light HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 309 of 1681

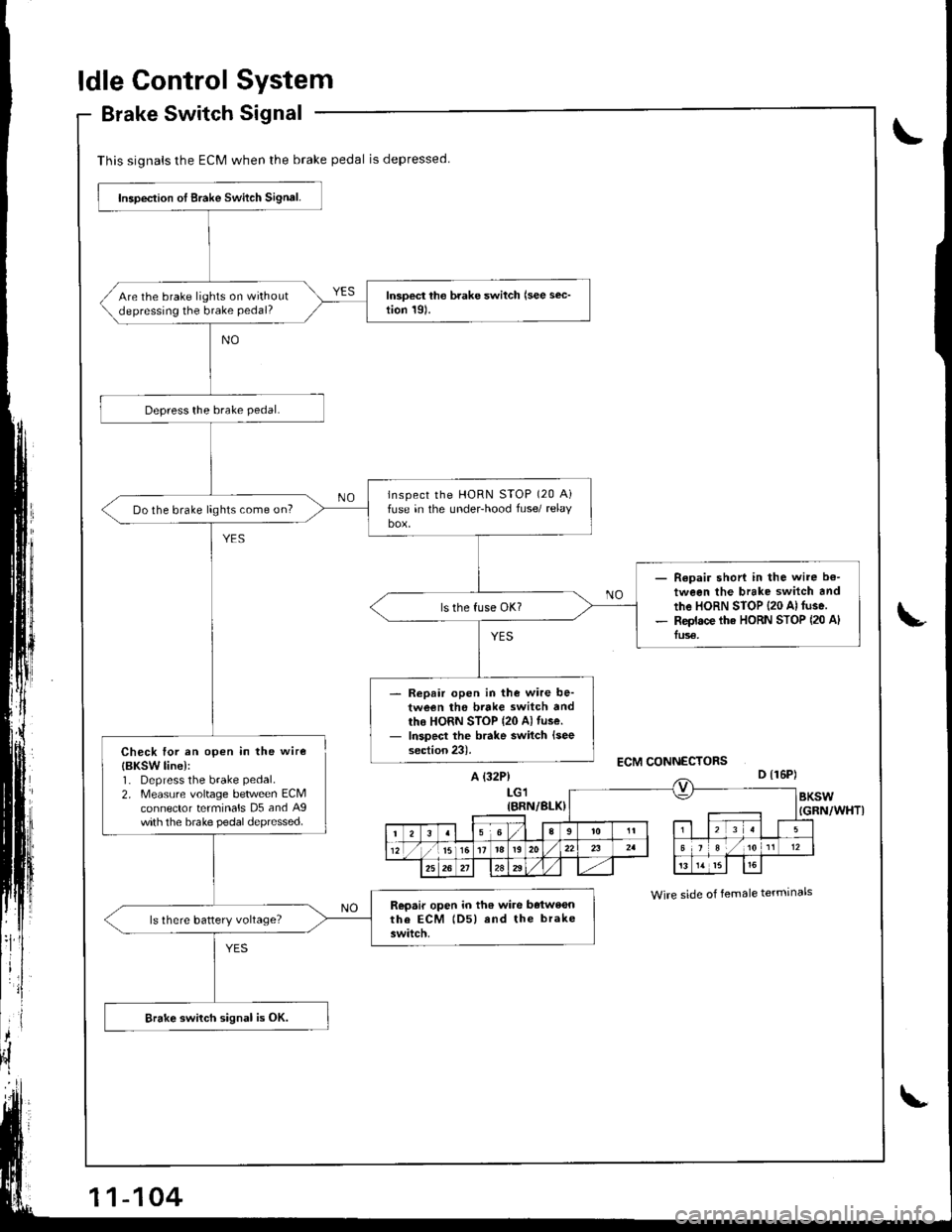

This signals the ECM when the brake pedal is depressed

Inspeclion ot Brake Switch Signal.

Are the brake lights on withoutdepressing the brake pedal?

lnspect the HoRN STOP (20 Aifuse in the under-hood fuse/ relaybox,Do the brake lights come on?

Repair shori in the wire b€-

tween the brake switch and

the HoRN STOP {20 Al fuse.Replace tha HORN STOP (20 AlIus€.

Repair open in the wire be-tween the brtke switch andtho HORN STOP {20 Al tuse.

Inspect the brake switch {seesection 23).Check tor an open in the wire

{BKSW line):1- Depress the brake pedal.

2. Measure voltage between ECMconnector terminals D5 and Agwith the brake pedal depressed.

Repair open io th6 wiae batweonthe EcM lDs) rnd the brakeswitch.

Brake switch signal is OK.

ldle ControlSystem

Brake SwitchSignal

L

L

A {32P}LGl{BRN/BLX}

D {16P)

Wrre side of female terminals

I

Page 316 of 1681

ldle Speed Setting

IDLEADJUSTINGSCREW

7.

6.Turn the ignition switch OFF.

Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM reset procedures.

Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pullthe parking brake lever up.

Start the engine, then check that the headlights are off.

ldle speed should be;

Bl88l €ngine:

Mfi750 i 50 rpm

A/T750150 rpm (in Park or neutral)

818C1 engine:750 i 50 rpm

818C5 engine: 800 i 50 rpm

NOTE: 81881, Bl8Cl engines - It the idle speed

increases to *1rpm, this means the EVAP system ispurging the canister. To stop the purging termporarily.

raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.

*1: 81881 engine

M/T: 820 i 50 rpm

Ay'T: 840 t 50 rpm

818Cl engine

850 I 50 rpm

(cont'd)

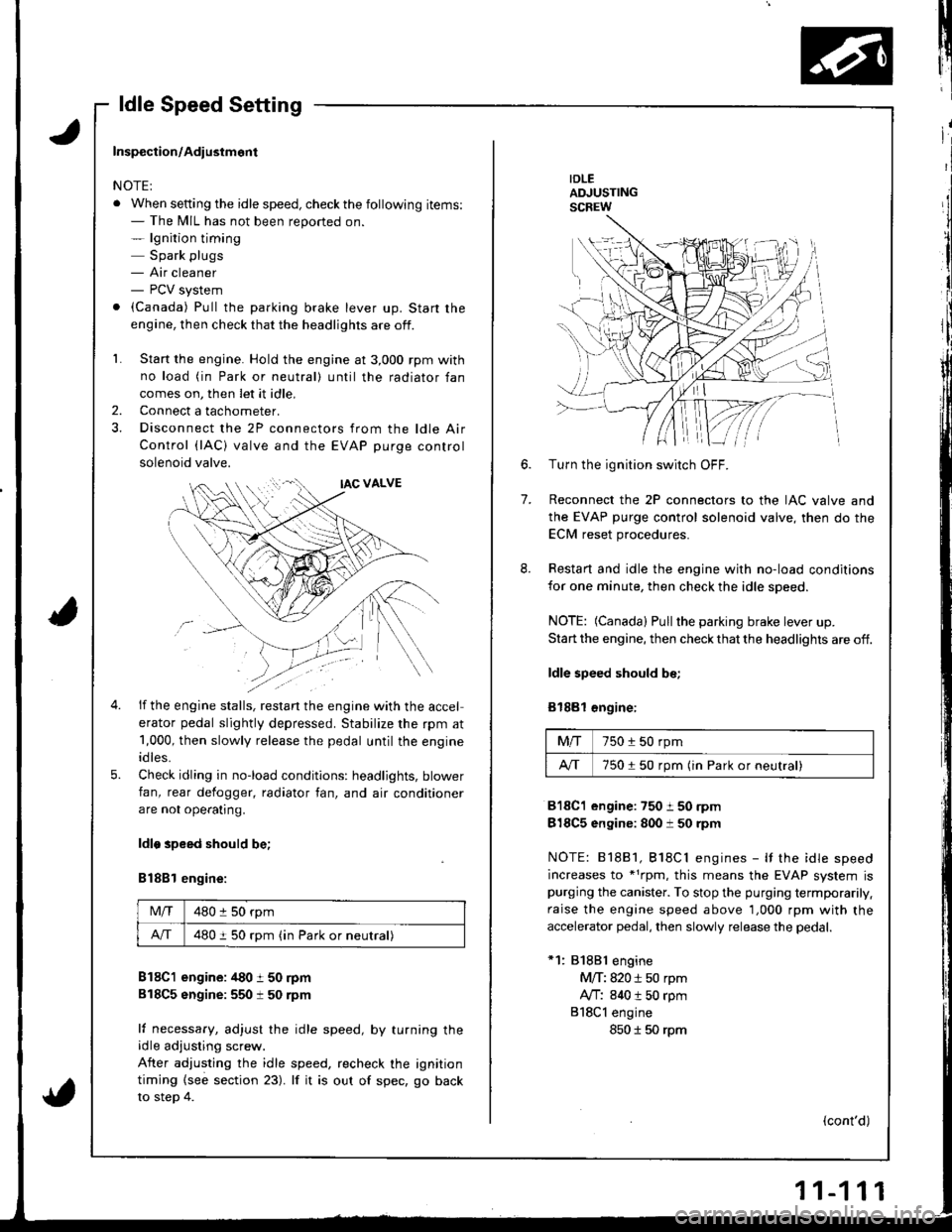

Inspection/Adiustmont

NOTE:

. When setting the idle speed, checkthe following items:- The MIL has not been reported on.- lgnition timing

Spark plugs- Air cleaner- PCV system

. (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Disconnect the 2P connectors from the ldle Air

Control (lAC) valve and the EVAP purge control

solenoid valve.

2.

5.

if the engine stalls, restan the engine with the accel

erator pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and air conditioner

are not ope€tlng.

ldlo speed should be;

B188l engine:

Mlf480 :l 50 rpm

A/T480 i 50 rpm (in Park or neutral)

B18C1 engine: /t80 t 50 rpm

818C5 sngine:550 t 50 rpm

lf necessary, adjust the idle speed, by turning theidle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing {see section 23). lf it is out of spec, go back

to steo 4.

Page 317 of 1681

ldle Control System

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 343 of 1681

t"iI

Emission Gontrol System

System Description

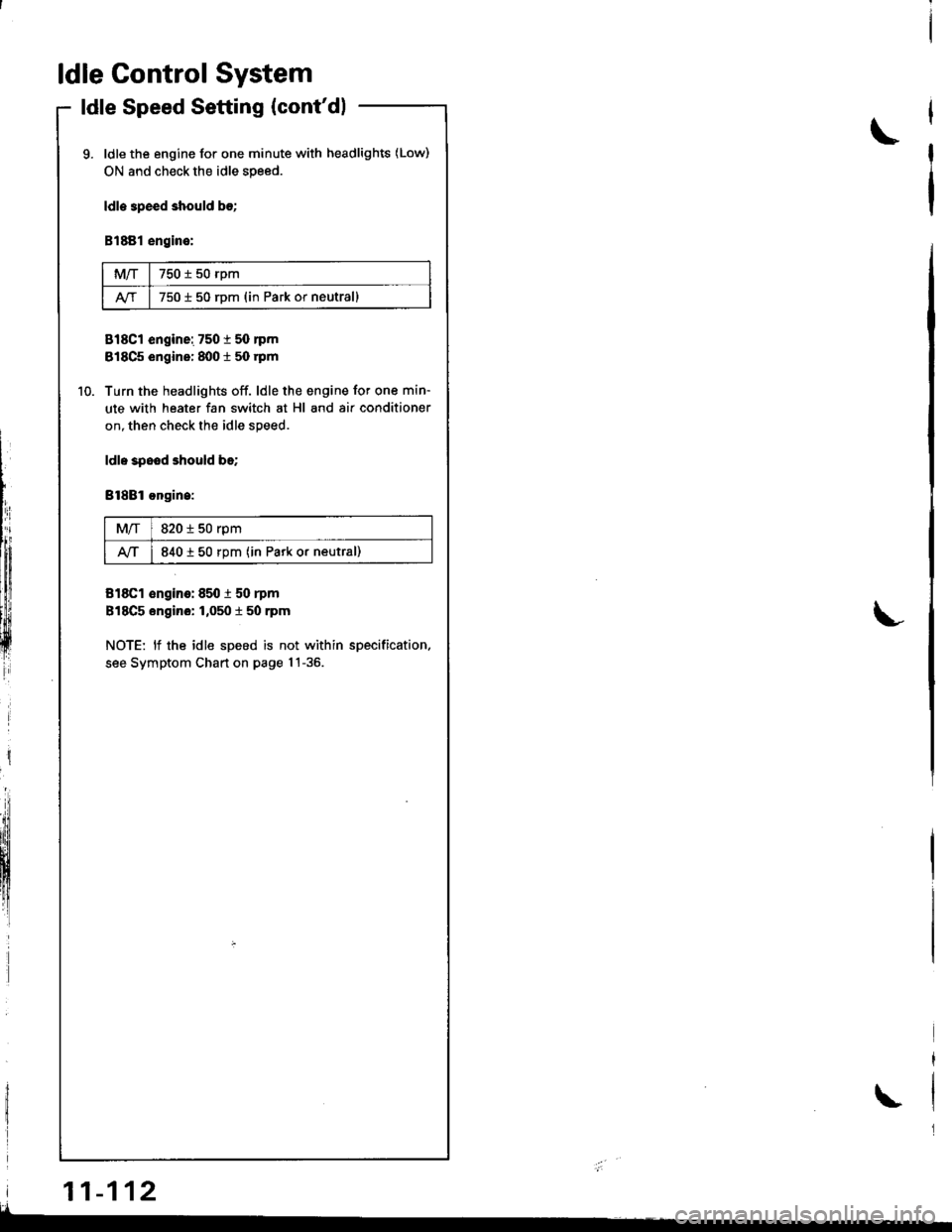

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 345 of 1681

'il

Emission Gontrol System

Positive Crankcase Ventilation (PCV) System

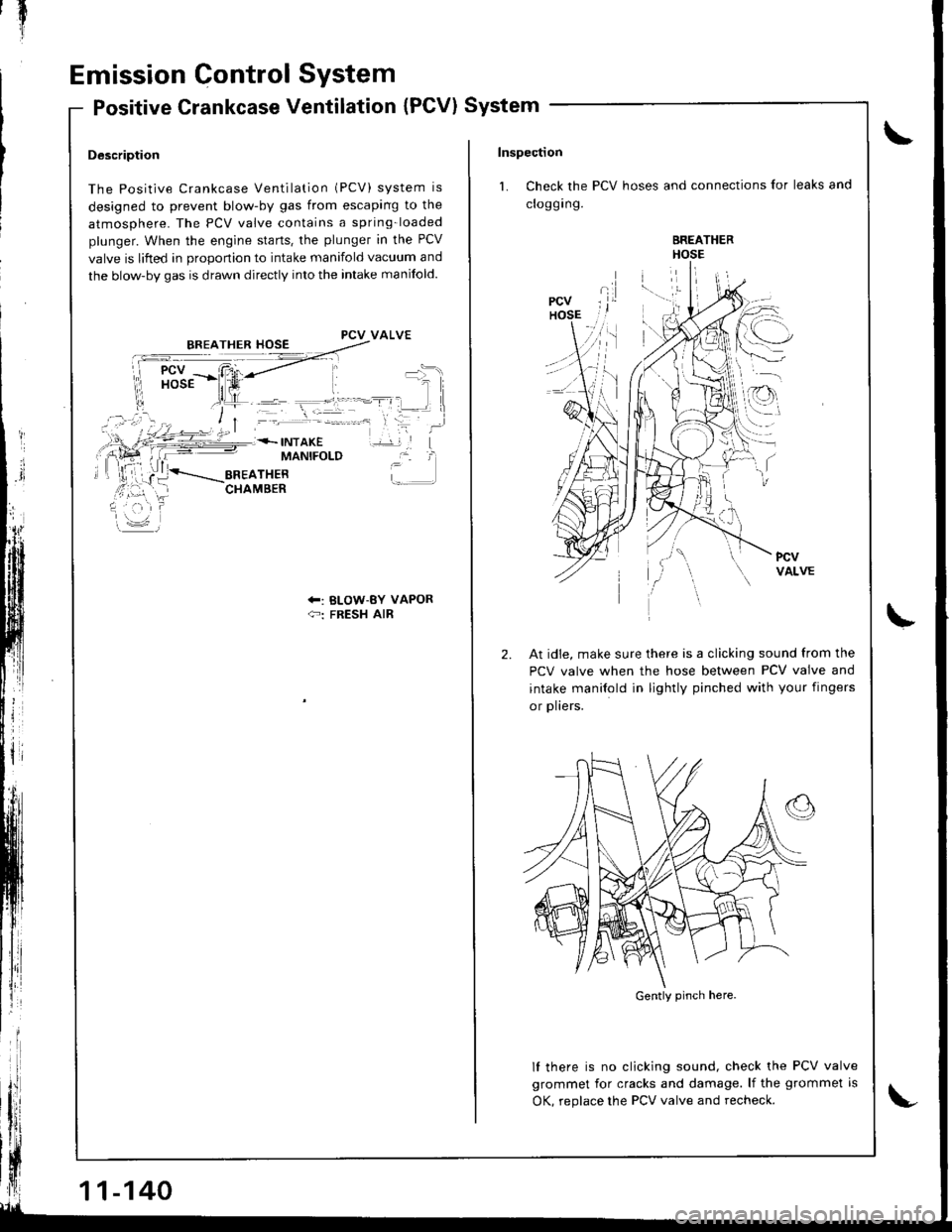

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts. the plunger in the PCV

valve is lifted in orooonion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

PCV VALVE

MANIFOLD

+: BLOW-BY VAPOR{-: FRESH AIR

11-140

Inspection

1. Check the PCV hoses and connections for leaks and

croggrng.

BREATHERHOSE

l.--:\

,.r

I

2.At idie, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manilold in lightly pinched with your fingers

or plters.

lf there is no clicking sound, check the PCV valve

grommet for cracks and damage. lf the grommet is

OK, reolace the PCV valve and recheck.

Gently pinch here.

Page 370 of 1681

Manual Transmission

Special Tools ............. 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Transmission Assembly

Removal ................. 13-4

lllustrated Index ................................... 13-8

Transmission Housing

Removal ................. 13-10

Peverse Change Holder, Reverse ldler Gear

jGlearance Inspection ....................... 13-1 1

Removal ................. 13-12

Change Holder Assembly

Clearance Inspection .....,.,....,,.....,,.. 13-13

Removal ................. 13-15

Disassembly/Reassembly ............... 13-16

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-17

Shift Rod

Removal ................. 13-18

Shift Fork Assembly

Index ................ ...... 13-19

Clearance lnspection ...................,.,. 13-20

Mainshaft Assembly

fndex ................ ......13-21

Clearance f nspection ..,,,.................. 13-22

Disassembly .......... 13-25

Inspection .............. 13-26

Reassembly ........... 13-21

Countershaft Assembly

Index ................ ...... 13-28

Clearance Inspection ....................... 13-29

Disassembly .......... 13-30

Inspestion .............. 13-31

Reassembly ........... 13-32

Synchro Sleeve, Synchro Hub

Inspection .............. 13-34

Installation ............. 13-34

Synchro Ring, Gear

Inspection .............. 13-35

Clutch Housing Bearing

Replacement ......... 13-36

Mainshaft Thrust Clearance

Adiustment ............ 13-38

Transmission

Reassembly ........... 13-41

Transmission Assembly

Installation ............. 13-46

Gearshift Mechanism

Overhaul ................ 13-51

Page 372 of 1681

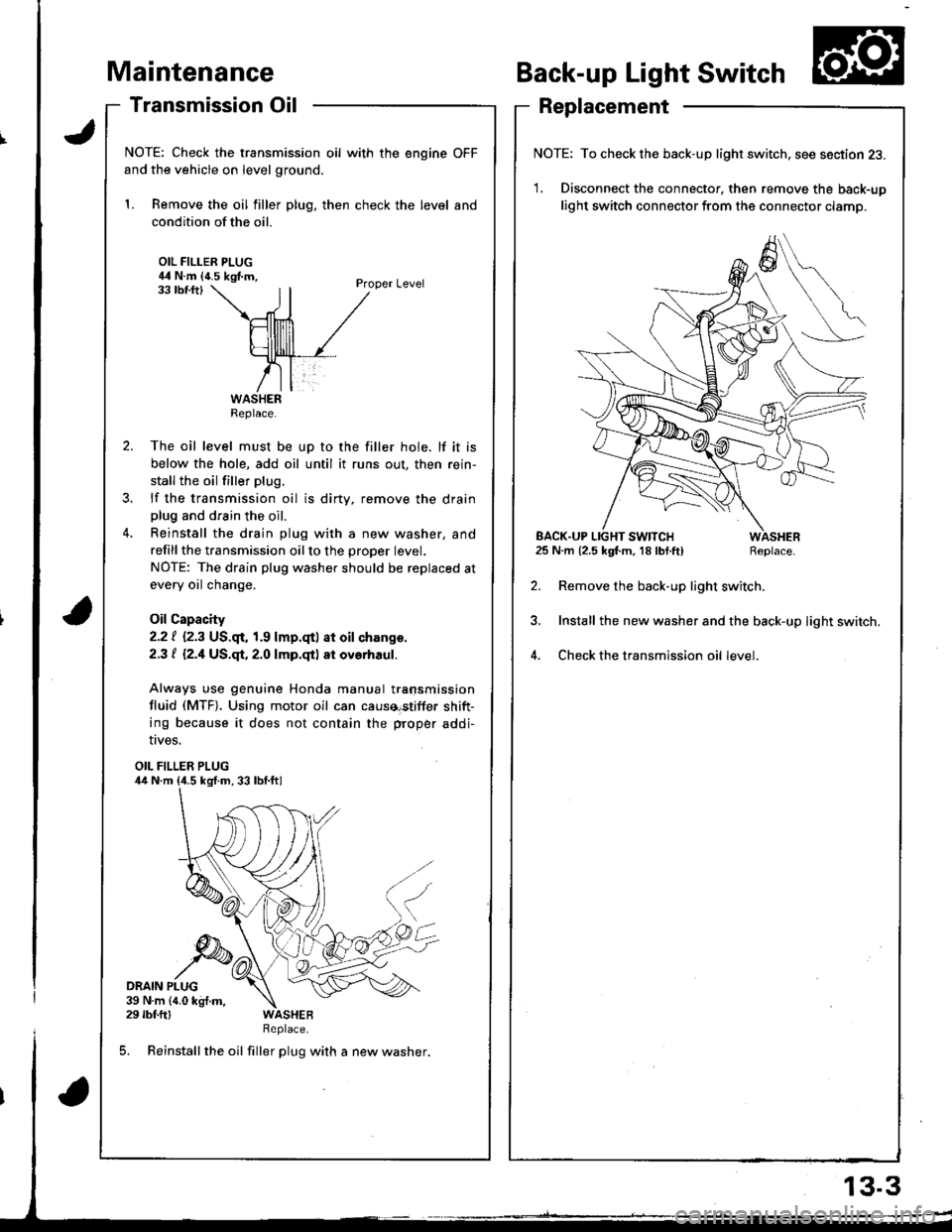

aintenance

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG44 N.m {4.5 kgf.m,Proper Level33 tbf.ftl

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out, then rein-

stall the oil filler plug.

lf the transmission oil is dirty, remove the drainplug and drain the oil.

Reinstall the drain plug with a new washer, and

refillthe transmission oilto the proper tevet.

NOTE: The drain plug washer should be replaced at

every oil change.

Oil Capacity

2.2 | i.2.3 US.qr,1.9 lmp.qtl at oil ch.nge.

2.3 t l2.1US.qt,2.O lmp.qtl at ovorhaul.

Always use genuine Honda manual transmission

fluid (MTF). Using motor oil can causa€tiffer shift-

ing because it does not contain the proper addi-

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch. see section 23.

1. Disconnect the connector, then remove the back-up

light switch connector from the connector clamp.

l.m {2.5 kgf.m, 18lbf.ft) Replace.

Remove the back-up light switch.

Install the new washer and the back-up light switch.

Check the transmission oil level.

!ves.

OIL FILLER PLUG

DRAIN PLUG39 N.m {4.0 kg{.m,29 rbf.ftlReplace.

5. Reinstall the oil filler plug with a new washer,

Replace.

EACK.UP LIGHT SWITCH25 N.m {2.5 kgf.m, 18 lbf.ft)

13.3

Page 373 of 1681

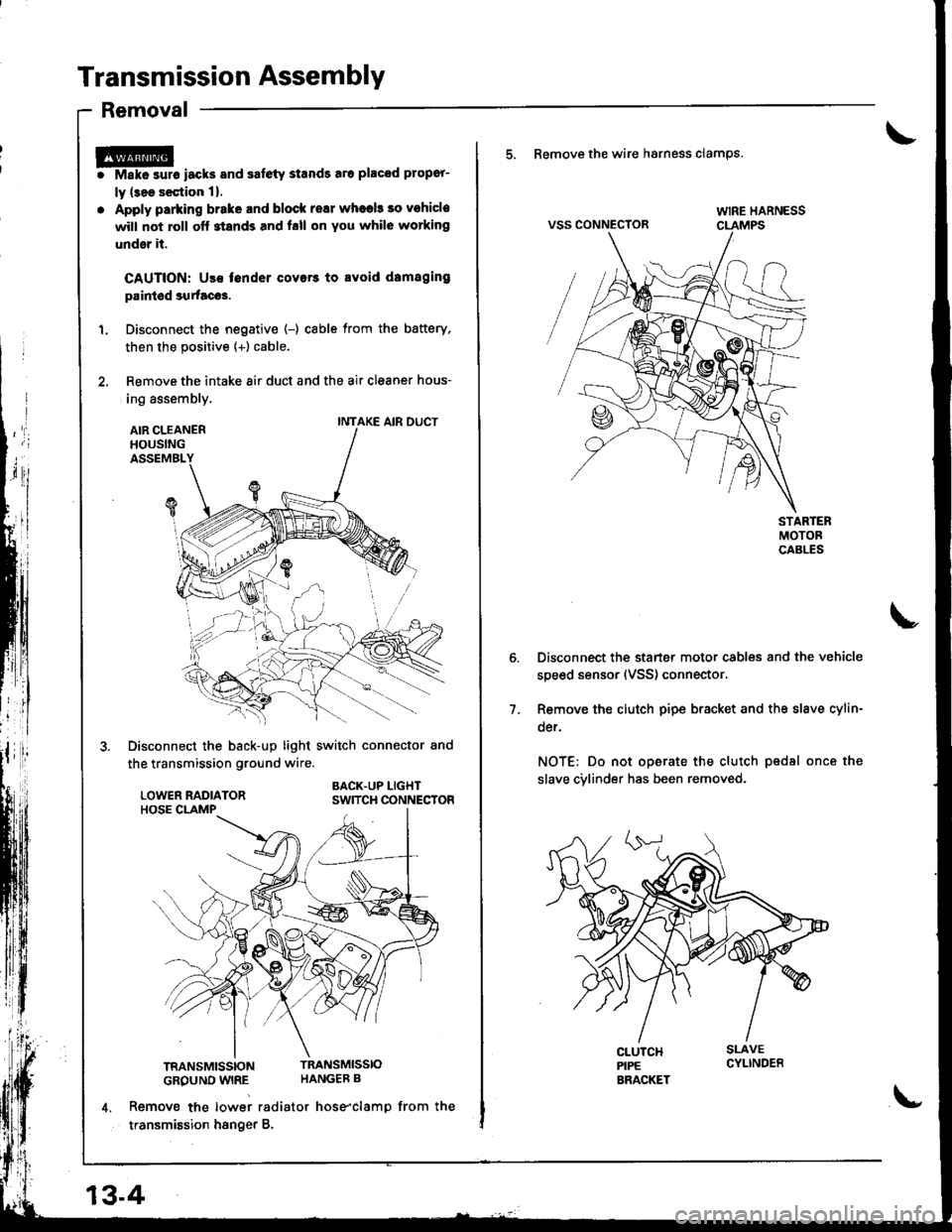

Transmission Assembly

Removal

r@i Make surs iacks and safety stands sro placod propor-

ly (3ee s€ction 1).

. Apply parking brake and block resr whaeb 30 vohicle

will not roll off stands and hll on You whil6 working

under it.

CAUTION: Use fender covers to svoid damaging

paintod surtacos.

1. Disconnect the negative (-) cable from the battery,

then the positive {+) cable.

2. Remove the intake 8ir duct and the air cleaner hous-

ing assembly,

AIR CLEANERHOUSINGASSEMBL

Disconnect the back-up light switch connector and

the transmission ground wire.

BACK.UP LIGHTSWITCH CONNECTOR

TRANSMISSIONTRANSMISSIO

GROUND WIRE HANGEB B

4. Remove tne lowei radiator hose"clamp from the

transmission hsnger B.

INTAKE AIR DUCT

13-4

\-

5. Remove the wire hsrness clamps.

VSS CONNECTOR

Disconnect the starter motor cables and the vehicle

speed sensor (VSS) connector.

Remove the clutch pipe bracket and the slave cylin-

der.

NOT€: Do not operate the clutch pedsl once the

slave cvlinder has been removed.

7.

Page 376 of 1681

Transmission Housing

Removal

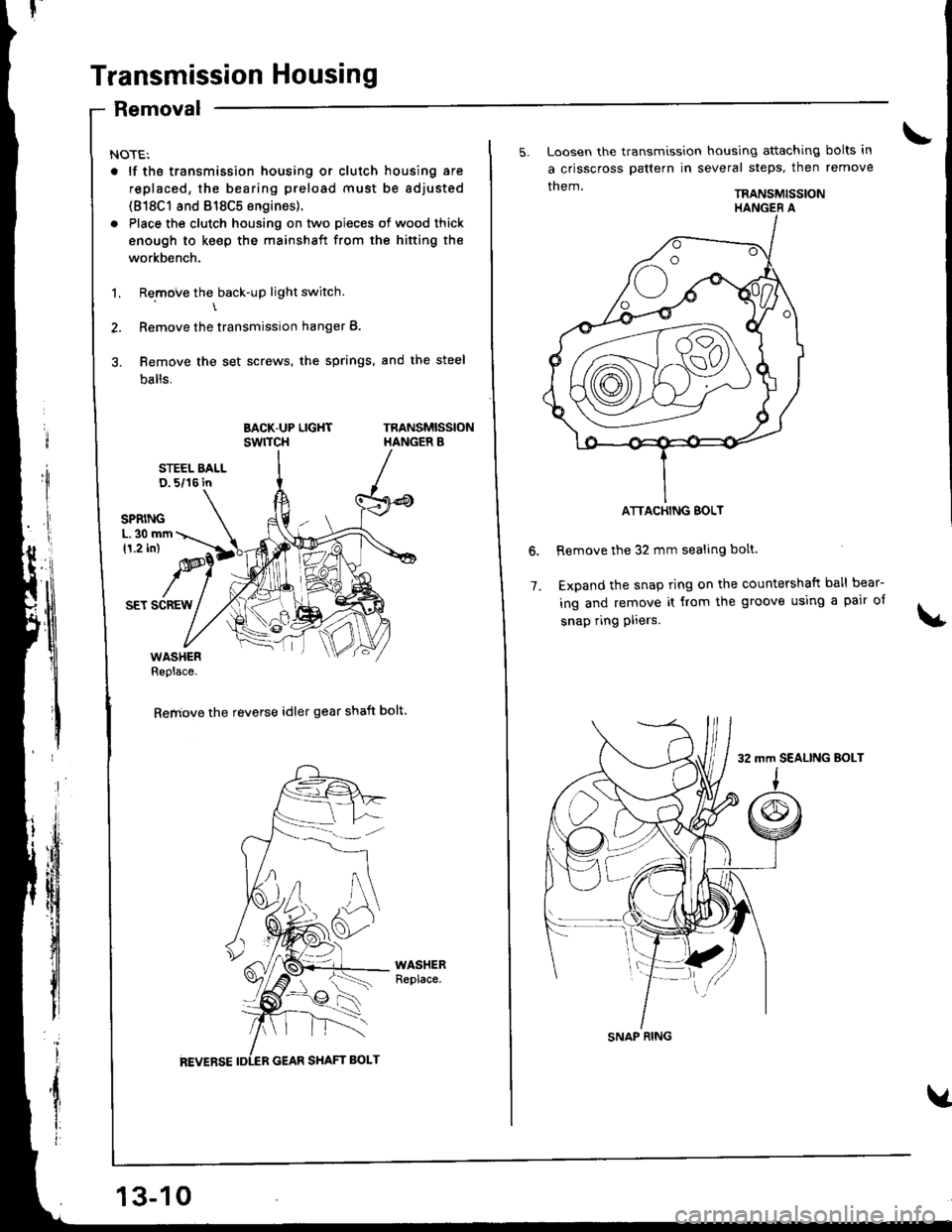

NOTE:

. lf tho transmission housing or clutch housing are

replaced, the bearing preload must be adjusted

(818C1 8nd 818C5 engines).

. Place the clutch housing on two pieces of wood thick

enough to keep the mainshaft from the hifting the

workbench.

1. Remove the back-up light switch.\

2. Remove the transmission hanger B.

3. Remove the set screws, the springs, and the steel

balls.

BACK-UP LIGHTswrTcHTRANSMISSIONHANGER B

STEEL BALLD. 5/16 in

SET SCREW

WASHERReplace.

Remove the reverse idler gear shaft bolt.

13-10

5. Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps, then remove

them.TRANSMISSION

Remove the 32 mm sealing bolt.

Expand the snap ring on the countershaft ball bear-

ing and remove it from the groove using a pair of

snap ring pliers.

6.

7.

ATTACHING BOLT

SNAP RING

32 mm SEALING BoLT

Page 410 of 1681

Transmission

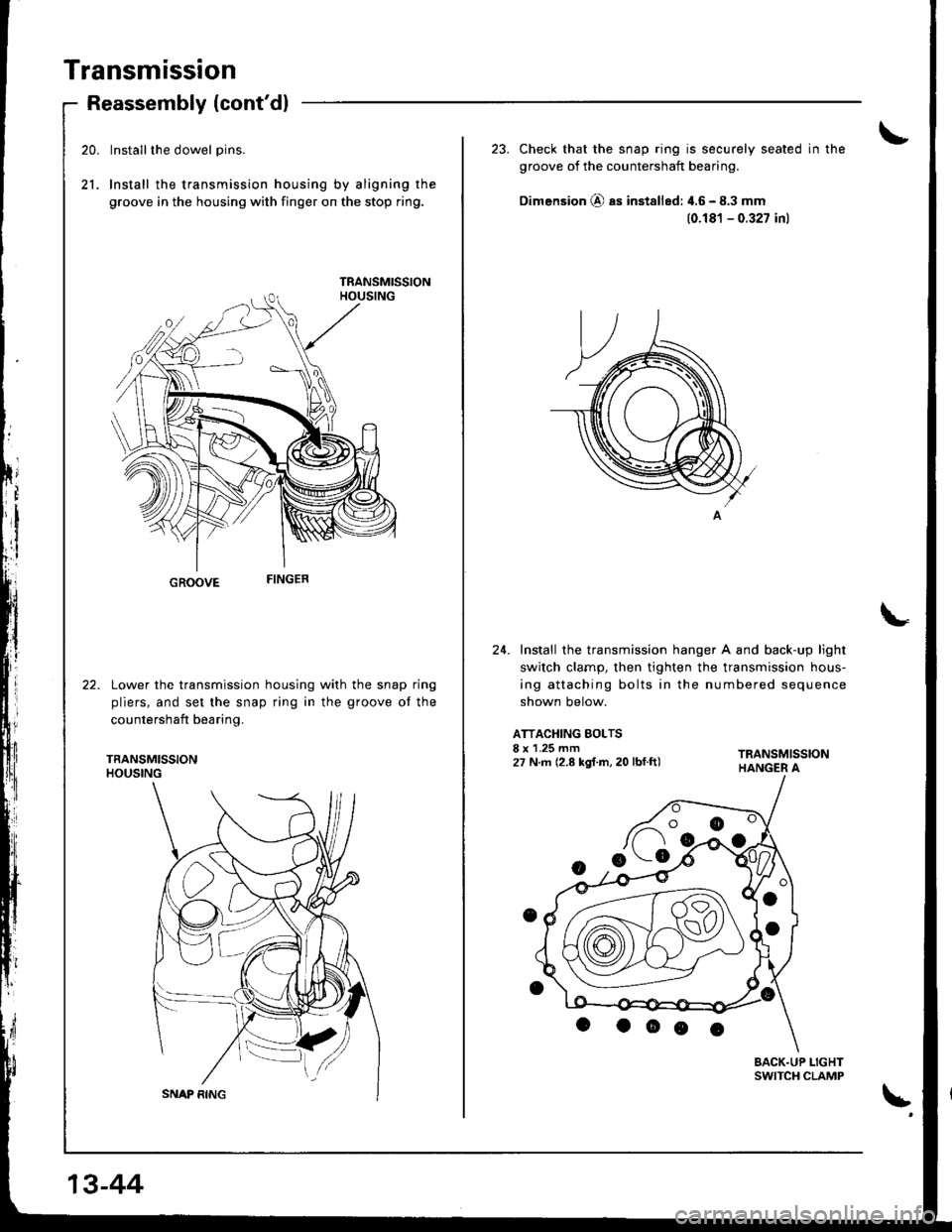

20.

21.

Reassembly (cont'dl

Installthe dowel pins.

Install the transmission housing by aligning the

groove in the housing with finger on the stop ring.

GROOVE

Lower the transmission housing with the snap ring

pliers, and set the snap ring in the groove of the

countershaft bearing.

TRANSMISSIONHOUSING

13-44

23. Check that the snap ring is securely seated in the

groove of the countershaft bearing.

Dimension @ as installed: 4.6 - 8.3 mm

(0.181 - 0.327 inl

24. Install the transmission hanger A and back-up light

switch clarnp, then tighten the transmission hous-

ing attaching bolts in the numbered sequence

shown below.

ATTACHING BOLTSI x 1.25 mm27 N.m (2.8 kgf.m, 20 lbf.ft)

BACK.UP LIGHTSWITCH CLAMP

\'