ground HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 504 of 1681

Replacement

(.

L

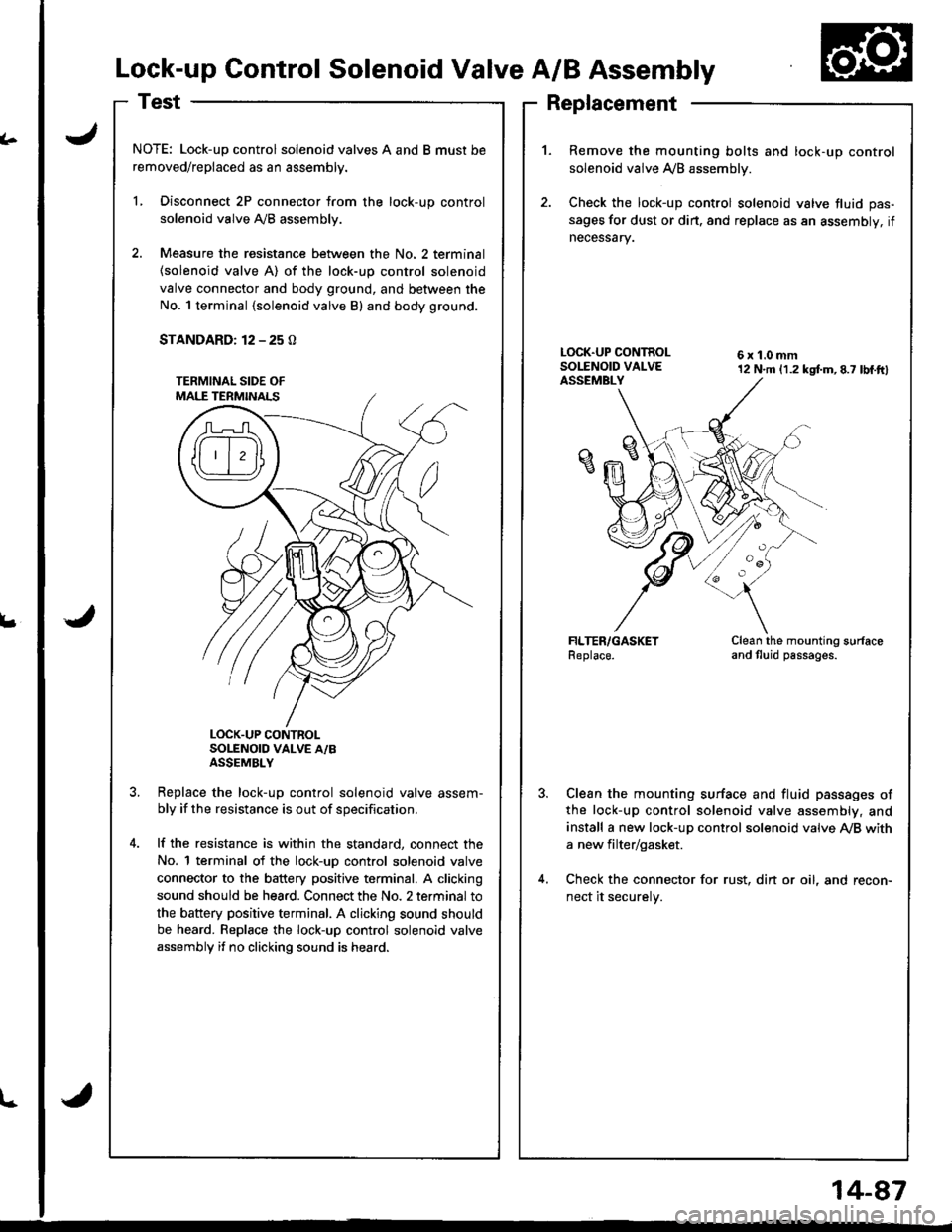

Lock-up Control Solenoid Valve A/B Assembly

NOTE: Lock-up control solenoid valves A and B must be

removed/replaced as an assembly.

L Disconnect 2P connector from the lock-up control

solenoid valve Ay'B assembly.

2. Measure the resistance between the No. 2 terminal

{solenoid valve A) of the lock-up control solenoid

valve connector and body ground, and between the

No. 1 terminal {solenoid valve B) and body ground.

STANDARD: 12 - 25 O

LOCK.UP CONTROLSOLENOID VALVE A/BASSEMBLY

Replace the lock-uo control solenoid valve assem-

bly if the resistance is out of specification.

lf the resistance is within the standard, connect the

No. 1 terminal of the lock-uD control solenoid valve

connector to the battery positive terminal. A clicking

sound should be hea.d. Connect the No. 2 terminal to

the battery positive terminal. A clicking sound should

be heard. Replace the lock-up control solenoid valve

assembly if no clicking sound is heard.

1.Remove the mounting bolts and lock-up control

solenoid valve A/B assemblv.

Check the lock-up control solenoid valve fluid pas-

sages for dust or dirt. and replace as an assembly, if

necessary.

6x1.0mm12 N.m (1.2 kgtm,8.7 lbf.ftl

Clean the mounting surfaceand tluid passages.

Clean the mounting surface and fluid passages of

the lock-up control solenoid valve assembly, and

install a new lock-up control solenoid valve Ay'B with

a new filter/gasket.

Check the connector for rust, din or oil, and recon-

nect it securelv.

l-

14-87

Page 505 of 1681

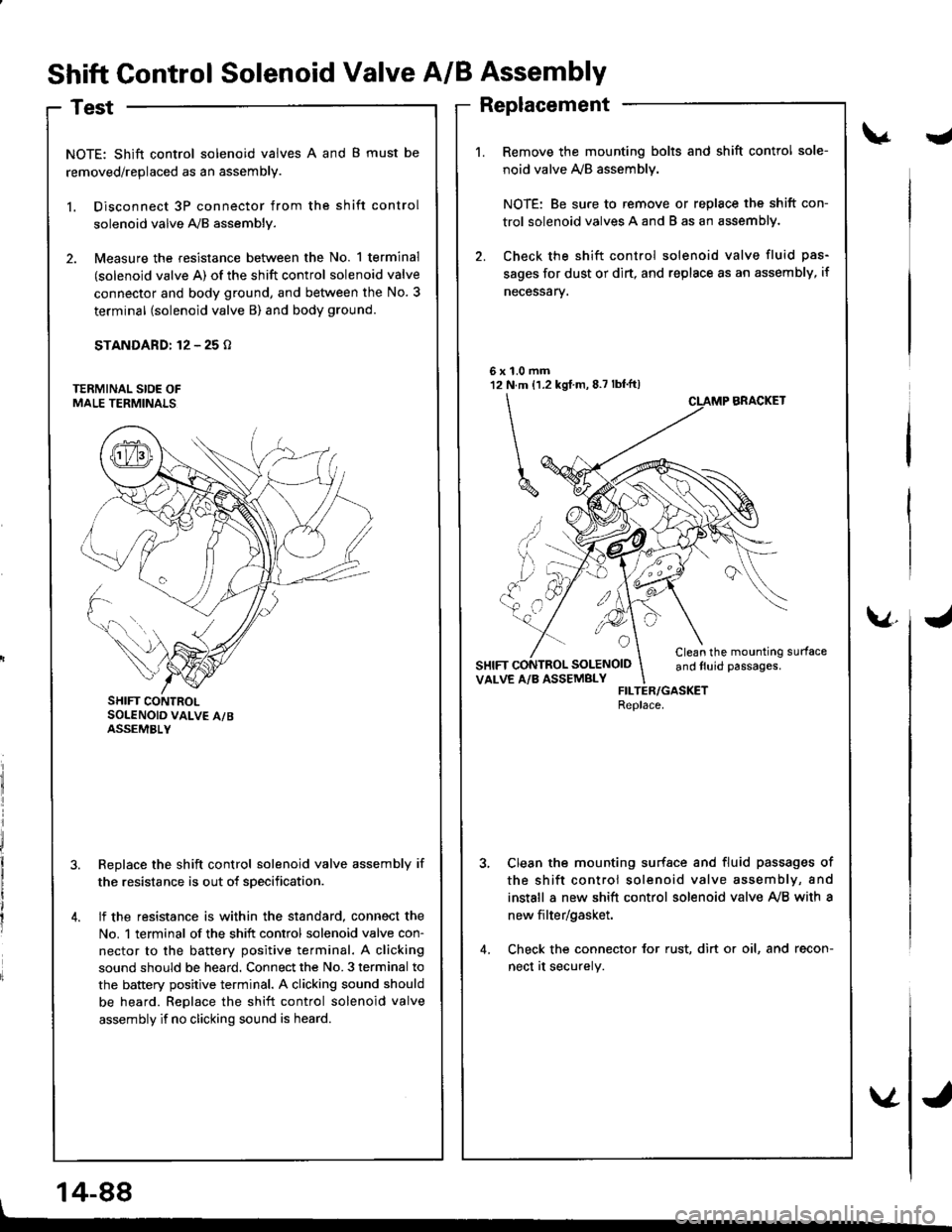

Shift Control Solenoid Valve A/B Assembly

Test

NOTE: Shift control solenoid valves A and B must be

removed/replaced as an assembly.

l. Disconnect 3P connector from the shift control

solenoid valve A,/B assembly.

2. Measure the resistance between the No. 1 terminal

(solenoid valve A) of the shift control solenoid valve

connector and body ground, and between the No. 3

terminal (solenoid valve B) and body ground.

STANDARD: 12 - 25 o

Replace the shift control solenoid valve assembly if

the resistance is out of sDecification.

lf the resistance is within the standard, connect the

No. 1 terminal of the shift control solenoid valve con-

nector to the battery positive terminal. A clicking

sound should be heard. Connect the No. 3 terminal to

the battery positive terminal. A clicking sound should

be heard. Replace the shift control solenoid valve

assembly if no clicking sound is heard.

J

1.0 mmN.m {1.2 kgf m, 8.7 lbf'ft)

\

^ ,, ..,'

UYM

6x't2

a

SOLENOID

v.

SHIFT CONTROLSOLENOID VALV€ A/BASSEMBLY

Replacement

Remove the mounting bolts and shift control sole-

noid valve ly'B assemblv.

NOTE: Be sure to remove or replace the shift con-

trol solenoid valves A and B as an assemblY.

Check the shift control solenoid valve fluid pas-

sages for dust or dirt, and replsce as an assembly, if

necessarv.

BRACKET

Clean the mounting surfaceand tluid passages.VALVE A/B ASSEMBLYFILTER/GASKETReplace.

Clean the mounting surfsce and fluid passages of

the shift control solenoid valve assembly, and

install a new shift control solenoid valve Ay'B with a

new filter/gasket.

Check the connector for rust, dirt or oil, and recon-

nect at securely.

14-88

Page 515 of 1681

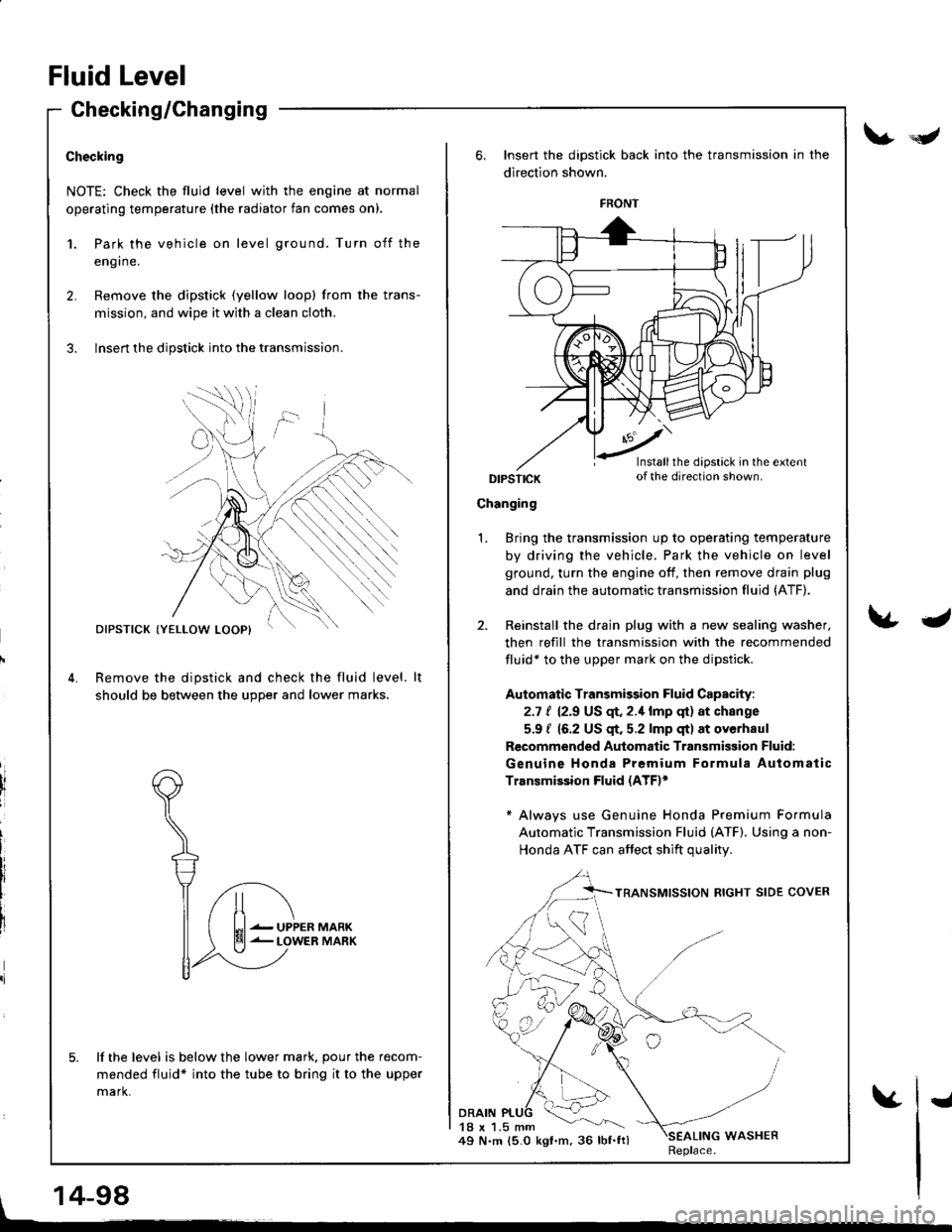

Checking/Changing

Checking

NOTE: Check the fluid level with the engine at normal

operating temperature (the radiator fan comes on).

1.

2.

Park the vehicle on level ground. Turn off the

eng I ne.

Remove the dipstick (yellow loopl from the trans-

mission, and wipe it with a clean cloth.

Insert the dipstick into the transmission.

Remove the dipstick and check the fluid level.

should be between the u9Der and lower marks.

lf the level is below the lower mark. pour the recom-

mended fluid* into the tube to bring it to the upper

mark.

DIPSTICK

UPPERLOWER

Insert the dipstick back into the transmission in the

direction shown.

DIPSTICK

Changing

DRAIN18 x 1.5 mm49 N.m 15.0 kgt.m, 36 lbf.ftl

Bring the transmission up to operating temperature

by driving the vehicle. Park the vehicle on level

ground, turn the engine off, then remove drain plug

and drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid* to the upper mark on the dipstick.

Automatic Transmission Fluid Capacity:

2.7 t 12.9 US qr,2.1lmp qt) at change

5.9 / 16.2 US $. 5.2 lmp qt) at overhaul

Recommended Automatic Transmisgion Fluid:

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATE*

* Always use Genuine Honda Premium Formula

Automatic Transmission Fluid (ATF). Using a non-

Honda ATF can affect shift qualitv

1.

WASHERReplace.

FRONT

Installthe dipstick in the extentof the direction shown.

Fluid Level

V*Y

\&J

, 14-98

vI

Page 521 of 1681

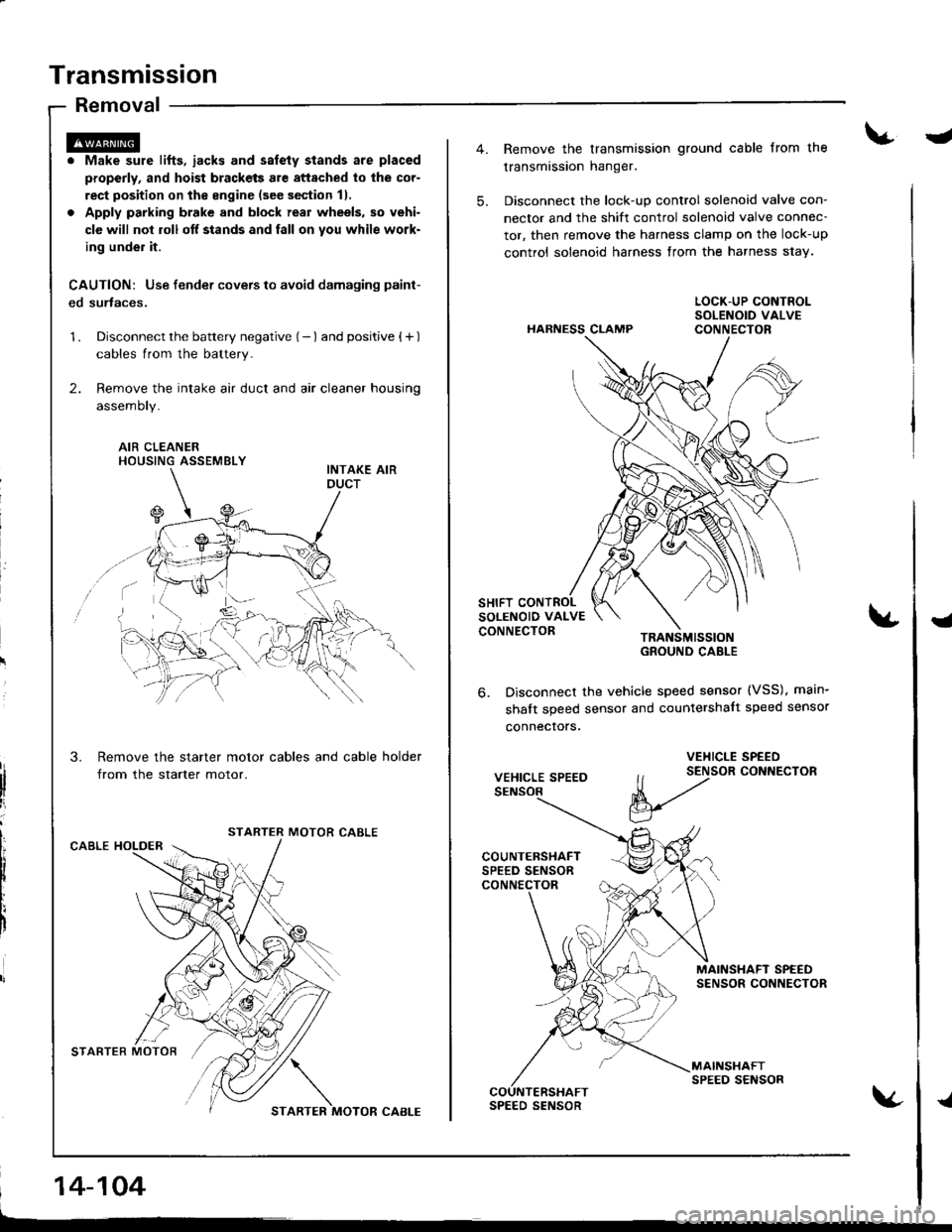

Transmission

Removal

. Make sure lifts, iacks and salety stands are placed

properly, and hoist brackets are attached to lhe cor-

rect position on the engine (see section 11.

. Apply parking brake and block real wheels, so vehi-

cle will nol roll off stands and fall on you while work-

ing under it.

CAUTION: Use fender covers to avoid damaging paint-

ed surtaces.

1 . Disconnect the battery negative (- ) and positive { + )

cables from the battery.

2. Remove the intake air duct and air cleaner housing

assemoty.

AIR CLEANERHOUSING ASSEMBLY

Remove the starter motor cables and cable holder

from the starter motor.

MOTOR CABLECABLE HOLDER

STARTER MOTOR'/,/ \

STARTER MOTOR CABI-E

14-104

-

5.

Remove the transmission ground cable from the

transmission hanger.

Disconnect the lock-up control solenoid valve con-

nector and the shift control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness s1ay.

HARNESS CLAMP

TRANSMISSIOIGROUND CABLE

Disconnect the vehicle speed sensor (VSS), main-

shalt speed sensor and countershalt speed sensor

connecrors.

{

6.

VEHICLE SPEED

VEHICLE SPEED

ll t2tor coNNEcroR

V

MAINSHAFT SPEEDSENSOR CONNECTOR

MAINSHAFTSPEED SENSORCOUNTERSHAFTSPEED SENSOR{

Page 554 of 1681

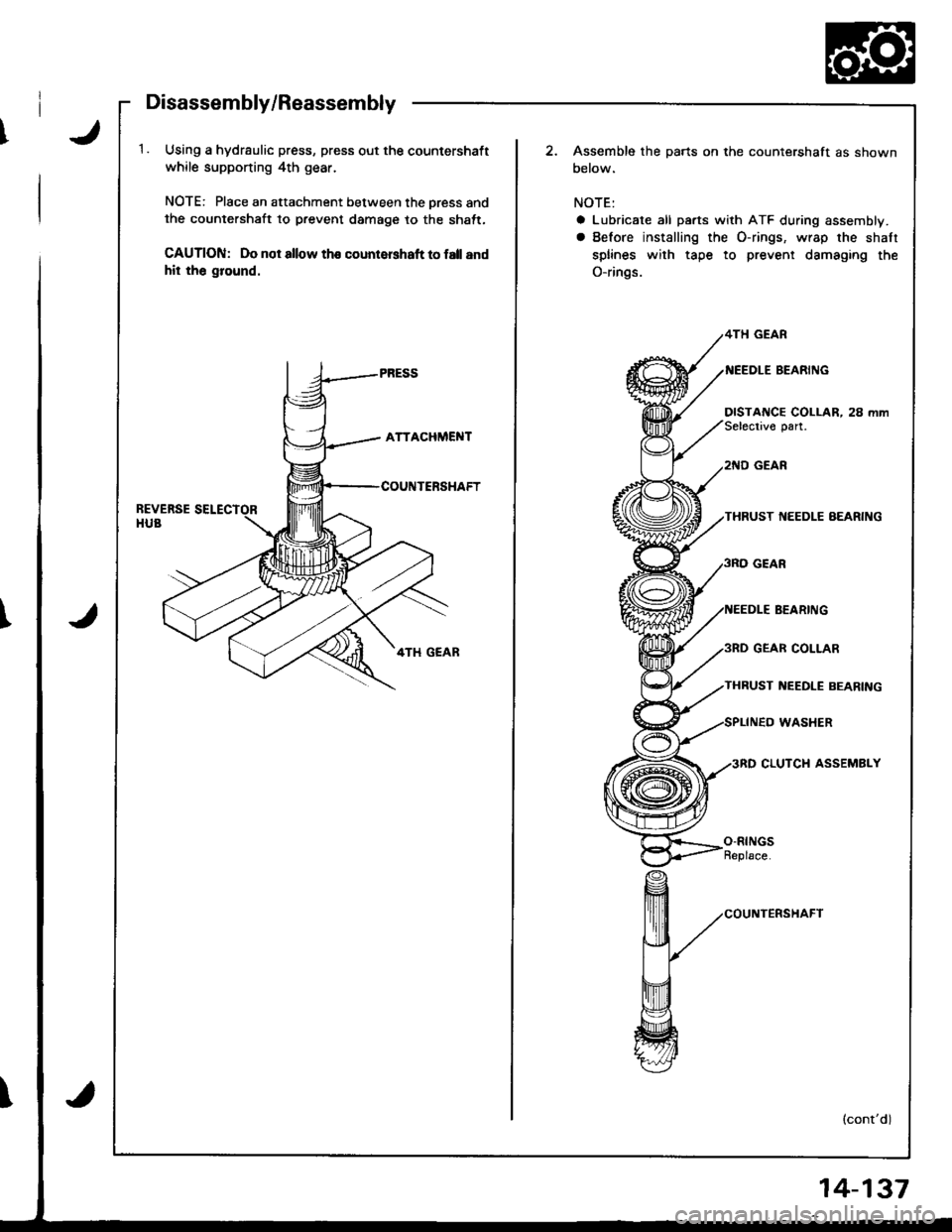

Disassembly/Reassembly

1. Using a hydrsulic press, press out the countershaft

while supponing 4th gear.

NOTE: Place an attachment between the oress andthe countershaft to prevent damage to the shatt,

CAUTION: Do not allow th€ count€rshaft to fall rnd

hit the ground.

T

T

2. Assemble the parts on the countershaft as shown

below.

NOTE:

a Lubricate all parts with ATF during assembly.

a Before installing the O-rings, wrap the shaft

splines with tape to prevent damaging the

O-rings.

'{EEDLE EEARIIIG

DISTANCE COLLAR, 28 mmSelectivo part.

THRUST NEEDLE BEARING

BEARING

GEAR COLLAR

TI{BUST NEEDLE BEARING

WASHER

CLUTCH ASSEMBLY

(cont'd)

14-137

Page 587 of 1681

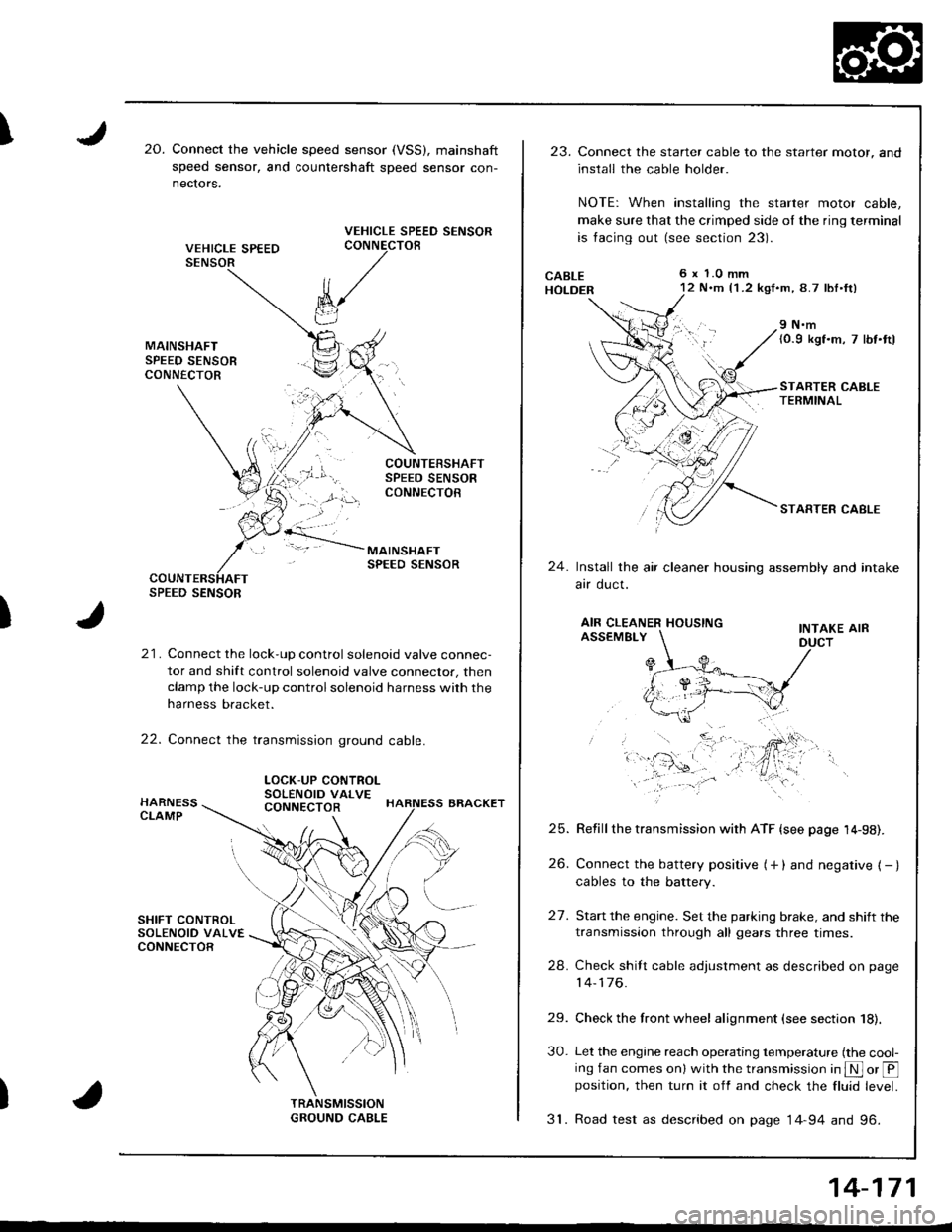

I20.Connect the vehicle speed sensor (VSS), mainshaft

speed sensor, and countershaft sDeed sensor con-

nectors.

VEHICLE SPEED SENSORCONNECTOB

)

k/

t"J

21. Connect the lock-up control solenoid valve connec-

tor and shift control solenoid valve conneclor, then

clamp the lock-up control solenoid harness with the

harness bracket.

22. Connect the transmission ground cable.

SPEED SENSOR

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

23.Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side ol the ring terminal

is facing out (see section 23).

6 x 1.0 mm12 N.m {1 .2 kgf.m, 8.7 lbl.ft)

9 N.m(0.9 kgf.m, 7 lbt.ttl

STARTER CABLETERMINAL

STARTER CABLE

24.Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGINTAKE AIRASSEMBLY

27.

Refill the transmission with ATF {see page 14-98).

Connect the battery positive (+ ) and negative { - }cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shilt cable adjustment as described on page

14-176.

Check the front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-ing fan comes onl with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-94 and 96.

25.

26.

24.

29.

30.

14-171

Page 717 of 1681

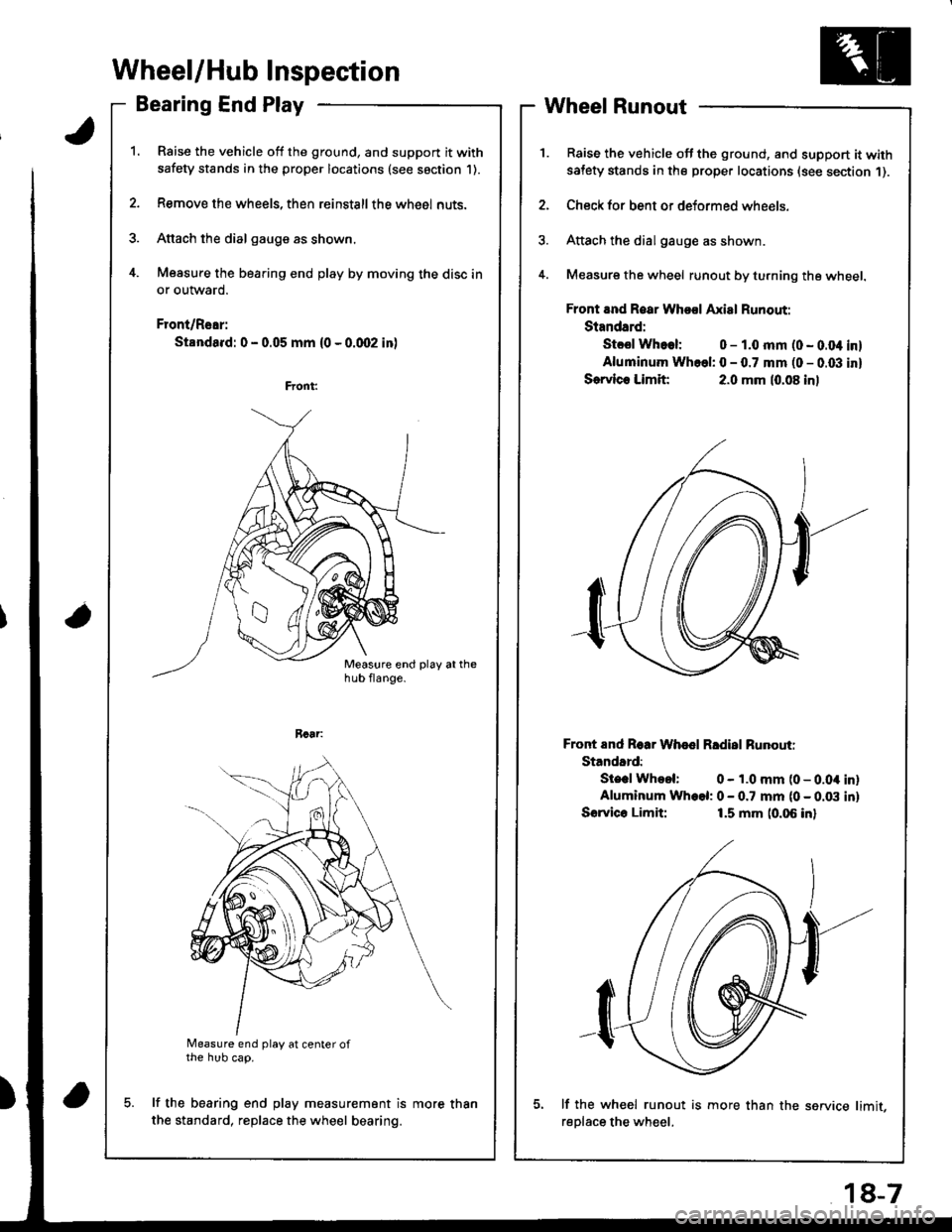

Wheel/Hub Inspection

Bearing End Play

Raise the vehicle off the ground, and support it with

safety stands in the proper locations (see saction 1).

Remove the wheels, then reinstallthe whe6l nuts.

Attach the dial gauge as shown.

Measure the bearing end play by moving the disc in

or outward.

Front/Rear:

Standa.d: 0 - 0.05 mm (0 - 0.qr2 in)

a

Measure end play at center ofthe hub cap.

lf the bearing end play measurement is

the standard, replace the wheel bearing.

Wheel Runout

Raise the vehicle off the ground, and support it withsatety stands in the proper locations (see section 1).

Check for bent or deformed wheels.

Attach the dial gauge as shown.

Measure the wheel runout by turning the wheel.

Front and Roar Whool Axial Runout:

Standard:

Stcsl Whoel: 0 - 1.0 mm (0 - 0.04 inl

Aluminum Whcel: 0 - 0.7 mm (0 - 0.03 inl

Sorvlc. Limit:2.0 mm (0.08 inl

Front End Roar Whod Rldisl Runouti

Standard:

Ste.l Whool: 0 - 1.0 mm (0 - 0.04 inlAluminum Wh.el: 0 - 0.7 mm (0 - 0.03 inl

Sorvico Limit:1.5 mm (0.06 inl

lf the wh€el runout is more than the service limit,

reDlace the wheel.

more than

18-7

Page 718 of 1681

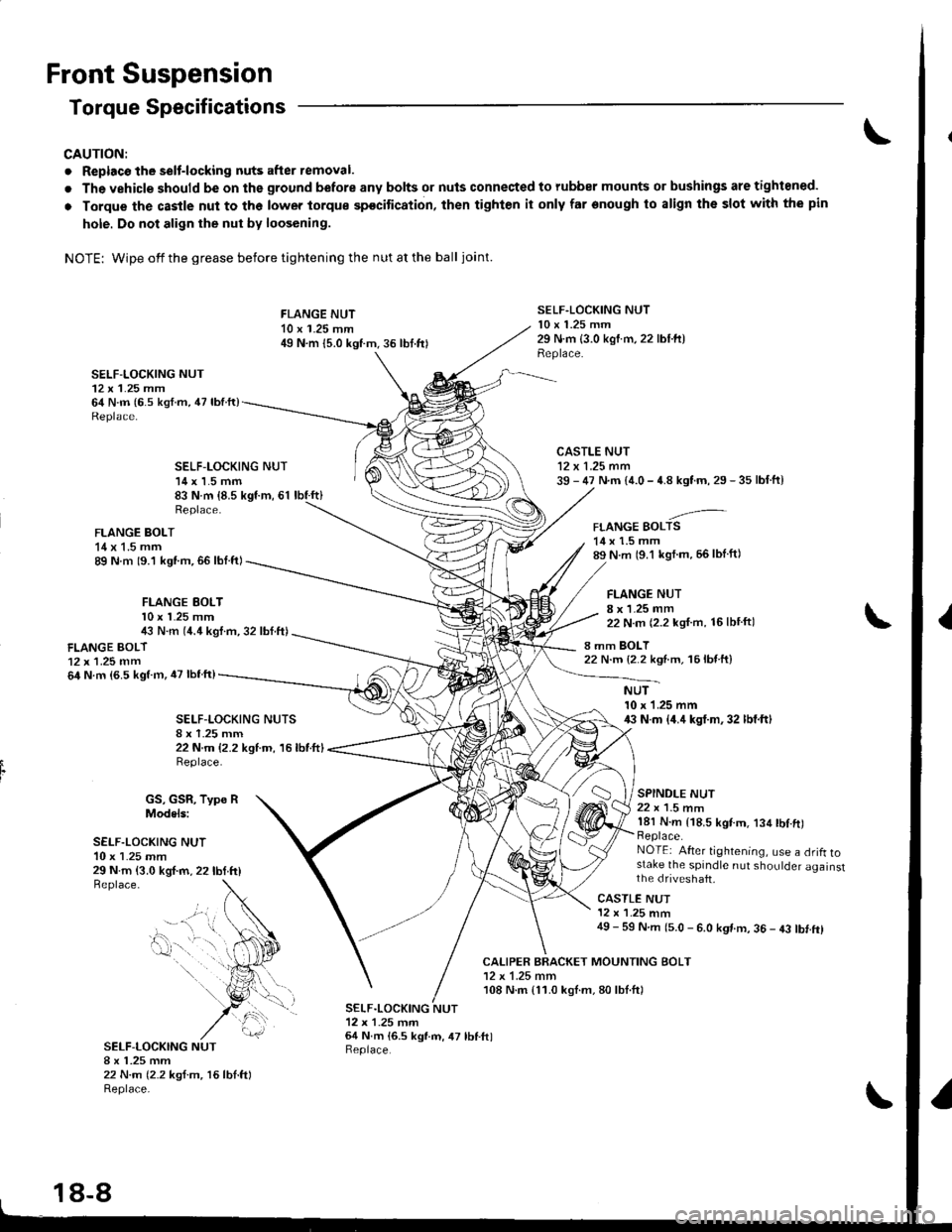

Front Suspension

Torque Specifications

CAUTION:

. Replacc the selt-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuls connected to rubber mounts or bushings are tightoned.

o Torque thc castle nut to the lower torque spocitication, then tighten it only far onough to align the slot with the pin

hole. Do not align the nut bv loosening.

NOTE: Wipe offthegrease before tightening the nutatthe ball joint.

SELF-LOCKING NUT12 x 1.25 mm64 N.m (6.s ksf.m, 47 lbfft)

FLANGE NUT10 x 1.25 mm49 N.m {5.0 kgtm.36 lbt.frl

SELF.LOCKING NUT10 x 1.25 mm29 N.m {3.0 kgtm,22 lbl.ft)Replace.

CALIPER BRACKET MOUNTING BOLT12 x 1.25 mm108 N.m {11.0 kgl.m,80lbl.ftl

SELF-LOCKING NUT14 x 1.5 mm83 N.m {8.5 kgf.m, 61 lbf.ft}

CASTLE NUT12 x 1.25 mm39 - 47 N.m {4.0 - 4.8 kgtm, 29 - 35 lbf.ft}

-'-FLANGE BOLTS14 x 1.5 mm89 N.m (9.1 kgl m, 56lblft)

FLANGE NUT8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbtftl

8 mm BOLT22 N.m {2.2 ksnm, 16lb{ ft}

Replace.

FLANGE BOLT14 x 1.5 mm89 N m 19.1 kgt.m,66 lbl.ftl

FLANGE EOLTl0 x l�25 mm4i, N.m (4.4 kgl.m, 32 lbf.ft)

FLANGE BOLT12x 1.25 mm64 N.m (6.5 kgtm, iU lbfftl

SELF-I-OCKING NUTS

22 N.m {2.2 kgtm, 16lbtftlReplace.

NUT10 x 1.25 mm43 N.m {4.4 kgt.m,32 lbf.ftl

SPINDLE NUT22 x 1.5 nm181 N.m {18.5 kgtm. 134 tbl.ft)Replace.NOTEi After tightening, use a drifl tostake the spindle nut shoulder againstthe dfiveshaft,29 N.m {3.0 kgf.m, 22lbtttlBeplace.

GS, GSR, Type RModels:

SELF.LOCKING NUT10 x 1.25 mm

SELF-LOCKING NUTI x 1.25 mm22 N.m (2.2 ksf.m, 16lbl.ftlReplace-

CASTLE NUT12 x '1.25 mm49 - 59 N.m (5.0 - 6.0 kgt m, 36 - 43 tbt.ftl

SELF.LOCKING NUT12x 1-25 tnrn64 N.m 16.5 kgl.m, 47 lbf.ftlReplace.

- --.." t,..

0-. .

18-8

Page 731 of 1681

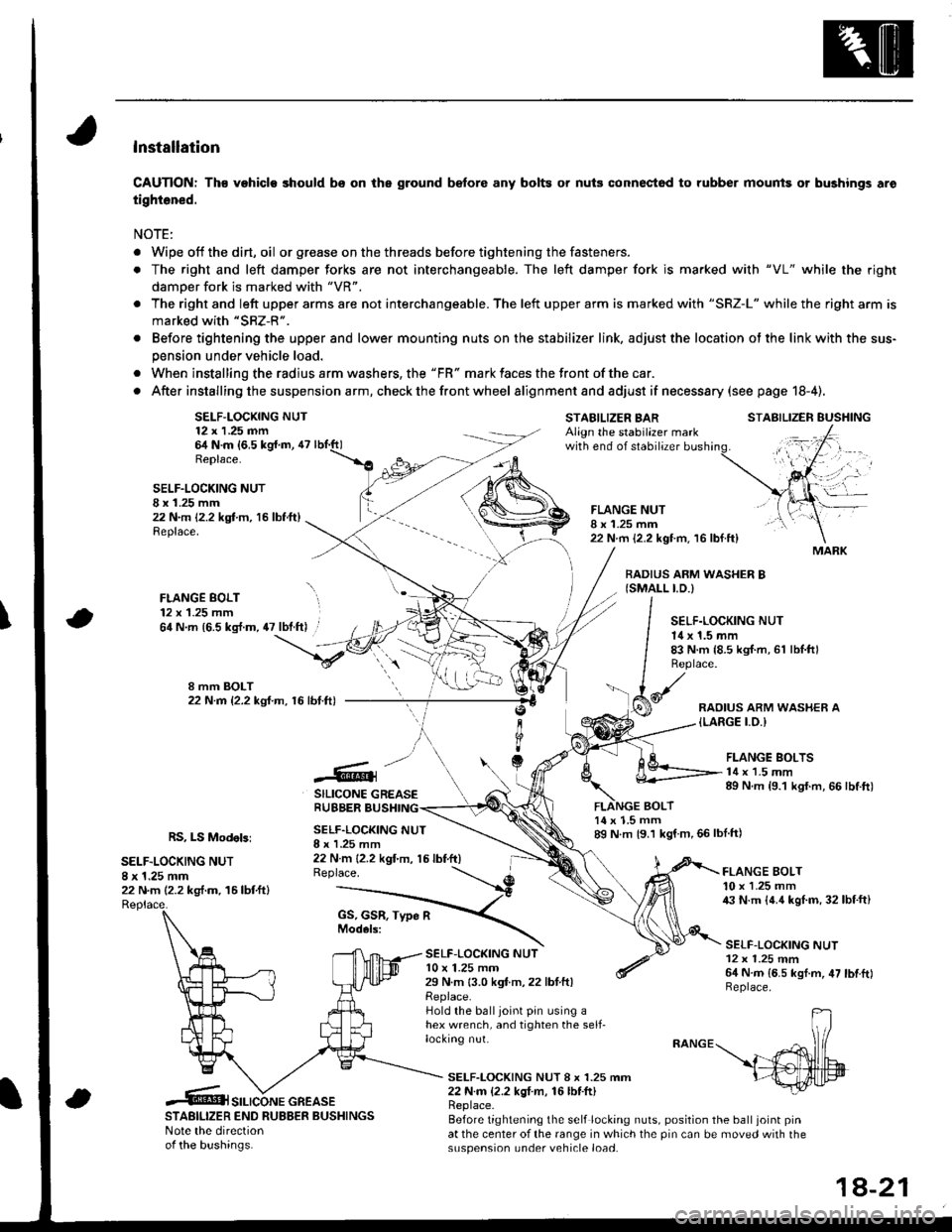

lnstallation

CAUTION: Th€ vehiclo should bs on the ground b€fore any bolts or nuis connectod to rubber mounis or bushings aro

tightened.

NOTE:

. Wipe off thedirt,oil or gr€ase on the threads before tightening the fasteners.

. The right and left damper forks are not interchangeable. The left damper fork is ma.ked with "VL" while the righr

damoer fork is marked with "VR".

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SRZ-L" while the right arm is

marked with "SRZ-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adjust the location ot the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front ofthe car.

. After installing the suspension a rm, check the front wheel alignmentand adjust if necesssry (see page 18-4).

SELF-LOCKING NUT12 x 1.25 nn64 N.m {6,5 kg{.m, 47Replace.

STABILIZER BARAlign the stabilazer markwith end of stabilizer

BOLT

STABILIZER EUSHING

SELF.LOCKING NUTI x 1.25 mm22 N.m 12.2 kgt m, 16 lbf.ft)Replace.

FLANGE BOLT12 x 1.25 mm

FLANGE NUTI x 1.25 mm22 N.m {2.2 kgt m. 16 lbf.ft}

BADIUS ARM WASHER B{SMALL I.D.)

\64 N.m {6.5 kg{.m, 47 lbt.ft) .SELF.LOCKING NUT14 x 1.5 mm83 N.m {8.5 kgI.m, 61 lbl.ftlReplace.

RAOIUS ARM WASHER A{LARGE I.O.I

.@]

SILICONE GREASERUBBER BUSHING

FLANGE BOLTS14 x 1.5 mm89 N.m {9.1 kgf.m, 66 lbtft)

RS, LS Modebi

SELF.LOCKING NUT8 x 1.25 mm22 N.m (2.2 kg,f.m. 16lbtftl

SELF.LOCKING NUTI x I .25 mm22 N m {2.2 kgt'm, 15 lbf.ft)Replace.

14 x 1.5 mm89 N m {9.1 kgf m,66lblft)

SELF-LOC(ING NUTl0 x 1.25 mm29 N.m 13.0 kgf.m,22 lbtftlReplace.Hold the balljoint pin using ahex wrench, and tighten the self-locking nut.

FLANGE BOLT10 x 1.25 mm43 N.m {4.4 kgl.m, 32lbf.ft}

SELF-LOCKING NUT12 x 1.25 mm64 N.m {6.5 kgf.m, 47 lbtftlReplace.

SELF-LOCKING NUT 8 x 1.25 mm22 N.m {2.2 kgI m, 16lbf.ft)

STABILIZER END RUBBER BUSHINGSNote the directionof the bushinas.

Replace.Before tightening the self locking nuts, position the ball joint pinat the center of the range in which the pin can be moved with thesuspension under vehicle load.

MARK

SILICONE GREASE

1A-21

Page 736 of 1681

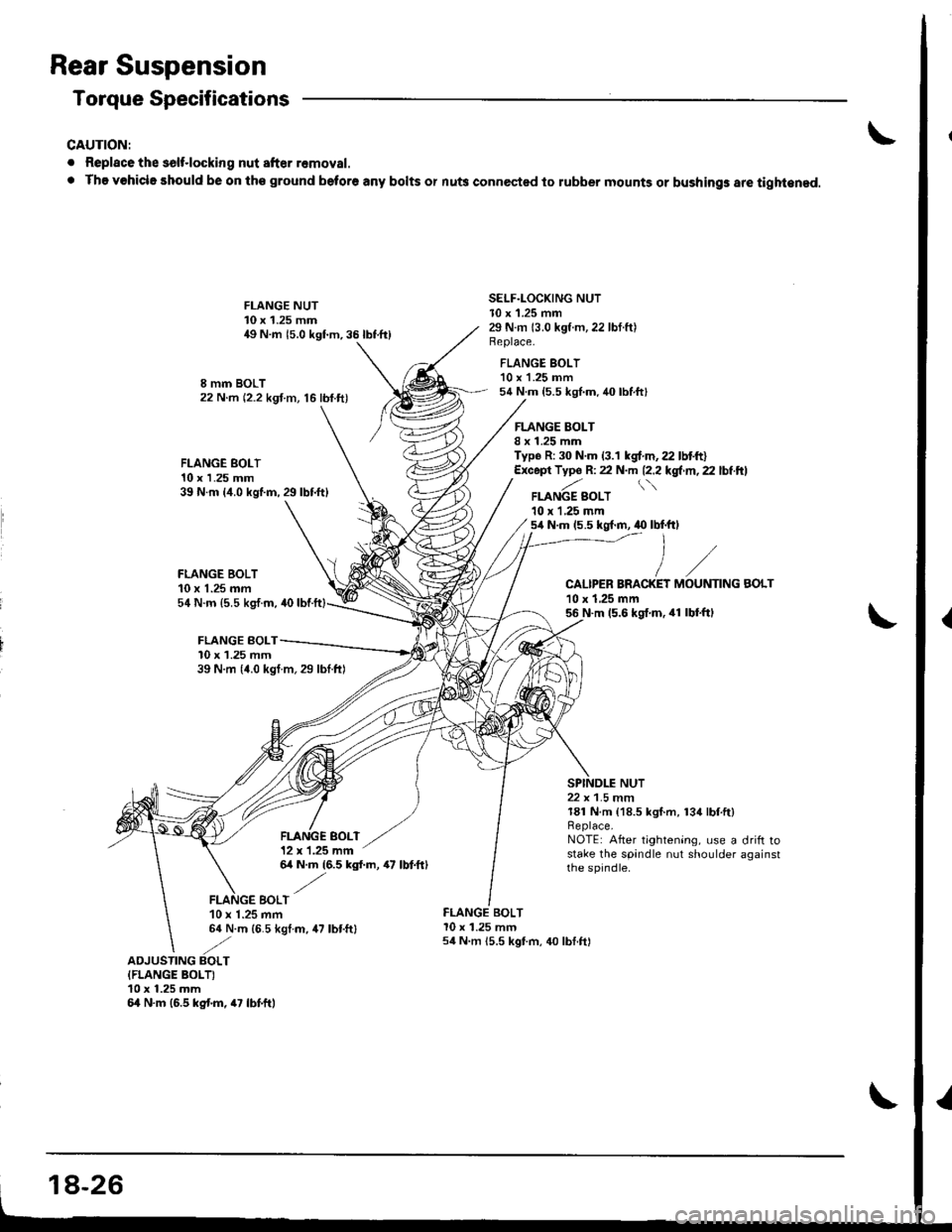

Rear Suspension

Torque Specifications

CAUTION:

. Replace the solt.locking nut after removal.

. The vohicle should be on th€ ground beto.6 any bolts or nu$ connected to lubber mounts or bushings are tight€ned.

FLANGE BOLT10 x 1.25 mm39 N.m {4.0 kgl.m,29lbtft}

FLANGE BOLT10 x 1.25 mm54 N.m (5.5 kg,f.m, 40

FLANGE BOLT10 x 1.25 mm

I mm BOLT22 N.m (2.2 kgf m, 16 lbf.ft)

FLANGE NUT10 x 1.25 mm49 N.m 15.0 kgf.m,35lbtft)

FLANGE SOLT12 x 1.25 mm

SELF.LOCKING NUTl0 x 1.25 mm29 N.m 13.0 kgt.m,22 lbf.ft)Beplace.

FLANGE BOLT'10 x 'l.25 mm54 N.m {5.5 kgl.m.40 lbtft}

FLANGE BOLTI x 1.25 mmTyp6 R: 30 N.m (3.1 kgf.m,22 lbtft)Except Typ6 R: 22 N.m 12.2l'gl'rn,2.lbiftl

FLANGE SOLT10 r L25 mm5,1N.m (5.5 kg{.m, .0 lbf.ftl

CALIPER BRACKET10 x 1,25 mm56 N.m (5.6 kgf.m. 41 lbl.ftl

NUT

MOUNTING

39 N.m 14.0 kgl m,29 lbtftl

BOLT

22 x 1.5 mm181 N.m {18.5 kgf.m, 134lbf.ft}Replace,NOTE: After tightening, use a drift rostake the spandle nut shoulder againstthe spjndle.64 N.m (6.5 kgl.m, 47 lbtftl

EOLT10 x 1.25 mm64 N.m (6.5 kgl.m, 47 lbtftl

FLANGE BOLTl0 x 1.25 mm54 N m 15.5 kgt m, 40 lbf.ft)

ADJUSTING BOLTIFLANGE BOLTI10 x 1.25 mm64 N.m (6.5 kg{.m, 47 lbf.ft,

18-26