models 23'00 models 24Radiator fanwith tuC 63without A,/C 63-2Rear parking lightsHatchback 110-12Sedan 110- 13Rear window defogger 64Seat belt reminder 73Security system 133Speedometer Il-1Spotlights 114-2Starting syslemAutomalictransmission 21l\.4anualtransmission 21-1Stereo sound system 150Supplemental restraint system (SRS) 47Tachometer 81- 1TaillightsHatchback 110-12Sedan 110-13Trailer lighting conneclor 118Trunk lid open indicator 114-3Trunk light (Sedan) 114-3Turn signal lightsHatchback 110-2Sedan 110-4Vehicle speed sensor (VSS) 33Wiper/washerFront 91Rear 92

10

).1

I

Xr

12Fg oAmerican Honda Motor Co., Inc. - All Rights Reserved Service Communications 275 pages