Cylinder HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 703 of 1681

Power Steering Gearbox

Reassembly {cont'd}

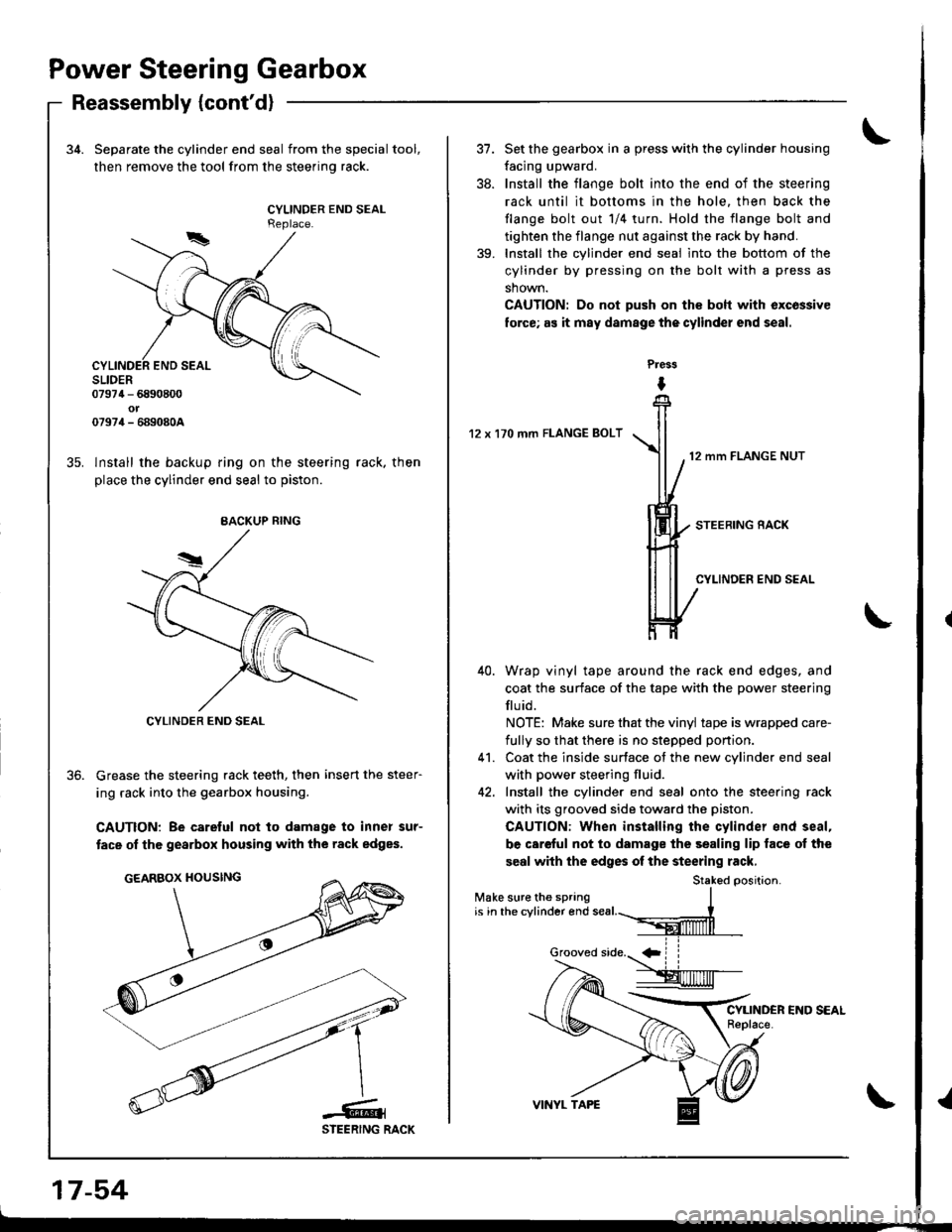

34. Separate the cylinder end seal from the special tool,

then remove the tool from the steerino rack.

CYLINDER END SEALReplace.

lnstall the backup ring on the steering rack. then

place the cylinder end seal to piston.

Grease the steering rack teeth, then insert the steer-

ing rack into the gearbox housing.

CAUTION: Be carelul not to damage to inner sur-

tace of the gearbox housing with the rack edges.

BACKUP BING

CYLINDER END SEAL

17-54

37.

38.

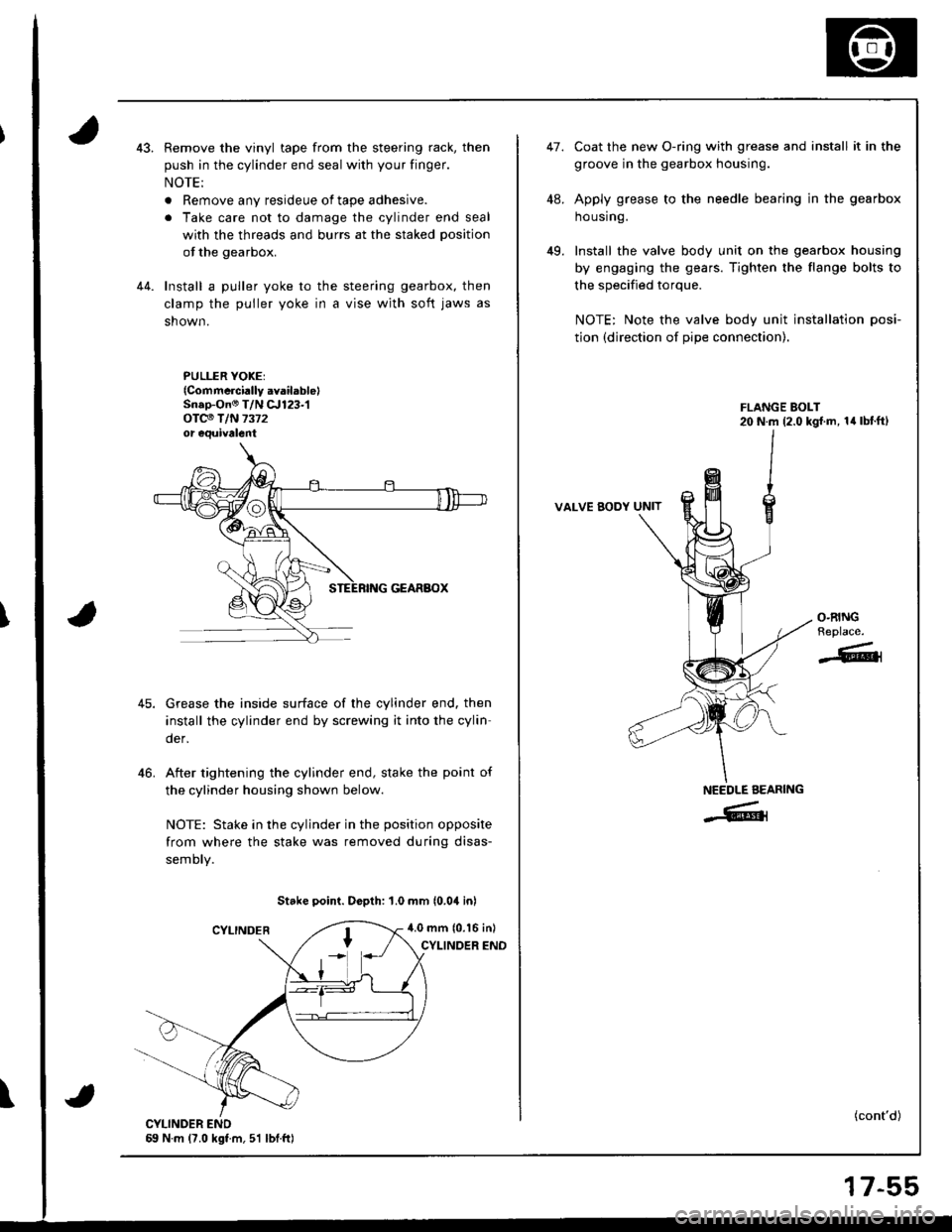

Set the gearbox in a press with the cylinder housing

facing upward.

Install the flange bolt into the end of the steering

rack until it bottoms in the hole. then back the

tlange bolt out 1/4 turn. Hold the flange bolt and

tighten the flange nut against the rack by hand.

Install the cylinder end seal into the bottom of the

cylinder by pressing on the bolt with a press as

shown.

CAUTION: Do not push on th€ boh with excossive

lorce; as it may damage thecylinder end seal.

Press

I

12 x 170 mm FLANGE BOLT

12 mm FLANGE NUT

Wrap vinyl tape around the rack end edges, and

coat the surface of the tape with the power steering

flu id.

NOTE: Make sure that the vinyl tape is wrapped care-

fully so that there is no stepped ponion.

Coat the inside surface of the new cvlinder end seal

with power steering fluid.

Install the cylinder end seal onto the steering rack

with its grooved side toward the piston.

CAUTION: When installing the cylinder end seal,

be careful not to damage the sealing lip face of the

seal with the edges of the steering rack,

Stak6d oosition.

39.

41.

Make sure the springis in the cylinder end

Page 704 of 1681

Remove the vinyl tape from the steering rack, then

push in the cylinder end seal with your finger.

NOTE:

. Remove any resideue of tape adhesive.

. Take care not to damage the cylinder end seal

with the threads and burrs at the staked position

of the gearbox.

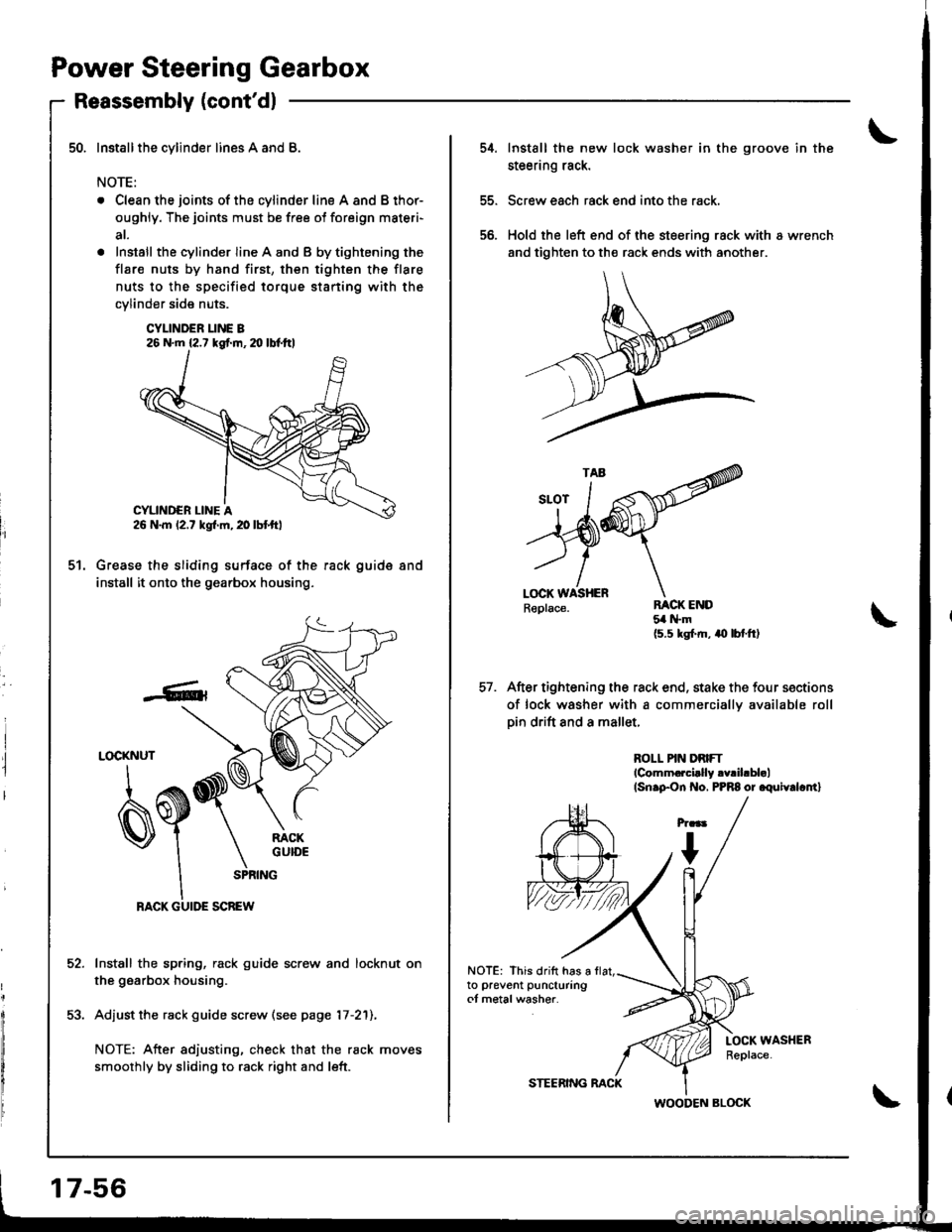

Install a puller yoke to the steering gearbox, then

clamp the puller yoke in a vise wjth soft jaws as

shown.

PULLER YOKEI{Commcrci.lly .vailablelSn.p-On@ T/N c.r123-1oTc€ T/N 7372or equivalent

Grease the inside surface of the cylinder end. then

install the cylinder end by screwing it into the cylin

der,

After tightening the cylinder end, stake the point of

the cylinder housing shown below.

NOTE: Stake in the cylinder in the position opposite

from where the stake was removed during disas-

semory.

Stake point. Dopth: 1.0 mm (0.04 inl

4.0 mm (0.16 inl

CYLINOER END

46.

\

47.

49.

coat the new o-ring with grease and install it in the

groove in the gearbox housing.

Apply grease to the needle bearing in the gearbox

ho using.

Install the valve body unit on the gearbox housing

by engaging the gears. Tighten the flange bolts to

the specified torque.

NOTE: Note the valve body unit installation posi-

tion (direction of pipe connection).

VALVE BODY UNIT

(cont'd)

O.RINGReplace.

-611

NEEDLE AEARING

-Grl

17-55

Page 705 of 1681

Power Steering Gearbox

Reassembly (cont'dl

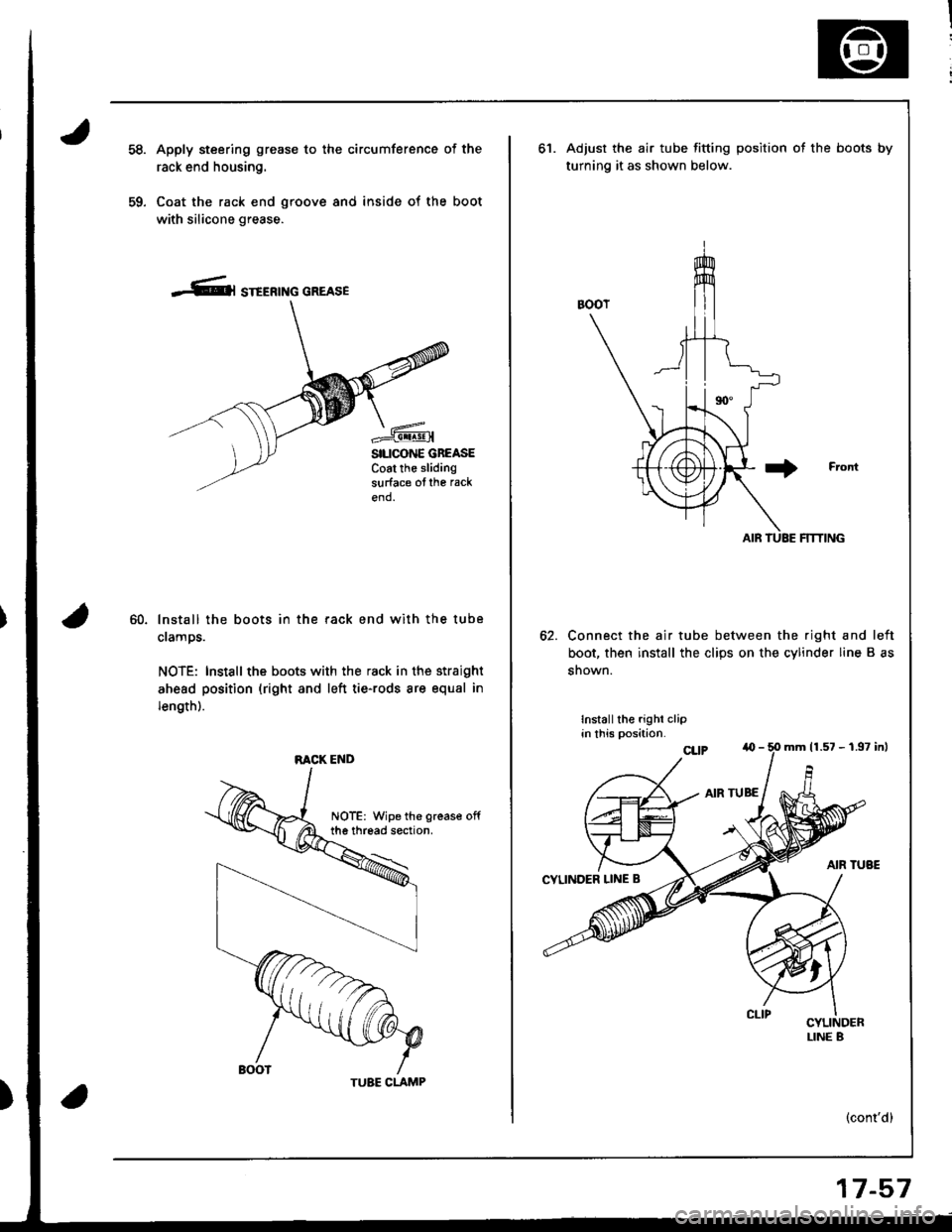

Installthe cylinder lines A and B.

NOTE:

. Clean the joints of the cylinder line A and B thor-

oughly. The joints must be free ol foreign materi-

at.

. Install the cylinder line A and B by tightening the

flar€ nuts by hand first, then tighten the flare

nuts to the specified torque staning with the

cylinder side nuts.

CYLINDER I-INE B26 N.m {2.7 kgf.m, m lbl.ftl

50.

5t.Grease the sliding surface of the rack guide

install it onto the gearbox housing,

and

52.

53.

LOCKNUT

q

SPRING

RACK GUIDE SCREW

Install the spring, rack guide screw and locknut on

the gearbox housing.

Adjust the rack guide screw (see page 17-2'll,

NOTE: After adiusting, check that the rack moves

smoothly by sliding to rack right and left.

17-56

STEERING RACK

WOODEN BLOCK

54.Install the new lock washer in the groove in the

steering rack.

Screw each rack end into the rack.

Hold the left end of the steering rack with I wrench

and tighten to th€ rack ends with another.

56.

After tightening the rack end, stake the four sections

of lock washer with a commerciallv available rollpin drift and a mallet.

RACK END5{ l{.m

{5.5 kgl.m, aO lbt.ftl

ROLL PIN DRIFTlcomm.rci.lly .v.ihbl.l(Sn.pon f{o, PPR8 or .quiv.lc.n}

LOCK WASHERReplace.

NOTE: This dritt has ato prevent puncturingot metal washer.

Page 706 of 1681

59.

Apply steering grease to the circumference of the

rack end housing.

Coat the rack end groove and inside of the boot

with silicone grease.

-Cl STEERTNG GREASE

SILICONE GBEASECoat the slidingsurface ofthe rack

end.

60.lnstall the boots in the rack end with the tube

clamps.

NOTE: Install the boots with the rack in the straight

ahead position (right and left tie-rods are equal in

length).

RACK END

TUBE CLAMP

17-57

ot.Adjust the air tube fitting position ot the boots by

turning it as shown below.

Connect the air tube between the right and left

boot, then install the clips on the cylinder line B as

snown.

Installthe righi clipin this position.

(cont'd)

mrn 11.57 - 1.97 inl

Page 753 of 1681

Brakes

Special Tools ............. 19-2

Component Locations

Index ................ ...... 19-3

Inspection and Adiustment

Brake system Rubber Parts

and Brake Booster ....................... 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. t9-7

Front Brake Pads

Inspection and Replacement .......... l9-B

Front Brake Disc

Disc Runout Inspection ................... 19-10

Disc Thickness and Parallelism

Inspection .......... 19-10

Front Brake Caliper

Disassembly/Reassembly ............... l9-1 l

Master Cylinder/Brake Booster

Removal/1nsta|lation ....................... 19-13

Master Cylinder Inspection ............. 19-14

Pushrod Clearance Adjustment ...... 19-14

Brake Booster Inspection,.............,, lg-15

Rear Brake Pads

Inspeetion and Replacement .......... l9-16

Rear Brake Disc

Disc Runout Inspection ................... 1 g-18

Disc Thickness and Parallelism

Inspection .......... t9-18

Rear Brake Caliper

Disassembly/Reassembly ............... l9-19

Brake Hoses/Lines

Inspection/Torque Specifications ... l9-20

Hose Replacement ...................... ..... 19-21

Parking Brake Gable

f nspection and Replacement ,......,.,19-22

Page 755 of 1681

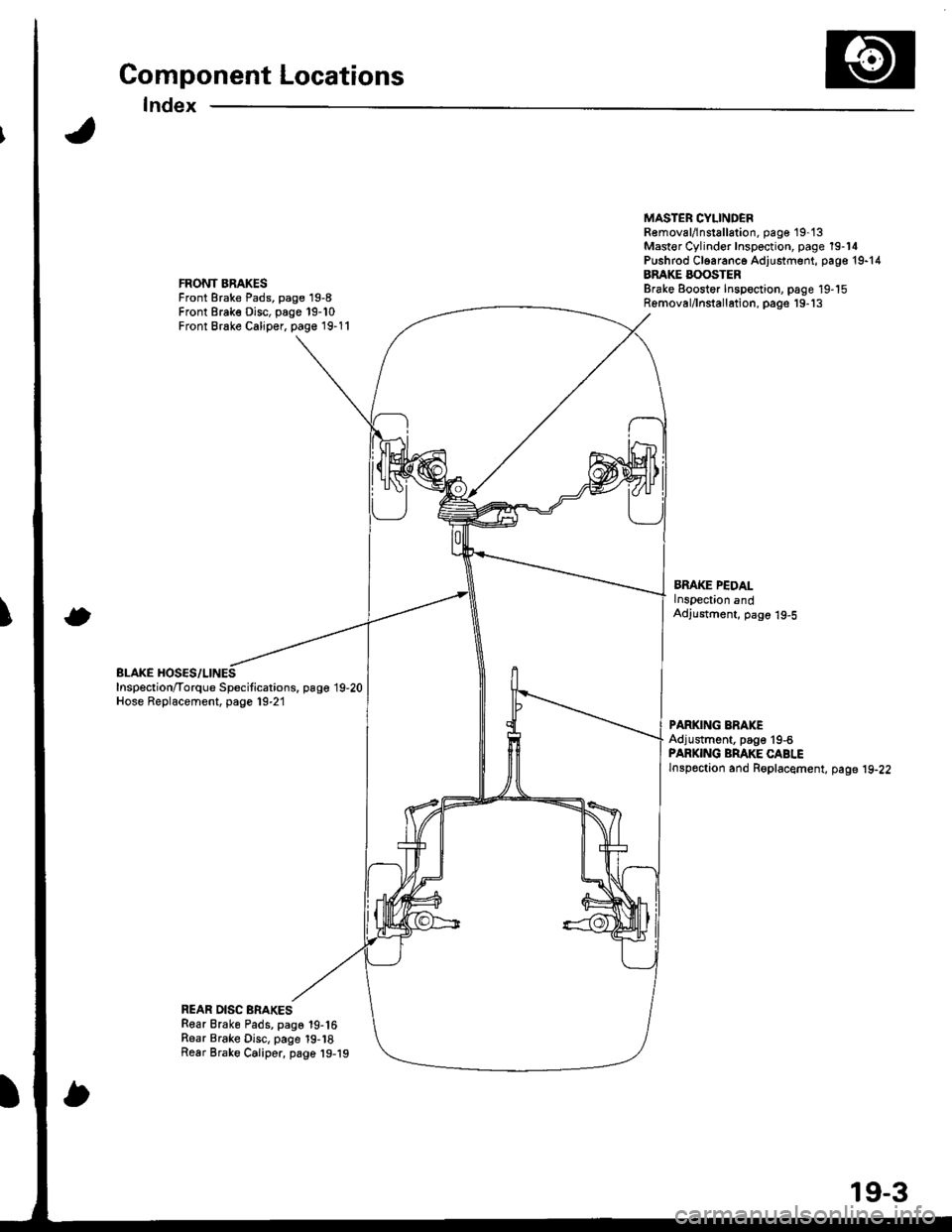

Component Locations

Index

FRONT BRAKESFront Brake Pads, page 19-8Front Brake Disc, page 19-10Front Brake Caliper, page 19-11

BLAKE HOSES/LINESInspection/Torque Specitications. page 19,20Hose Replacement, page 19-21

MASTER CYLINDEBR€moval/lnstallation, pag€ 19-'t3Mast€r Cylinder Inspection, page 19-14Pushrod Cl6aranc6 Adjustment, page 19-14BRAKE BOOSTERBrake Eoostor Inspoction, page 19-15Removal/lnstallation, pags'19-'13

BMKE PEDALlnspection andAdjustment, page 19-5

PARKING ERAKEAdjustment, page'19-6PARKING BRAKE CABLElnspoction and Roplacement, page 19-22

REAR DISC BRAKESRear Brake Pads, page 19-16Rear Brake Disc, page 19-18Rear Brake Caliper, page 19-19

19-3

Page 756 of 1681

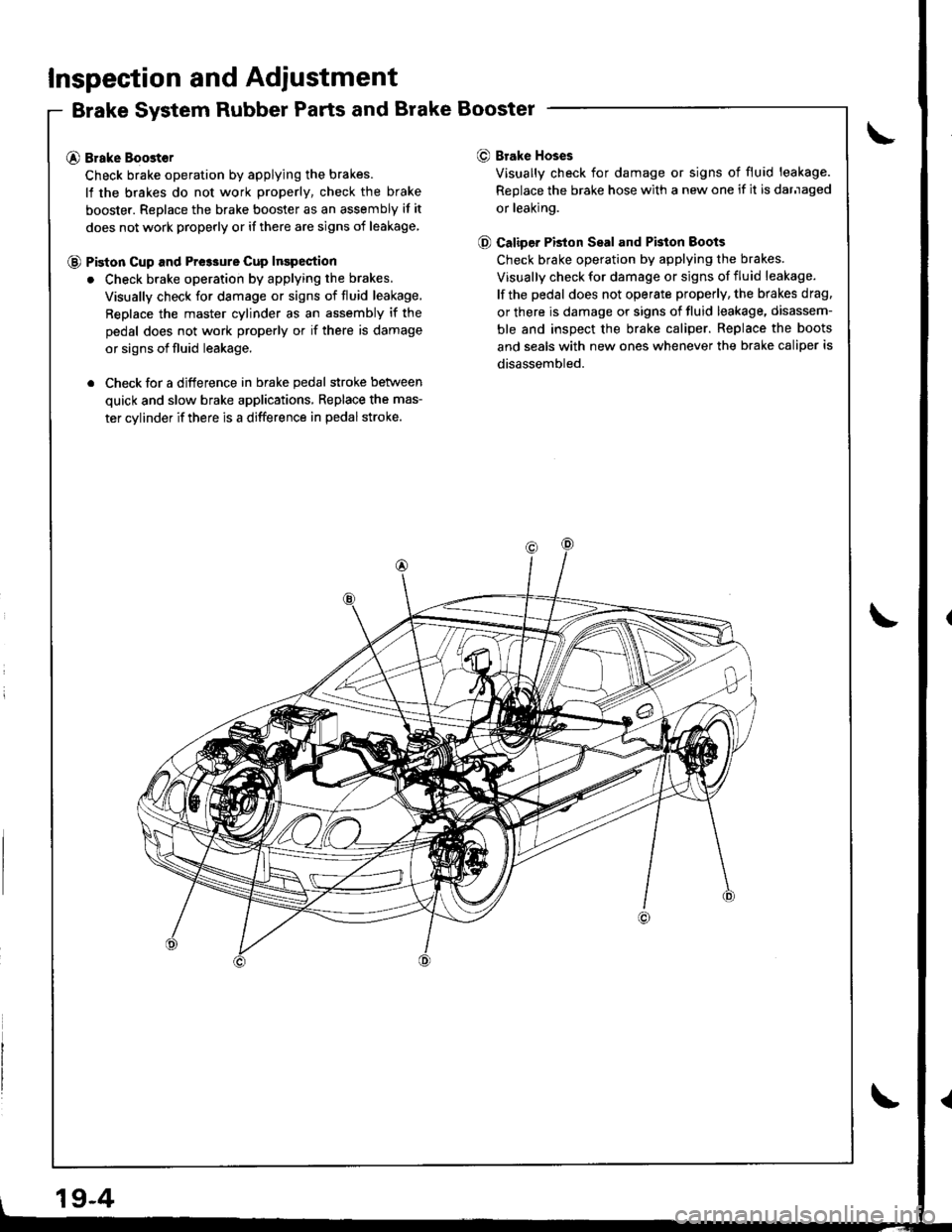

Inspection and Adiustment

Brake System Rubber Parts and Brake Booster

@ Brake Boost€r

Check brake operation by applying the brakes.

lf the brakes do not work properly, check the brake

booster. Replace the brake booster as an assembly if it

does not work properly or if there are signs of leakage

@ Piston cup and Pre3sure cup Inspection

. Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage,

Replace the master cylinder as an assembly if the

pedal does not work properly or if there is damage

or signs of fluid leakage.

. Check for a difference in brake pedal stroke betlveen

quick and slow brake applications, Replace the mas-

ter cylinder if there is a difference in pedal stroke.

O Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is darnaged

or leaking.

@ Caliper PBton Seal and Pkton Boots

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

lf the pedal does not operate properly, the brakes drag.

or there is damage or signs of fluid leakage, disassem-

ble and inspect the brake caliper. Replace the boots

and seals with new ones whenever the brake caliper is

disassembled.

19-4

Page 759 of 1681

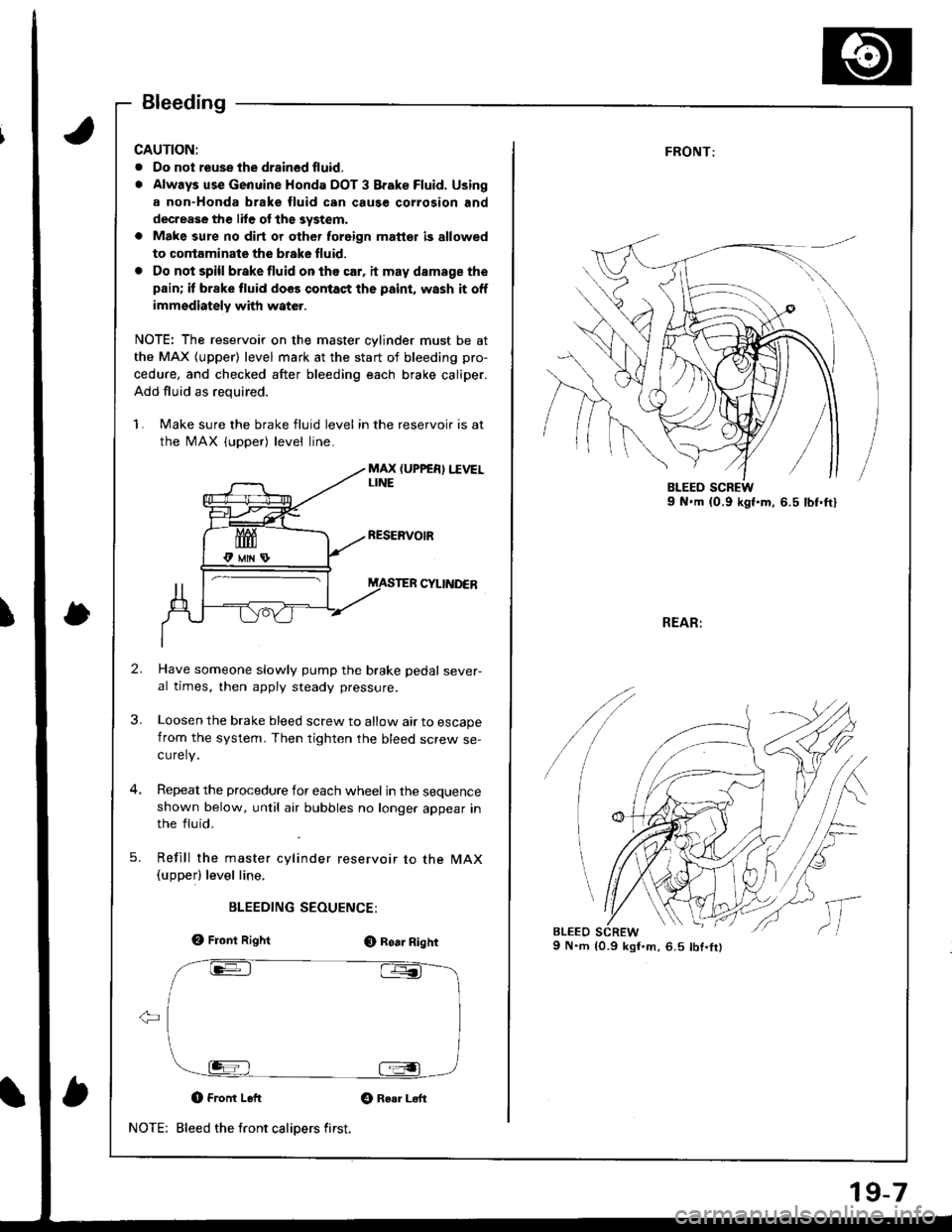

Bleeding

CAUTION:

. Oo not reuse the drsined fluid,

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the lile of the system,

a Make sure no dirt or other foreign matt€t is allowed

to contaminate the brske fluid.

. Do not spill brake fluid on tho car, it may damage the

pain; if brake fluid does contact the paint, wash it off

immediately with water.

NOTE: The reservoir on the master cylinder must be at

the MAX (upper) level mark at the start of bleeding pro-

cedure, and checked after bleeding each brake caliper.

Add fluid as required.

1. Make sure the brake fluid level in the reservoir is at

the MAX (upper) level line.

MAX (UPPER) I.IVELLINE

CYIINDER

Have someone slowly pump the brake pedal sever-al times, then apply steady pressure.

Loosen the brake bleed screw to allow air to escapefrom the system. Then tighten the bleed screw se-curely.

Repeat the procedure for each wheel in the sequenceshown below, until atr bubbles no longer appear inthe fluid.

Refill the master cylinder reservoir to the MAX(upperl level line,

BLEEDING SEOUENCE:

e, Front RightO Roa. Right

O Front Left Gt Raar L€ft

Bleed the front calipers first.NOTE:

19-7

FRONT:

REAR:

9 N.m {0.9 kgI'm,6.5 lbt.fr)

/

lc

,,

l,

Page 765 of 1681

Master Cylinder/Brake Booster

I'RemovaUlnstallation

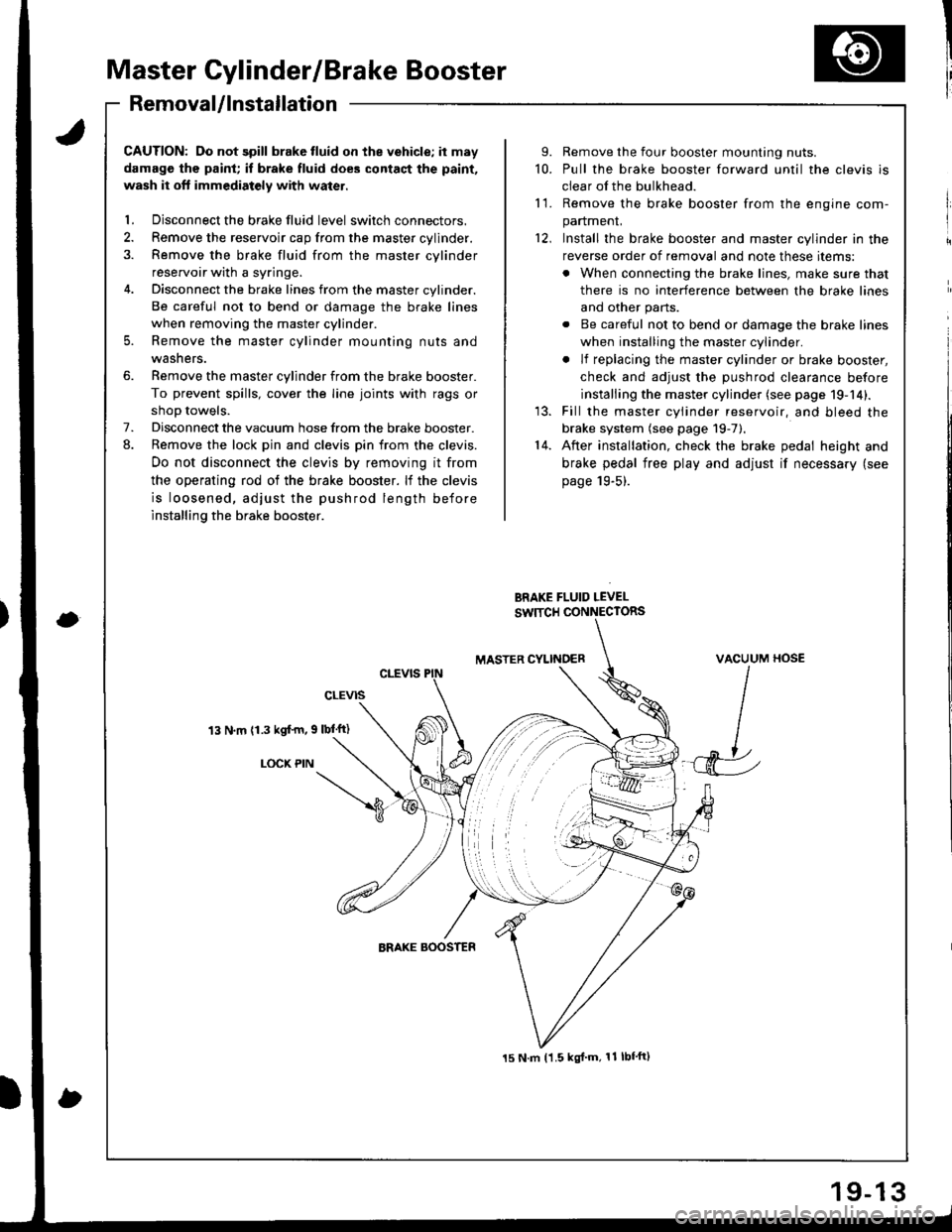

CAUTION: Do not spill brake tluid on the vehicle; it may

damage the paint; if brake fluid does contact the paint,

wash it oft immediatoly with water.

l. Disconnect the brake fluid level switch connectors.

2. Remove the reservoir cap from the master cylinder.

3. Remove the brake fluid from the master cvlinder

reservoir with a syringe.

4. Disconnect the brake lines from the master cylinder.

Be careful not to bend or damage the brake lines

when removing the master cylinder.

5. Remove the master cylinder mounting nuts and

washers.

6. Remove the master cylinder from the brake booster.

To prevent spills, cover the line joints with rags or

shoD towels.

7. Disconnect the vacuum hose from the brake booster.

8. Remove the lock pin and clevis pin from the clevis.

Do not disconnect the clevis by removing it from

the operating rod of the brake booster. lf the clevis

is loosened, adjust the pushrod length before

installing the brake booster.

13 N.m (1.3 kgf'm, 9 lbl'ft)

LOCX PIN

9. Remove the four booster mounting nuts.

10. Pull the brake booster forward until the clevis is

clear of the bulkhead.

11. Remove the brake booster from the enqine com-

panmenL

12, Install the brake booster and master cylinder in the

reverse order of removal and note these items:

. When connecting the brake lines, make sure that

there is no interference between the brake lines

and other parts.

. Be careful not to bend or damage the brake lines

when installing the master cylinder.

. lf replacing the master cylinder or brake booster,

check and adiust the DUshrod clearance before

installing the master cylinder (see page 19-14).

13. Fill the master cylinder reservoir, and bleed the

brake system (see page 19-7).'14. After installation, check the brake pedal height and

brake pedal free play and adjust if necessary (see

page 19-5).

BRAKE FLUID LEVEL

SW]TCH CONNECTORS

MASTER CYLINOERVACUUM HOSE

J

15 N.m t1.5 kgl'm, 11 lbf'ft)

Page 766 of 1681

Master Cylinder/Brake Booster

Master Cylinder InspectionPushrod Clearance Adjustment

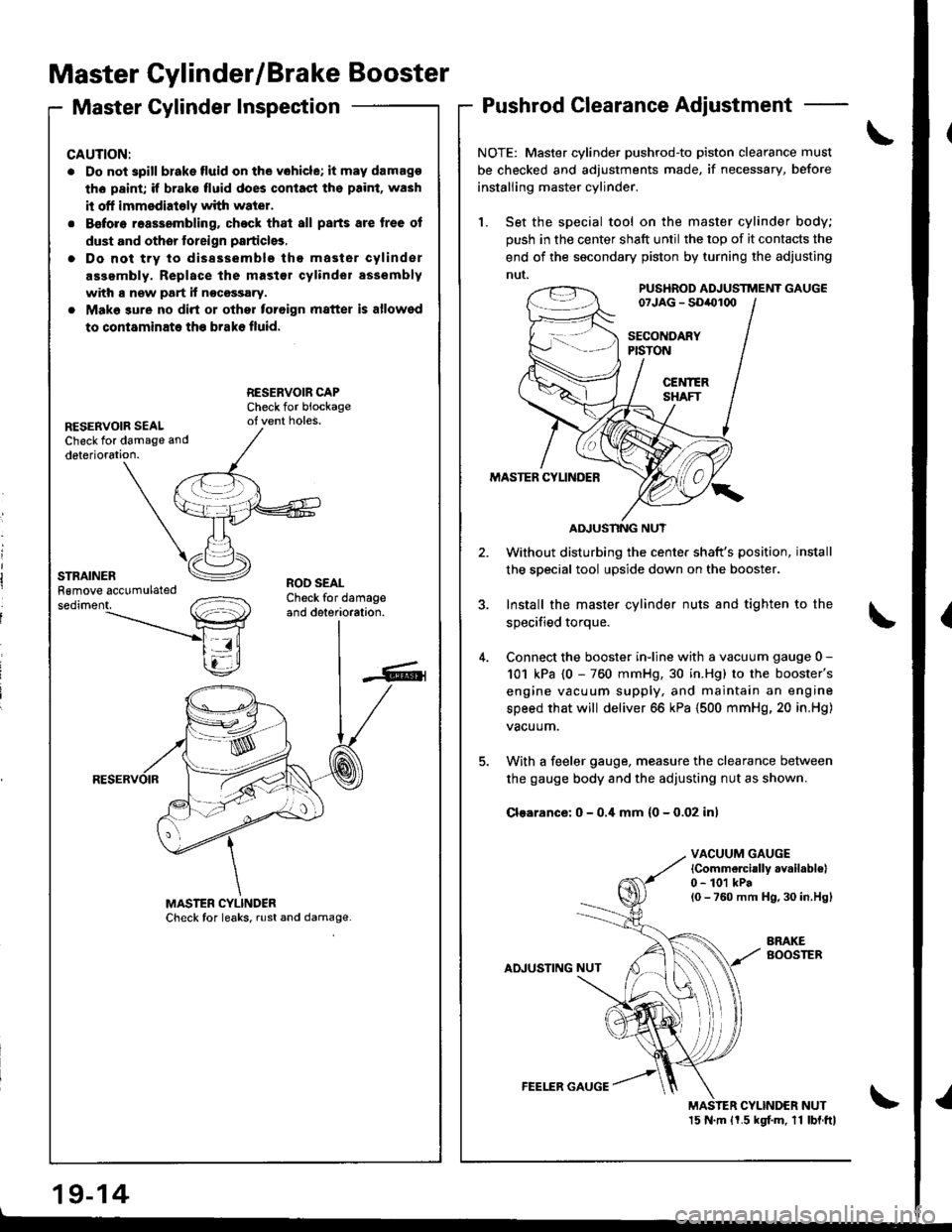

NOTE: Master cylinder pushrod'to piston clearance must

be checked and adjustments made, if necessary, before

installing master cylinder.

1. Set the special tool on the master cylinder body;

push in the center shaft until the top of it contacts the

end of the socondary piston by turning the adjusting

nut.PUS'IROD ADJUSTTTiENT GAUGE07JAG - SDiOl(xl

SECOITDARYPISTON

CEl{IERSHAFT

MASTER CYLINDER

Without disturbing the center shaft's position,

the soecial tool upside down on the booster.

3. Install the master cylinder nuts and tighten to the

sDecified toroue.

4. Connect the booster inline with a vacuum gauge 0 -

101 kPa {0 - 760 mmHg, 30 in.Hg) to the booster's

engine vacuum supply, and maintain an engine

speed that will deliver 66 kPa (500 mmHg, 20 in.Hg)

vacuum.

5. With a feeler gauge, measure the clearance between

the gauge body and the adjusting nut as shown.

Clsarance: 0 - 0,i[ mm (0 - 0.02 inl

VACUUM GAUGElCommelcially availabl€|0 - 101 kPal0 - 760 mm H9,30 in.Hgl

AINUSTING NUT

BRAKEBOOSTEB

MAS'ER CYLINDER NUT15 N.m ll.5 kgf.m. 11 lbl.ftl

CAUTION:

. Do not spill blake fluid on the vohicle; it may damago

th6 paint; if brake fluid does contast ths paint, wash

it off immsdiately with water.

. Before reassembling. chock that all parts are tree of

dust and othor toreign particlgs,

. Do not trv to dissssemblo the master cylinder

assembly. Replace the mast€r cylinder assembly

with s new part if nocossary.

. Make sure no dirt or othor toroign matter is allowed

to contaminate th€ brako fluid.

RESERVOIR SEALCheck for damage and

deterioration.

ROD SEALCheck for damageand deterioration.

AIIUSNNG NUT

19-14

FEELER GAUGE