Cylinder HONDA INTEGRA 1998 4.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 767 of 1681

1.

8.

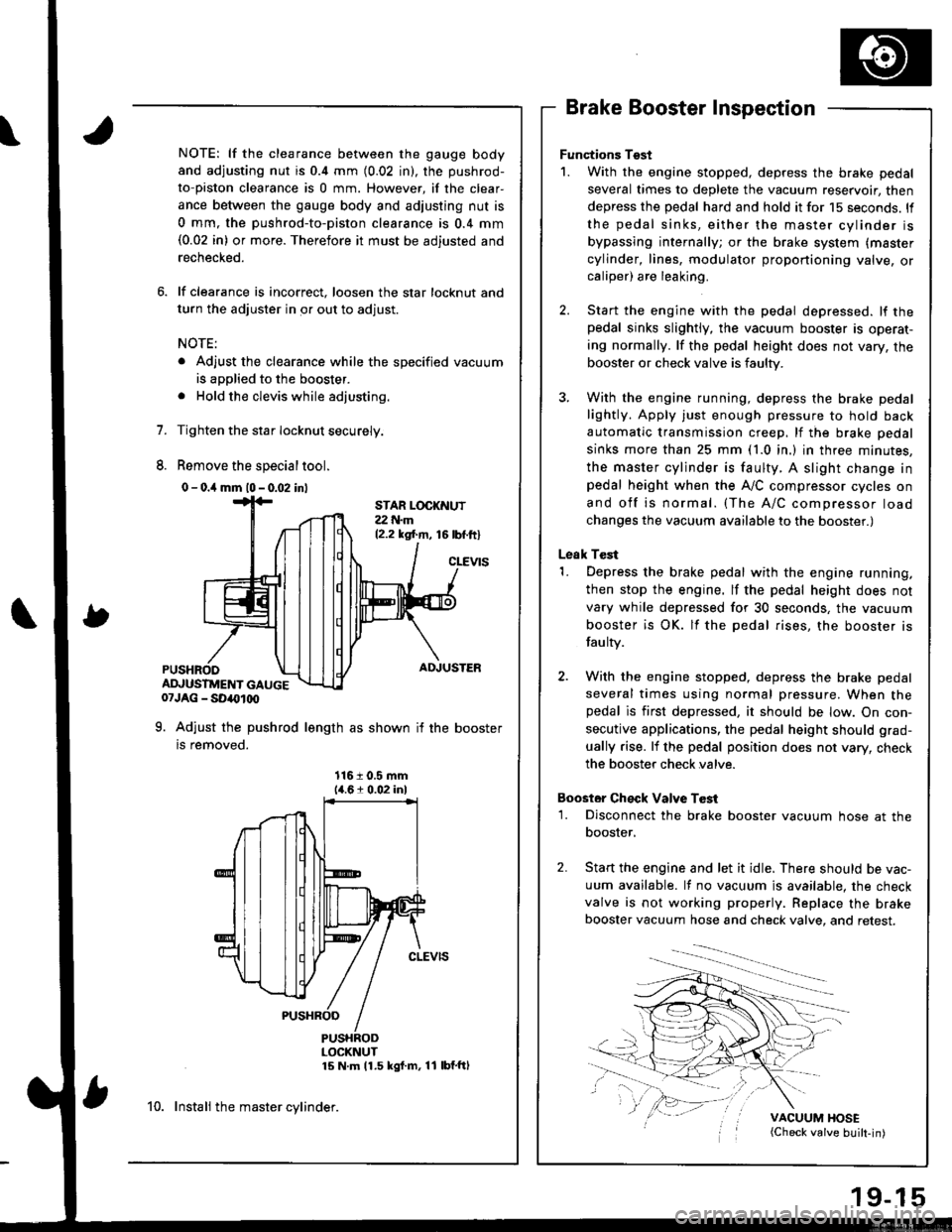

NOTE: lf the clearance between the gauge body

and adjusting nut is 0.4 mm (0.02 in), the pushrod-

to-piston clearance is 0 mm. However, if the clear-

ance between the gauge body and adjusting nut is

0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore it must be adjusted and

rechecked.

lf clearance is incorrect, loosen the star locknut and

turn the adjuster in or out to adjust.

NOTE:

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star Iocknut securely.

Remove the special tool.

0 - o.il mm l0 - 0.02 inl

Brake Booster Inspection

Functions Tgst

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds. ll

the pedal sinks, either the master cylinder is

bypassing internally; or the brake system (master

cylinder, lines, modulator proportioning valve, orcaliper) are leaking.

Start the engine with the pedal depressed. lf thepedal sinks slightly, the vacuum booster is operat-

ing normally. lf the pedal height does not vary, the

booster or check valve is faulty.

With the engine running, depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep, lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cylinder is faulty. A slight change inpedal height when the A,,/C compressor cycles on

and off is normal. (The A/C compressor load

changes the vacuum available to the booster.)

Leak Test

1. Depress the brake pedal with the engine running,

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises, the booster is

fau lty.

2. With the engine stopped, depress the brake pedal

several times using normal pressure. When thepedal is first depressed, it should be low. On con-

secutive applications, the pedal height should grad-

ually rise. lf the pedal position does not vary, check

the booster check valve.

Boostor Ch€ck Valve T6st

1. Disconnect the brake booster vacuum hose at the

booster,

Start the engine and let it idle. There should be vac-

uum available. It no vacuum is available. the check

valve is not working properly. Replace the brake

booster vacuum hose and check valve, and retest.

VACUUM HOSE(Check valve built-in)

STAR LOCKNUT22 t{.m12.2 ksl.m, 16lbf.ftl

cLEVtS

ADJUSTER

ADJUSTMENT GAUGE07JAG - SD40t00

9. Adjust the pushrod length as shown if the booster

is removed.

1161 0.5 mm14.61 0.02 inl

PUSHRODLOCKNUT15 N m 11.5 kgf m, 11 lbf'ftl

10. Instali the master cylinder.

Page 769 of 1681

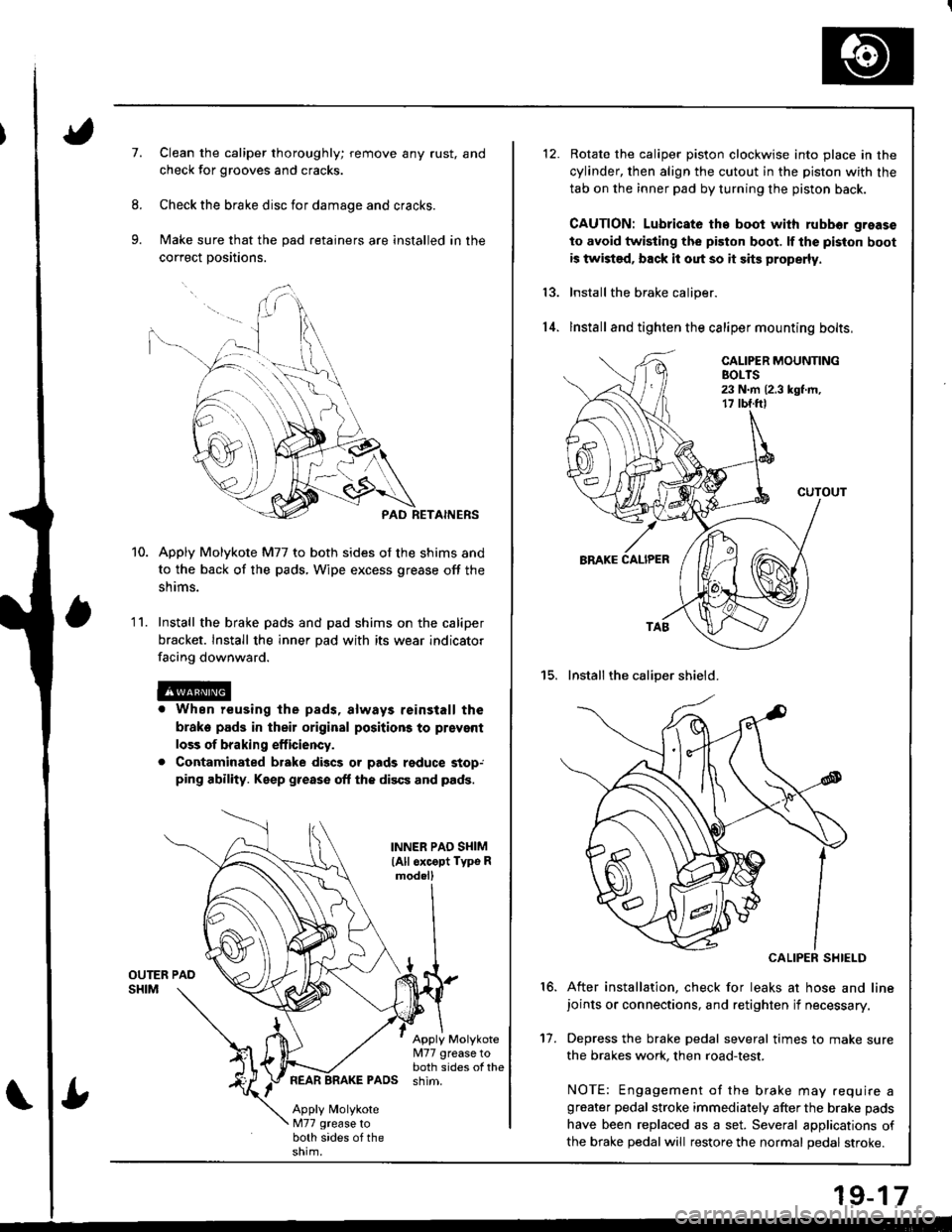

7.Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

Check the brake disc for damage and cracks.

Make sure that the pad retainers are installed in the

correct positions.

PAD RETAINERS

Apply Molykote M77 to both sides of the shims and

to the back of the pads, Wipe excess grease off the

snrms.

Install the brake pads and pad shims on the caliper

bracket. Install the inner pad with its wear indicator

facing downward.

r When reusing the pads, always reinstall the

brake pads in their original positions to prsvent

loss of braking efficiency.

. Contaminated brake discs or pads reduce stop,ping ability. Keep grease off the discs and pads.

1 '�I.

INNER PAO SI{IM

lAll oxcopt Typo Rmod.ll

Apply Molykote[I77 grease toboth sides of thePADS shim.

Apply MolykoteM77 grease toboth sides of the

Rotate the caliper piston clockwise into place in the

cylinder, then align the cutout in the piston with the

tab on the inner pad by turning the piston back.

CAUTION: Lubricato th€ boot with rubbor grease

to avoid twisting the piston boot. lf the piston boot

is twist€d, back it out so it sits properly.

Install the brake caliper.

lnstall and tighten the caliper mounting bolts,

15. Installthe caliper shield.

CALIPER SHIELD

After installation, check for leaks at hose and linejoints or connections, and retighten if necessary.

Depress the brake pedal several times to make sure

the brakes work, then road-test.

NOTE: Engagement of the brake may .equire agreater pedal stroke immediately after the brake pads

have been replaced as a set. Several applications of

the brake pedal will restore the normal pedal stroke.

13.

14.

16.

't7.

19-17

Page 772 of 1681

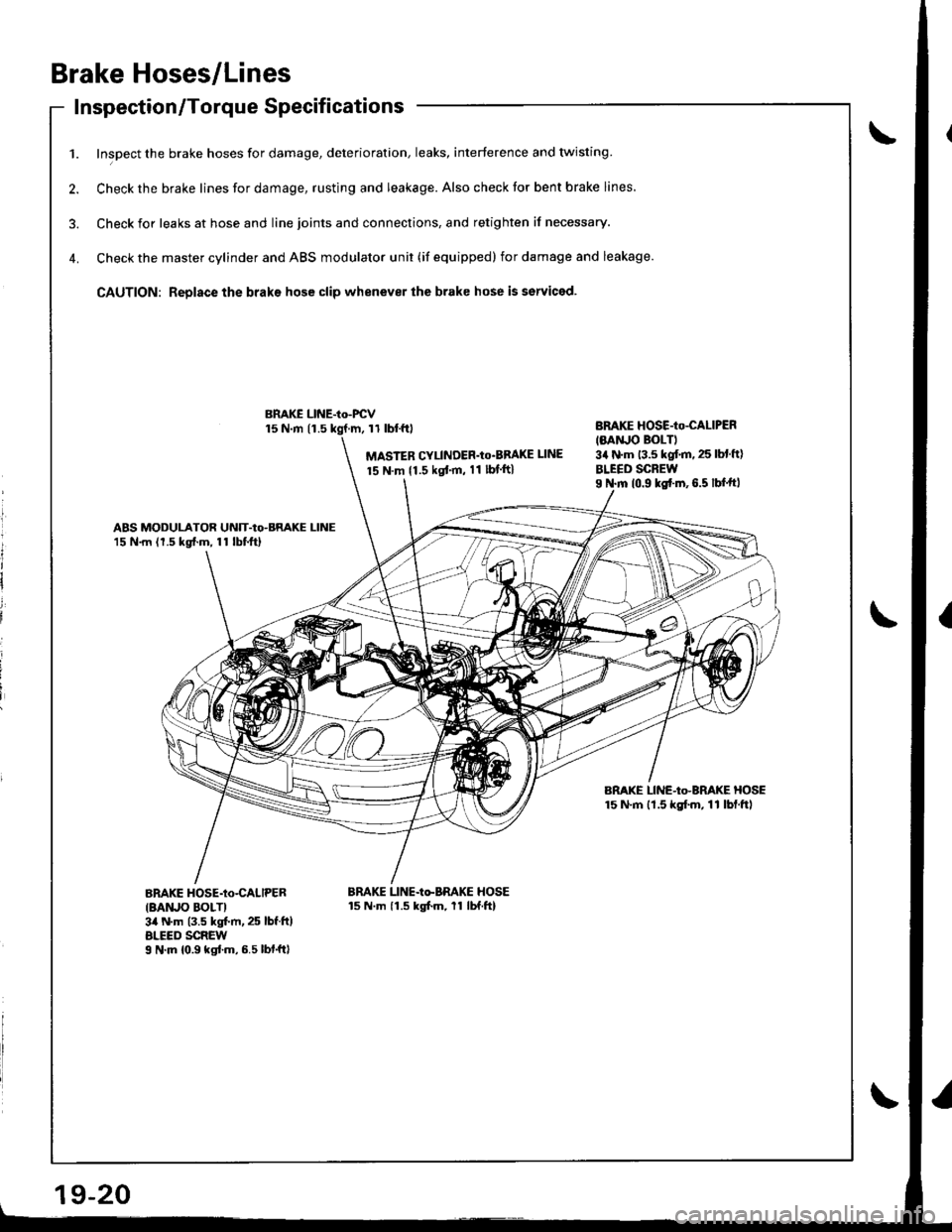

Brake Hoses/Lines

Inspection/Torque Specif icationsInspecuon/ | orque Dpecl carlon

1. Inspect the brake hoses for damage, deterioration, leaks, interference and twisting

2. Check the brake lines for damage, rusting and leakage. Also check tor bent brake lines.

3. Check ior leaks at hose and line joints and connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit (if equipped) for damage and leakage.

CAUTION: Replace the braks hose clip whenever the brake hose is serviced.

15 N.m 11.511 tbl.f0

MASTER CYLINDER'Io'BBAKE UNE

15 N.m {1.5 kgt'm, 11 lbf ft}

BnAKE HOSE-Io-CALIPER

IMNJO BOLTI3a N'm 13.5 kgf.m. 25 lbl ft)

BLEED SCREWI N.m 10.9 ks{.m,6.5 lbf.ftl

ABS MODULATOR UNIT-Io-BRAKE LINE15 N.m (1.5 kg{.m, 11 lbtftl

BRAKE LINE-Io-BRAKE HOSE15 N'm lt.5 kgf.m, 11 lbf.ftl

BnAKE HOSE-Io-CALIPER

IBAruO BOLTI3il N.m (3.5 kgt m, 25 lbf.ft)ALEED SCREWI N'm 10.9 kgtm,6.5lbf.ftl

BRAKE LINE-Io-BRAKE HOSE15 N.m 11.5 kgfm, 11 lbf.ftl

BMKE LINE-Io-FCV

l

It

I

i

i

i

Page 780 of 1681

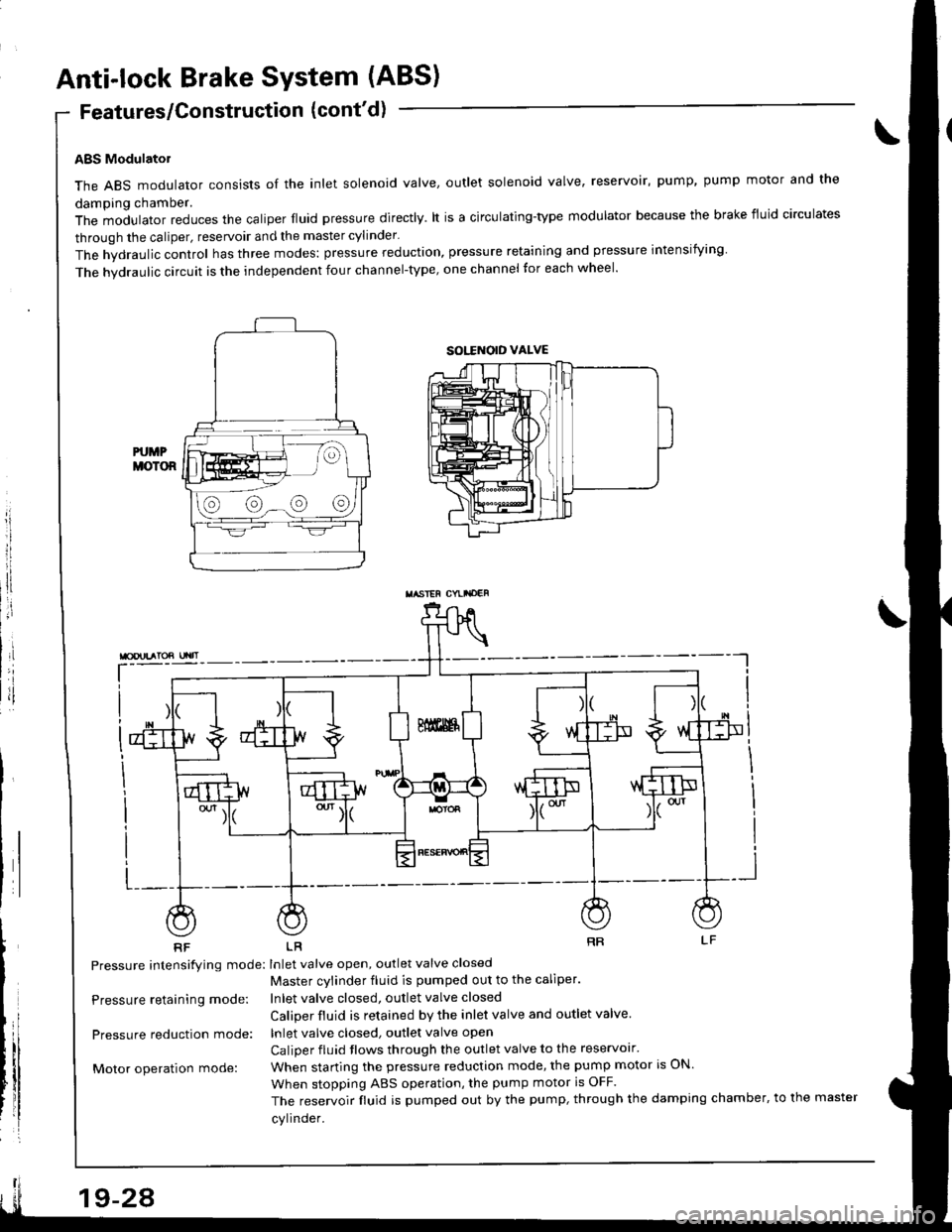

Anti-lock Brake System (ABS)

Features/Construction (cont'd)

ABS Modulatol

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and the

damping chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fiuid circulates

through the caliper, reservoir and the master cylinder.

The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensiiying

The hvdraulic circuit is the independent four channel-type, one channel tor each wheel'

L-__

RF LR

Pressure intensifying mode: Inlet valve open, outlet valve closed

Master cvlinder fluid is pumped out to the caliper.

Inlet valve closed, outlet valve closed

Caliper fluid is retained by the inlet valve and outlet valve.

lnlet valve closed, outlet valve open

Caliper fluid flows through the outlet valve to the reservolr'

When starting the pressure reduction mode, the pump motor is ON.

When stopping ABS operation, the pump motor is OFF.

The reservoir fluid is pumped out by the pump, through the damping chamber, to the master

cylinder.

\

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

sott orD vALvE

@@-@@

TASIEF CYLI'OEF

19-24

Page 788 of 1681

Troubleshooting Precautions

Kickback

L The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

Pump Motol

1. The pump motor operates when the ABS is functioning.

2. The ABS control unit checks the pump motor operation during initial diagnosis and when the vehicle is started. You

mav hear the motor operate at this time, but it is normal

Brake Fluid Replacement/Air Bleeding'1. Brake fluid replacement and air bleeding procedures are the same as vehicles without ABS. To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowcharts procedures assume that the cause of the problem is still present and the ABS indica-

tor is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Find out when the ABS indjcator came on. such as during initial diagnosis. during ABS control, after ABS control,

when vehicle speed was at a certain speed, etc.

3, When the ABS indicator does not come on during the test-drive, but troubleshooting is performed based on the DTC,

check for loose connectors, poor contact at the terminals, etc. before you start troubleshooting'

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustrations show the female terminals with a single outline and the male terminals with a double outline.

Page 813 of 1681

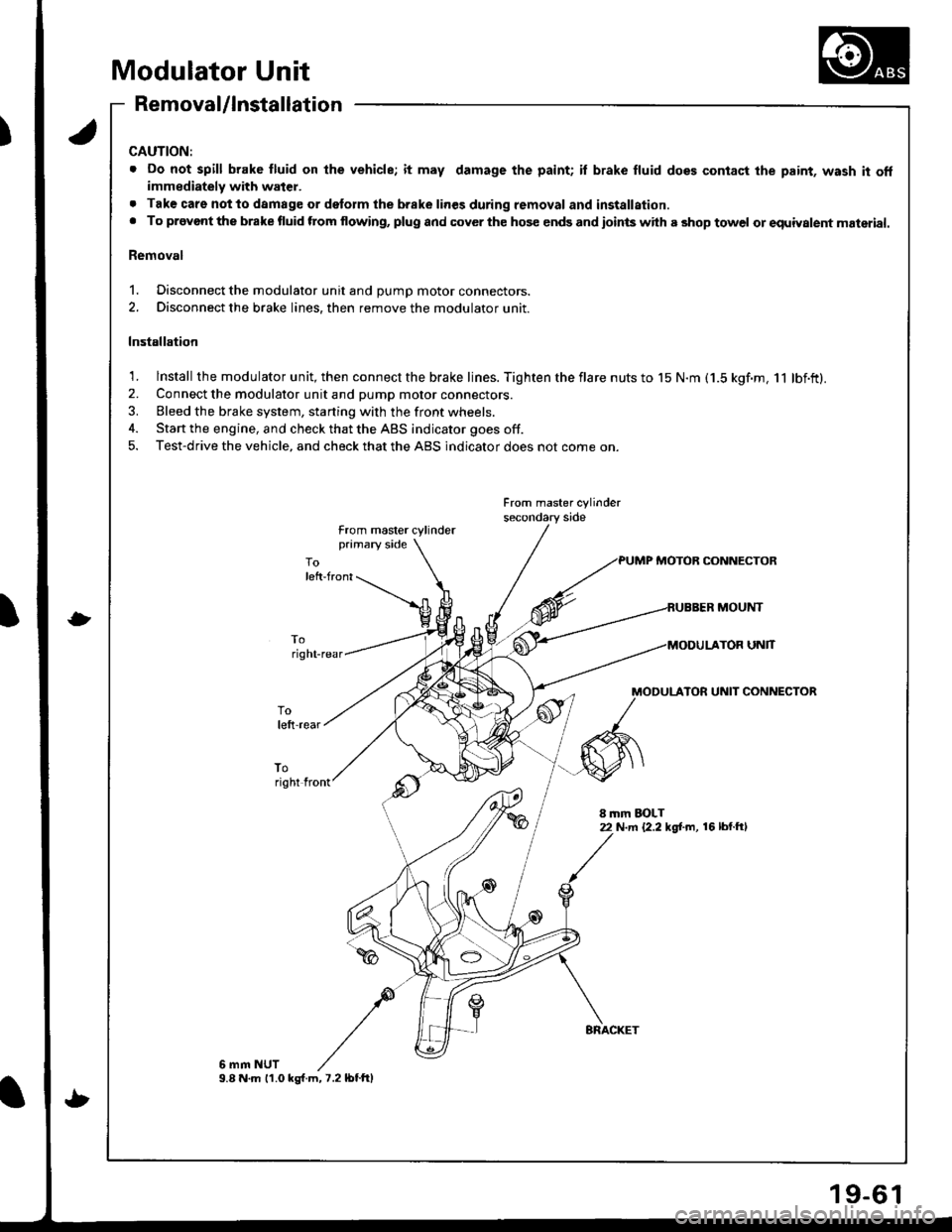

Modulator Unit

Removal/lnstallation

CAUTION:

. Do not spill brake fluid on lhe vehicle; it may damage the paint; il brake fluid does contact the paint, wash it offimmediately with water.

. Tak€ care notto damage or delorm the brake lines during removal and installation.. To provont the brake fluid ftom flowing, plug and cover the hos€ ends and ioints with a shop towel or equiyalent material.

Removal

1. Disconnect the modulator unit and DUmD motor connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installation

1. lnstall the modulator unit, then connect the brake lines. Tighten the flare nuts to 15 N.m (1.5 kgf.m, 11 lbf.ft).2. Connect the modulator unit and pump motor connectors.

3. Bleed the brake system, starting with the front wheels.

4. Start the engine, and check that the ABS indicator goes off.

5. Test-drive the vehicle, and check that the ABS indicator does not come on.

From master cylinder

from master cylinderprimary side

PUMP MOTOB CONNECTOR

MOUNT

UNlT

MODULATOR UNIT CONNECTOR

toright front

8 mm EOLT22 N.m {2.2 kg[.m, 16 lbl.ftl

6 mm NUT9.8 N.m 11.0 ks{.m,7.2lbtftl

9-6

Page 816 of 1681

!

Body

Bumpers

Front Bumper Replacement ....................-..... 20-111

Rear Bumpar Replacemeni

Hatchback ................. 20-1/B

Sedan .................... ....20-111'Carpet

. Repfacemenl .,.,.,.,,..-....-.20-126

Consoles, Front and Rear

* Replacement ..................20-130

Dashboard

Component Removal/lnstallation ................ 20-133

Replacement Precautions ...........,................. 20-138

R€placement ....,.,...........20-139

Doors

Door Index Hatchback ................................... 20-2

Front Door Index Sedan .................,.,..,.,....,.. 20-18

Rear Door Index Sedan ........,.,........,.............. 20-30

Emblems

Installation .....................20-167

FenderwellTrim

+ Replacement., ................20.162

Fram€ Repair Chart .-..........20-170

Hatch

Replacoment .......,..........20-118

Adiustment .................... 20-150

Hatch Latch and Lock Cylinder

Replacement ..,.,..... ........ 20-158

Hstch Spoiler

Replacement ......... .......-.20.161

Hatch Weatherstrip/Trunk Lid Wsatherstrip

Replacement ..................20.163

Headliner

ReDlacement

Hatchbsck ,.,....,......,.. 20-98

Sedan .........................................................20-100

Hood

Replacsment ......... ......... 20.146

Adiustment ....................20-117

lnterior Trim

Reolacement

Hatchback ................. 20-91

Sedan .........................................................20-9,1

Mirrors

Power Mirror Reolacement ..........,................ 20-49

Mirrol Holder Removal ............................,..... 20.50

Mirror Holder Installation .............................. 20-50

Mirror Visor and Mirrot Covet

Replacement

Haichback ............20-51

Sedan .................................................... 20-51

Rearview Mirror Reolacement ..........-....-.-.... 20.52

Roof Molding Rep|acament ................................ 20.164

Door and Sid€ Moldings

Replacement .,..........,..... 20-165

Moonroot

lnd6x

Hatchback -................20-77

Sodan .........................................................20-8il

Opener and Latch

Replacement .......... ......,. 20-156

Opensr Cables

Replacamsnt .,.,...,.. ......., 20-154

Retainers and W€atherstrip

Replacement .................. 20-160

Seats

Front Seat Romoval ....................................... 20-103

Front Seat Replacement ...........................,.,.. 20-104

Front Soat Disassembly and Reassembly ...20-106

Torsion Bar ReDlacomant .....,...,......,.......,..,., 2O-1O7

Seat Eelt Switch Ha.ness Location ..,...,.,.,..,2O-1O7

Front Seat Cover Replacemont ..,....,..,..,.....,. 20-108

Rear Soat Roplscemont

Hatchback ................. 20.110

Sedan.........................................................20-112

R€al Seat Cover Replacomont ...................... 20-114

Seat Belts

Front Seat Beh Replacement

Hatchback..................20.117

Sedan20-r18

Rear S6at Bolt R€plac€ment

Hatchback .-......-.-......20-121

Sedan.......................-.-....-.-..........-.............20-122

fnspection ......-.-.,....-.-....20-121

Chifd Seat Anchor Plate ................................ 20-125

Side Sill Panol

Beplacom€nt .................. 20-166

Sub-frame ........................... 20.169

Trunk Lid

Replacement ......... ..,..,.,.20-151

Adiustmeni .................... 20-153

Trunk Lid Latch and Lock Cvlindot

Replac€ment ......... ......... 20-159

Trunk Trim

Replacement .,.,,.,........... 20-97

Windshield, Rear Window, Ouarter Glass

lndex

Hatchback ...........,,.20-53

!

S6dan ......................................................... 20.54

Page 818 of 1681

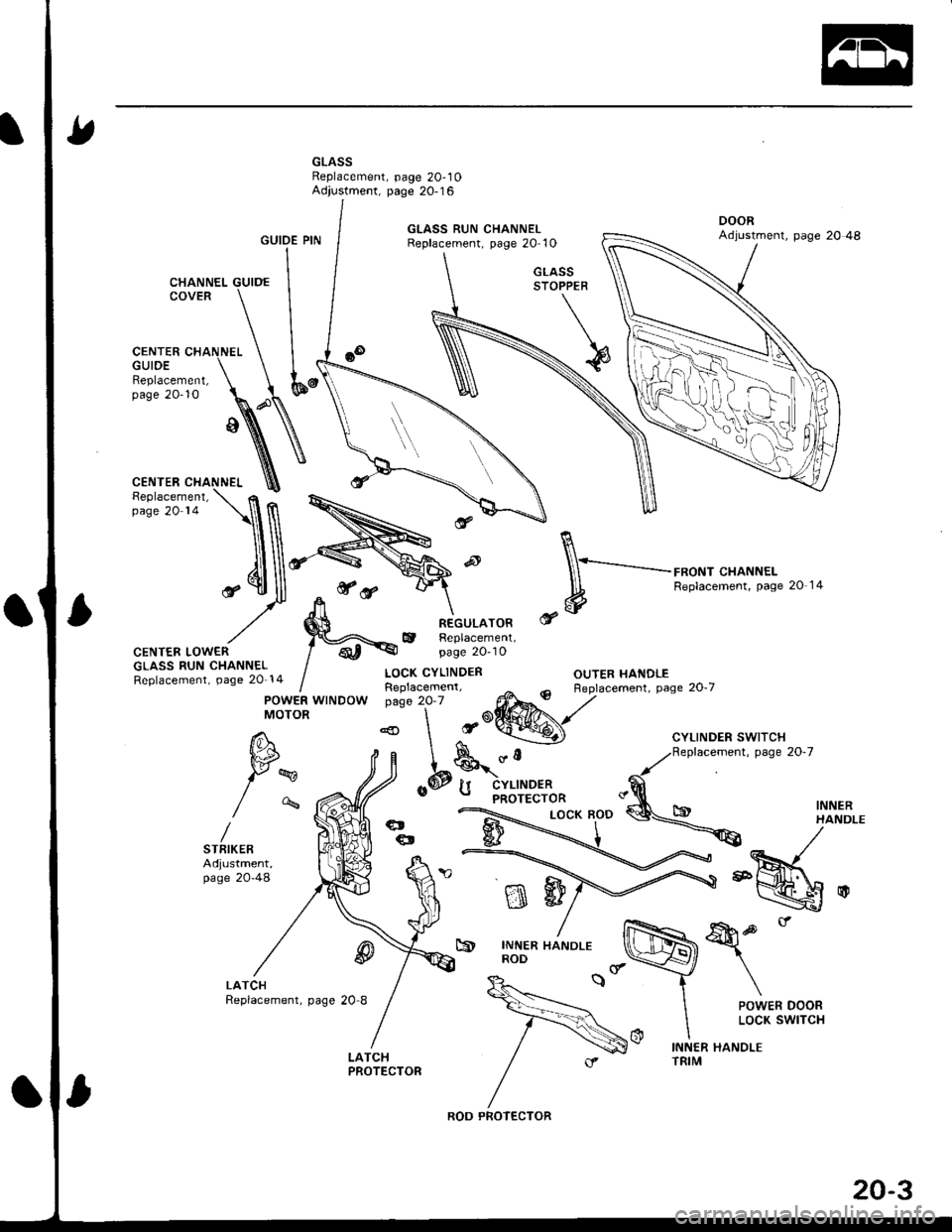

GLASSReplacement, page 20,10Adjustment, page 20-16

GUIDE PIN

CENTER CHANNELGUIDE

,**ry

R

\-_-..........-..-.-,*oNr .HANNEL

* #

Replacemenr. pase 20 14

OUTER HANDLE

mw

&p.'

\

POWER DOORLOCK SWITCH

c9INNER HANDLEROD

INNER HANDLETRIM

Replacement,page 20-10

CENTER LOWERGLASS RUN CHANNELReplacement, page 20-14

@

LOCK CYLINDER

REGULATORReplacement,page 2O-10

POWER WINDOWMOTOR

W

/-%

STFIKERAdjustment,page 20-48

@

ROD PROTECTOR

20-3

Page 823 of 1681

Doors

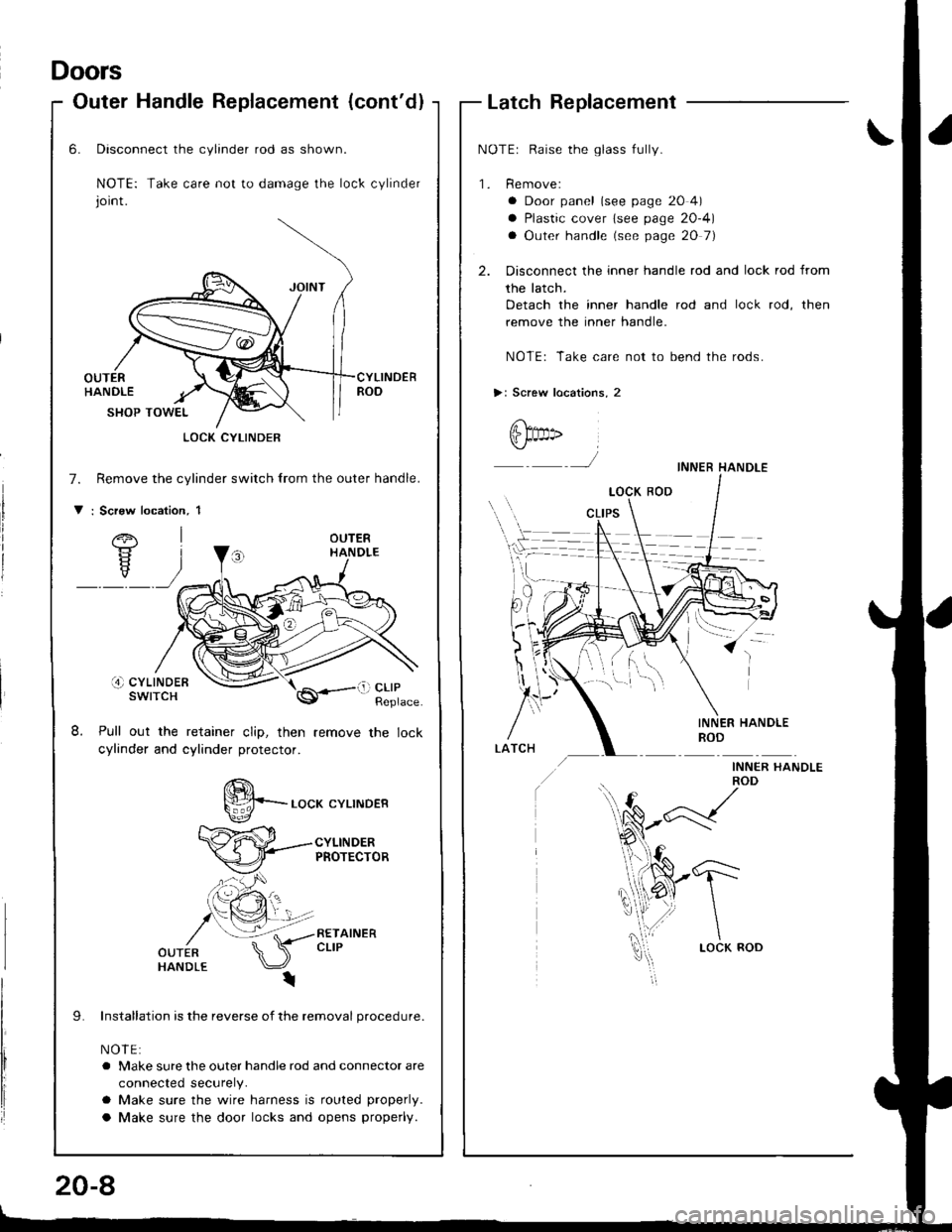

Outer Handle Replacement (cont'dlLatch Replacement

NOTEr Raise the glass fully.

'1. Remove:

a Door panel (see page 20 4)

a Plastic cover lsee page 20-4)

a Outer handle (see page 20 7)

2. Disconnect the inner handle rod and lock rod from

the latch.

Detach the inner handle rod and lock rod, then

remove the inner handle.

NOTE: Take care not to bend the rods.

>: Screw locations, 2

@t" ,

J

INNER HANDLEROD

INNER I{ANDLE

-1"'-

\

\LOCK ROD

)

INNER HANDLEROD

6.

8.

Disconnect the cylinder rod as shown.

NOTE: Take care not to damage the lock cylinder

joint.

OUTERHANDLECYLINDERROD

7.

V

SHOP TOWEL

Remove the cylinder switch lrom the outer handle.

: Scrsw location, 1

OUTERHANDLE

i4) cYLtNDERswtTcH

Pull out the retainer clip, then

cylinder and cylinder protector.

LOCK CYLINDER

li) clrPReplace

S*-.o"* .YLTNDER

CYLINDERPROTECTOR

RETAINERCLIP

Installation is the reverse of the removal procedure.

NOIE:

a Make sure the outer handle rod and connector are

connected securely.

a Make sure the wire harness is routed properly.

a Make sure the door locks and opens properly.

20-8

Page 824 of 1681

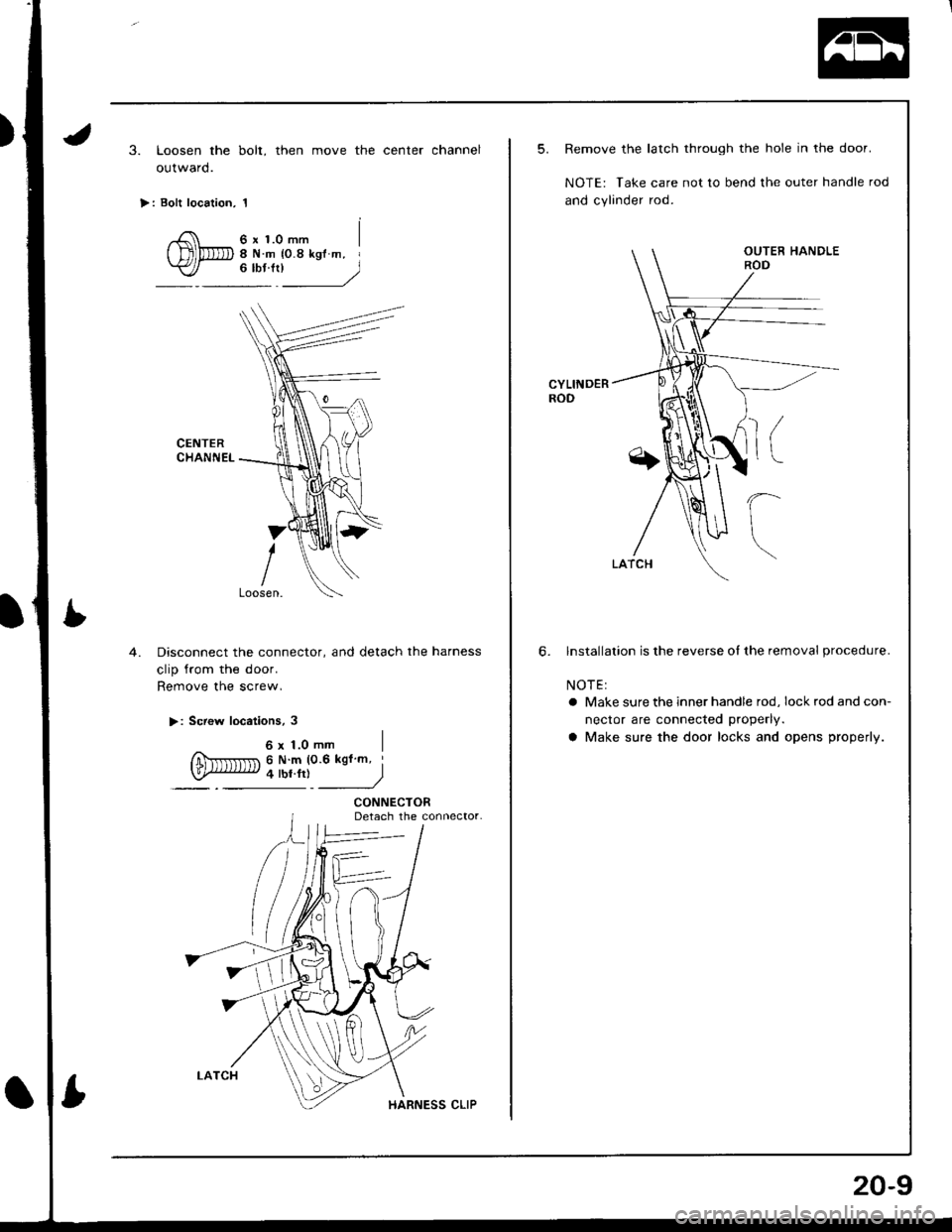

3. Loosen the bolt, then move the center channel

outward.

>: Bolt location, 1

6 x 1.0 mm8Nm {0.8kglm, I"*'l____)

CENTERCHANNEL

4.Disconnect the connector, and detach the harness

clip from the door.

Remove the screw,

>: Screw locations, 3

6x1.0mm IfiNrrlr

nr 6 N m (0.6 kgfm '

law iw.r,i )

CONNECTORDetach the connector.

5. Remove the latch through the hole in the door.

NOTE: Take care not to bend lhe outer handle rod

and cylinder rod.

CYLINDERROD

6. lnstallalion is the reverse of the removal procedure.

NOTEI

a Make sure the inner handle rod, lockrodandcon-

nector are connected properly.

a Make sure the door locks and opens properly.

20-9