oil HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 365 of 1681

rtr

1

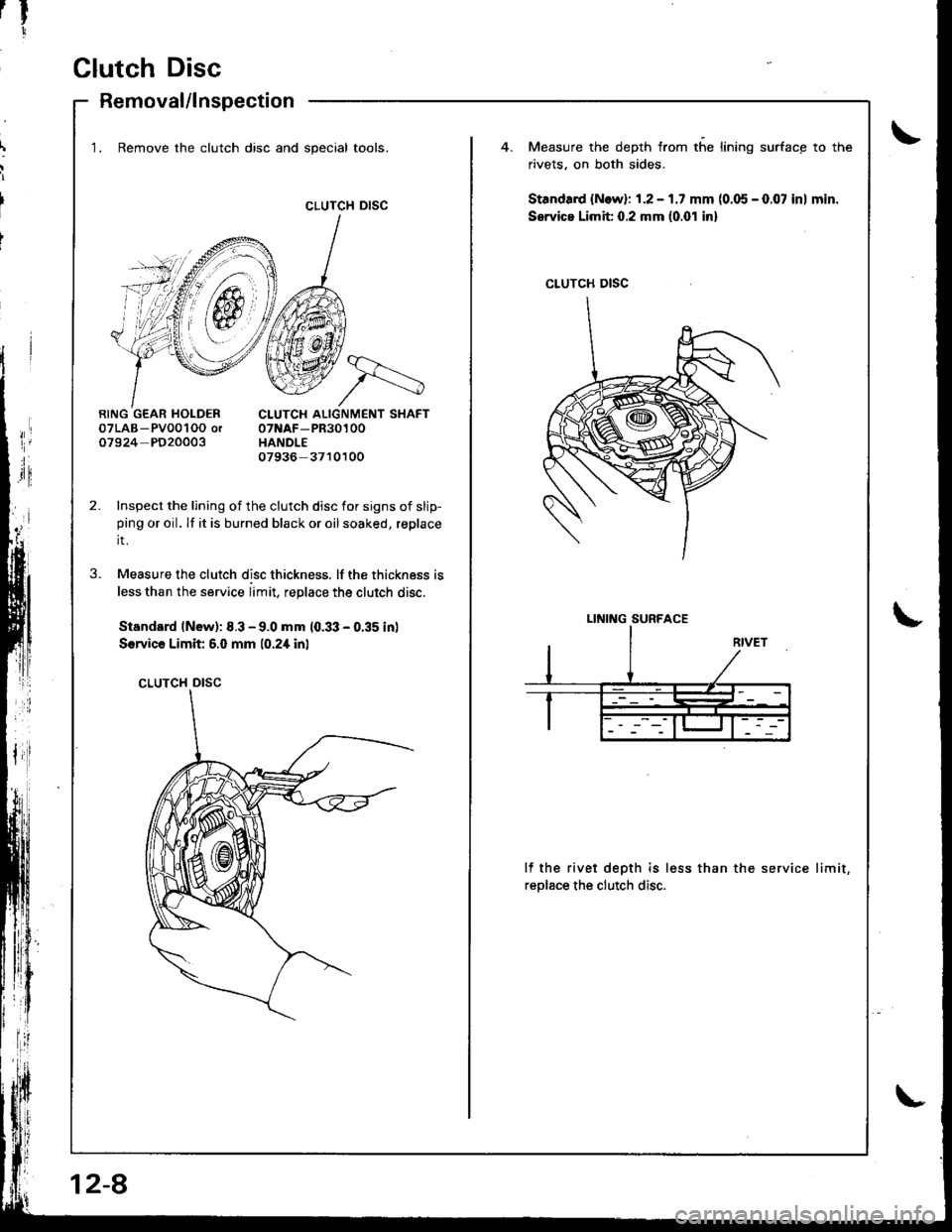

Clutch Disc

Removal/lnspection

CLUTCH DISC

1. Remove the clutch disc and special tools.Measure the depth from the lining surface to the

rivets. on both sides.

Standa.d {N.w}: 1.2 - 1.7 mm (0.05 - 0.07 in} min.

Service Limit 0.2 mm (0.01 inl

07LAB- Pv001OO or07924 PD20003

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936- 3710100

Inspect the lining of the clutch disc for signs of slip-ping or oil. lf it is burned black or oil soaked, replace

it.

Measure the clutch disc thickness. lf the thickness is

less than the service limit, replace the clutch disc.

Standard lNew): 8.3 - 9.0 mm 10.33 - 0.35 in)

Sorvica Limit 6.0 mm 10.2i[ inl

CLUTCH DISC

3.

lf the rivet depth is less than the service limit,

reolace the clutch disc.

CLUTCH DISC

LINING SURFACE

12-8

Page 370 of 1681

Manual Transmission

Special Tools ............. 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Transmission Assembly

Removal ................. 13-4

lllustrated Index ................................... 13-8

Transmission Housing

Removal ................. 13-10

Peverse Change Holder, Reverse ldler Gear

jGlearance Inspection ....................... 13-1 1

Removal ................. 13-12

Change Holder Assembly

Clearance Inspection .....,.,....,,.....,,.. 13-13

Removal ................. 13-15

Disassembly/Reassembly ............... 13-16

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-17

Shift Rod

Removal ................. 13-18

Shift Fork Assembly

Index ................ ...... 13-19

Clearance lnspection ...................,.,. 13-20

Mainshaft Assembly

fndex ................ ......13-21

Clearance f nspection ..,,,.................. 13-22

Disassembly .......... 13-25

Inspection .............. 13-26

Reassembly ........... 13-21

Countershaft Assembly

Index ................ ...... 13-28

Clearance Inspection ....................... 13-29

Disassembly .......... 13-30

Inspestion .............. 13-31

Reassembly ........... 13-32

Synchro Sleeve, Synchro Hub

Inspection .............. 13-34

Installation ............. 13-34

Synchro Ring, Gear

Inspection .............. 13-35

Clutch Housing Bearing

Replacement ......... 13-36

Mainshaft Thrust Clearance

Adiustment ............ 13-38

Transmission

Reassembly ........... 13-41

Transmission Assembly

Installation ............. 13-46

Gearshift Mechanism

Overhaul ................ 13-51

Page 372 of 1681

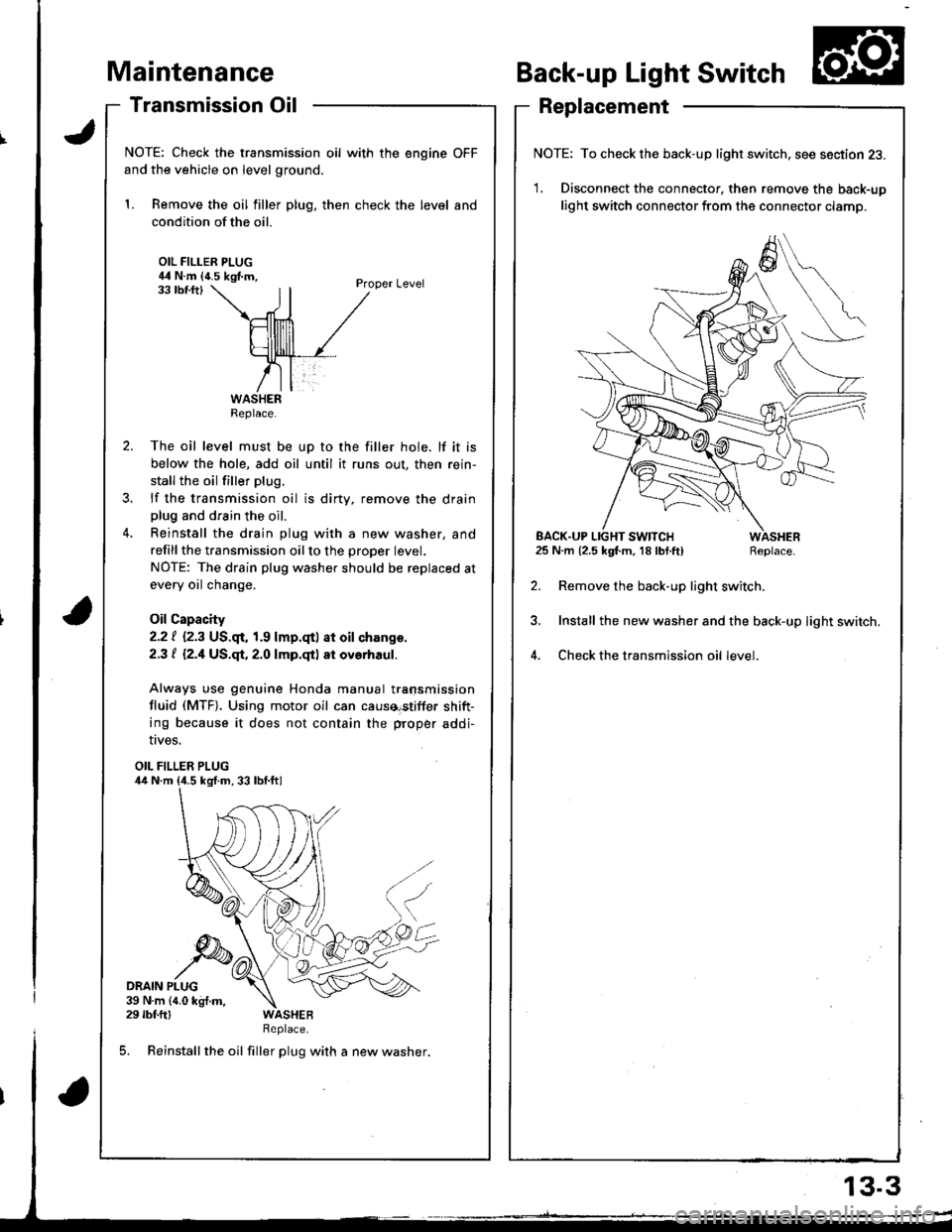

aintenance

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG44 N.m {4.5 kgf.m,Proper Level33 tbf.ftl

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out, then rein-

stall the oil filler plug.

lf the transmission oil is dirty, remove the drainplug and drain the oil.

Reinstall the drain plug with a new washer, and

refillthe transmission oilto the proper tevet.

NOTE: The drain plug washer should be replaced at

every oil change.

Oil Capacity

2.2 | i.2.3 US.qr,1.9 lmp.qtl at oil ch.nge.

2.3 t l2.1US.qt,2.O lmp.qtl at ovorhaul.

Always use genuine Honda manual transmission

fluid (MTF). Using motor oil can causa€tiffer shift-

ing because it does not contain the proper addi-

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch. see section 23.

1. Disconnect the connector, then remove the back-up

light switch connector from the connector clamp.

l.m {2.5 kgf.m, 18lbf.ft) Replace.

Remove the back-up light switch.

Install the new washer and the back-up light switch.

Check the transmission oil level.

!ves.

OIL FILLER PLUG

DRAIN PLUG39 N.m {4.0 kg{.m,29 rbf.ftlReplace.

5. Reinstall the oil filler plug with a new washer,

Replace.

EACK.UP LIGHT SWITCH25 N.m {2.5 kgf.m, 18 lbf.ft)

13.3

Page 374 of 1681

I

T

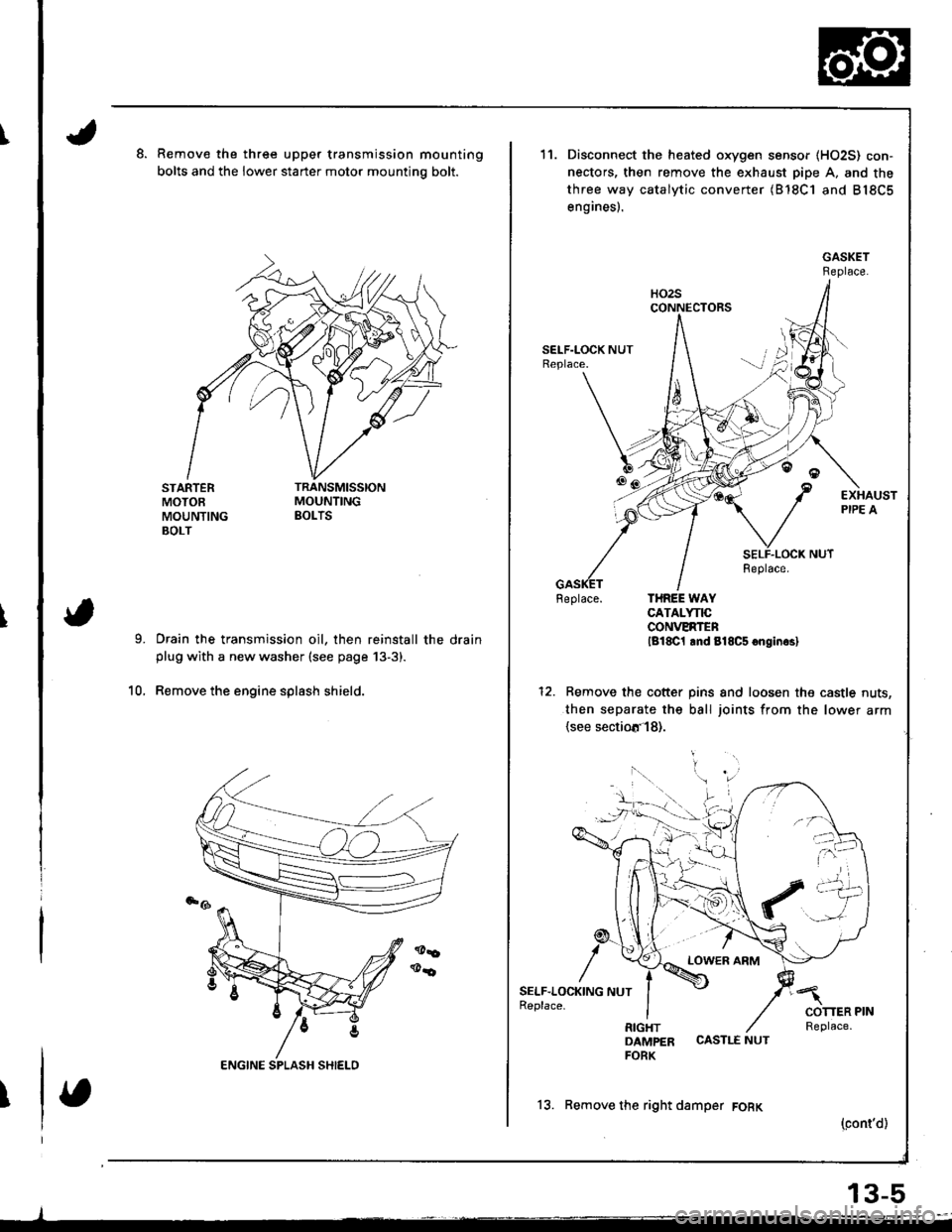

Remove the three upper transmission mounting

bolts and the lower starter motor mountino bolt.

STARTERMOTOEMOUNTINGBOLT

Drain the transmission oil, then reinstall the drainplug with a new washer (see page 13-3).

Remove the engine splash shield.10.

11.

6tr!

/

SELF.LOC1(ING NUTReplace.

Disconnect the heated oxygen sensor (HO2S) con-

nectors, then remove the exhaust pipe A. and the

three way catalytic converter (B'18C1 and B18C5

engines).

Feplace. THREE WAYCATALYNCCONVERTENlg18C1 lnd 818C5 onginrsl

Remove the cotter pins and loosen the castle nuts,

then separate the ball joints from the lower arm(see sectiotr'l8).

LOWER ARM

DAMPER CASTLE NUTFORK

13. Remove the right damper FORK

(cont'd)

13-5

Page 375 of 1681

Transmission Assembly

Removal (cont'dl

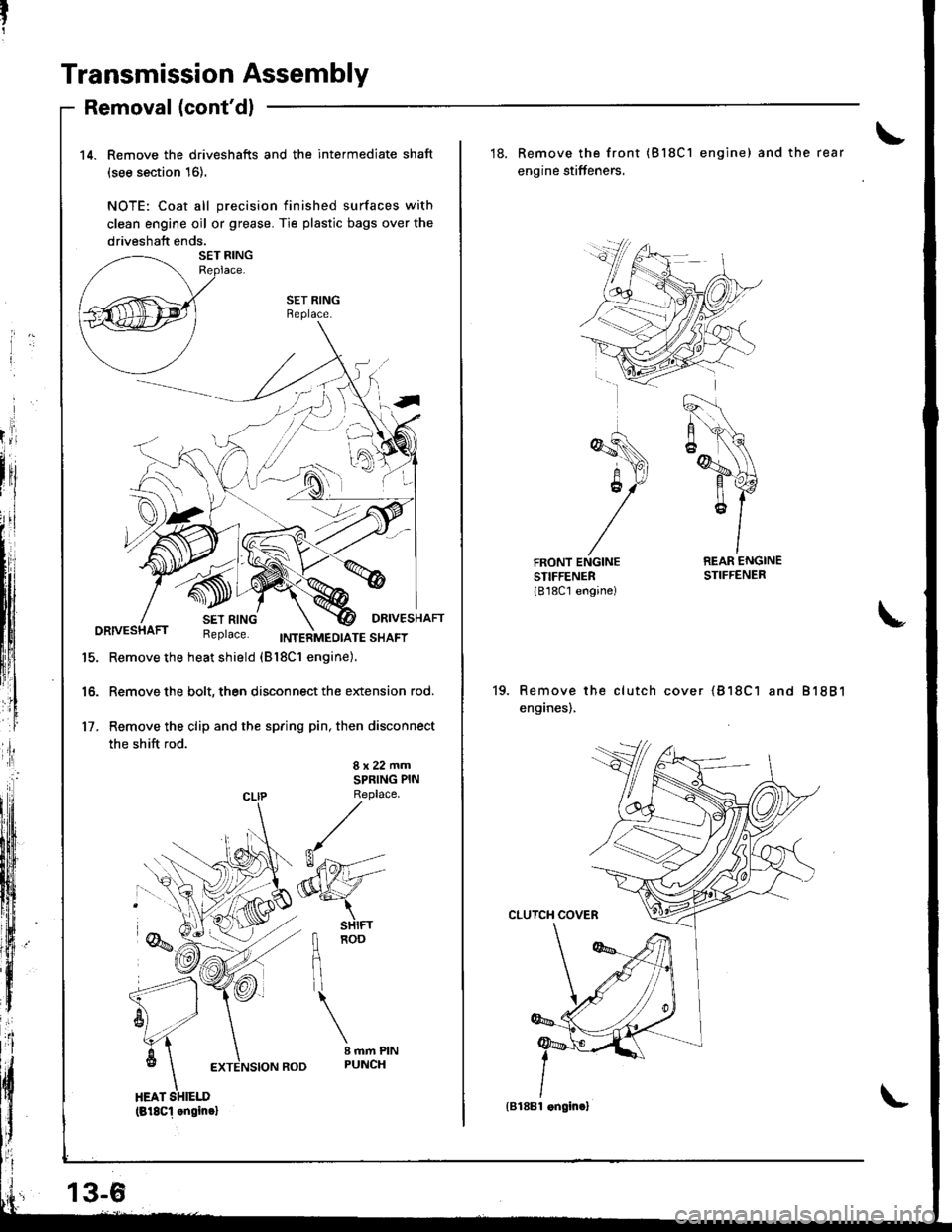

14. Remove the driveshafts and the intermediate shaft

(see section 16).

NOTE: Coat all precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends.

SET RINGBeplace.

DRIVESHAFTDRIVESHAFT Replace. trweinnro,ora ""ot

15. Remove the heat shield (Bl8c1 engine).

16. Remove the bolt, then disconnect the extension rod.

17. Remove the clip and the spring pin, then disconnect

the shift rod.

8x22mmSPRING PIN

CLIP Replace

fl noo

flil

\

I mm PINPUNCH

(818c1 .ngin.l

13-6

'18. Remove the front (Bl8C1 engine) and the rear

engine stiffeners,

REAR ENGINESTIFFENER

Remove the clutch cover {818C1 and 81881

enganes),

{B188l .ngin.}

Page 377 of 1681

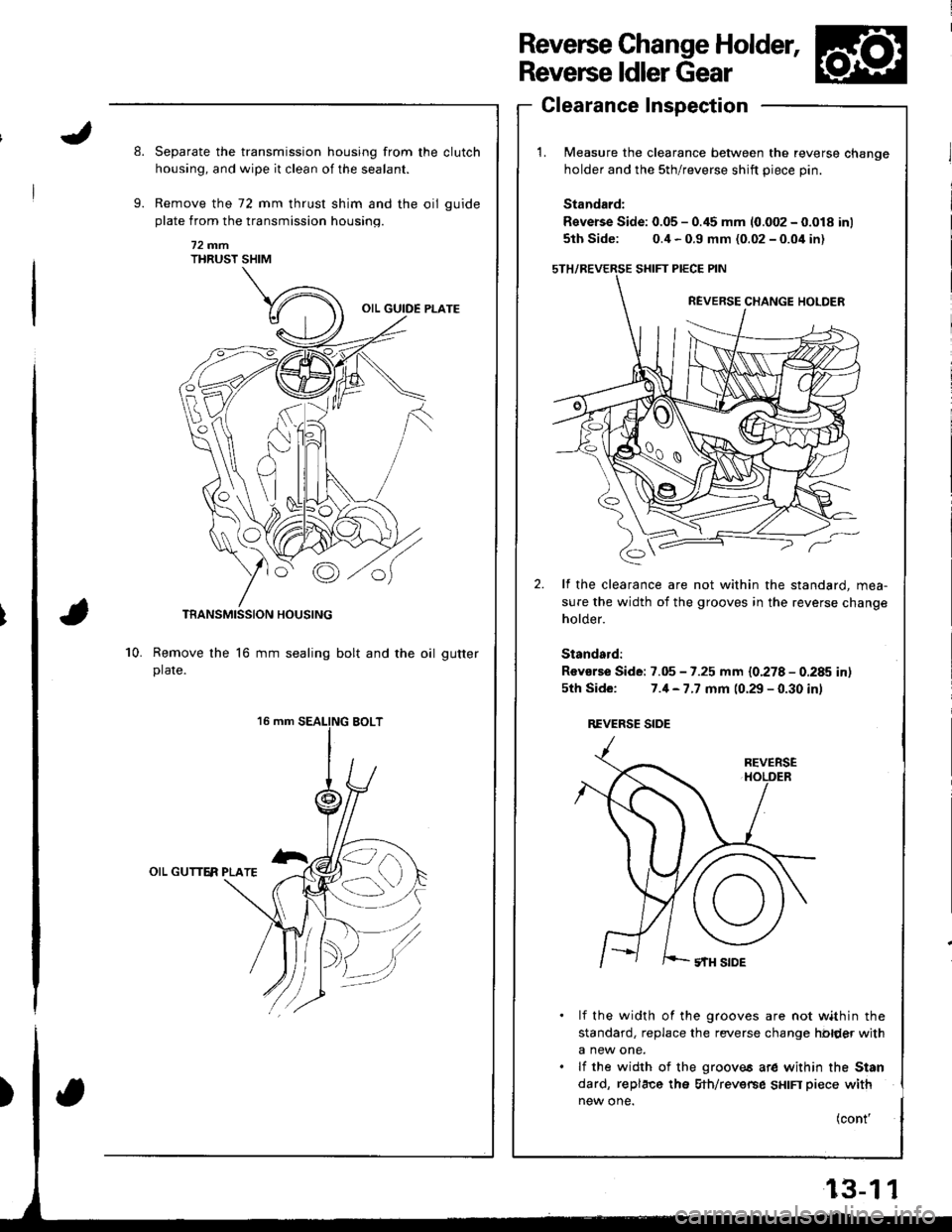

8.

9.

f;:Y:fffrf#:J'uer' Sl[

Measure the clearance between the reverse change

holder and the sth/reverse shift piece pin.

Standard:

Reverse Side: 0.05 - 0.45 mm (0.002 - 0.018 inl

5th Side: 0.4 - 0.9 mm (0.02 - 0.04 in)

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing

72 fifiTHRUST SHIM

10. Remove the l6 mm sealing bolt and the oil gutter

plate.

OIL GUTT6R PLATE

lf the clearance are not within the standard, mea-

sure the width of the grooves in the reverse change

holder.

Standard:

Revsrse Side: 7.05 - 7.25 mm {0.278 - 0.285 in)

5th Side: 7.4-7.7 mm (0.29 - 0.30 in)

REVERSE SIDE

lf the width of the grooves are not within the

standard, replace the rsverse change hbtder with

a new one.

lf the width of the grooves ar€ within the Stan

dard, replace the 9th/revense sHtFI piece wlth

new one.

(cont'

Page 384 of 1681

Shift Rod

- Removal

13-18

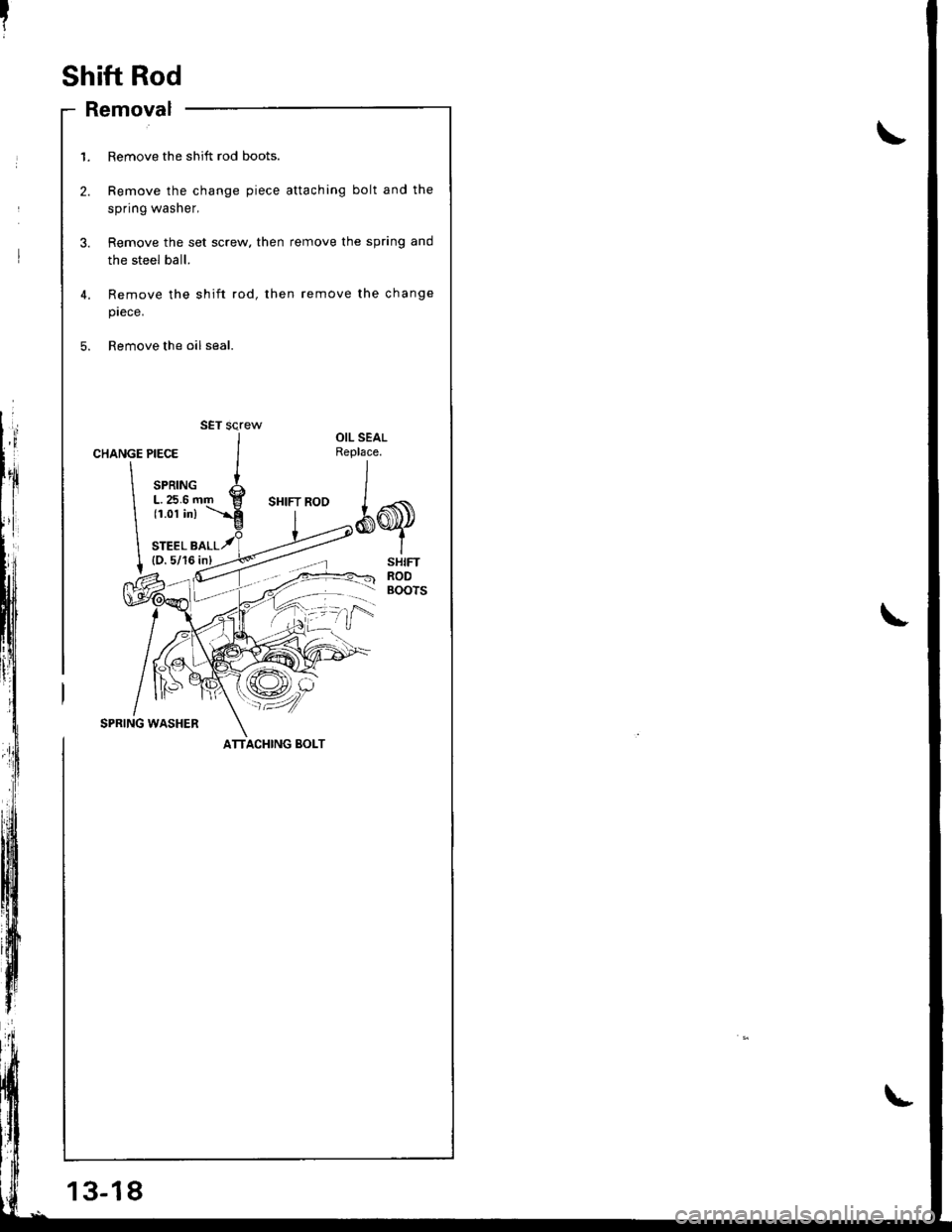

1. Remove the shift rod boots.

2. Remove the change piece attaching bolt and the

spring washer,

3. Remove the set screw. then remove the spring and

the steel ball.

4,

5.

Remove the shift rod, then remove the change

prece.

Remove the oil seal.

CHANGE

\

\

I

PIECE

SPRINGL.25.6 r(1.01 in)

STEEL B(D.5/16

OIL SEALReplace.

*q

SHIFTRODBOOTS

SPRING WASHER

SET screw

ATTACHING BOLT

Page 392 of 1681

I

Mainshaft Assembly

Inspection

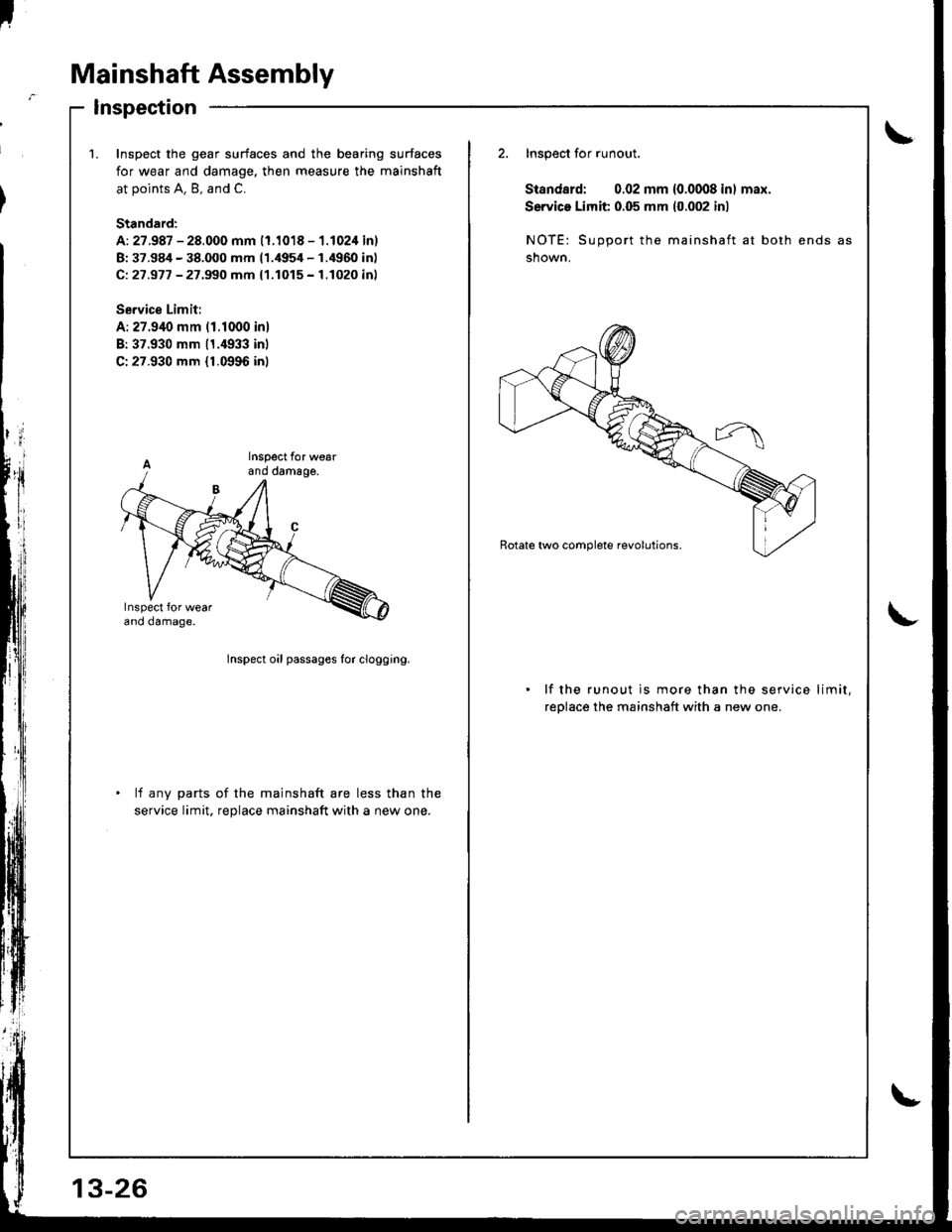

\1.Inspoct the gear surfaces and the bearing surfaces

for wear and damage, then measure the mainshaft

at points A. B, and C.

Standard:

A: 27.987 - 28.000 mm (1.1018 - 1.1024 inl

B: 37.984 - 38.000 mm 11.4954 - 1.4960 inl

Ci 27 .977 - 27 .99O mm { 1.1015 - 1.1020 inl

Se.vice Limit:

A: 27.940 mm 11.1000 inl

B:37.930 mm 11.4933 inl

C:27.930 mm {1.0996 inl

2. Inspect for runout.

Standard: 0.02 mm 10.0008 inl max.

Service Limit 0.05 mm (0.002 inl

NOTE: Support the mainshaft at both ends

shown.

lnspect oil passages for clogging.

lf the runout is more than the service limit,

reolace the mainshaft with a new one.

lf any parts of the mainshaft are less than the

service limit, reDlace mainshaft with a new one.

Page 397 of 1681

I

t

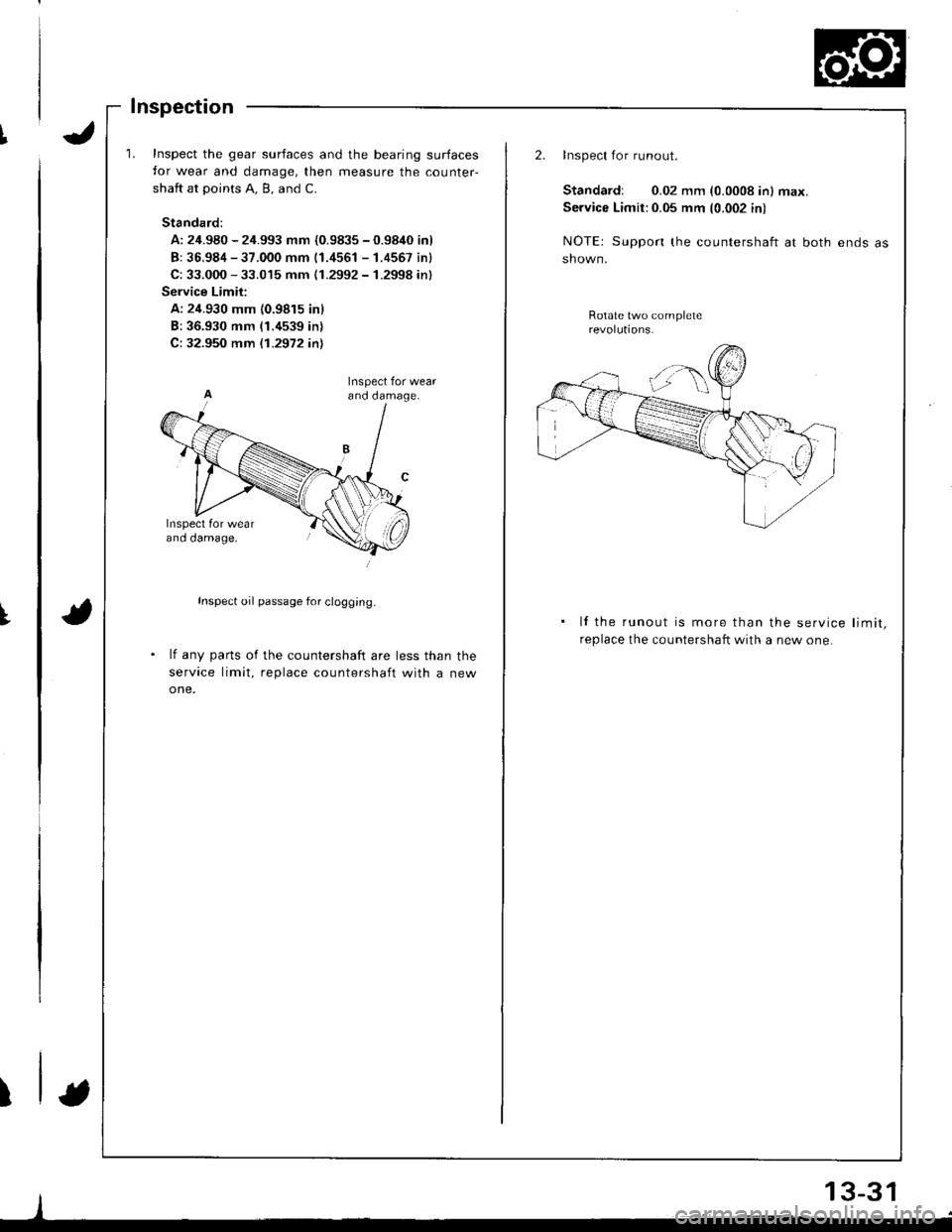

Inspect the gear surfaces and the bearing surfaces

for wear and damage, then measure the counter-

shaft at points A. B, and C.

Standard:

A: 24.980 - 24.993 mm {0.9835 - 0.9840 inl

B: 36.984 - 37.000 mm 11.4561 - 1.4557 inl

C: 33.000 - 33.015 mm (1.2992 - 1.2998 inl

Service Limit:

A: 24.930 mm {0.9815 inl

B:36.930 mm (1.4539 in)

C: 32.950 mm {.1.2972 inl

Inspect oil passage for clogg;ng.

lf any parts of the countershaft are less than the

service limit, replace countershaft with a new

one.

ano oamage,

I

2.Inspect for runout.

Standardr 0.02 mm (0.0008 in) max.

Service Limit:0.05 mm (0.002 in)

NOTE: Support the countershaft at both ends

shown.

Rotate two complete

lf the runout is more than the service limit,

replace the countershaft with a new one.

13-31

-,i

Page 401 of 1681

Synchro Ring, Gear

Inspection

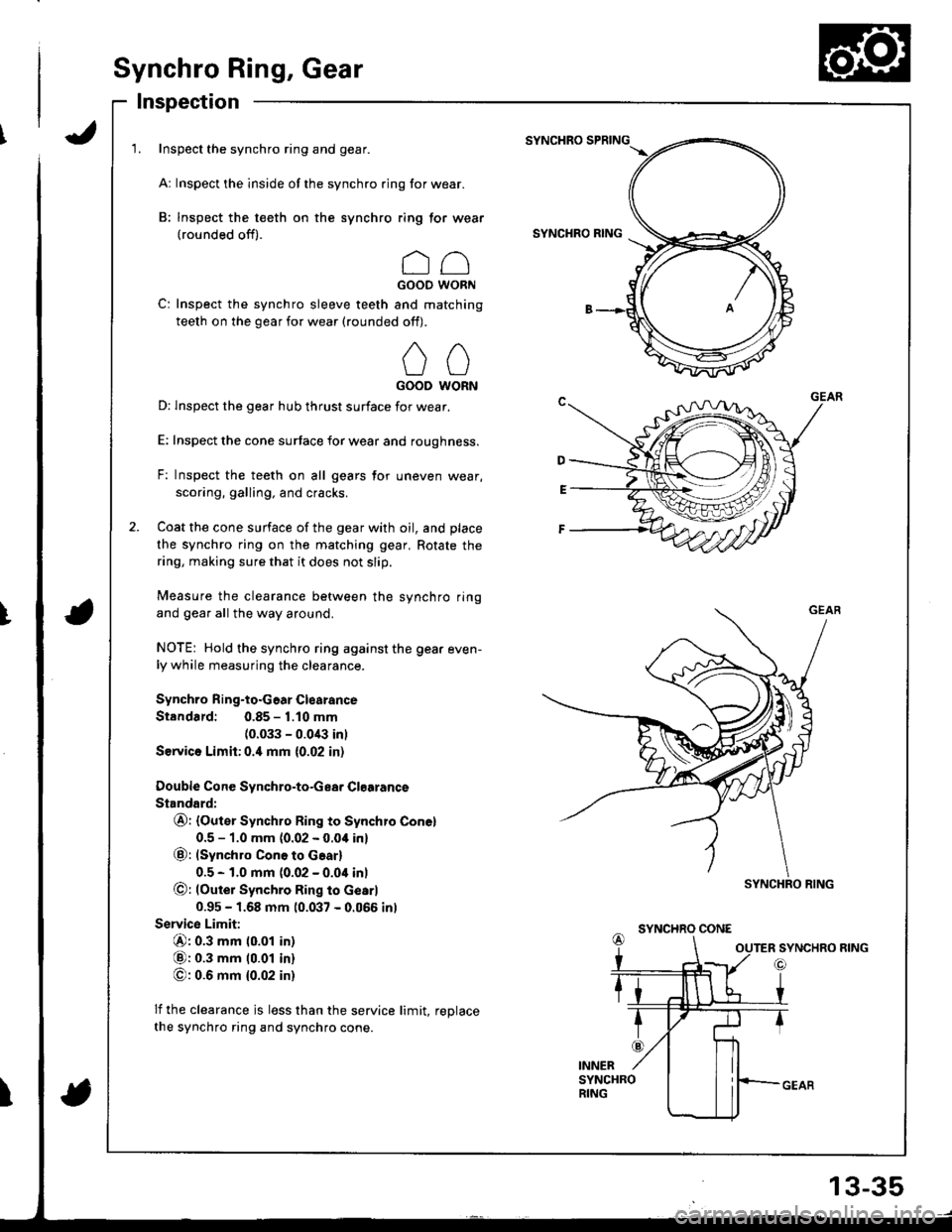

1. Inspect the synchro ring and gear.

Ar Inspect the inside of the synchro ring for wear.

B: Inspect the teeth on the synchro ring tor wear(rounded off).

ccGOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded off).

00GOOD WORN

D: lnspect the gear hub thrust surface for wear.

E: Inspect the cone surtace for wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling. and cracks.

Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear, Rotate the

ring, making sure that it does not slip.

Measure the clearance between the synchro ring

and gear all the way around.

NOTE: Hold the synchro ring against the gear even-ly while measuring the clearance.

Synchro Ring-to.Goar Clearance

Standard: 0.85 - 1.10 mm

(0.033 - 0.0/B inl

Service Limh:0.4 mm {0.02 in)

Double Cone Svnchro-to-Gea. Clgarance

Standard:

@r (Outer Synchro Ring to Synchro Conel

0.5 - 1.0 mm {0.02 - 0.04 in}

@: (synchro ConG to Gear)

0.5 - 1.0 mm (0.02 - 0.04 inl

@: lOute; Synchro Ring to Gearl

0.95 - 1.68 mm 10.037 - 0.066 inl

Servic€ Limit:

@: 0.3 mm (0.01 in)

@: 0.3 mm 10.01 in)

O: 0.6 mm {0.02 in}

lf the clearance js less than the service limit, reDlace

the synchro ring and synchro cone.

SYNCHRO SPRING

SYNCHRO RING

SYNCHRO CONE

I

SYNCHRO RING

13-35