ground HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 466 of 1681

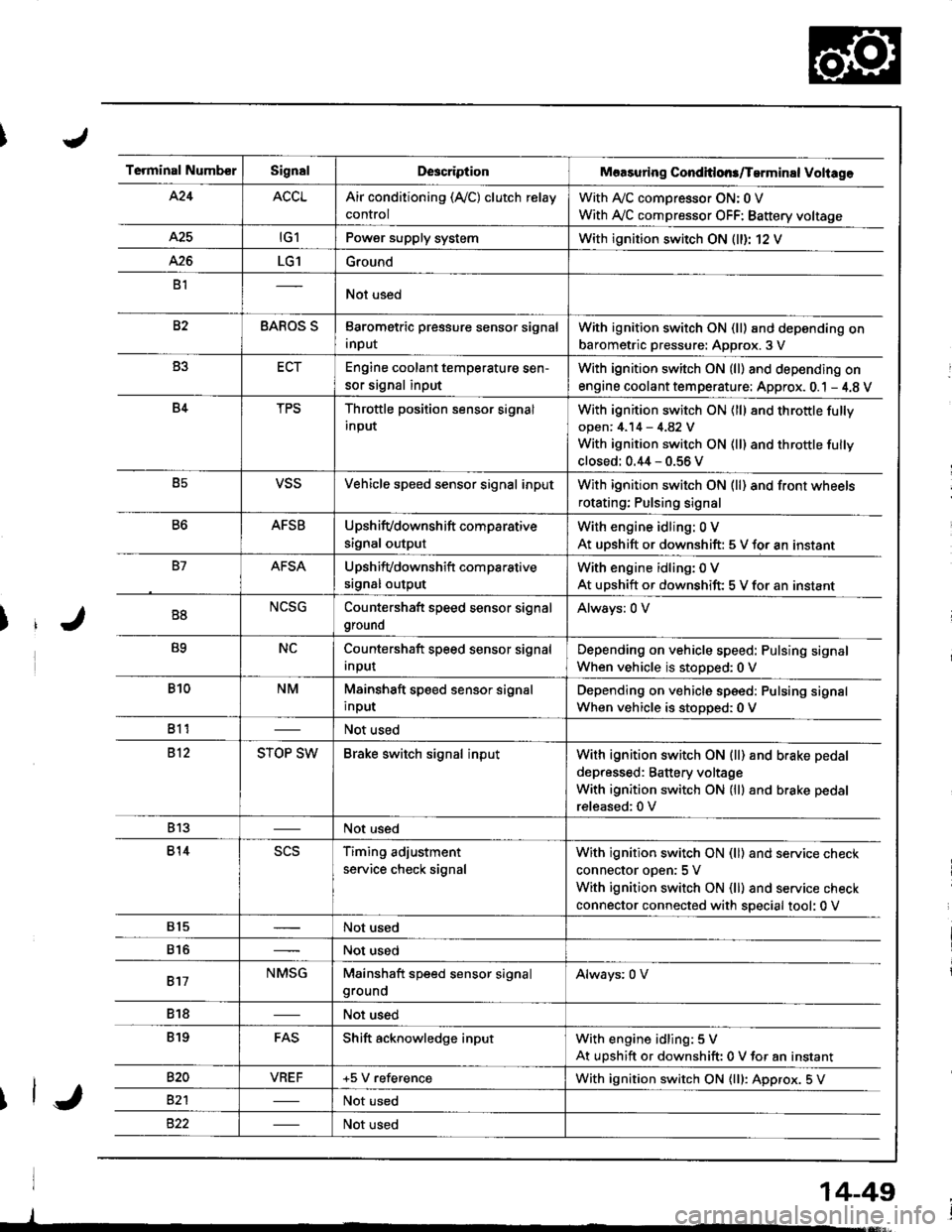

Terminal NumberSignalDescriptionMaasuring Conditlons/Tarminal Voliage

424ACCLAir conditioning (Ay'C) clutch relay

control

With A,/C comDressor ON: 0 V

With Ay'C compressor OFF: Battery voltage

A25tG1Power supply systemWith ignition switch ON (ll)r 12 V

426LG1Ground

B1Not used

82BAROS SBarometric pressure sensor signal

input

With ignition switch ON (ll) and depending on

barometric pressure: Approx. 3 V

B3ECTEngine coolant temperature sen-

sor signal input

With ignition switch ON (ll) and depending on

engine coolant tem perature: Approx. 0.1 - 4.8 V

B4TPSThrottle position sensor signal

input

With ignition switch ON (ll) 8nd throttle fully

open: 4.14 - 4.82 V

With ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

B5VSSVehicle speed sensor signal inputWith ignition switch ON (ll) and front wheels

rotating; Pulsing signal

B6AFSBUpshifvdownshift comparative

signal output

With engine idling: 0 V

At uDshift or downshift: 5 V for an instant

B7AFSAUpshifvdownshift com parative

srgnal output

With engine idling: 0 V

At upshift or downshift: 5 V for an instant

B8NCSGCountershaft speed sensor signal

ground

Always: 0 V

B9NCCountershaft speed sensor signal

Input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped:0 V

B10NMMainshaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stoDoed: 0 V

811Not used

812STOP SWBrake switch signal inputWith ignition switch ON {ll) and b.ake pedal

depressed: Battery voltage

With ignition switch ON (lll and brake pedal

released:0 V

813Not used

814scsTiming adjustment

service check signal

With ignition switch ON (ll) and service check

connector oDen:5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

815Not used

816Not used

817NMSGMainshaft speed sensor signalgroundAlways: 0 V

818Not used

819FASShift acknowledge inputWith engine idling: 5 V

At upshift or downshift: 0 V for an instant

820VBEF+5 V referenceWith ignition switch ON {lll: Approx. 5 V

82'lNot used

Not used

14-49

Page 476 of 1681

\/

J

14-59

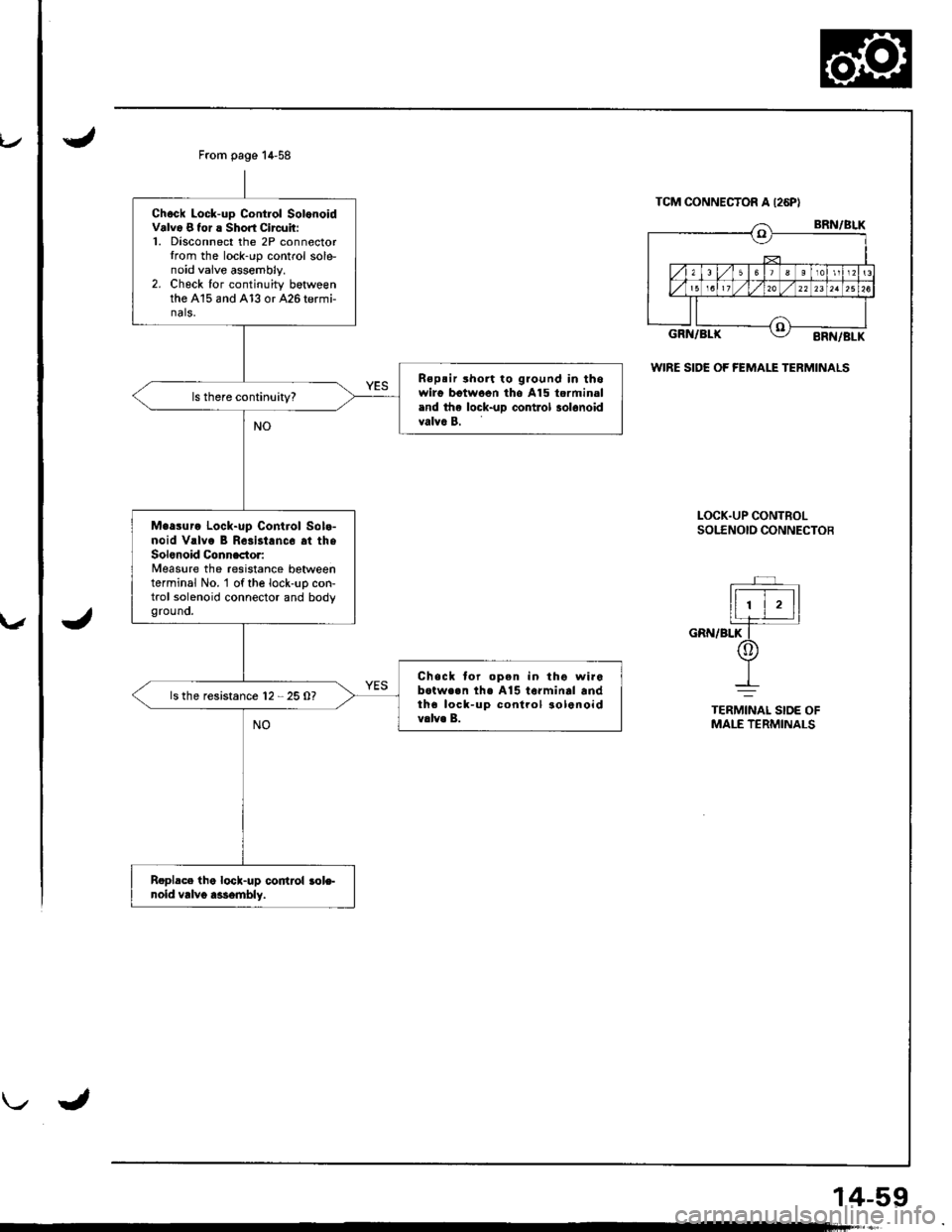

From page 14-58

Chock Lock-up Contlol SolonoidValv6 8 tor ! Short Circuit:1. Disconnect the 2P connectorIrom the lock-rrp control sole-noid vaive assembly.2. Check for continuity betweenthe A15 and A13 or 426 termi-nals.

Rspsir rhort to ground in thowirg bgtwoen tho A15 torminaland the lock-uD control 3ol6noidvalva B.

Maasuro Lock-up Control Sola-noid V.lvo B Rosist.nc6 at theSolonoid Connactor:Measure the resistance betweenterminal No. 'l of the lock-uo con-trol solenoid connector and bodygrouno.

Chack tor open in tho wir6botwe.n th€ A15 to.minal andtha lock-up conlrol aolenoidv.lv. B.

ls the resistance 12 - 25 O?

Roplace lhe lock-up codrol role-noid vrlvo a$embly.

TCM CONNECTOR A I26PI

WIRE SIDE OF fEMALE TERMINALS

LOCK.UP CONTBOLsotf Noto coNNEcToB

r '

ll ' | , llIr_e_rtjl

cnrurefiT-/Or

-L--=

TERMINAI SIDE OFMALE TERMINALS

Page 484 of 1681

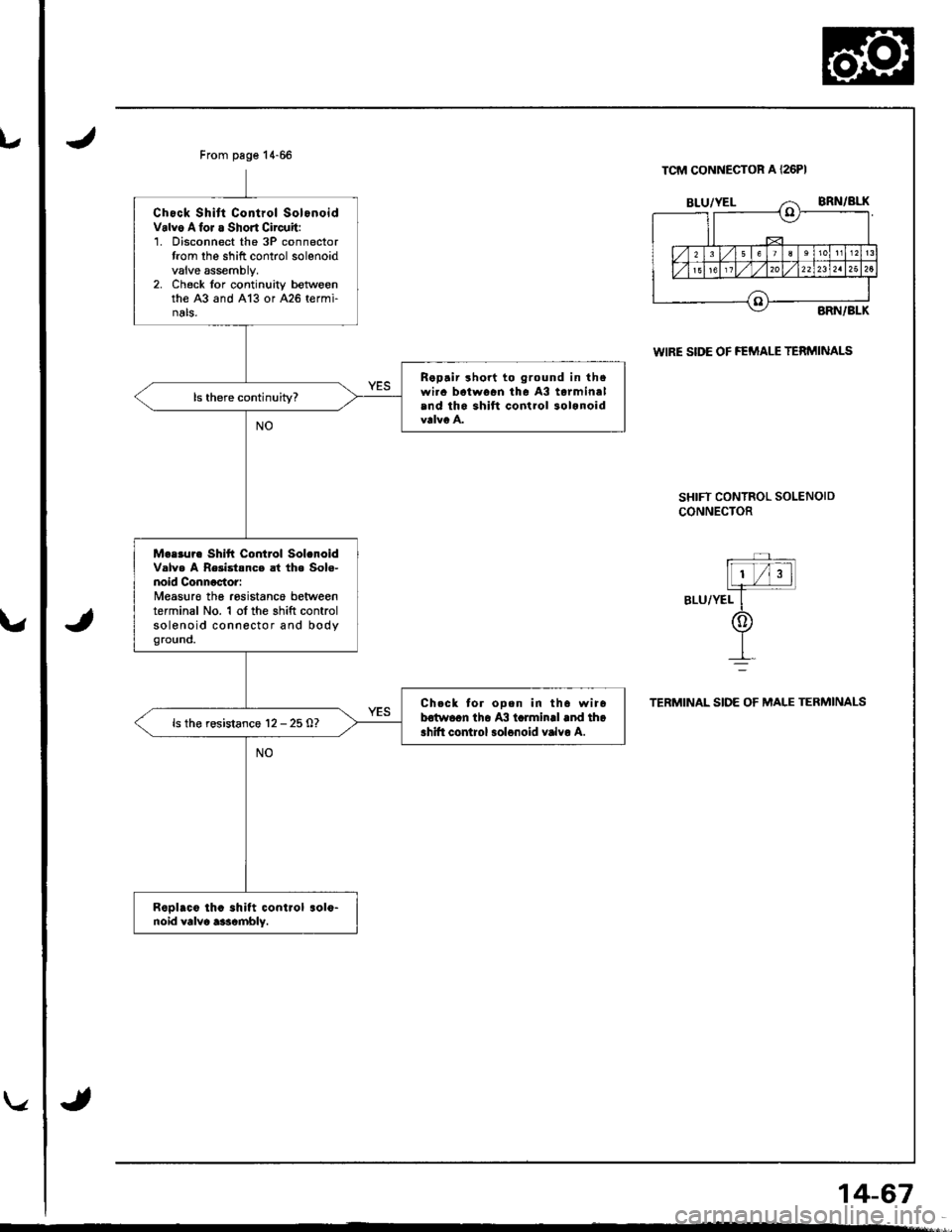

From pege 14-66

Chock Shitt Control SolonoidValvo Alor a Short Circuit:1. Disconnect the 3P connectortrom lhe shift control solenoidvalve assembly,2. Check lor continuity betwoenthe A3 and A13 or A26 termi-nals,

Rapair sho.t to ground in thswi.c batwocn tha A3 torminalind th6 shift control 3olanoid

Mearur. Shitt Control Sol.noidValv. A Re3istsnce at th. Sol€-noid Connactor:Measur€ the rosistance betweenterminal No. 1 of the shift controlsolenoid connector and bodyoround.

Chcck tor ooen in th6 wir6betwocn the A3 tclminll .nd tho.hift control 3ol6noid vrlvo A.ls the rosistsnce 12 - 25 0?

Repl.c6 th. .hltt control .016-noid valvo aarcmbly.

TCM CONNECTOR A I26PI

WIRE SIDE OF FEMALE TERMINALS

SHIFT CONTROL SOLENOID

CONNECTOR

Ll /i3 tL

ar-urvelf-

@

IL--

TERMINAL SIDE OF MALE TERMINALS

14-67

Page 486 of 1681

u

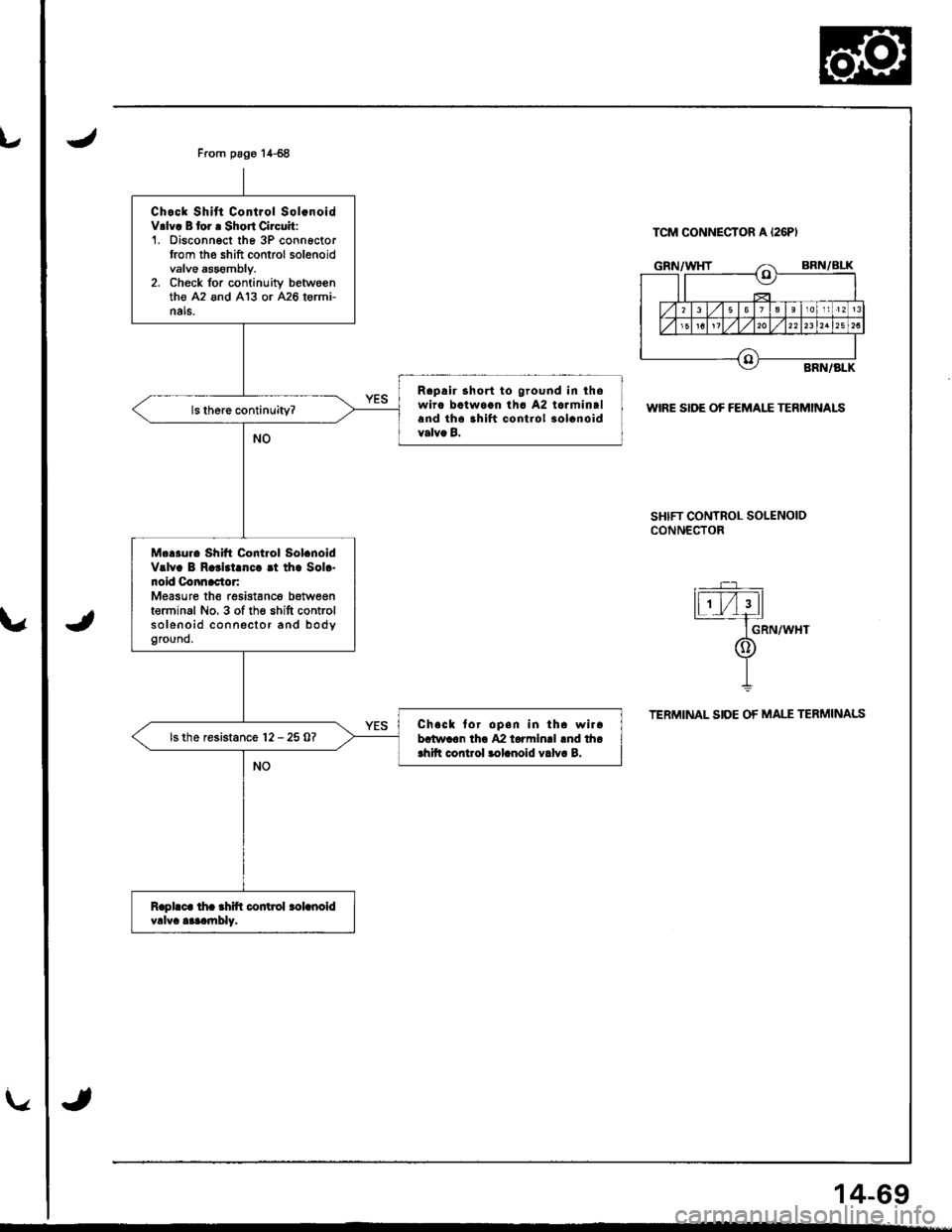

From pag€ 14-68

Chock Shitt Control Sol.noidV.lv! B tor r Short Circuit:1. Disconngct th6 3P connoctortrom the shift control solenoidvalve sssombly.2. Check for continuitv betwo€nth€ A2 and 413 or 426 tormi-nals.

Rapalr lhort to ground in ihowirc batwoan lhc A2 tarminaland th6 ihlft control 30lcnoidvalva B.

M...ur. Shift Control Sol.noidValv. B R.rid.[c. rt tha Sol.-noid Connactor:Measure the resistanc6 betweenterminal No, 3 of th€ shitt controlsolenoid connector and bodyground,

Ch.ck for open in lh. wi..batwaon th6 42 torminrl rnd thoahitt control lolanoid valva B.

ls the resistance l2 - 25 0?

TCM CONNECTON A I26PI

WIRE SIDE OF FEMALE TERMINALS

SHIFT CONTROL SOLENOIDCONN€CTOR

GRN/WHT

TERMINAL SIDE OF MALE TERMINALS

14-69

Page 487 of 1681

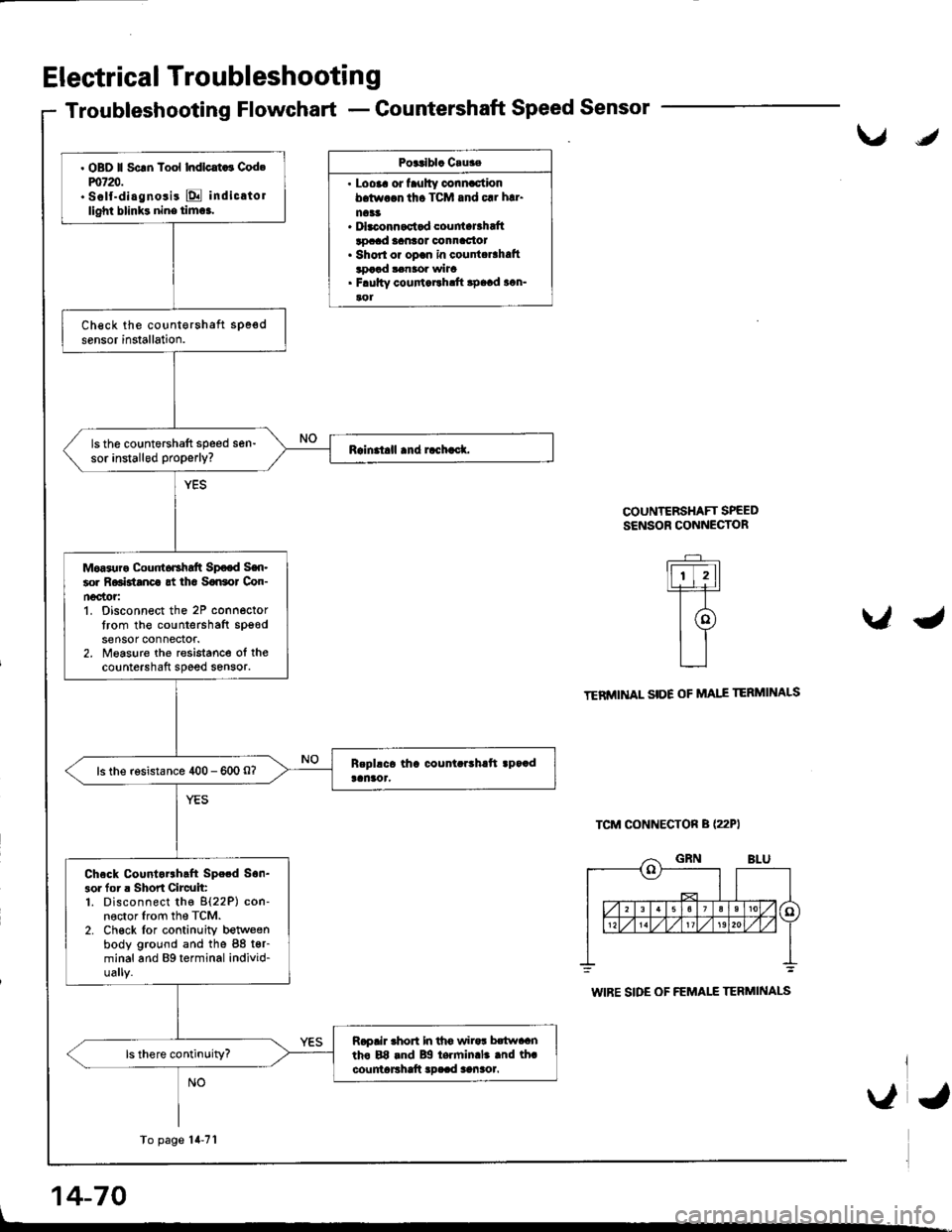

Electrical Troubleshootin g

Troubleshooting Flowchart - Countershaft Speed Sensor

Posalbla Cruae

. Loora or faulty connactionb.tw.$ tho TCM and 61 h!1.

na33. Dbconnactad couniaBhaftlocad lantot oonnac{ot. Shorl or opan in counta6hatttDaad $naor wha. F.ultv coufiaEh.ft apaad acn-aol

COUNTERSHAFT SPEEDSENSOR CONNECTOR

\IJ

U\lO

.-_

lfr-trtlL+l-r-T-

t@tl

L__l

TENMINAL SIDE OF MAIE

TCM CONNECTON B (22PI

TERMINALS

L

14-70

WIBE SIDE OF FEMALE TERMINALS

. OBD ll Scrn Tool Indlcat ! Cod.m720.. Self-diagnosis E indicatollighl blinks nine tim6.

ls the countershaft speed sen-sor installed properly?

Moas{ra Cour 6Ghaft Sp€od Sen-60r R6Btanca gt iha SaGol Con-n€c'tor:1. Disconnect the 2P connectortrom the countershafl spgodsensor connectof.2. Measure the resistance ol thecountershaft speed sensor.

ls the rosistance 400 - 600 O?

Check Countorrhcft Spe.d Son-3ol for r Shon Circuit:1. Disconnect the 8{22P) con-nector lrom the TCM.2. Ch€ck lor continuity betweenbody ground and the 88 t€r-minal and Bg terminal individ-ually.

Rapair rhon In th6 wiro! hwaantho E8 rnd Bg te.min.l. .nd th.countaFhaft !D..d aanaol.

To page'14-71

\,a,

Page 492 of 1681

v

u

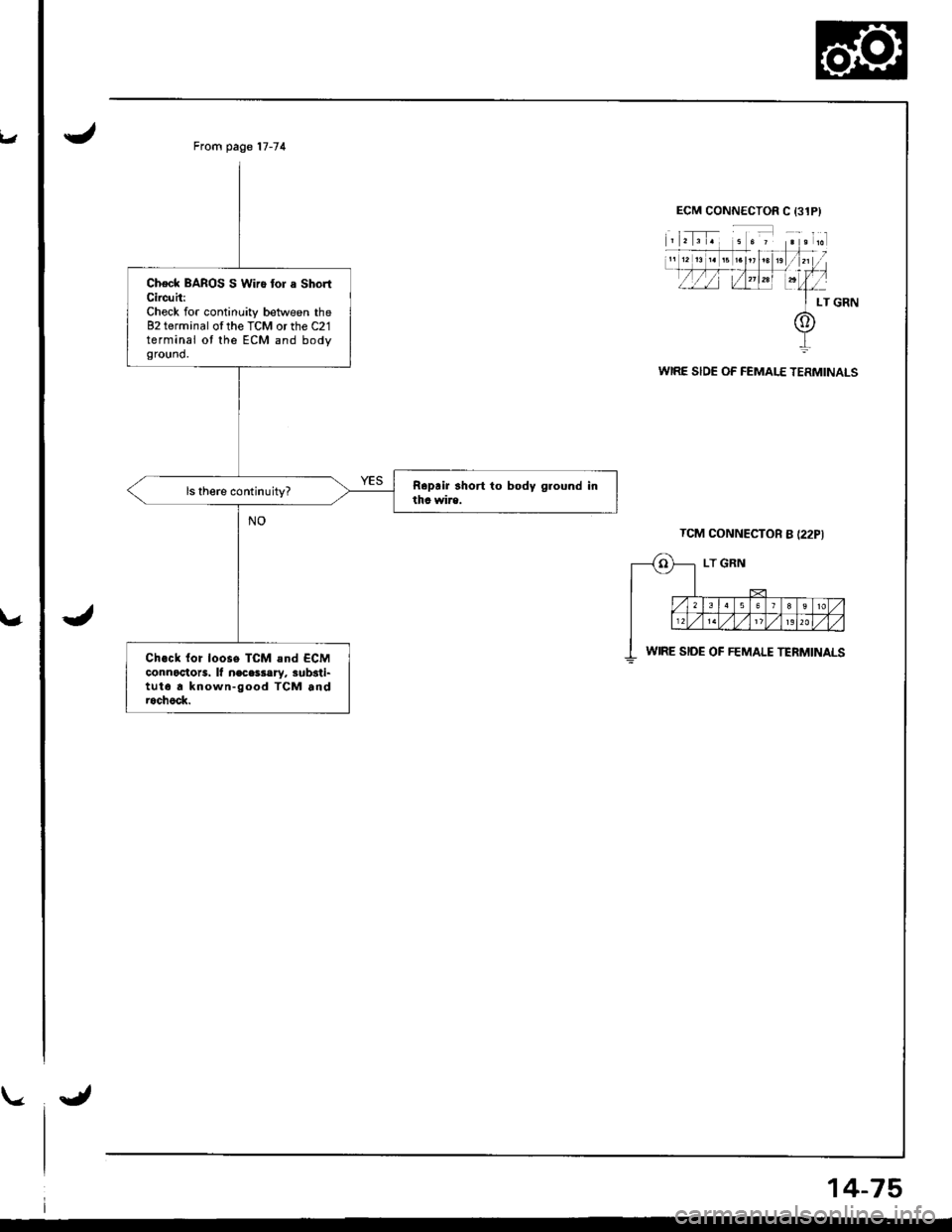

From page 17-74

Check BAROS S Wiro tor a ShortCircuh:Check for continuity between the82 terminal ofthe TCM or the C21terminal ot the ECM and bodyground.

Ch.ck {or loose TCM and ECMconnoctots. lf n€cessary, sub3ti-tut6 a known-good TCM androchock.

WIRE SIDE OF FEMALE TERMINALS

TCM CONNECTOR B {22PI

WIRE SIDE OF FEMALE TERMINALS

14-75

Page 494 of 1681

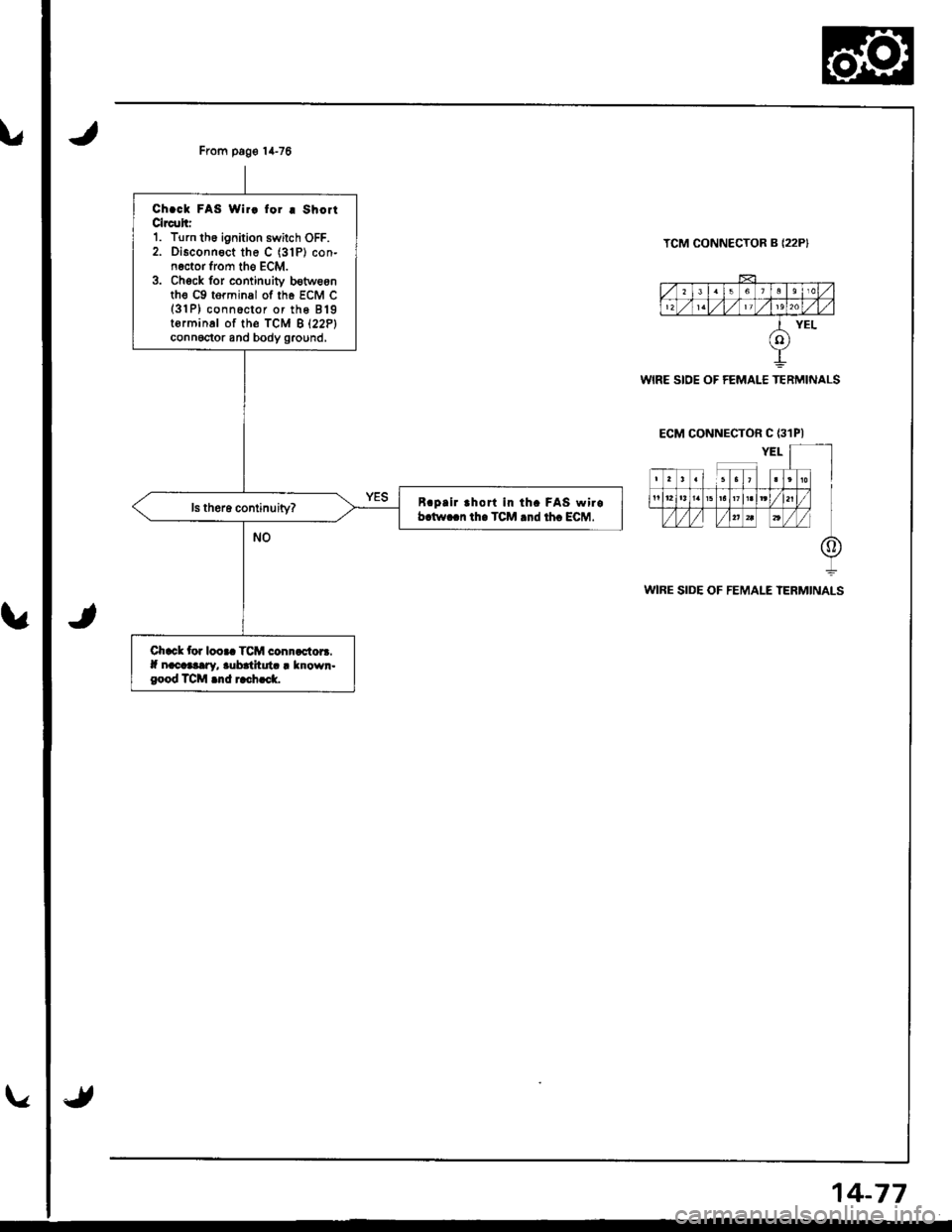

From pag€ 14-76

Ch.ck FAS Wir! for I ShoitClrc!hr1. Turn th6 ignition swilch OFF.2. Disconnect the C (31P) con-n€ctor from tho ECM.3. Chock for continuiv b€tweonth€ c9 torminal of th6 EcM c(3'lP) conn6ctor or the 819torminal of th€ fcM B l22Plconnoctor and body ground,

B.pllr rhort in th. FAS wirob.tw..n th. TCM .nd th. ECM.

Chack tor looaa TCM connactora.lf nacaaary, aubatltuta I known.good TCM .nd rach..k.

TCM CONNECTOR B {22P}

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR C {31PI

WIRE SIDE OF FEMALE TERMINALS

14-77

Page 495 of 1681

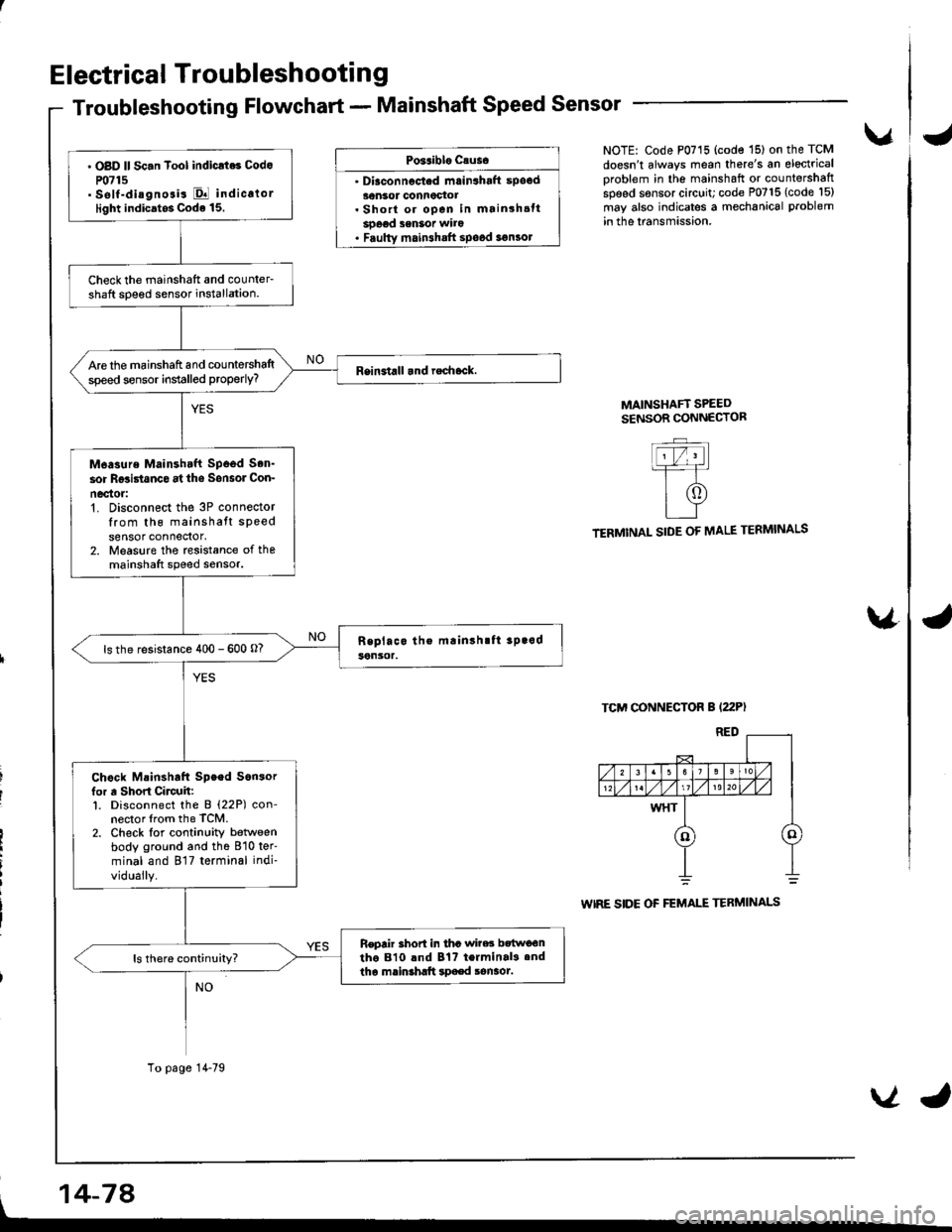

Electrical Troubleshootin g

Troubleshooting Flowchart - Mainshaft Speed Sensor

Po3aiblo causo

' Diaconnocted mrin3haft spocd30nsor connoctot. Short or open in mainshsttsoeod senSot wito. Faulty main3halt spood 3€n3ol

vNOTE: Code P0715 (code '15) on the TCM

doesn't always mean there's an electrical

oroblem in the mainshaft or countershaftspeed sensor circuit; code P0715 (code l5)

may also indicates a mechanical problem

in the lransmission.

MAINSHAFT SPEEDSENSOR CONNECTOR

TERMINAL SIDE OF MALE TERMINALS

TCM CONNECTOR B (22P)

WIRE SIDE OF FEMALE TERMINALS

\4

' OBD ll Sc.n Tool indicrt6 Codo

P0715' self-diagnosis El indicalorlight indicatos Code 15.

Check the mainshatt and counler-shaft soeed sensor installation.

Are the mainshaft and countershaltspeed sensor installed properly?

M6asure Mainshtft Spood Son'

sor Rgsi5tanco at ths Sonsol Con-

nec'tor:'t. Disconnect the 3P connectorIrom th6 mainshatt speedsensor connedor,2. Measure the rcsistance of themainshaft speed sensor.

ls the resistance 400 - 600 o?

Chock Mainshaft Speed Son3orfor a Short Circuh:l. Disconnect the B (22P) con-nector lrom the TCM.2. Check lor continuity betlveenbody ground and the 810 ter'

minal and 817 terminal indi-

vidually.

Repair 3hort in tha wi?es bttwo€ntho 810 lnd Bt? terminal3.ndtha mainshltt spaed sonaot.

To page 14-79

, 14-74

VJ

Page 499 of 1681

Electrical Troubleshooting

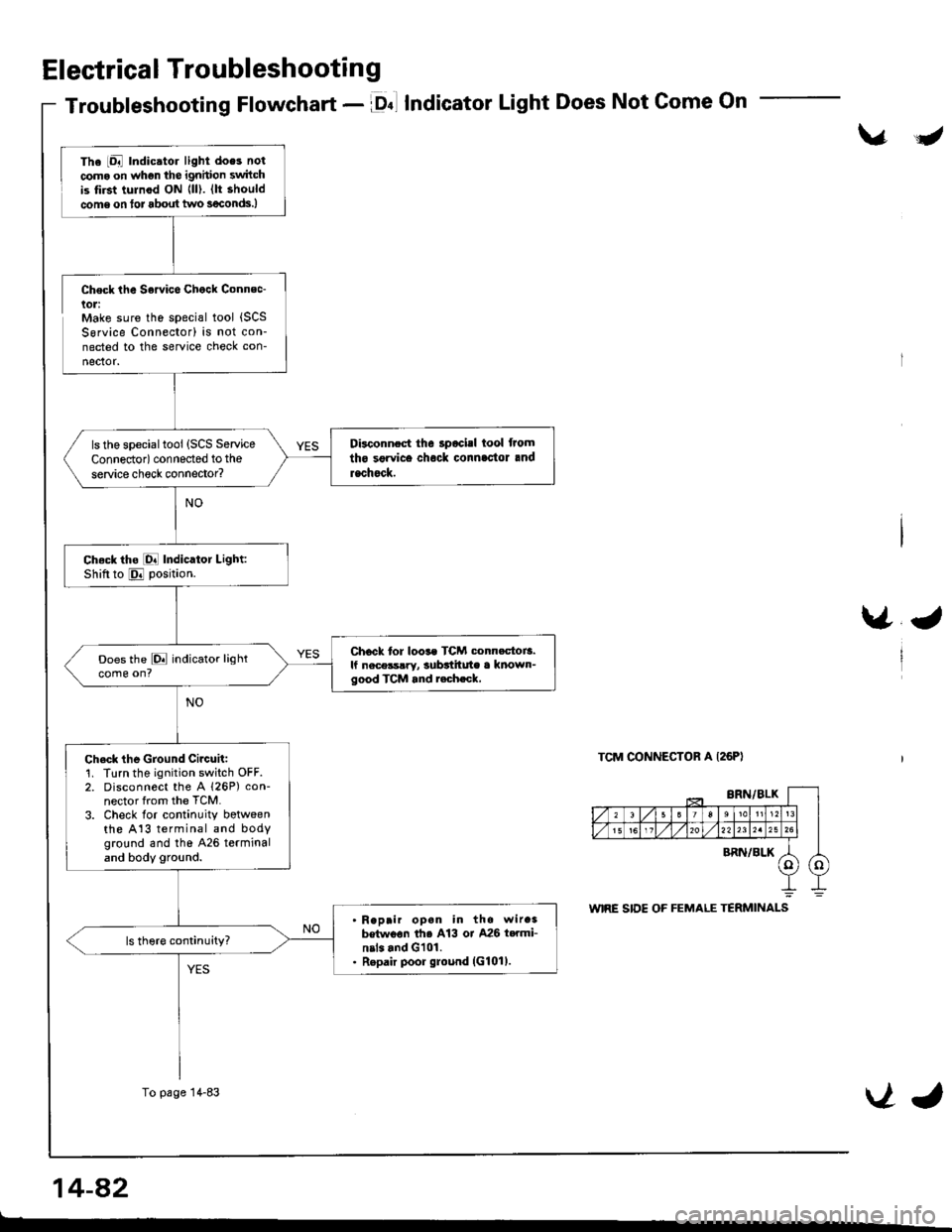

Troubleshooting Flowchart - lDnl IndicatorLight Does Not Come On

\/J

Check the Sowice Chock Connec-lol:Make sure the special tool {SCSSorvice Connector) is not con-nected to the service check con-

nector.

\/J

TCM CONNECTOR A I26PI

The iDal Indic.tor light does not

coma on whgn the ignhion switchis tirst tulnod ON {ll). (lt should

come on tor about two s€conds.)

Disconnect the 3pocisl tool from

tho sgrvice chock connlc'tor and

rachock.

ls the specialtool (SCS Service

Connedor) connected to the

service check connector?

Ch.ck tho [O! Indicator Light:Shiftto E position.

Chock tor loos. TCM conn.ctoi3.lf nece3s!ry, subttitute a known-good TCM and r.ch.ck,

Does the E indicator lightcome on?

Ch.ck the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the A 126P) con-nector from the TCM.

3. Check lor continuity botweenthe A13 terminal and bodyground and tho 426 terminaland body ground.

Reprir opan in the wir.3betwoon th6 A13 or A26 t..mi-nil. and G101.Repair poor ground (G101).

To page 14-83VJ

14-a2

t-

Page 501 of 1681

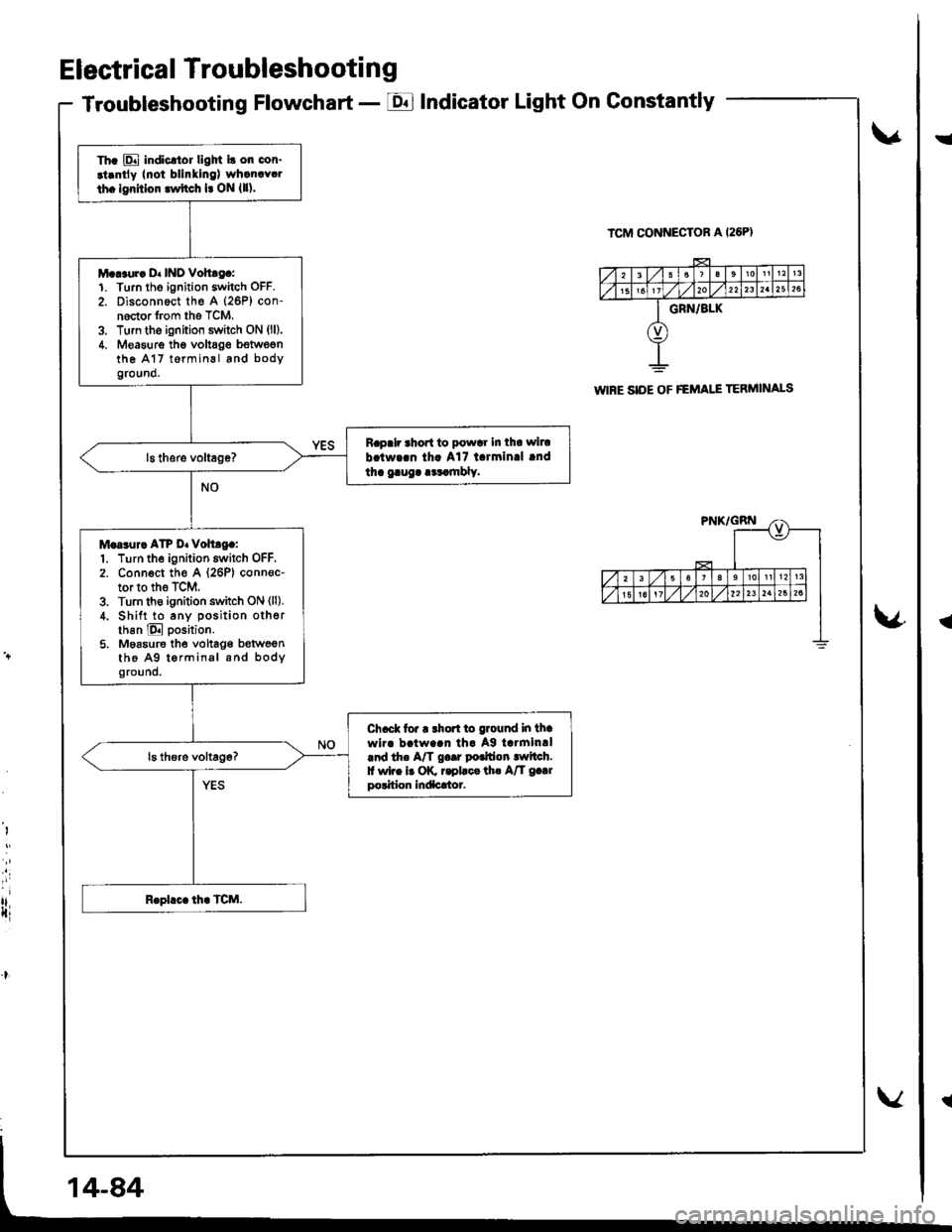

Electrical Troubleshooting

Troubleshooting Flowchart - EIndicator Light On Gonstantly

v

ICM CONNECTOR A I26PI

\4

I

i

rlIti

Th. E indicltor ligM i! on cor.

.t.ntly Inoi blinllng) wh.n.Y.l

th. lgrhior lwftch l. ON {ll).

M...ur. D. INO Vohtg.:1. Turn tho ignition switch OFF.

2. Disconnect th€ A (26P) con-noctor from the TCM.3. Turn the ignition switch ON (ll).

4. Measure thg voltag€ bstwegnthe A17 t6rminal and bodyground.

Rapalr ahort to powar In tha wiru

b.tw..n th. A17 l.rmin.l lnd

tha gaug. .cr.mbly.

M.a3ur. ATP D. voh.g.:1. Turn the ignition switch OFF.2. Conn€ct th€ A (26P) conn€c-tor to the TCM.3. Turn th€ ignition switch ON (ll).

4, Shift to any position otherthan E position.

5. Moasure the vohag€ b€tweenthe A9 tormin.l and bodyground.

Ch.ck tor r rhort to ground in thawir. b!tw..n th. Ag tarmin.l.nd th. A/T g..r potfion lwltch.f wi.e b OK r.pllca th. A/T g.|rpolition Indacrtor.

WIRE SIDE OF FEMAI.I TERMINALS

!

{