Cylinder HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 87 of 1681

\-

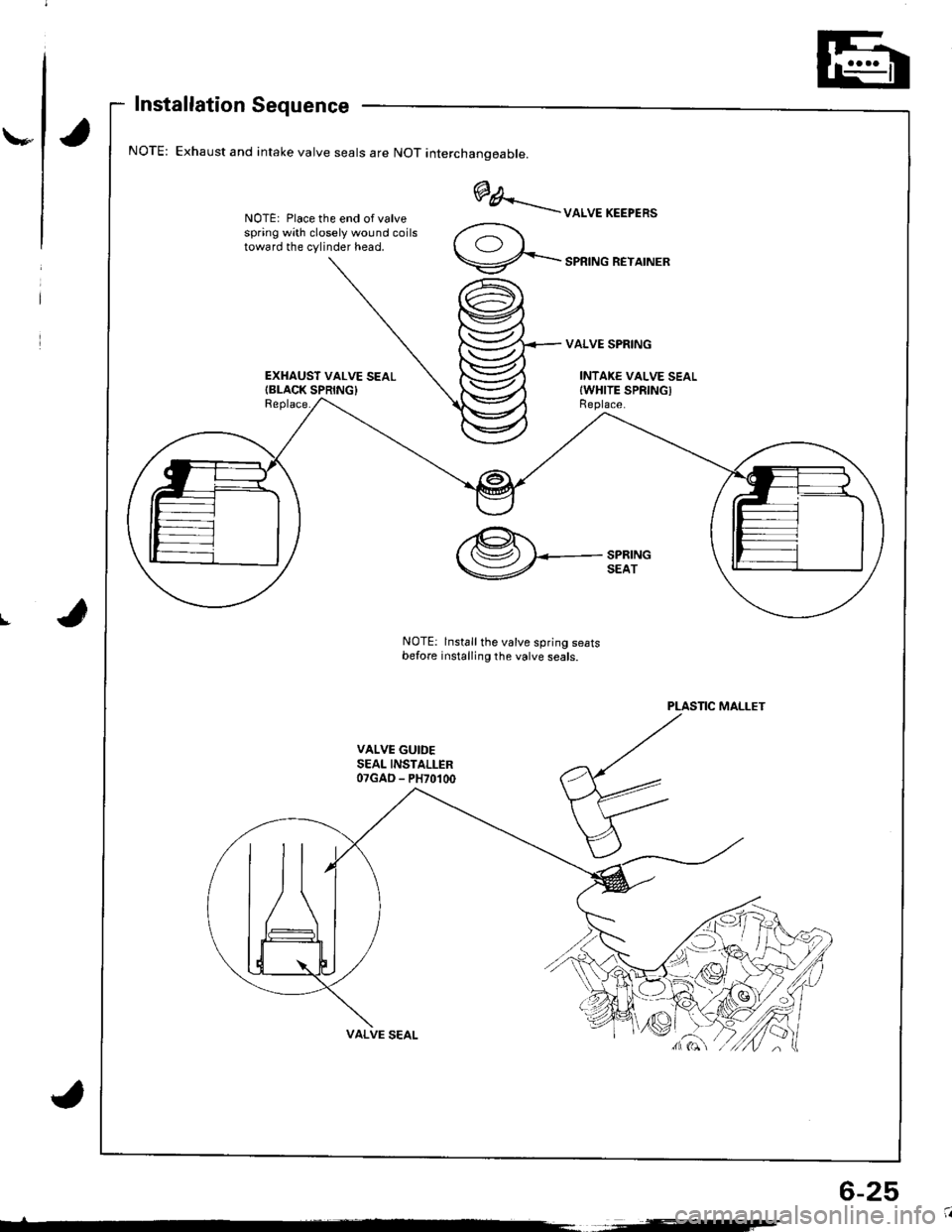

Installation Sequence

Exhaust and intake valve seals are NOT interchanoeable.

NOTE: Place the end of valvespring with closely wound coilstoward the cylinder head.

EXHAUST VALVE SEALIBLACK SPRING}Replace.

@A..'..--uoruEKEEPER'

9-...-'PRTNGREYATNER

VALVE SPRING

INTAKE VALVE SEALIWHITE SPRINGIReplace.

I

PLASTIC MALLET

VALVE GUIDESEAL INSTALLER07GAD - PH70100

,@.t.'( (Sz) I<-- SPRING

V SEAT

NOTE: lnstall the valve spring seatsbefore installing the valve seals.

6-25

Page 88 of 1681

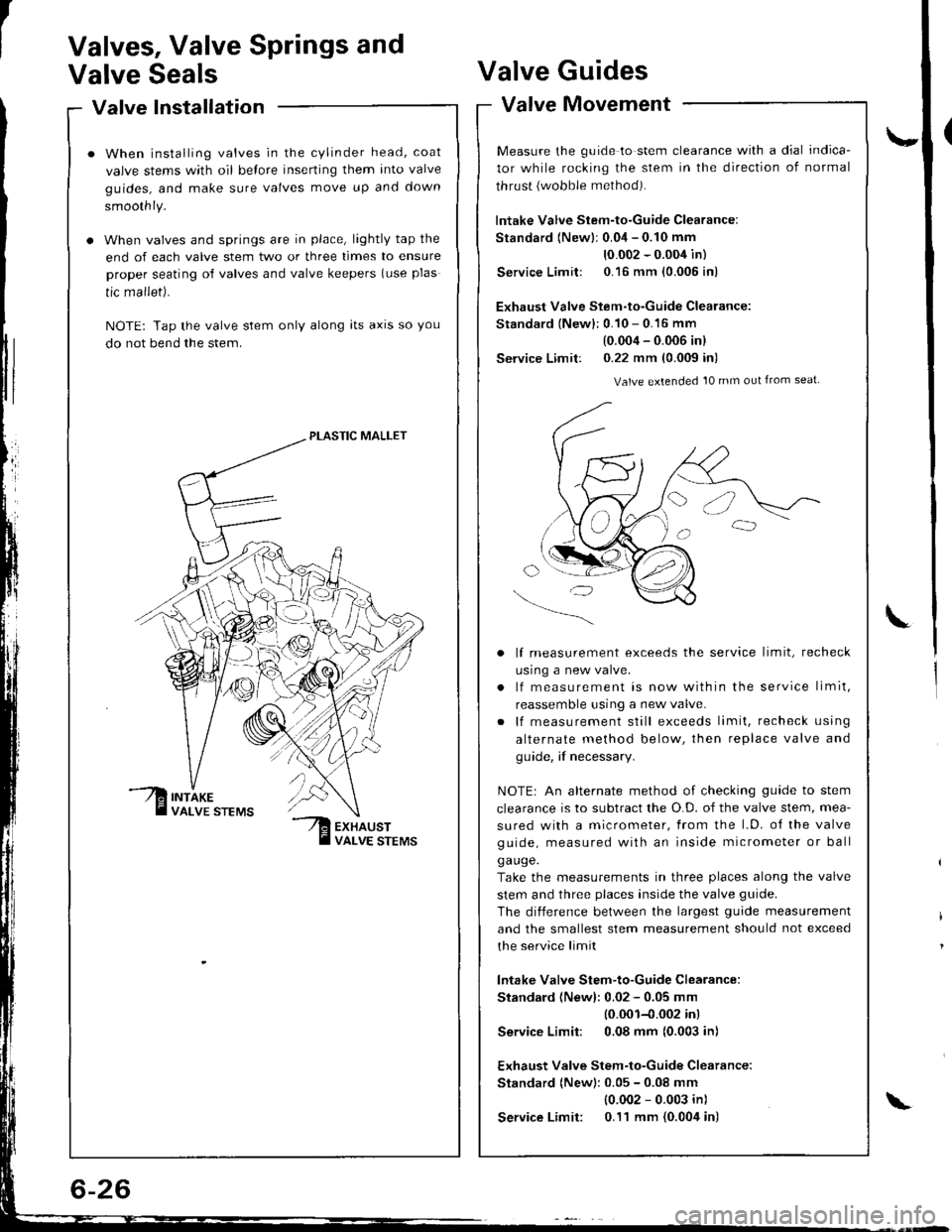

Valve Installation'alve Inslallauon -

When installing valves in the cylinder head, coat

valve stems with oil belore inserting them into valve

guides, and make sure valves move up and down

smoothly.

When valves and springs are in place, lightly tap the

end of each valve stem two or three times to ensure

proper seating of valves and valve keepers (use plas

tic mallet).

NOTE: Tap the valve stem only along lts axrs so you

do not bend the stem.

PLASTIC MALLET

Valves, Valve Springs and

Valve SealsValve

Valve

Guides

Movement

\-

L

valve tvtovemenr -

Measure the guide to stem clearance with a dial indica-

tor while rocking the stem in the direction of normal

thrust {wobble method).

lntake Valve Stem-to-Guide Clearance:

Standard {Newlr 0.04 - 0.10 mm

10.002 - 0.004 in)

Service Limit: 0.16 mm {0.005 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard {New}: 0.10 - 0.16 mm

(0.004 - 0.006 inl

Service Limit: 0.22 mm (0.009 in)

Valve extended 10 mm out from seat

lf measurement exceeds the service limit, recheck

usrng a new valve.

lf measurement is now within the service limit,

reassemble using a new valve.

lf measurement still exceeds limit, recheck using

alternate method below, then replace valve and

guide, if necessary.

NOTEr An alternate method of checking guide to stem

clearance is to subtract the O.D. of the valve stem, mea-

sured with a micrometer, from the l.D. o{ the valve

guide, measured with an inside micrometer or ball

ga uge.

Take the measurements in three places along the valve

stem and three places inside the valve guide.

The diiference between the largest guide measurement

and the smallest stem measurement should not exceed

the service limit

lntake Valve Stem-to-Guide Clearance:

Standard (Newl: 0.02 - 0.05 mm

10.001-{.002 inl

Service Limit: 0,08 mm (0.003 in)

Exhaust Valve Stem-to-Guide Clearance:

Standard (New): 0.05 - 0.08 mm

{0.002 - 0.003 in)

Service Limit: 0.11 mm {0.004 in)\

Page 89 of 1681

\,

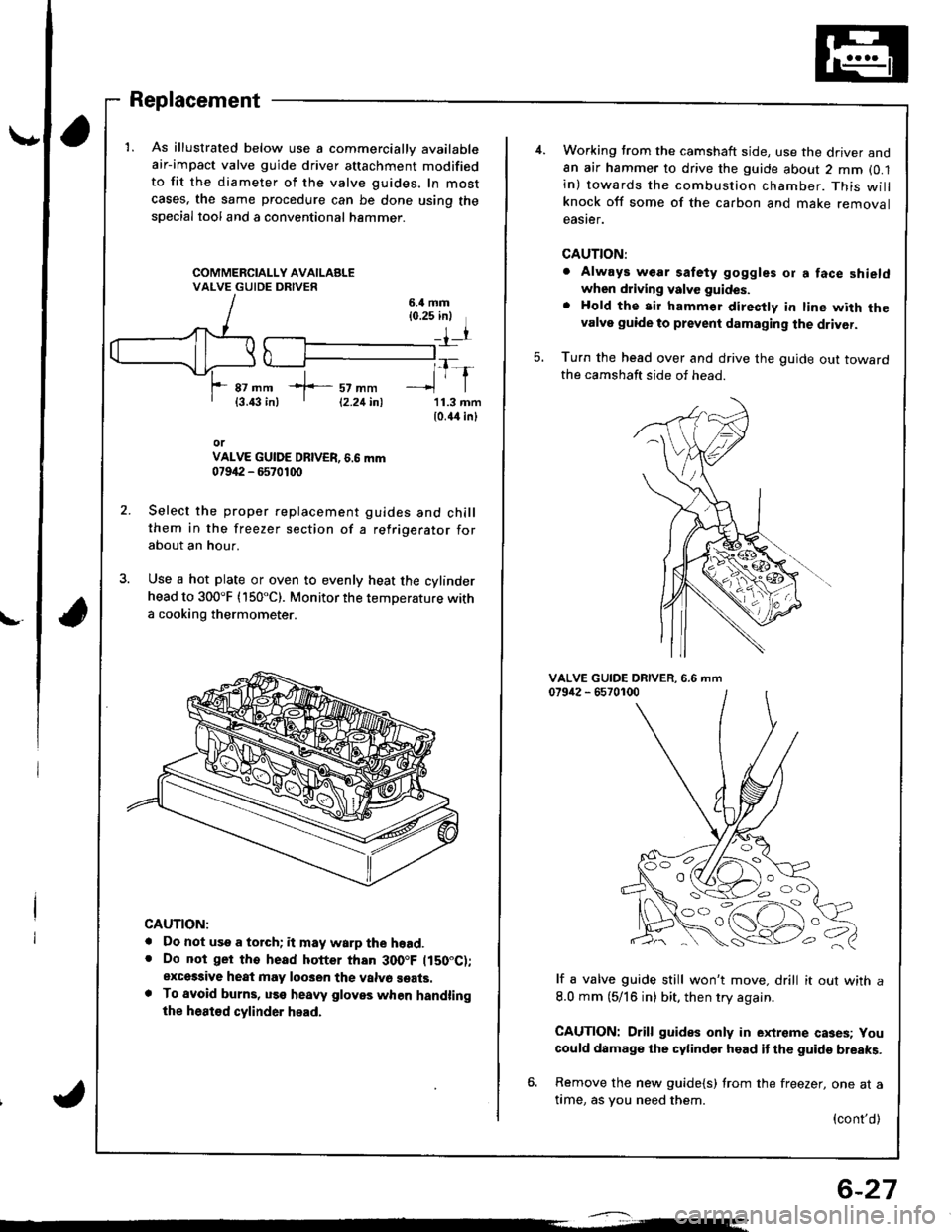

Replacement

1. As illustrated below use a commercially available

air-impact valve guide driver attachment modified

to fit the diameter of the valve guides, In most

cases, the same procedure can be done using thespecial tool and a conventional hammer.

6.il mm{0.25 inl

rr

*f-::rtl1-r87 mm{3.43 in)11.3 mm10.44 inl

orVALVE GUIDE DBIVER, 6.6 mm07942 - 6570100

Select the proper replacement guides and chillthem in the freezer section of a refrigerator forabout an hour.

Use a hot plate or oven to evenly heat the cylinderhead to 300"F (150"C). Monitor the temperature witha cooking thermometer.

CAUTION:

. Do not use a torch; it may warp the hoad.. Do not ger tho head hotter than 300.F ltS0"C);exces3ive heat may loo3en the valvo seats.. To avoid burns, uss heaw gloves when handlingthe heat€d cylinder head.

12.21inl

6-27

Working trom the camshaft side, use the driver and8n air hammer to drive the guide about 2 mm (0.1

in) towards the combustion chamber. This willknock off some of the carbon and make removaleaster.

CAUTION:

. Always wear safety goggles or a face shieldwhen driving valve guides.

. Hold the air hammer direcfly in line with thevalve guide to prevent damaging the driver.

Turn the head over and drive the guide out towardthe camshaft side of head.

5.

VALVE GUIDE DRIVER.079i12 - 65701006.6 mm

lf a valve guide still won't move. drill it out with a

8.0 mm (5/16 in) bit, then try again.

CAUTION: Drill guides only in extreme cases; You

could damage the cylinder head it the guide breaks.

6. Remove the new guide{s) from the freezer, one at atime, as you need them.

{cont'd)

OO

'o c,

Page 91 of 1681

\

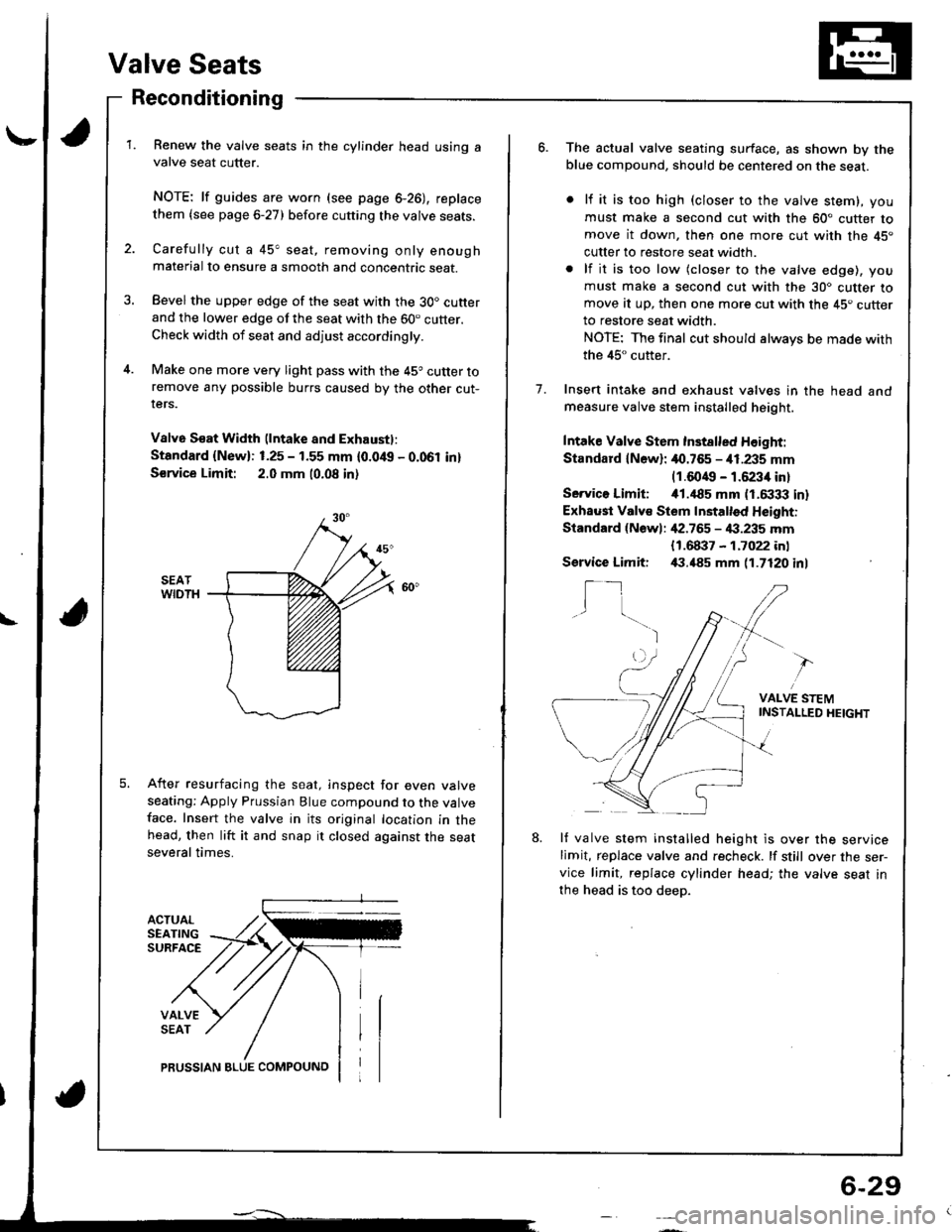

Valve Seats

Reconditioning

ACTUALSEATINGSURFACE

VALVESEAT

Renew the valve seats in the cylinder head using avalve seat cutter.

NOTE: lf guides are worn (see page 6-26), replace

them {see page 6-27) before cutting the valve seats.

Carefully cut a 45" seat, removing only enoughmaterial to ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30. cutterand the lower edge of the seat with the 60. cutter.Check width of seat and adjust accordingly.

Make one more very light pass with the 45o cutter toremove any possible burrs caused by the other cut-rers.

V8lv6 S€at Width (lntake and Exhaustl:

Standard {New}: 1.25 - 1.55 mm {0.0/t{, - 0.061 in}

S€rvice Limit: 2.0 mm 10.08 in)

After resurfacing the seat, inspect for even valveseating: Apply Prussian Blue compound to the valveface. Insert the valve in its original location in thehead, then lift it and snap it closed against the seatseveral times.

PRUSSIAN BLUE COMPOUNO

6-29

o.The actual valve seating surface, as shown by theblue compound, should be centered on the seat.

lf it is too high (closer to the valve stem), you

must make a second cut with the 60" cutter tomove it down, then one more cut with the 45"

cutter to restore seat width.

lf it is too low (closer to the valve edge), you

must make a second cut with the 30. cutter tomove at up, then one more cut with the 45. cutterto restore seat width.

NOTE: The final cut should always be made with

the 45" cutter.

Insert intake and exhaust valves in the head andmeasure valve stem installed height.

Intake Valve Stem Inst8lled Height:

Standard lN6wl: 40.765 - i11.235 mm(1.6049 - 1.6234 in)

Servico Limiti i01.,|85 mm (1.6333 in)

Exhaust Valv€ Stem Installed Height:

Standard {Newl: ,[2.765 - 4:1.235 mm

1.

{1.68i}7 - 1.7022 inl,(1.485 mm 11.7120 inlService Limit:

I_1I

VALVE STEMINSTAI-LED HEIGHT

8.lf valve stem installed height is over the servicelimit, replace valve and recheck. lf still over the ser-vice limit, replace cylinder head; the valve seat in

the head is too deep.

Page 92 of 1681

Cylinder Head

Wapage

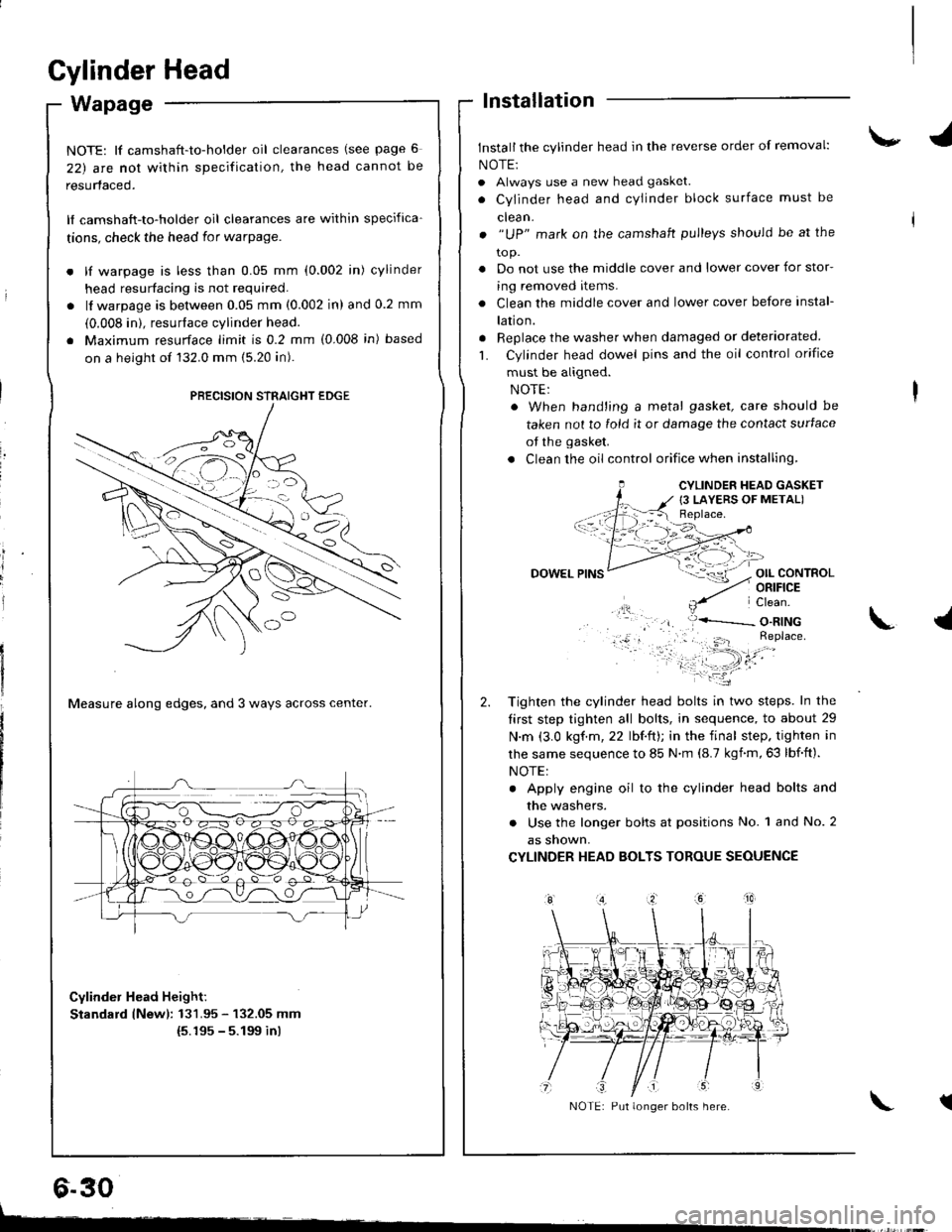

NOTE: lf camshaft-to-holder oil clearances (see page 6

22) arc nol within specification, the head cannot be

resurfaced.

lf camshaft-to-holder oil clearances are within specifica-

tions, check the head for warpage.

lf warpage is less than 0.05 mm (0.002 in) cylinder

head resurfacing is not required.

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in). resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Measure along edges, and 3 ways across center.

Cylinder Head Height:

Standard lNewl: 131.95 - 132.05 mm(5.195 - 5.199 inl

lnstallation

Install the cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cYlinder block surface must be

clean.

. "UP" mark on the camshaft pulleys should be at the

to p.

. Do not use the middle cover and lower cover for stor-

ing removed items.

. Clean the middle cover and lower cover before instal-

lation.

. Replace the washer when damaged or deteriorated

L Cylinder head dowel pins and the oil control orifice

must be aligned.

. When hand'ing a metal gasket, care should be

taken not to fold it or damage the contact surface

of the gasket.

. Clean the oil control orifice when installing,

OIL CONTROLORIFICE

PRECISION STRAIGHT EDGE

6.30

CYLINDER HEAD GASKET

{3 LAYERS OF METAL)

DOWEL

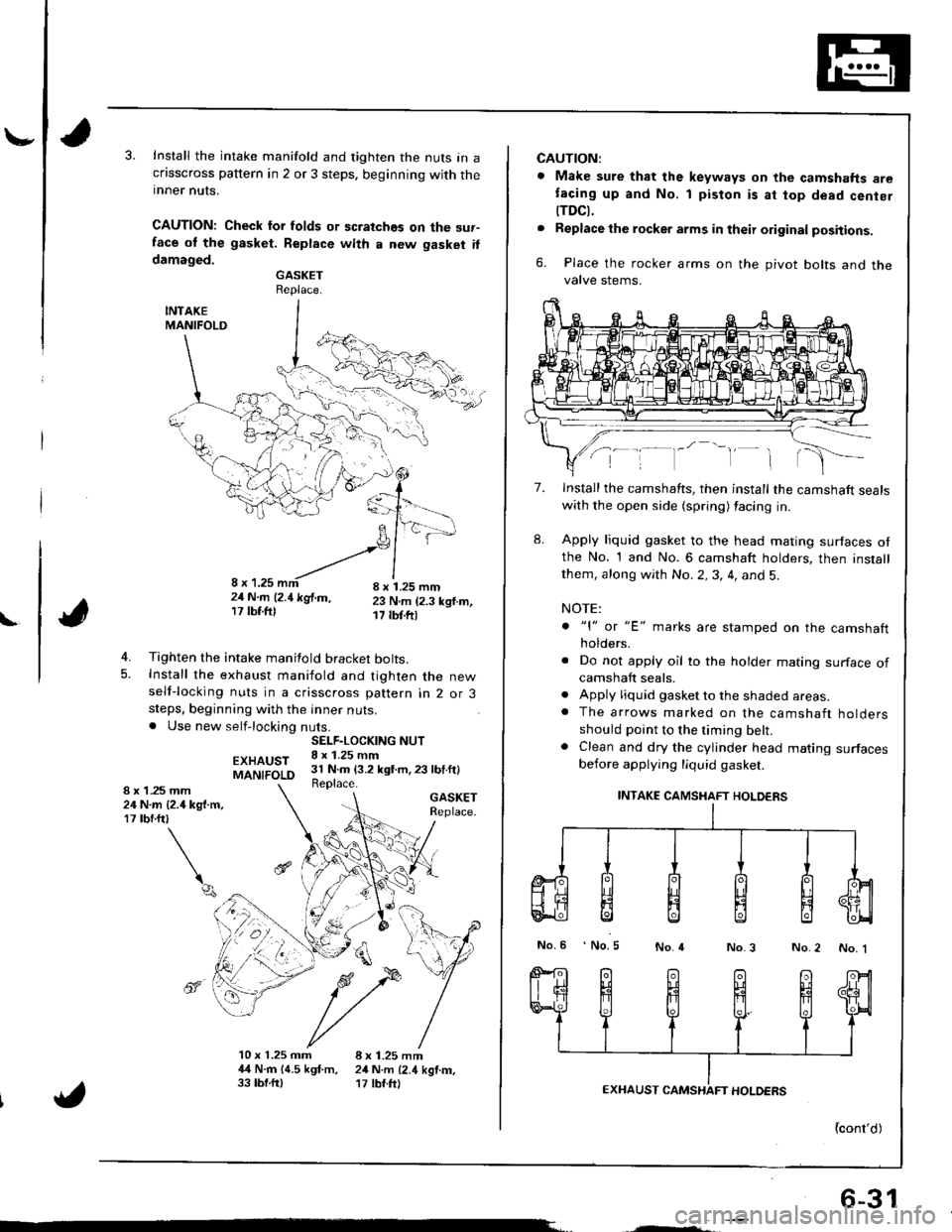

Tighten the cylinder head bolts in two steps. In the

tirst step tighten all bolts, in sequence, to about 29

N.m (3.0 kgf.m,22 lbf.ft); in the final step. tighten in

lhe same sequence to 85 N.m (8.7 kgnm,63 lbf.ft).

NOTE:

. Apply engine oil to the cylinder head bolts and

the washers.

. Use the longer bolts at positions No. 1 and No. 2

as snown,

CYLINDER HEAD BOLTS TOROUE SEOUENCE

\.l

tNOTE: Put longer bolts here.

t-

Page 93 of 1681

\-

L

Install the intake manifold and tighten the nuts in acflsscross pattern in 2 or 3 steps. beginning with theinner nuts.

CAUTION: Check lor folds or scratches on the sur-face ol the gasket. Replace with a new gasket ildamaged.GASKETReplace.

INTAKEMANIFOLD

4. Tighten the intake manifold bracket bolts.5. Install the exhaust maniiold and tighten the newself-locking nuts in a crisscross pattern in 2 or 3steps, beginning with the inner nuts.. Use new self-locking nuts.

EXHAUSTMANIFOLD

GASKETReplace.

4

10 x 1.25 mm 8 x 1.25 mm4,{ N.rn 14.5 kgf.m, 24 N.m {2.4 kgtm,33 tbf.ftl '17 tbf.ft)

SELF.LOCKING NUT8 x 1.25 mm31 N.m (3.2 kgt m,23 lbf.ft)Replace.1 .25 mmN.m {2.4 kg{.m,rbrftt

\q

8x2417

",', r, ^-'-"-!,1,,,';-21N.m l2.1kglm, 23 N.m (2.3 ksf.m,17lbf.ftl 17 tbf.ftr

6-31

CAUTION:

. Make sure that the keyways on the camshafts aretacing up and No. 1 piston is at top dead cenier

tTDCt.. Replacethe rocker arms in their original positions.

6. Place the rocker arms on the pivot bolts and thevalve stems.

7.

8.

Install the camshafts, then install the camshaft sealswith the open side (spring) facing in.

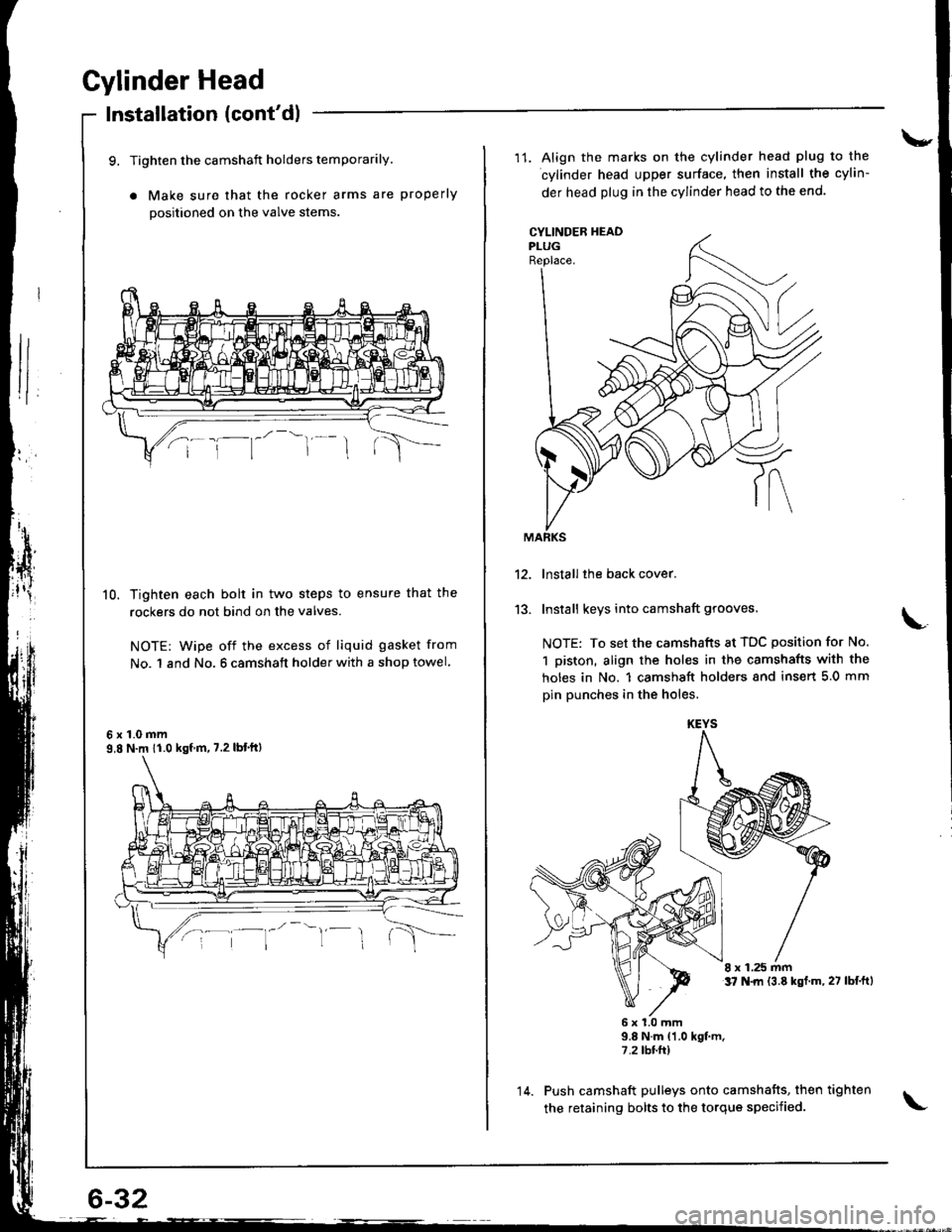

Apply liquid gasket to the head mating surfaces otthe No. 1 and No. 6 camshaft holders, then installthem, along with No.2,3, 4, and 5.

NOTE:

. "l" or "E' marks are stamped on the camshaftholders.

. Do not apply oil to the holder mating surface ofcamshaft seals.. Apply liquid gasket to the shaded areas.. The arrows marked on the camshaft holdersshould point to the timing belt.. Clean and dry the cylinder head mating surfacesbefore applying liquid gasket.

INTAKE CAMSHAFT HOLDERS

No.6 No.5No.4No.3 No.2 No. 1

{cont'd)

Page 94 of 1681

Cylinder Head

Installation (cont'dl

9, Tighten the camshaft holders temporarily.

a Make sure that the rocker arms are properly

positioned on the valve stems

10. Tighten each bolt in two steps to ensure that the

rockers do not bind on the valves.

NOTE: wipe off the excess of liquid gasket from

No. 1 and No. 6 camshaft holder with a shop towel

6x1.0mm9,8 N.m 11.0 kgf m, 7.2 lbt'ftl

\-

11. Align the marks on the cylinder head plug to the

cylinder head upper surface, then install the cylin-

der head plug in the cylinder head to the end.

CYLINDEB HEADPLUGReplace.

13.

lnstall the back cover.

Install keys into camshaft grooves.

NOTE: To set the camshafts at TDC position for No.

1 piston, align the holes in the camshafts with the

holes in No. 1 camshsft holders snd insert 5.0 mm

pin punches in the holes.

8 x 1.25 mmt7 N.|rl {3.8 kst.m,27 lbf.ftl

6x1.0mm9.8 N.m {1.0 kgt m.7.2 tbr.ft)

Push camshaft pulleys onto camshafts, then tighten

the retaining bolts to the torque specified.

KEYS

14.

Page 95 of 1681

15.

16.

17.

Install the timing belt (see page 6-12).

Adjust the valve clearance (see page 6-3).

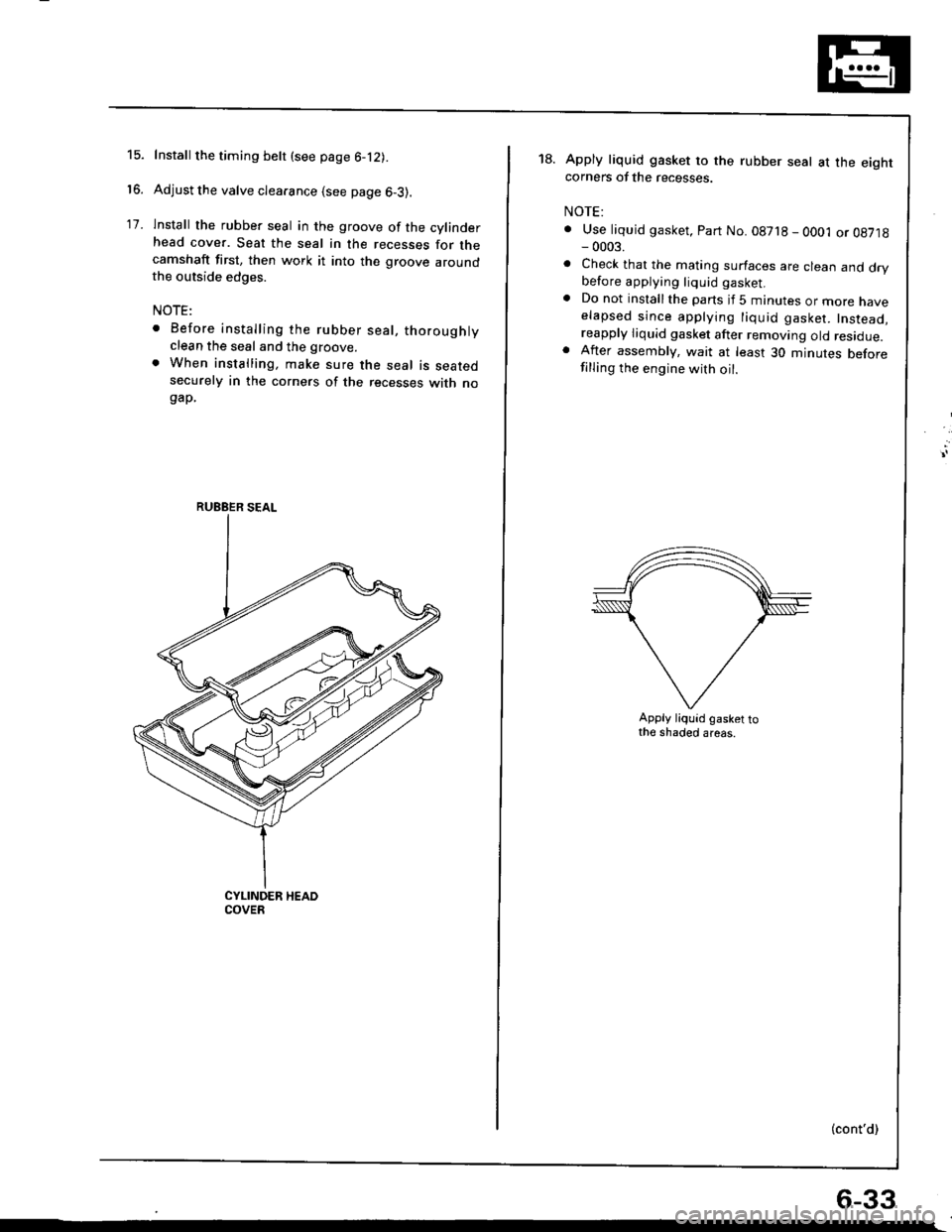

lnstall the rubber seal in the groove of the cylinderhead cover. Seat the seal in the recesses for thecamshaft first, then work it into the groove aroundthe outside edges.

NOTE:

. Before installing the rubber seal, thoroughlyclean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

RUEBER SEAL

18.Apply liquid gasket to the rubber seal at the eightcorners of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - OO01 or 08718- 0003.

. Check that the mating surfaces are clean and drybefore applying liquid gasket.. Do not installthe parts if 5 minutes or more naveelapsed since applying liquid gasket. Instead,reapply liquid gasket after removing old residue.. After assembly, wait at least 30 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

(cont'd)

6-33

Page 96 of 1681

Cylinder Head

Installation (cont'dl

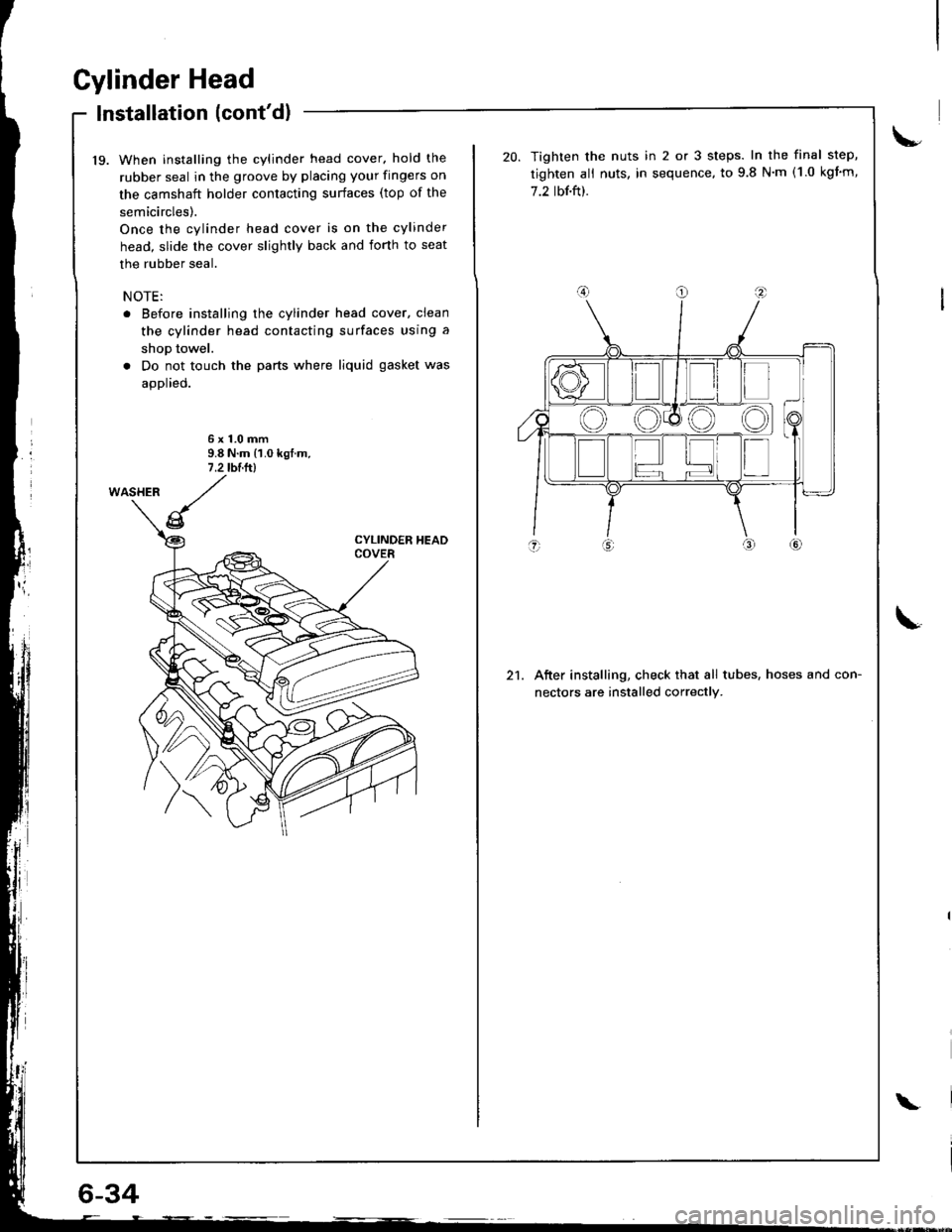

19. When installing the cylinder head cover. hold the

rubber seal in the groove by placing your fingers on

the camshaft holder contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and iorth to seat

the rubber seal.

NOTE:

. Before installing the cylinder head cover, clean

the cylinder head contacting surfaces using a

shop towel.

. Do not touch the parts where liquid gasket was

applied.

6x1.0mm9.8 N.m {1.0 kgf.m,7 .2 tblltl

6-34

\

21.

Tighten the nuts in 2 or 3 steps. In the final step,

tighten ali nuts, in sequence, to 9.8 N'm (1.0 kgim,

7.2 tbf.ft).

After installing, check that all tubes, hoses and con-

nectors are installed correctly.

Page 155 of 1681

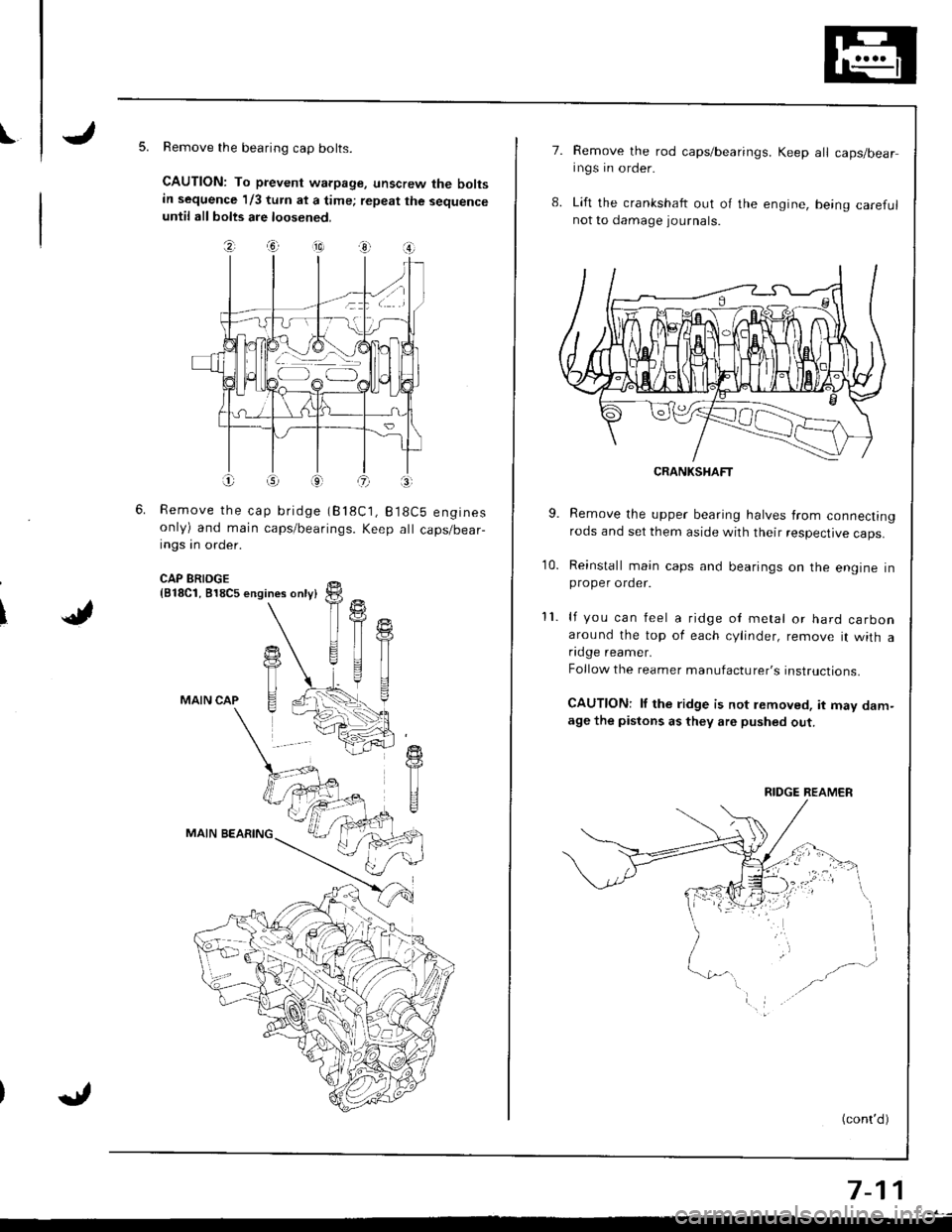

IRemove the bearing cap bolts.

CAUTION: To prevent warpage, unscrew the boltsin sequence 1/3 turn at a time; repeat the sequenceuntil all bolts are loosened.

\J

?, .ia --10) 3r O

Remove the cap bridge (818C1, B18Cb enginesonly) and main caps/bearings. Keep all caps/bear-ings in order.

CAP BRIDGE{818C1, 818C5 engines only}

MAIN CAP

MAIN BEARING

11

T

T

TI

7.Remove the rod caps/bearings. Keep all caps/bearings in order.

Lift the crankshaft out o{ the engine, being care{ulnot to damage journals.

CRANKSHAFT

9. Remove the upper bearing halves from connectingrods and set them aside with their respective caps.

10. Reinstall main caps and bearings on the engine inproper order.

11. lf you can feel a ridge oI metal or hard carbonaround the top of each cylinder, remove it with afldge reamer.

Follow the reamer manufacturer's instructions.

CAUTIONT lf the ridge is not lemoved, it may dam-age the pistons as they are pushed out.

(cont'd)

7-11

RIDGE REAMER