Cylinder HONDA INTEGRA 1998 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 248 of 1681

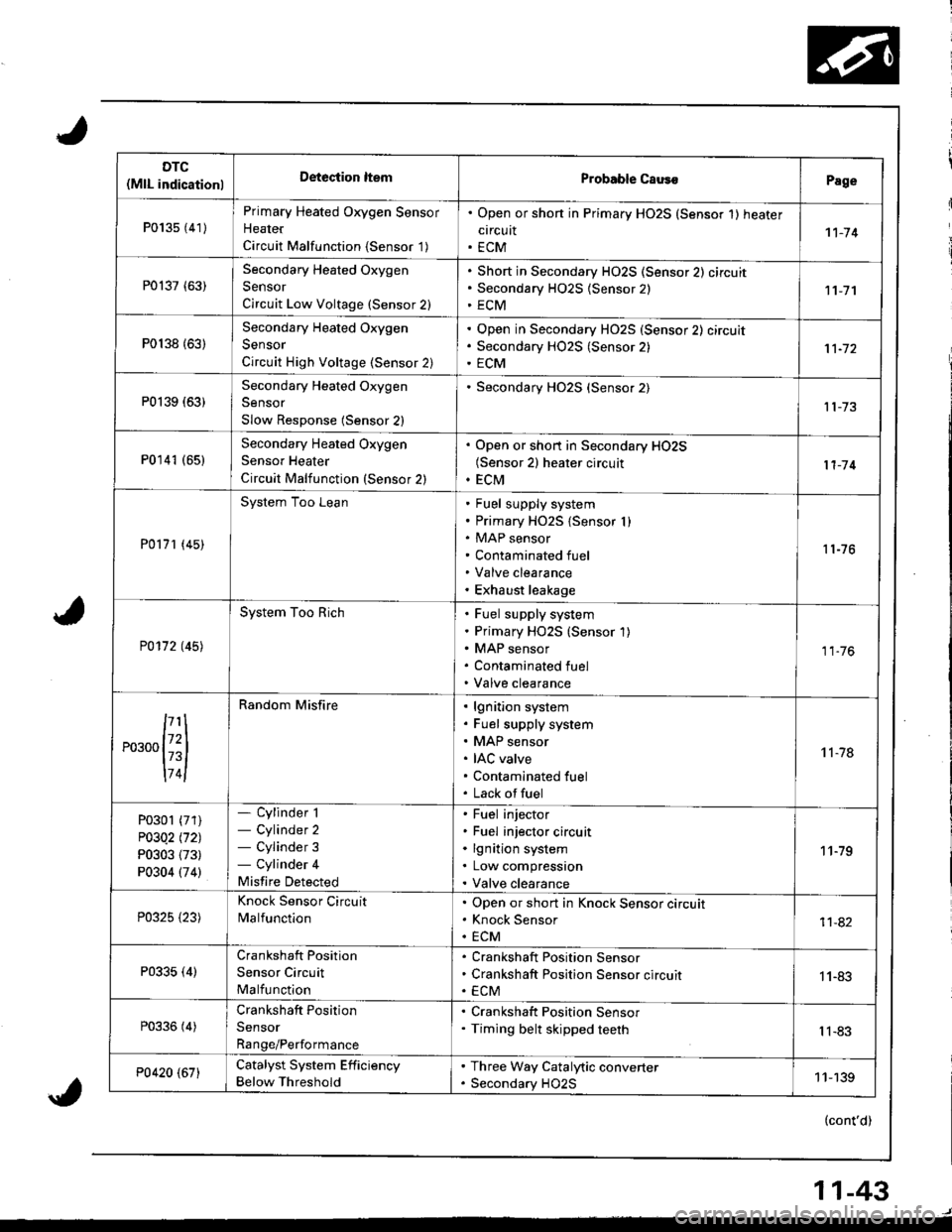

DTC(MlL indicationlDeteciion ltemProbable CausoPage

P013s {41)

Primary Heated Oxygen Sensor

Heater

Circuit Malfunction {Sensor '1)

. Open or shon in Primary HO2S (Sensor 1) heater

circuit. ECM1't-74

P0137 (63)Secondary Heated Oxygen

Sensor

Circuit Low Voltage (Sensor 2)

Short in Secondary HO2S (Sensor 2) circuit

Secondary H02S {Sensor 2)

ECM11-7'l

P0138 {63)

Secondary Heated Oxygen

Sensor

Circuit High Voltage (Sensor 2)

Open in Secondary HO2S (Sensor 2) circuit

Secondary HO2S (Sensor 2)

ECM

P0139 (63)Secondary Heated Oxygen

Sensor

Slow Response (Sensor 2)

Secondary HO2S (Sensor 2)

P0141 (651Secondary Heated Oxygen

Sensor Heater

Circuit Malfunction (Sensor 2)

. Open or short in Secondary HO2S(Sensor 2) heater circuit. ECM11-'14

P0171 (45)

System Too LeanFuel supply system

Primary HO2S {Sensor I )MAP sensor

Contaminated fuel

Valve clearance

Exhaust leakage

11-76

P0172 t45l

System Too RichFuel supply system

Primary HO2S (Sensor 1)

MAP sensor

Contaminated fuel

Valve clearance

11.76

,...,{iil

174l

Random Misfirelgnition system

Fuel supply system

MAP sensor

IAC valve

Contaminated fuel

Lack offuel

't 1-78

P0301 (71)

P03Q2 l'121

P0303 (73)

P0304 (74)

- Cylinder 1- Cylinder 2- Cylinder 3- Cylinder 4

Misfire Detected

Fuel injector

Fuel injector circuit

lgnition system

Low compression

Valve clearance

11-79

P0325 {23)

Knock Sensor Circuit

MalfunctionOpen or short in Knock Sensor circuit

Knock Sensor

ECM11-82

P0335 (4)Crankshaft Position

Sensor Circuit

Malfunction

Crankshaft Position Sensor

Crankshaft Position Sensor circuit

ECM1 1-83

P0336 (4)Crankshaft Position

Sensor

Range/Performance

. Crankshaft Position Sensor. Timing belt skipped teethIl-83

P0420 (67)Catalyst System Efficiency

Below Threshold

. Three Way Catalytic converter. Secondary HO2S11-139

(cont'd)

11-43

Page 250 of 1681

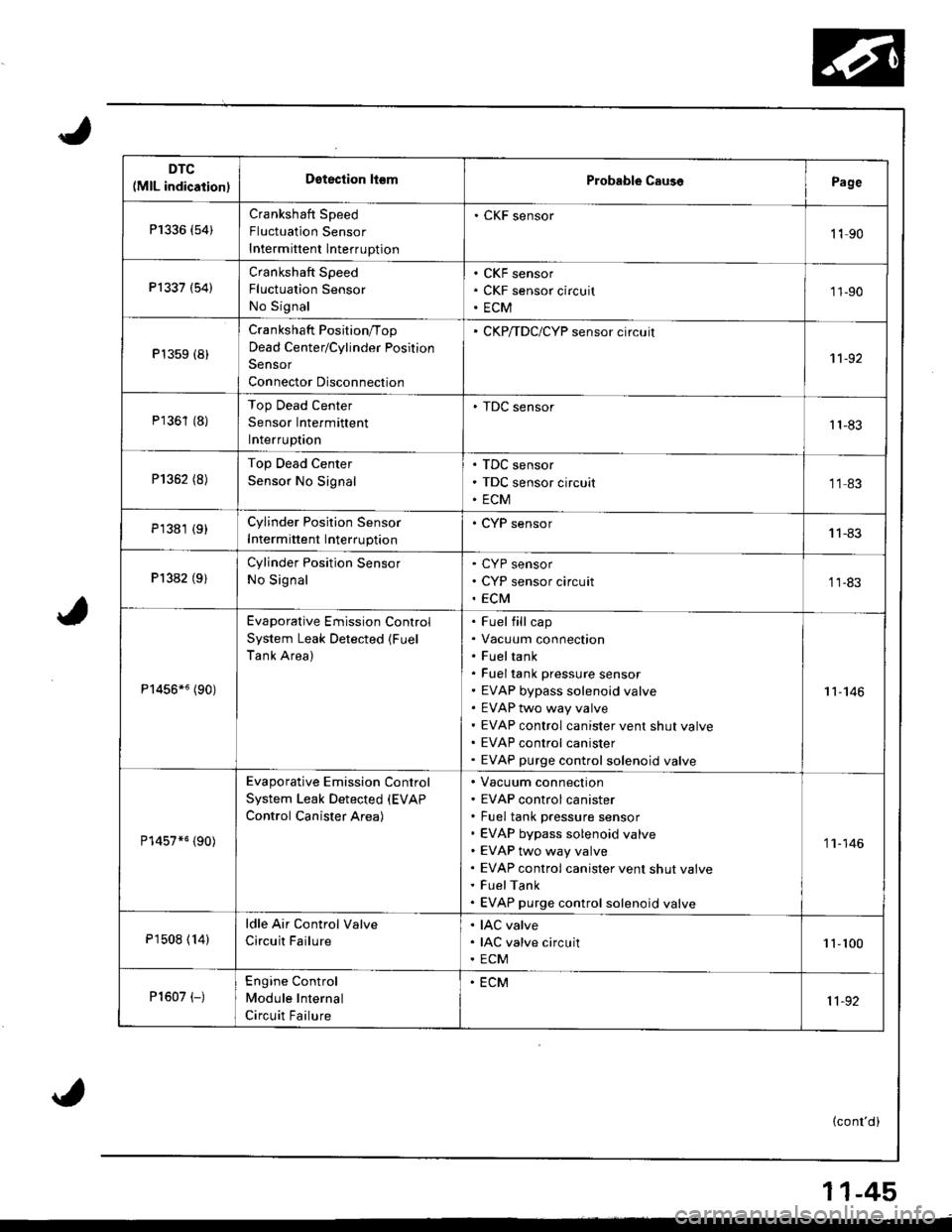

DTC(MlL indication)Dstection ll€mProbable CausePage

P1336 (54)Crankshaft Speed

Fluctuation Sensor

Intermittent lnterruption

. CKF sensor

1190

Pl337 (54)Crankshaft Speed

Fluctualion Sensor

No Signal

CKF sensor

CKF sensor circuit

ECM

'11-90

P't359 (8)

Crankshaft Position/Top

Dead Center/Cylinder Position

Sensor

Connector Disconnection

CKP/TDC/CYP sensor circuit

1't -92

P1361 (8)Top Dead Center

Sensor Intermittent

Interruptaon

. TDC sensor't1-83

P1352 (8)Top Dead Center

Sensor No Signal

TDC sensor

TDC sensor circuit

ECM

1183

P1381 {9}Cylinder Position Sensor

Intermittent Interruption

. CYP sensor11-83

Pl382 (9)Cylinder Position Sensor

No Signal

CYP sensor

CYP sensor circuit

ECM

11-83

P1456*6 (90)

Evaporative Emission Control

System Leak Detected (Fuel

Tank Area)

Fuel fill cap

Vacuum connection

Fueltank

Fuel tank pressure sensor

EVAP bypass solenoid valve

EVAP two way valve

EVAP control canister vent shut valve

EVAP control canister

EVAP purge control solenoid valve

11-146

P14s7*5 {90)

Evaporative Emission Control

System Leak Detected (EVAP

Control Canister Area)

Vacuum connection

EVAP control canister

Fuel tank pressure sensor

EVAP bypass solenoid valve

EVAP two way valve

EVAP control canister vent shut valve

FuelTank

EVAP purge control solenoid valve

'1 'l - 146

P1508 ( 14)

ldle Air Control Valve

Circuit Failure

IAC valve

IAC valve circuit

ECM

1 1-100

P1607 (-)Engine Control

Module Internal

Circuit Failure

. ECM

11-92

(cont'd)

11-45

Page 284 of 1681

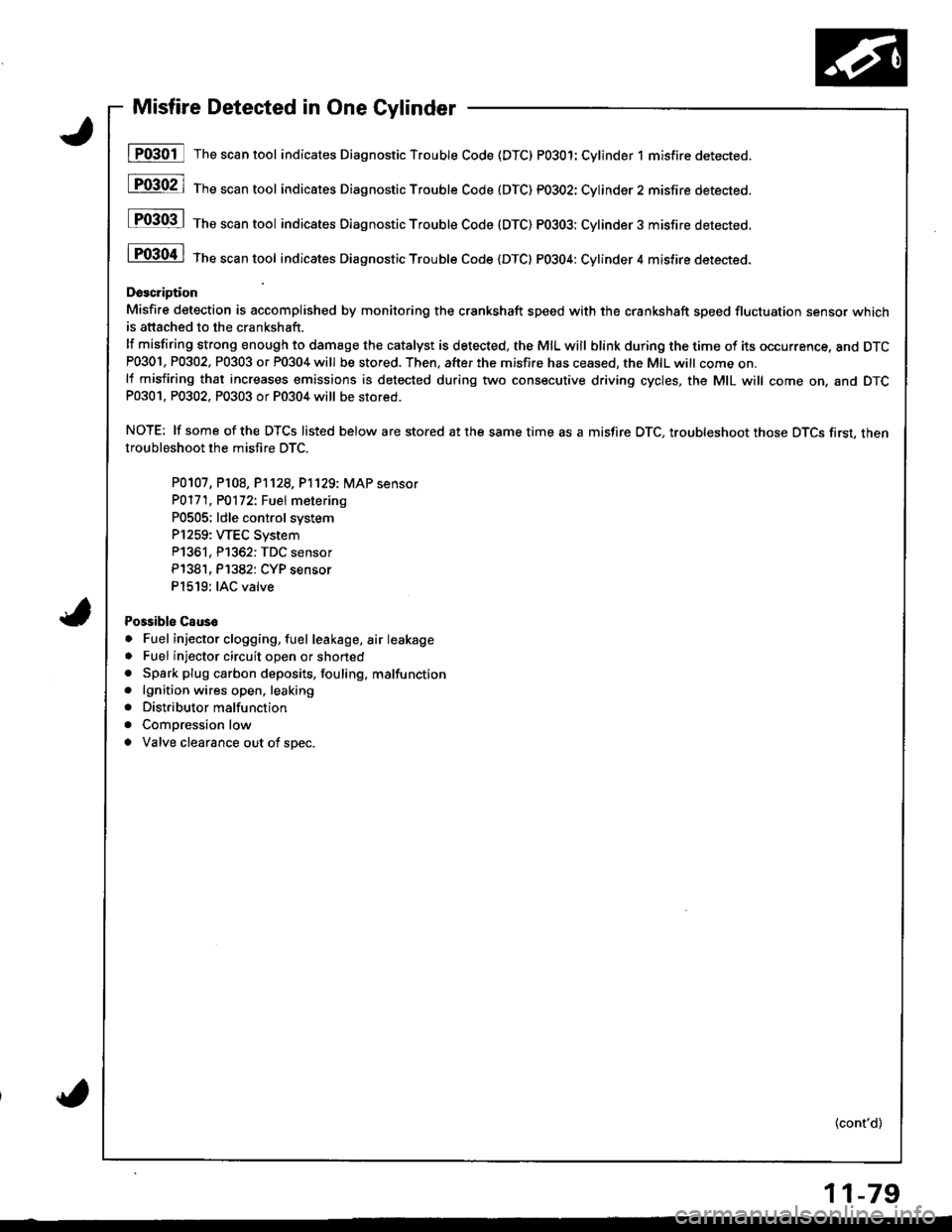

Misfire Detected in One Cylinder

I P0301 The scan tool indicates Diagnostic Trouble Code (DTC) PO3O1:Cylinder 1 misfire detected.

[F03021 1;," """n tool indicares Diagnostic Troubte Code (DTC) pO3O2: Cylinder2 misfire detected.

P0303 | ths sssn tool indicates Diagnostic Trouble Code (DTC) PO3O3: Cylinder3 misfire detected.

i P0304 | tne scan tool indicates Diagnostic Trouble code {DTC} PO3O4: Cylinder 4 misfire detected.

Doscription

Misfire detection is accomplished by monitoring the crsnkshaft speed with the crankshaft speed fluctuation sensor whichis attached to the crankshaft.

lf misfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and DTCP0301, P0302, P0303 or P0304 will be stored. Then, after the m;sfire has ceased, the MIL witt come on.lf misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and DTCP0301, P0302, P0303 or P0304 will be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTC, troubleshoot those DTCS first, thentroubleshoot the misfi.e DTC.

P0107, P108, P1128,P'1129:� MAP sensor

PO171, PO172t Fuel metering

P0505; ldle control system

P1259: WEC System

P1361, P1362: TDC sensor

P138'1, P1382: CYP sensor

P1519: IAC valve

Possibls Caus6

. Fuel injector clogging, fuel leakage, air leakage

. Fuel injector circuit open or shoned. Spark plug carbon deposits, fouling, malfunction. lgnition wires open, leaking

. Distributor malfunction

. Compression low

a Valve clearance out of spec.

(cont'd)

11-79

Page 285 of 1681

PGM.FI

Misfire

System

Detected in One Cylinder (cont'd)

)

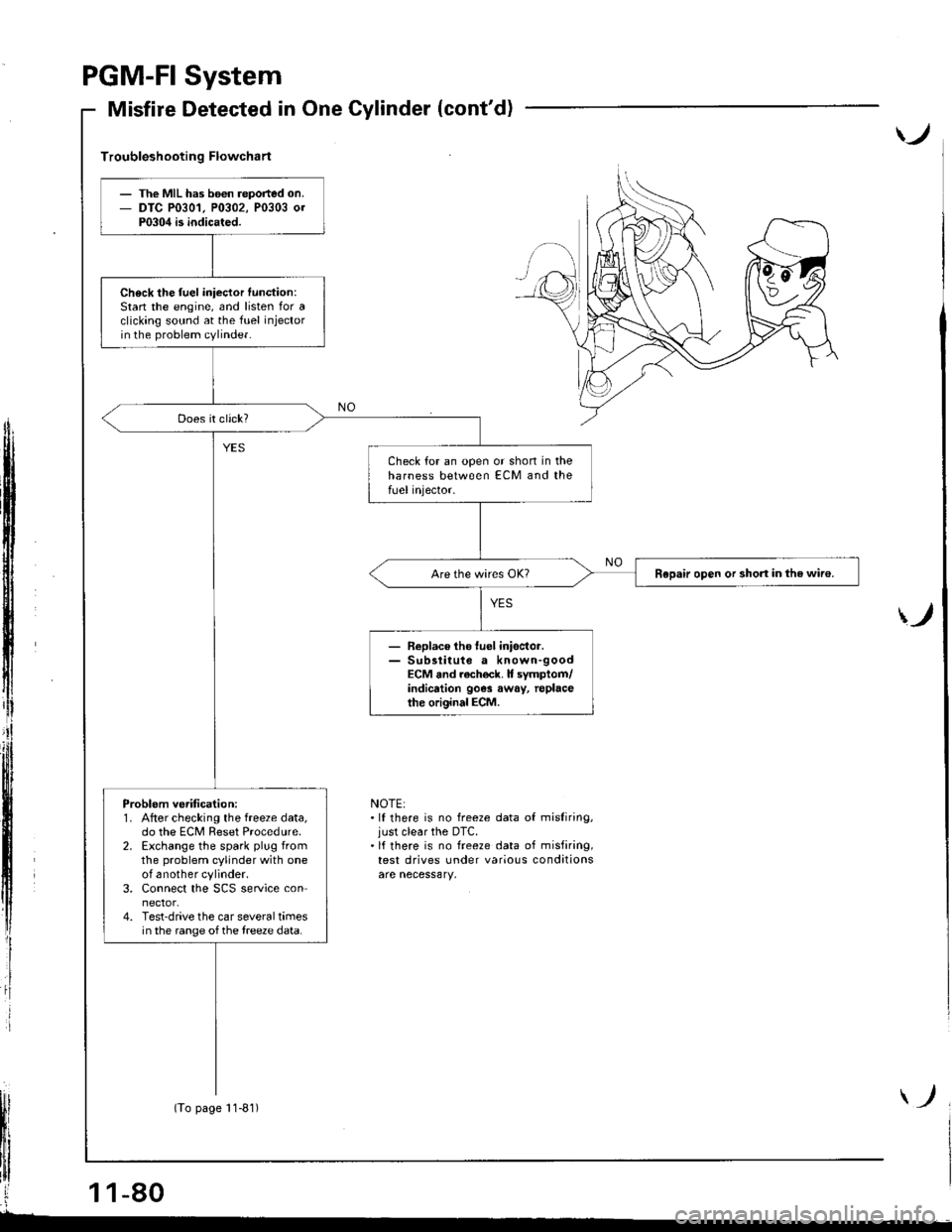

Troubleshooting Flowchart

ff

i

)

NOTE:.lf there is no freeze data of misliring,just clear the DTC.'lf there is no freeze data of misfiring,test drives under various conditions

The MIL has b6€n reported on.DTC P0301, P0302, P0303 0rP0304 is indicated.

Check the fuel iniector function:Stan the engine, and listen for aclicking sound at the fuel injectorin the problem cylinder.

Check for an open or shon in theharness between ECM and thefUel injector.

Repair open or short in the wiro.

- Replace tho luel inisctor.- Sub3titute a known-goodECM and rach€ck. It symptom/indicrtion 90e3 away, replacethe original ECM.

Problem ve.ification:1. After checking the freeze data,do the ECM Reset Procedure.2. Exchange the spark plug fromthe problem cylinder with oneof another cylinder.3. Connect the SCS service connector.4. Test-drive the car several timesin the range of the treeze data.

(To page 11-81)

Page 286 of 1681

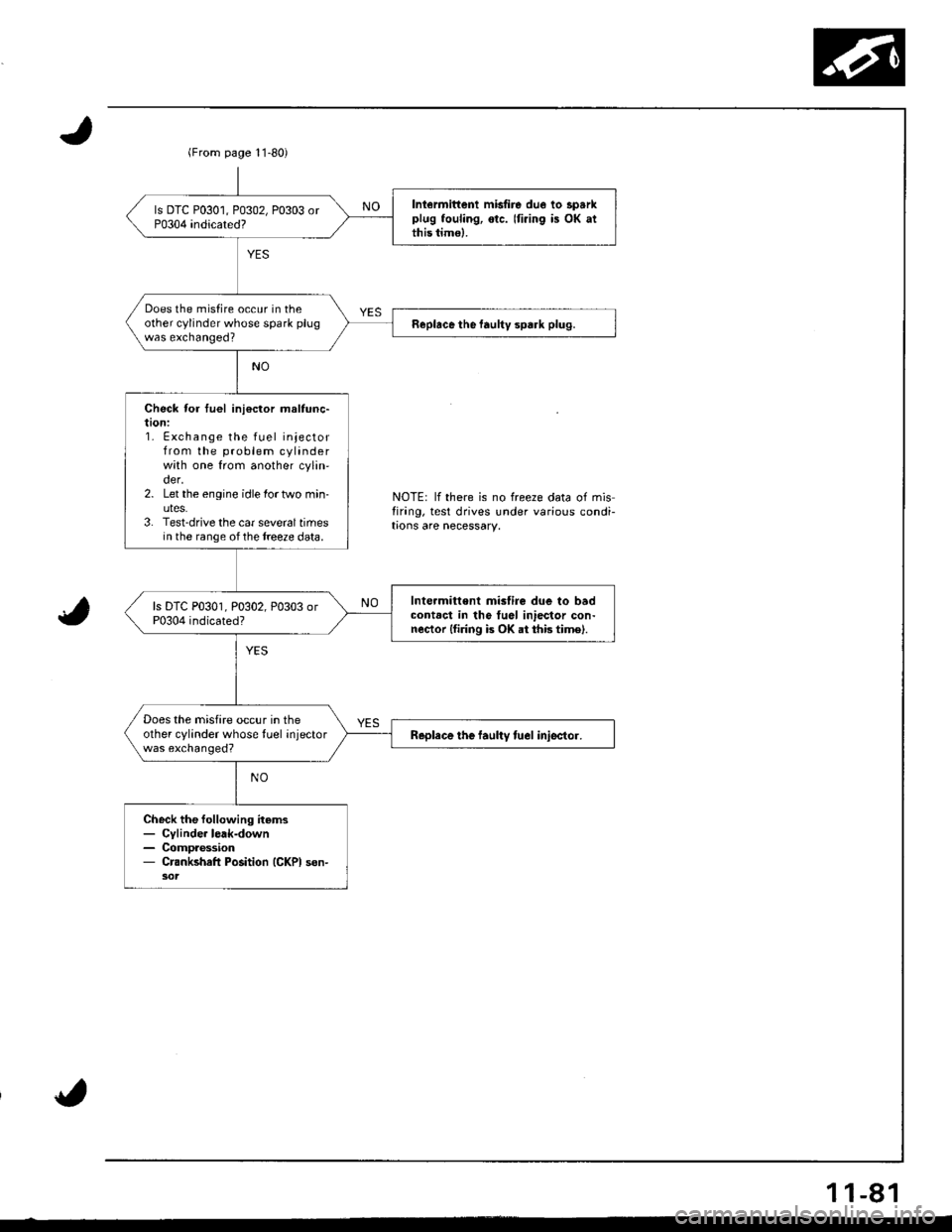

(From page l1-80)

Iniermittenl misfire due lo sparkplug fouling, otc. Iti.ing is OK atthis timo).

Does the misfire occur in theother cylinder whose spark plugwas exchanged?Replace the faultv spark plug.

Check for tuel ini€ctor maltunc-taon:1. Exchange the fuel injectorfrom the problem cylinderwith one from another cylin'der.2. Let the engine idle lortwo min-uteS.3. Test-drive the car sevoraltimesin the range ofthe treeze data.

Int€rmitt€nt mislire due to badcontact in tho tuel iniector con-nector lfiring is OK at thb time).

Does the misfire occur in theother cylinder whose tuel injectorwas exchanged?Replace the laultv tuel iniector.

Check the following items- Cylinde. lerk-down- Compaession- Crankshafl Position (GKPI son-

NOTE: lf there is no freeze data of misfirang, test drives under various condi-trons are necessary.

1 1-81

Page 288 of 1681

t@

tFffi6l

F136il

l-P1362l

Fi3BTl

tFE82-l

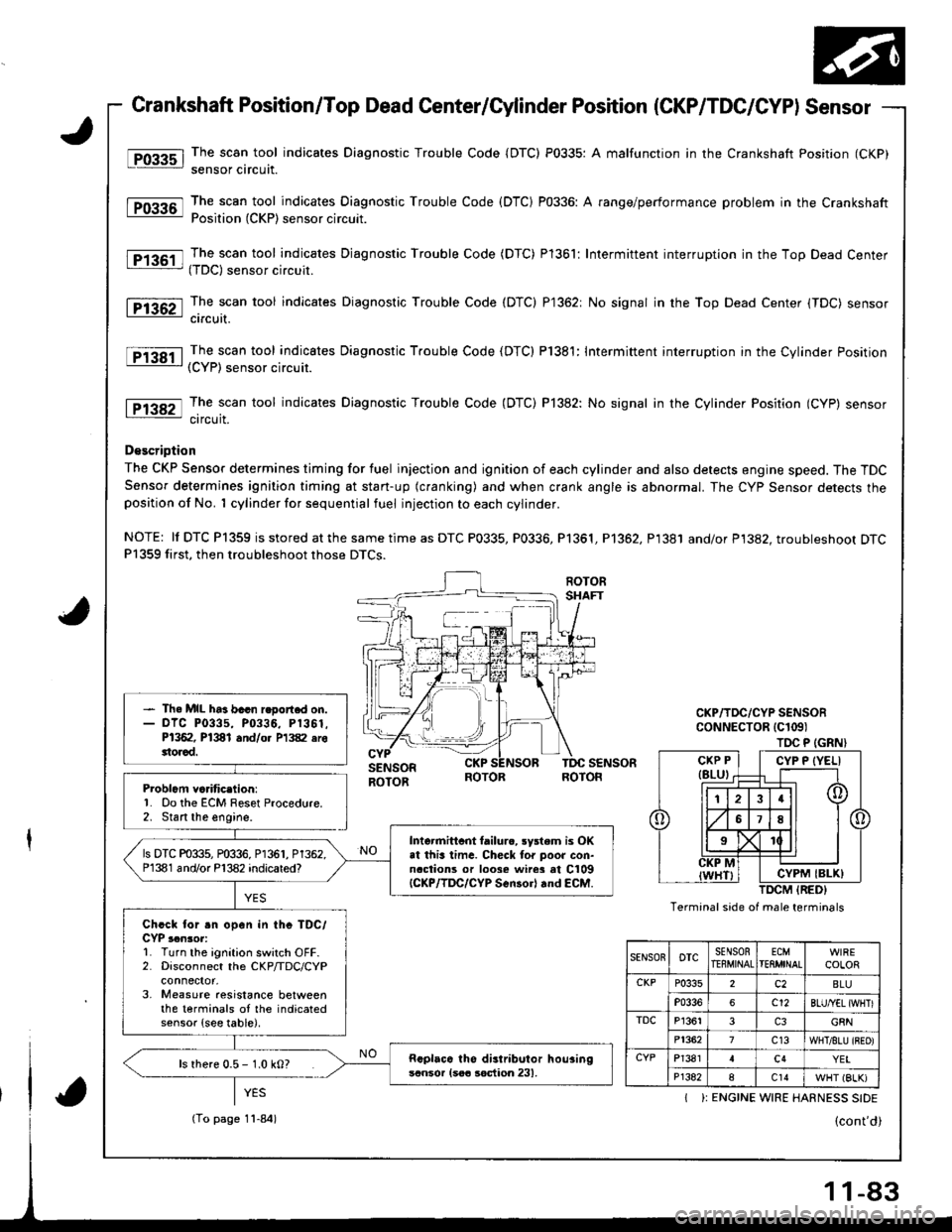

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code {DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the CrankshaftPosition (CKP) sensor circuit.

The scan tool indicates Djagnostic Trouble Code (DTC) Pl361: Intermittent interruption in the Top Dead Center(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensorcircuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P]382: No signal in the Cylinder Position (CYP) sensorcircuit.

D€scription

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDCSensor determines ignition timing at stan-up (cranking) and when crank angle is abnormal. The Cyp Sensor detects theposition of No. 1 cylinder for sequential fuel injection to each cylinder.

NOTE: ll DTC P1359 is stored at the same time as DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382. troubleshoot DTCP1359 first, then troubleshoot those DTCS.

Problcm va.itic.lion:'1. Do the ECM Reset Procedure.2. Stan the engine.

- Th. MIL ha3 bacn r.oort.d on.- olc P0335, P0336, P1361.P1362, P1381 and/o. P1382 erottorad.

Intormittcnt tailurc, rystem is OKat this lima. Checl tor poor con-naclions or loose wire3 at C109{CKP/lDC/CYP Scn30rl rnd €CM.

ls DTC P0335, P0336, P1361, P1362.P1381 and/or P'l382 indicared?

Chcck for .n open in thc TDC/CYP ,.n3or:L Turn the ignition switch OFF.2. Disconnect the CKP/TDC/CYP

3, Measure aesistance betweenthe terminals oI the indicatedsensor {see table).

Rcplaca tho distributor hou3ingscnsor {soa soction 231,ls rhere 0.5 - 1.0 kO?

TOC P (GRN}

Termanal side of male terminals

CYP P {YELI

CYPM IBLK)

SENSOnoTcSENSORTEEMINALECMTEflMINALCOLOR

CKPP0335c2BLU

P0336c12BLU/YEL {WHTI

TDCP13613G8N

P13627c13WHT/8LU {BEO)

CYPP13814c4YEI

P1382ac14WHT (BLK)

I ): ENGINE WIRE HARNESS SIDE

(To page 11-84)

-83

Page 289 of 1681

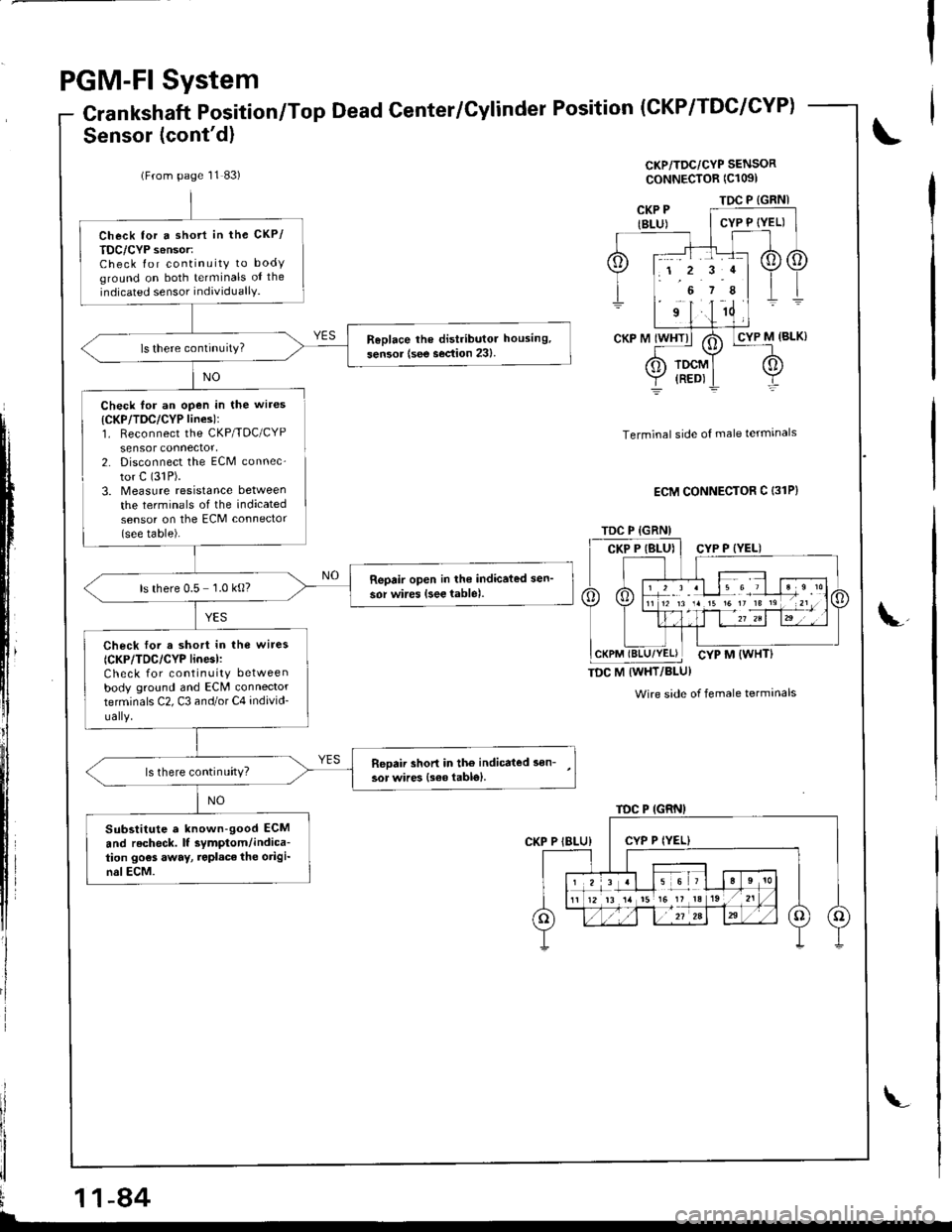

PGM-FI System

Crankshaft Position/Top Dead Center/Cylinder Position

Sensor (cont'd)

(CKP/TDC/CYP)

CKP/TDC/CYP SENSOR

ooNNECTOR (Cl091

NO

il

,ll

I

Check for an open in the wires

{CKP/TDC/CYP lines):1. Reconnect the CKP/TDC/CYPsensor connector,2. Disconnect the ECM connec-

tor C (31P).

3. Measure resrstance between

the terminals of the indicatedsensor on the ECM connector(see table).

Terminal side of male termrnals

ECM CONNECTOR C {31P}

TDC M IWHT/BLU}

Wire side of female terminals

i

ii!\

(From page 11 83)

Check tor a shott in the CKP/

TDC/CYP s6nsor:Check for continuity to bodyground on both terminals oI the

indicated sensor individuallY.

ReDlace lhe distributor housing,

sen3or {see section 23}.

Reoair open in lhe indicated sen'

sor wires {see lable).ls there 0.5 1.0 kg?

Check lor a short in the wire3

{CKP/TDC/CYP linesl:Check for continuity betweenbody ground and ECM connectorterminals C2, C3 and/or C4 individ-

ually.

Reoaii shon in tho indicated son-

3or wires {s€6 table}.ls there continuity?

Substitute a known-good ECM

and recheck. lf symptom/indica-tion go€s away, repl.ce the origi-nslECM.

TDC P {GRNI

TDC P (GRN)

1 2 r .l le 6 7

TDC P {GRN)

1 2 3 al 15 6 ,

12 13 14 t5 16 It 13

11-84

Page 297 of 1681

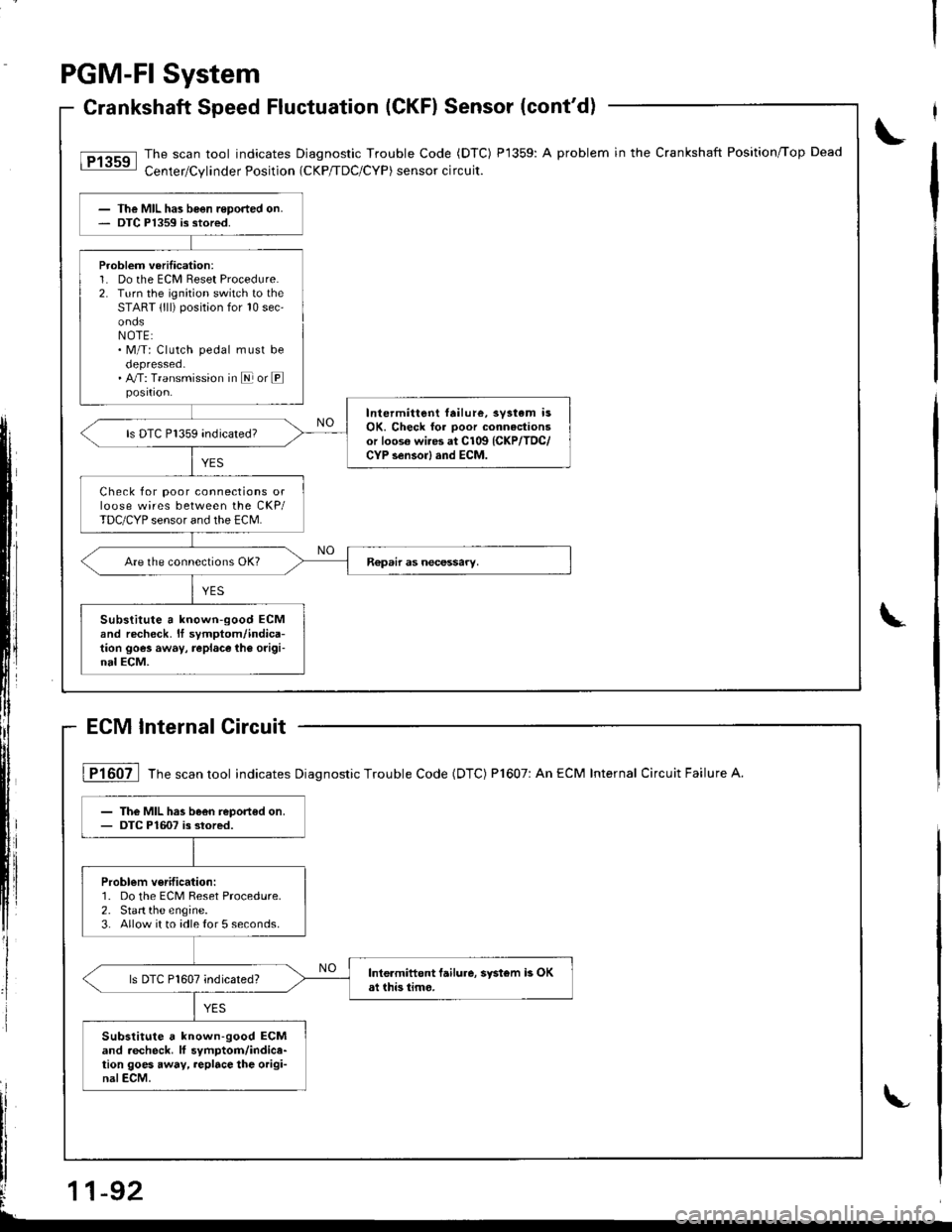

nsnan upeeo rlucruauon lunF, Densor lconr q,

The scan tool indicates Diagnostic Trouble Code (DTC) P1359: A problem in the Crankshaft Position,Top Dead

Cenler/Cylinder Position (cKP/TDC/CYP) sensor circuit.tPr3ssl

The MIL has been reported on.DTC P1359 is stored.

Problem verilication:1. Do the ECM Reset Procedure.2. Turn the ignition switch to theSTART {lll) positaon for 10 sec'

NOTE:. M/T: Clutch pedal must be

. A/T: Transmission in E or E

Intermittent failure, svstem isOK. Check for ooor connactionsor loos€ wi.es at C109 {CKP/TDC/CYP sensorl and ECM.

ls DTC P1359 indicated?

Check for poor connections orloose wires between the CKP/TDC/CYP sensor and the ECM.

Substitute a known-good ECMand recheck. It symptom/indica-tion goes away, replace ih6 origi-nal ECM.

PGM-FI System

Crankshaft Speed Fluctuatio(CKFI Sensor (cont'd)

ECM lnternal Circuit

\

L

I P1607 Tfre scan tool indicates Diagnostic Trouble Code (DTC) Pl607: An ECM Internal Circuit Failure A.

The MIL has been reported on.DTC P16O7 is stored.

Problem verification:1. Do the ECM Reset Procedure.2. Start the engine.3. Allow it to idle {or 5 seconds.

Inte.miftent failure, systom L OKst this iimo.ls DTC P1607 indicated?

Substitute a known-good ECMand .echeck. lf symptom/indica-tion goes away, replace the origi-nalECM.

-92

Page 337 of 1681

In

Intake Air System

Throttle Body

$;

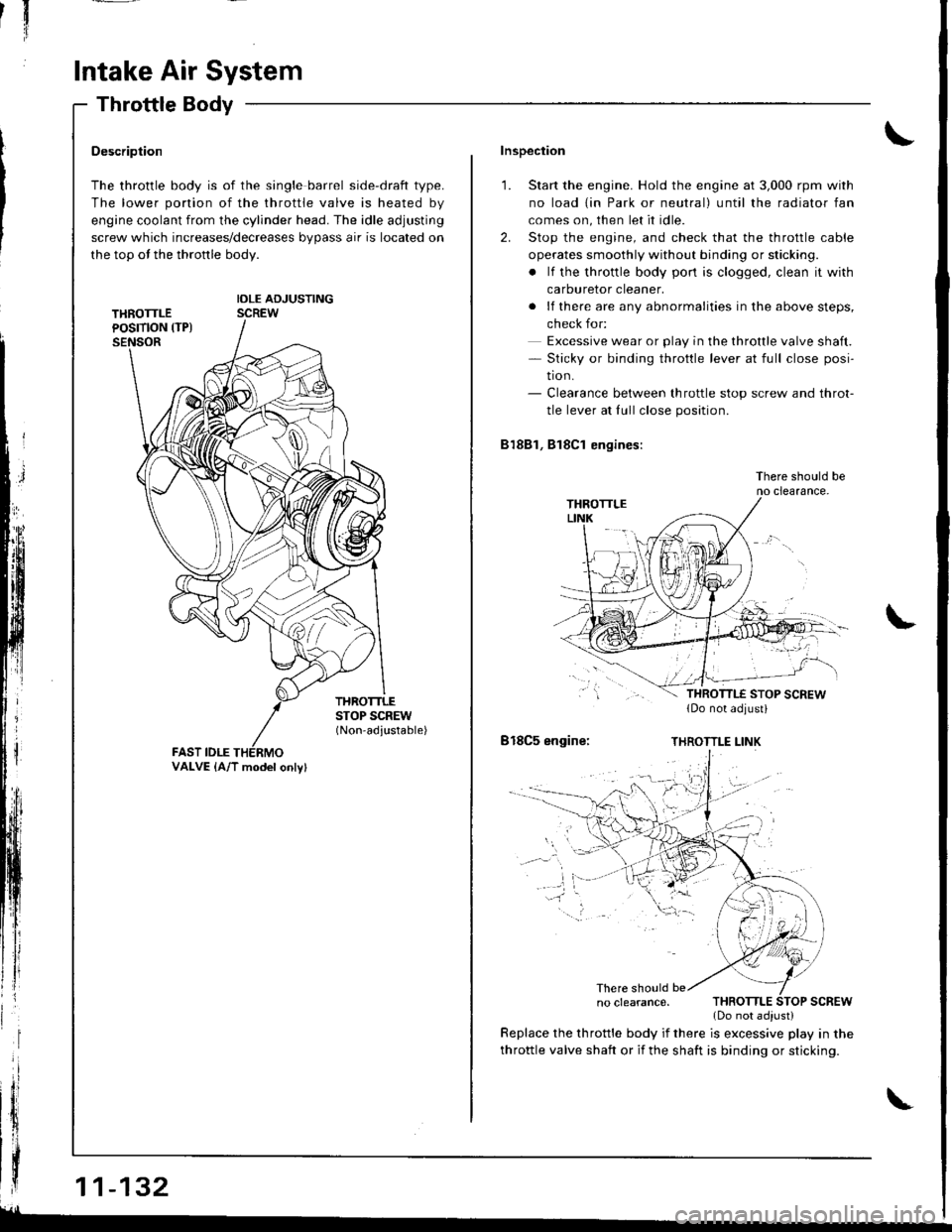

Description

The throttle body is of the single barrel side-draft type.

The lower portion of the throttle valve is heated by

engine coolant from the cylinder head. The idle adjusting

screw which increases/decreases bypass air is located on

the top ot the thronle body.

IDLE ADJUSTINGSCREW

THROTTLESTOP SCREW(Non-adjustable)

FAST IDLE

| | .o clearance. THRoTTLE SToP scREw

{ | | _ .lDonotadiust)

| | y:::::::T,"9":::.'"Tl::f ,::i1::"1" fllyll-'n"

VALVE {A/T model onlv}

Inspection

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Stop the engine, and check that the throttle cable

operates smoothly without binding or sticking.

. lf the throttle body pon is clogged, clean it with

carburetor cleaner.

. lf there are any abnormalities in the above steps,

check for:

Excessive wear or play in the throttle valve shaft.- Sticky or binding throttle lever at full close posi-

tion.- Clearance between throttle stop screw and throt-

tle lever at fullclose position.

81881, Bl8Cl engines:

There should beno clearance.

818C5 engine:THROTTLE LINK

There should be

throttle valve shaft or if the shaft is binding or sticking.

glL-

Page 358 of 1681

Clutch

Speciaf Tools ........ .'--"" 12-2

lflustrated Index ........ ".' 12-3

Clutch Pedal

Adjustment "..".""'...' 12-4

Clutch Master Cylinder

Removal/lnstallation -'.' 12-5

Slave Cylinder

Removal/lnstallation '..' 12-6

Pressure Plate

Removal/lnspection .'-.' 12-7

Clutch Disc

Removal/lnspection '...' 12-a

Flywheel, Flywheel Bearing

fnspection ' 12-9

Replacement .................'............. 1 2-9

Clutch Disc, Pressure Plate

lnstallation ................. 12-10

Release Bearing

Removal/lnspection "'.' 12-11

fnstaffation ".""".-'."'. 12-12