sensor HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 287 of 1681

I

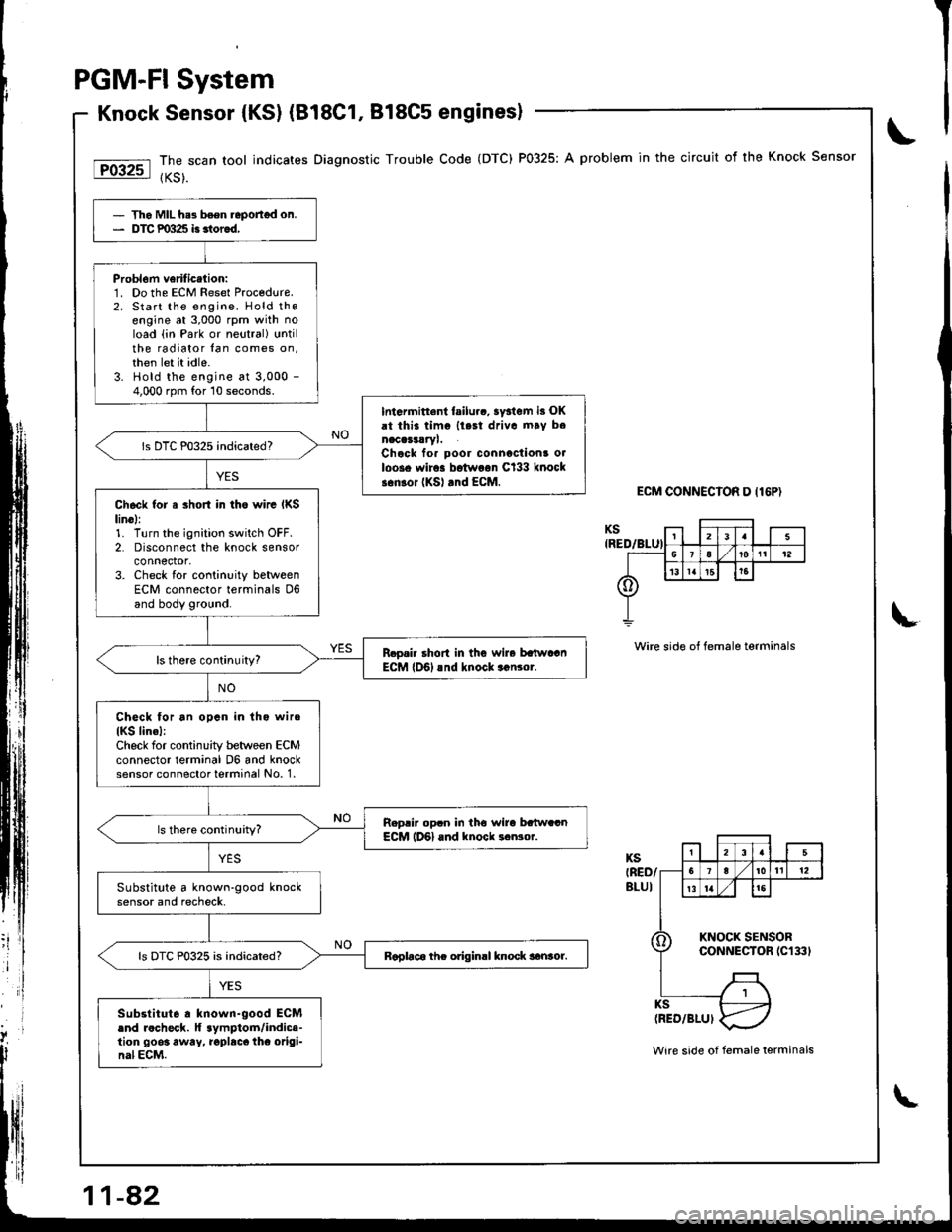

PGM-FI System

Knock Sensor {KSl (B18C1, 818C5 enginesl

The scan tool indicates Diagnostic Trouble Code (DTC) P0325: A problem in the circuit of the Knock Sensor

{KS).

ECM CONNECIOR D I16P)

Wire side of female terminals

- Tho MIL he3 b6en.eportgd on.- DTC P0325 i3 3tor6d,

Probl6m veriticalion:1. Do the ECM Reset Proc€dure.2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral} untilthe radiator lan comes on,then let it idle.3. Hold the engine at 3,000 -

4,000 rpm for 10 seconds.

Intarmitt.nl failurc, ay3tem i3 OKrt thii timc llest driva mav b.naccrsrryl.Chcck for poor connactions o.loos. wir.. botw..n Cl33 knocks.nlor (KSl rnd EcM.

Ch6ck {or a 3hort in tho wirc IKSlin6l:1. Turn the ignition switch OFF.2. Disconnect the knock sensorconnector,3. Check for continuity betweenECM connector terminals D6and body ground.

R.o.i. short in thG wire batwaanECM lD6l rnd knock..n3or.

Check for an opcn in lho wiro

IKS lin.l:Check for continuity between ECMconnector terminal D6 and knocksensor connector terminal No. 1.

Reprir op.n in tho wira bttw..nECM lD6l and knock ..Nor.

Substitute a known-good knocksensor and recheck.

Raplac6 thc odginrl knock sanror.ls DTC P0325 is indicated?

Substitut6 . known-good ECM.nd rocheck. lf aymptom/indic.-tion 9003 away, .opbcc thc origi-nal ECM.Wire side of female terminals

Page 288 of 1681

t@

tFffi6l

F136il

l-P1362l

Fi3BTl

tFE82-l

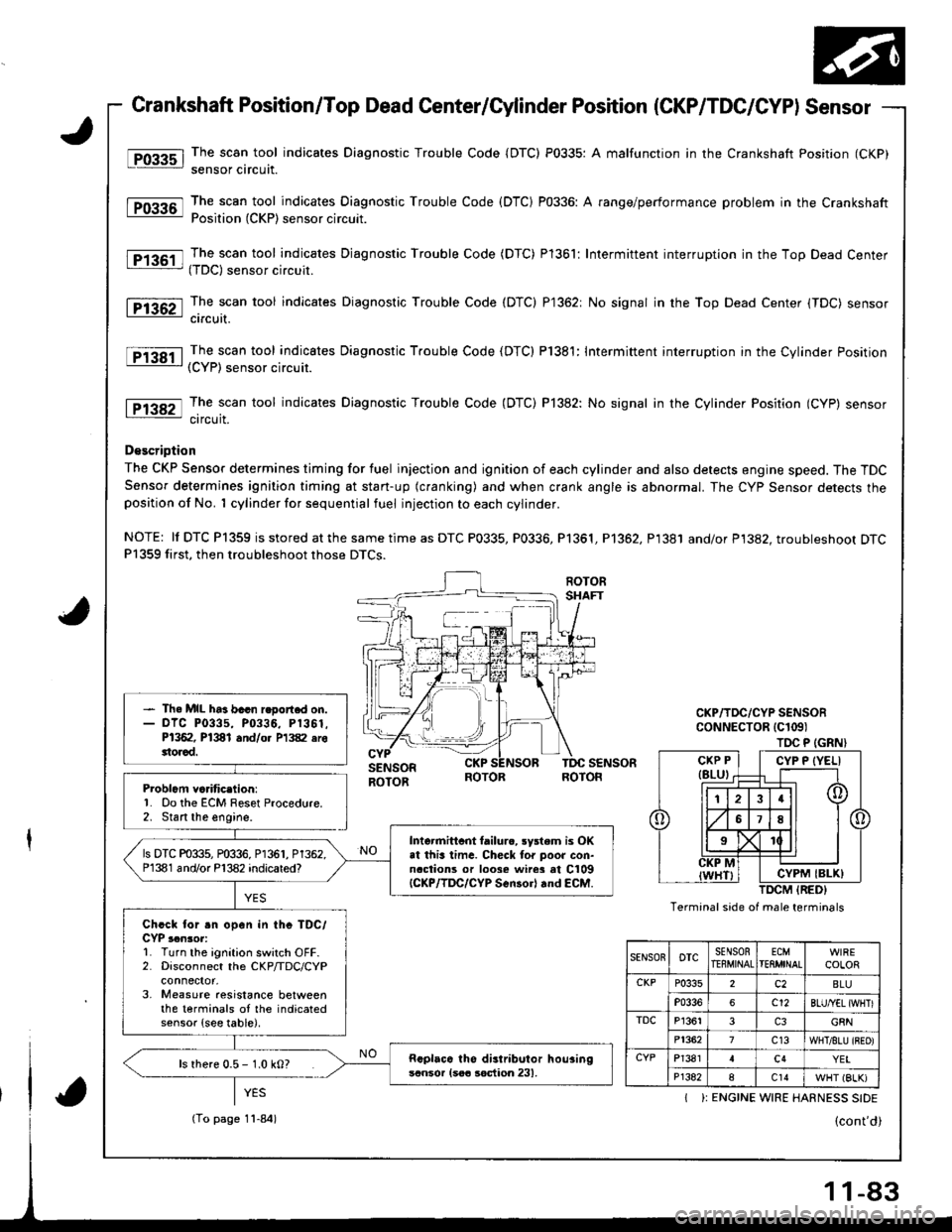

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code {DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the CrankshaftPosition (CKP) sensor circuit.

The scan tool indicates Djagnostic Trouble Code (DTC) Pl361: Intermittent interruption in the Top Dead Center(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensorcircuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P]382: No signal in the Cylinder Position (CYP) sensorcircuit.

D€scription

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDCSensor determines ignition timing at stan-up (cranking) and when crank angle is abnormal. The Cyp Sensor detects theposition of No. 1 cylinder for sequential fuel injection to each cylinder.

NOTE: ll DTC P1359 is stored at the same time as DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382. troubleshoot DTCP1359 first, then troubleshoot those DTCS.

Problcm va.itic.lion:'1. Do the ECM Reset Procedure.2. Stan the engine.

- Th. MIL ha3 bacn r.oort.d on.- olc P0335, P0336, P1361.P1362, P1381 and/o. P1382 erottorad.

Intormittcnt tailurc, rystem is OKat this lima. Checl tor poor con-naclions or loose wire3 at C109{CKP/lDC/CYP Scn30rl rnd €CM.

ls DTC P0335, P0336, P1361, P1362.P1381 and/or P'l382 indicared?

Chcck for .n open in thc TDC/CYP ,.n3or:L Turn the ignition switch OFF.2. Disconnect the CKP/TDC/CYP

3, Measure aesistance betweenthe terminals oI the indicatedsensor {see table).

Rcplaca tho distributor hou3ingscnsor {soa soction 231,ls rhere 0.5 - 1.0 kO?

TOC P (GRN}

Termanal side of male terminals

CYP P {YELI

CYPM IBLK)

SENSOnoTcSENSORTEEMINALECMTEflMINALCOLOR

CKPP0335c2BLU

P0336c12BLU/YEL {WHTI

TDCP13613G8N

P13627c13WHT/8LU {BEO)

CYPP13814c4YEI

P1382ac14WHT (BLK)

I ): ENGINE WIRE HARNESS SIDE

(To page 11-84)

-83

Page 289 of 1681

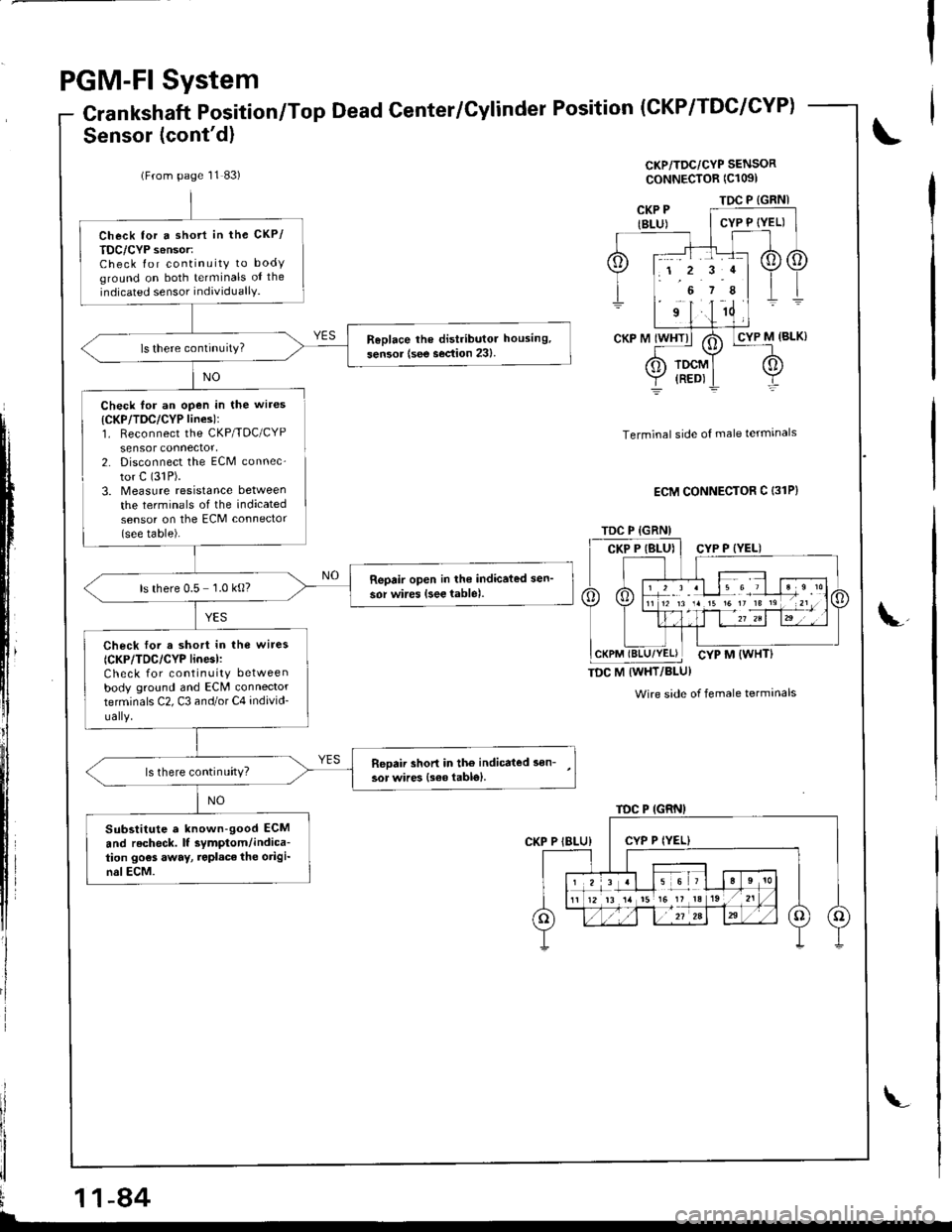

PGM-FI System

Crankshaft Position/Top Dead Center/Cylinder Position

Sensor (cont'd)

(CKP/TDC/CYP)

CKP/TDC/CYP SENSOR

ooNNECTOR (Cl091

NO

il

,ll

I

Check for an open in the wires

{CKP/TDC/CYP lines):1. Reconnect the CKP/TDC/CYPsensor connector,2. Disconnect the ECM connec-

tor C (31P).

3. Measure resrstance between

the terminals of the indicatedsensor on the ECM connector(see table).

Terminal side of male termrnals

ECM CONNECTOR C {31P}

TDC M IWHT/BLU}

Wire side of female terminals

i

ii!\

(From page 11 83)

Check tor a shott in the CKP/

TDC/CYP s6nsor:Check for continuity to bodyground on both terminals oI the

indicated sensor individuallY.

ReDlace lhe distributor housing,

sen3or {see section 23}.

Reoair open in lhe indicated sen'

sor wires {see lable).ls there 0.5 1.0 kg?

Check lor a short in the wire3

{CKP/TDC/CYP linesl:Check for continuity betweenbody ground and ECM connectorterminals C2, C3 and/or C4 individ-

ually.

Reoaii shon in tho indicated son-

3or wires {s€6 table}.ls there continuity?

Substitute a known-good ECM

and recheck. lf symptom/indica-tion go€s away, repl.ce the origi-nslECM.

TDC P {GRNI

TDC P (GRN)

1 2 r .l le 6 7

TDC P {GRN)

1 2 3 al 15 6 ,

12 13 14 t5 16 It 13

11-84

Page 290 of 1681

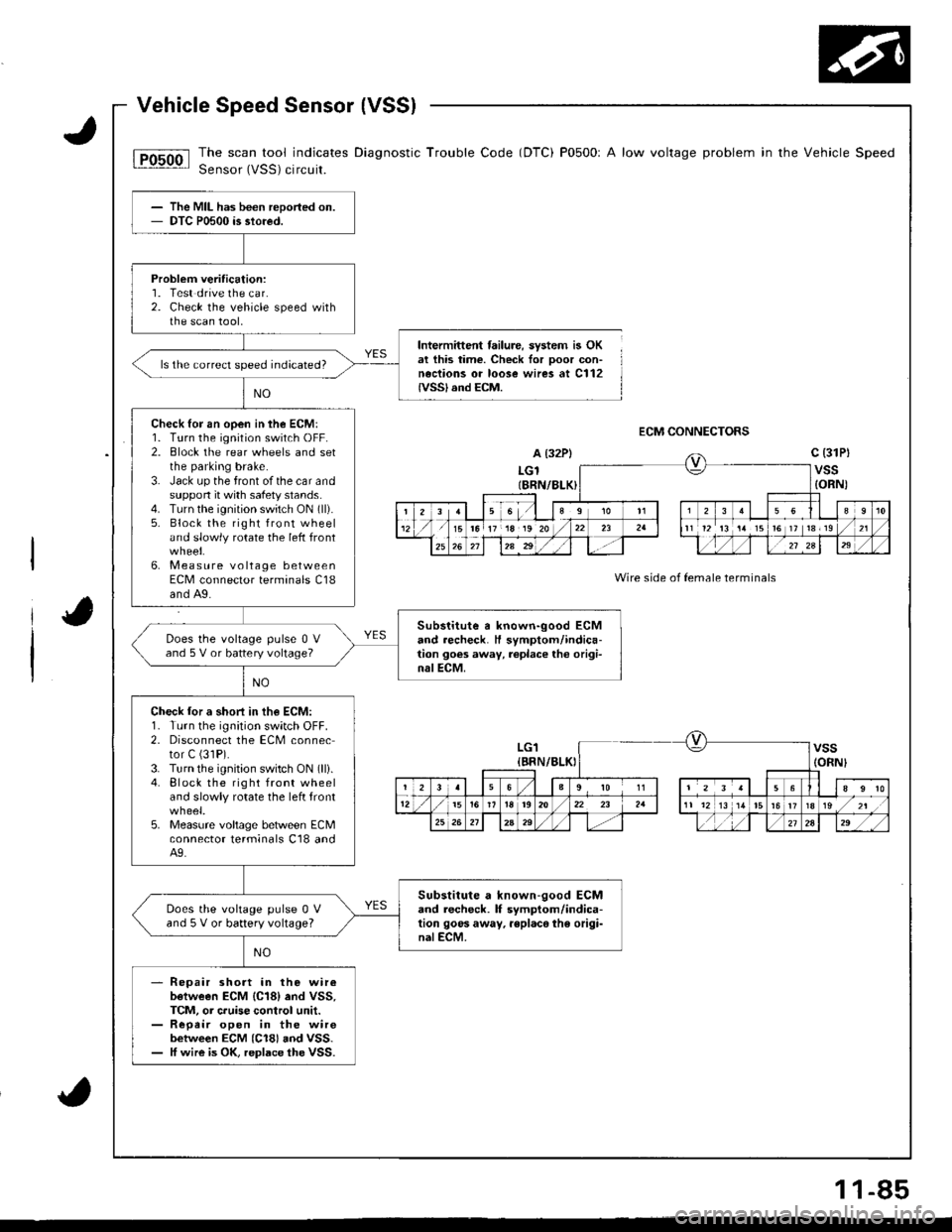

The scan tool indicates Diagnostic Trouble Code (DTC) P0500r A low voltage problem in the Vehicle Speed

Sensor (VSS) circuit.

Intermittent failure, system is OKat this time. Check for ooor con-neciions or loose wires at C112IVSSI and ECM.

ECM CONNECTORS

A (32P)

LGlIBRN/8LK)

c (31Pt

vss{ORN)

Wire side of female terminals

The MIL has been reported on.DTC P0500 is stored.

Probleft veritication:1. Test drive the car.2. Check the vehicle speed withthe scan tool,

ls the correct speed indicated?

Check lor an open in the ECM:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the front of the car andsuppon it with safety stands.4. Turn the ignition switch ON (ll).

5. Block the right front wheeland slowly rotate the left front

6. Measure voltage betweenECM connector terminals C18and A9.

Substitute a known-good ECMand recheck. H symptom/indica-tion goes away, replace tho origi-nalECM.

Does the voltage pulse 0 Vand 5 V or battery voltage?

Check lor a shori in th€ ECM:1. Turn the ignition switch OFF.2. Disconnect the ECM connector C (31P).

3. Turn the ignition switch ON (lli.4. Block the right front wheeland slowly rotate the left front

5. Measure voltage between ECMconnector lerminals C18 andA9.

Substitute a known-good ECMand lecheck. lf symptom/indica-tion goos away. rsplaco the origi-nalECM.

Does the vohage pulse 0 Vand 5 V or battery voltage?

Repair short in the wireb€tween ECM {C18} end VSS,TCM, or cruise control unit.Repeir open in the wirebetween ECM (C18) aod VSS.ff wire is OK, replace the VSS.

ra 17 18 19 20t6 ]t 13r19

LG1{BRN/BLKIvss(ORNI

23563910 1156

12i5r92022 23 2a11 1213 1/tr6ts/zt

25262Aa9,/2724," ,/ ,,:

1 1-85

Page 291 of 1681

PGM-FI System

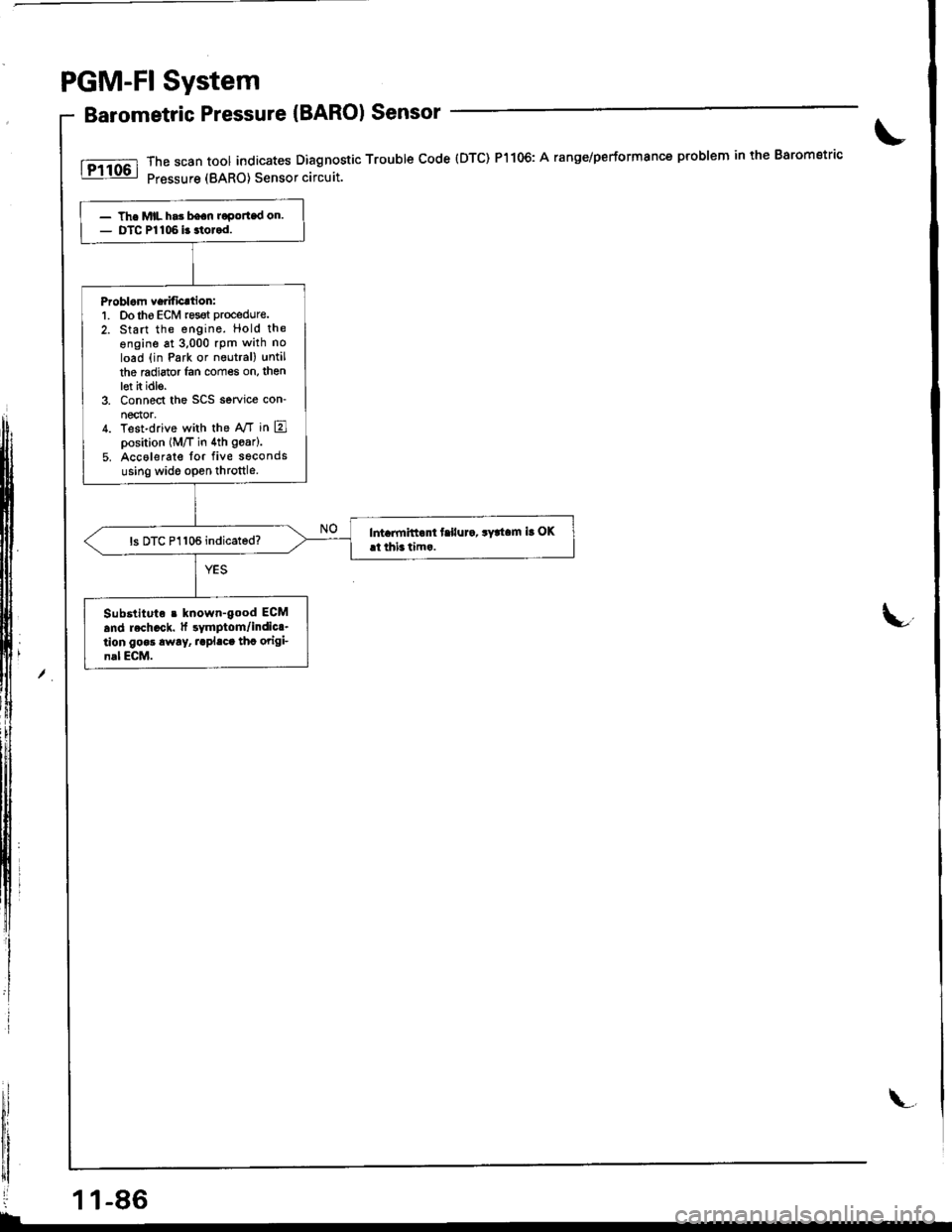

Barometric Pressure {BARO) Sensor

rrt*l ;:"""::::[Ti5li"$::::#nostic

rroubre code (Drc) P1106: A ranse/performance p'oblem in the Barometric\

,xl

lu,

i-

- The MIL h.3 bean roportad on.- DTC Pl106 i3 3tolod.

Problom Ye.ification:1. Dotho ECM resot procedure.

2. Start the engine. Hold the

ongine at 3,000 rpm with no

load (in Park or neutral) until

the mdiator lan comes on, thenlet h idle.3. Connect the SCS service con-

nector,4. Test-drive with the A,/T in E]position (M/T in 4th goar).

5. Accolerate for five seconds

using wide open throttle.

Int imitt.nt f.llur., .y!t.m ir OKrt thi. tim..ls DTC P1106 indicated?

Substltuto r known-good EGM

and rech.ck. tf rymptom/indic..lion gooa rway, raplaca thc origi_n.l ECM.

11-86

\.

Page 292 of 1681

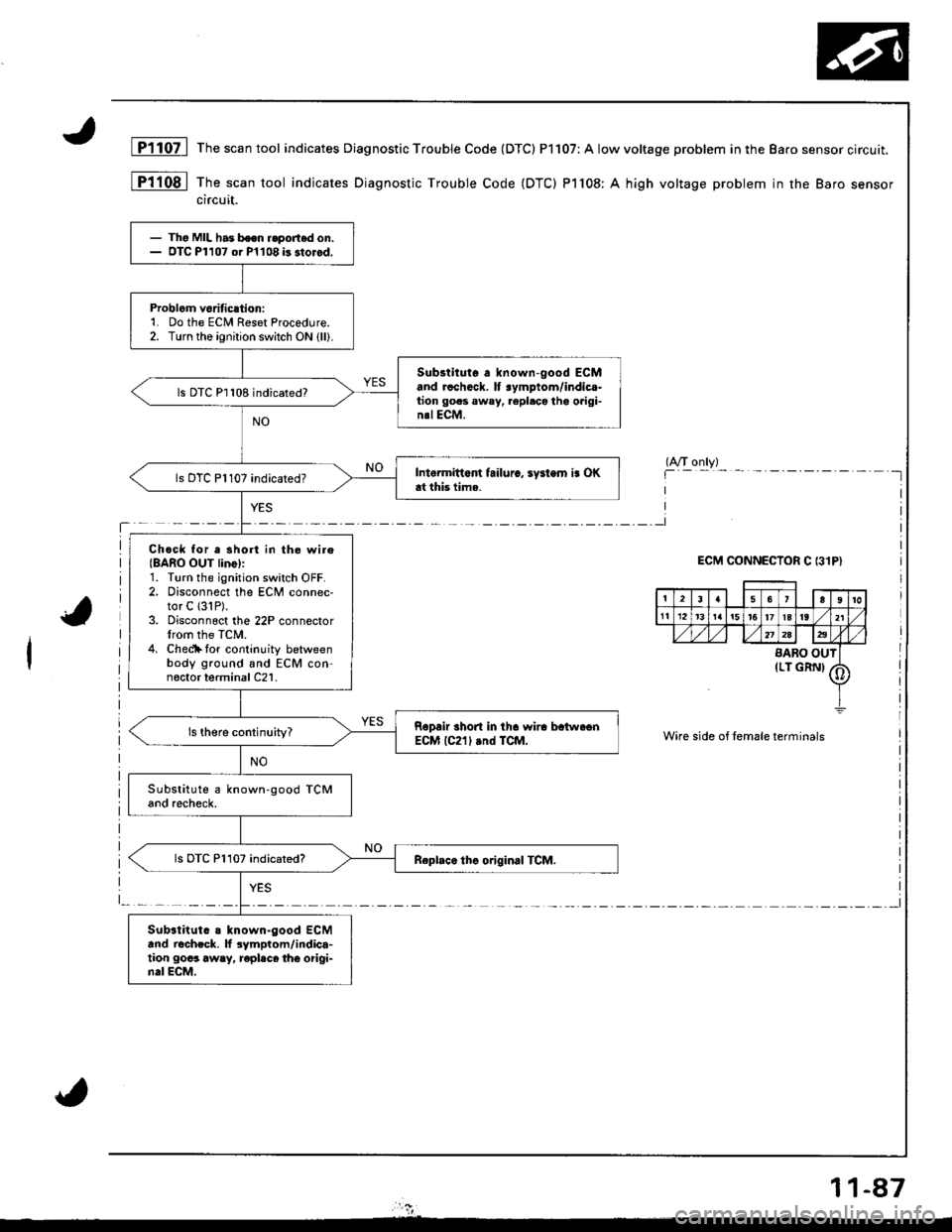

- Thg MIL has been reportod on.- OTC Pl107 or P1108 b stor6d.

Problgm v6riticrtion:1. Do the ECM Reset Procedure.2. Turn the ignition switch ON (ll).

Substitut6 a known-good ECMand rcchack. lt lymptom/indic.-lion go.s away, replrco lha origi-n.lECM.

ls DTC Pl108 indicated?

Intermitt.nt failurc, sy3lem i. OKat this time.ls DTC P1107 indicared?

Ch.ck for e short in th6 wire(8ARO OUT line)l1. Turn the ignition switch OFF.2. Disconnect the ECM connec-tor C 131P).3. DisconnBct the 22P connectorlrom the TCM.4. Chechtor continuity betweenbody ground and ECM con'nsctorterminalC2l.

Repair shon in tha wira bctwesnECM lC21) .nd TCM.

ls OTC Pl107 indicated?

Substitutc s known-good ECMtnd rochcck. lf symptom/indica-tion 9063 aw.y, replsco tho origi-n.l ECM.

1P1108 | The scan tool indicates Diagnostic Trouble Code (DTC) P1108: A high voltage problem in the Baro sensorcircuit.

(A/T only)

ECM CONNECTOR C (31P}

Wire side of temale terminals

P1107 | The scan tool indicates Diagnostic Troubte Code (DTCI P1107: A low voltage problem in the Baro sensor circuit.

11-87

. a,_

2aEt0

1lt31517l819 ./2l

EARO OUTI{Lr GRN) 6

Page 293 of 1681

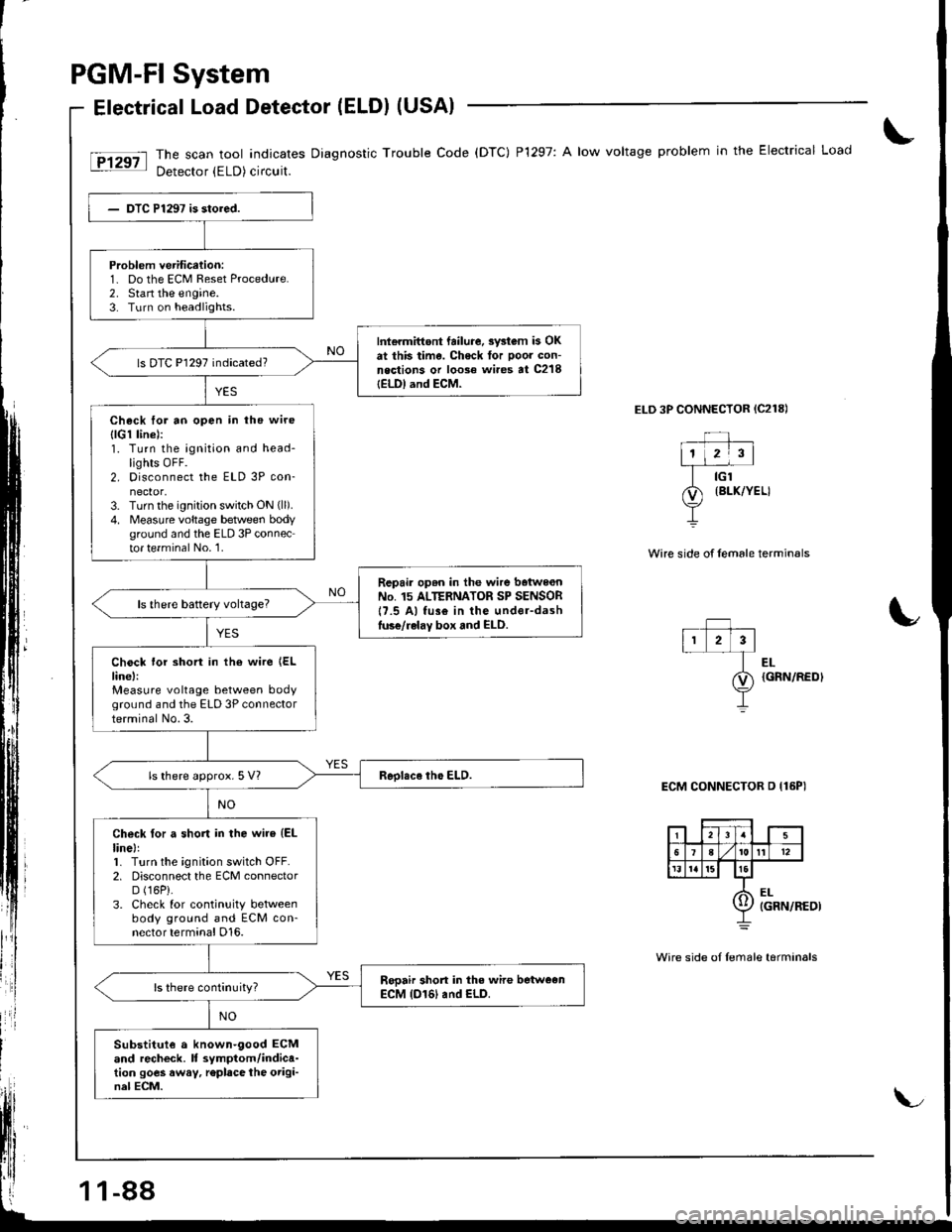

PGM-FI System

Electrical Load Detector (ELDI (USAI

The scan tool indicates Diagnostic Trouble Code (DTC) P1297: A low voltage problem in the Electrical Load

Detector (ELD) circuit.

ELD 3P CONNECTOR {C218)

Wire side of female termin€ls

Problem verification:1- Do the ECM Reset Procedure.2. Stan the engine.3. Turn on headlights.

Int€rmittont failure. swtom b OKat this time. Check tor poor con-neqtions or loose wi.es at C218IELDI and ECM-

ls DTC P1297 indicated?

Check for ao open in the wire

{lG1 linel:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con-nector,3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen bodyground and the ELD 3P connector te.minal No.'1.

Repair op6n in the wire baiwe€nNo. 15 ALTERNATOR SP SENSOR17.5 Al fus€ in the under-dashluse/relay box and ELD.

Chock lor short in the wire {ELline,:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 5 Vl

Check for a short in the wire (EL

linel:1. Turn the ignition switch OFF.2. Disconnect the ECM connectorD (16P).

3. Check for continuity betweenbody ground and ECM con-nector terminal D16.

Sooair short in the wire betweenECM (D161 and ELD.

Substitut€ a known-9ood ECMand recheck. It symptom/indica-tion goes away, r€place the origi-nal ECM.

EL{GRN/REDI

ECM CONNECTOR D {16PI

Wire side oI Iemale tarminals

11-88

Page 295 of 1681

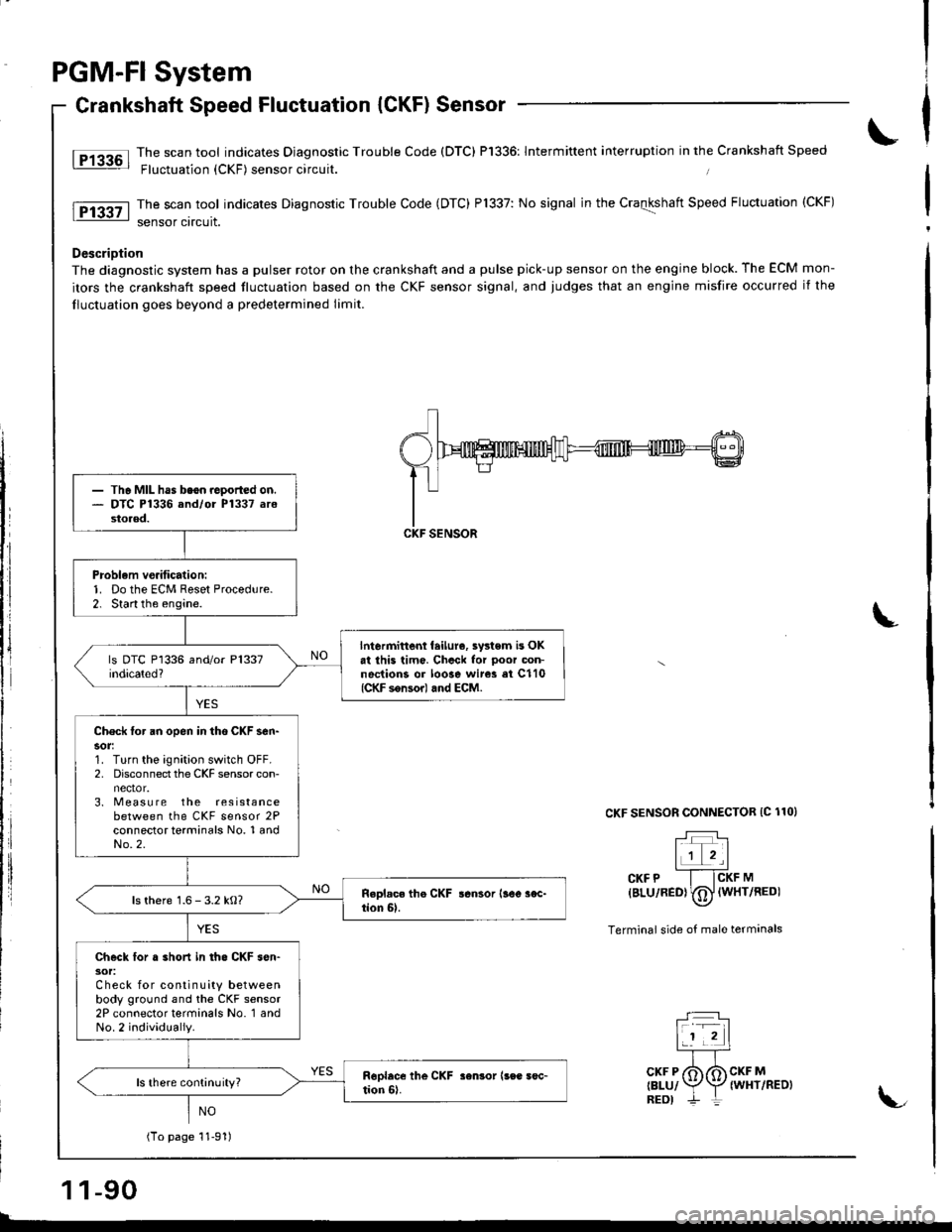

PGM-FI System

Crankshaft Speed Fluctuation {CKF) Sensor

lT13a6l Tje scan tool indicates Diagnostic Trouble Code (DTC) P'1336: lntermittent interruption in the Crankshaft Speed: Fluctuation {CKF) sensor orcurt.

The scan tool indicates Diagnostic Trouble Code (DTC) P1337: No signal in the Craqkshatt Speed Fluctuation (CKF)

sensor circuit.

DescriDtion

The diagnostic system has a pulser rotor on the crankshaft and a pulse pick-up sensor on the engine block. The ECM mon-

itors the crankshaft speed tluctuation based on the CKF sensor signal, and judges that an engine misfire occurred it the

lluctuation goes beyond a predetermined limit.

CKF SENSOR CONNECTOR IC 110)

T:lr+T

IJI',Icrr e -f-fcxr na

{BLU/RED} (D lwHr/REDI

Terminal side of male termanals

- The MIL has beon.ooorted on.- DTC P1336 and/or P1337 arostoaed.

Problem vo.itication:1. Do the ECM Reset Proced!re.2. Start the engine.

lntermittent feilure, swtem is OKat ihis timo. Chcck for ooor oon-noctions or loose wir* ei C110(CKF sonsor) and ECM.

Check for an open in tho CKF sen-sor:1. Turn the ignition switch OFF.2, Disconnect the CKF sensor con-

3. Measu re the resistancebetween the CKF sensor 2Pconnector terminals No. 1 andNo.2.

ls there 1.6 - 3.2 kO?

Check lor . short in tho CKF sen-30t:Check for continuity betweenbody ground and the CKF sensor2P connector terminals No. 1 andNo.2 individually.

ls there continuity?

(To page 11-91)

1 1-90

T:]lf -rl11 2|

TTcKF P /6 6 CKF M

relul Y\Z twxvneotneot ,-- | L

Page 296 of 1681

![HONDA INTEGRA 1998 4.G Repair Manual Ch.ck tor an open in tho wiras{CKF lino3l:1. Reconnect the CKF sensorconnector.2. Disconnoct lhe ECM connector C {31P).3. Measure resistance betweenECM connector terminals C1and C]1.

Rsprir open in HONDA INTEGRA 1998 4.G Repair Manual Ch.ck tor an open in tho wiras{CKF lino3l:1. Reconnect the CKF sensorconnector.2. Disconnoct lhe ECM connector C {31P).3. Measure resistance betweenECM connector terminals C1and C]1.

Rsprir open in](/img/13/6069/w960_6069-295.png)

Ch.ck tor an open in tho wiras{CKF lino3l:1. Reconnect the CKF sensorconnector.2. Disconnoct lhe ECM connec'tor C {31P).3. Measure resistance betweenECM connector terminals C1and C']1.

Rsprir open in thc wiro bctw6cnECM lC1, Cllland thc CKF !.nsor.ls there 1.6- 3.2 kO?

Check fo. a aho.t in tho wi.o!(CKF lines):Check for continuity betweenbody ground and ECM connectorterminal C1 and C11 individually.

Rapair ihort in the wire betweenECM {C1, C11) lnd th. CKF sensor.ls there continuity?

Sub3titute a known.good ECMsnd recheck. lt 3ymptom/indicr-tion gogr away, replaco the origi-nal ECM.

ECM CONNECTOB C (12PI

CKF P

CKF M(wHT/REDI

Wire side of female terminals

BLU/RED}

o\Y

I35I

1tt5t0t921

272aE

(cont'd)

1 1-91

Page 297 of 1681

nsnan upeeo rlucruauon lunF, Densor lconr q,

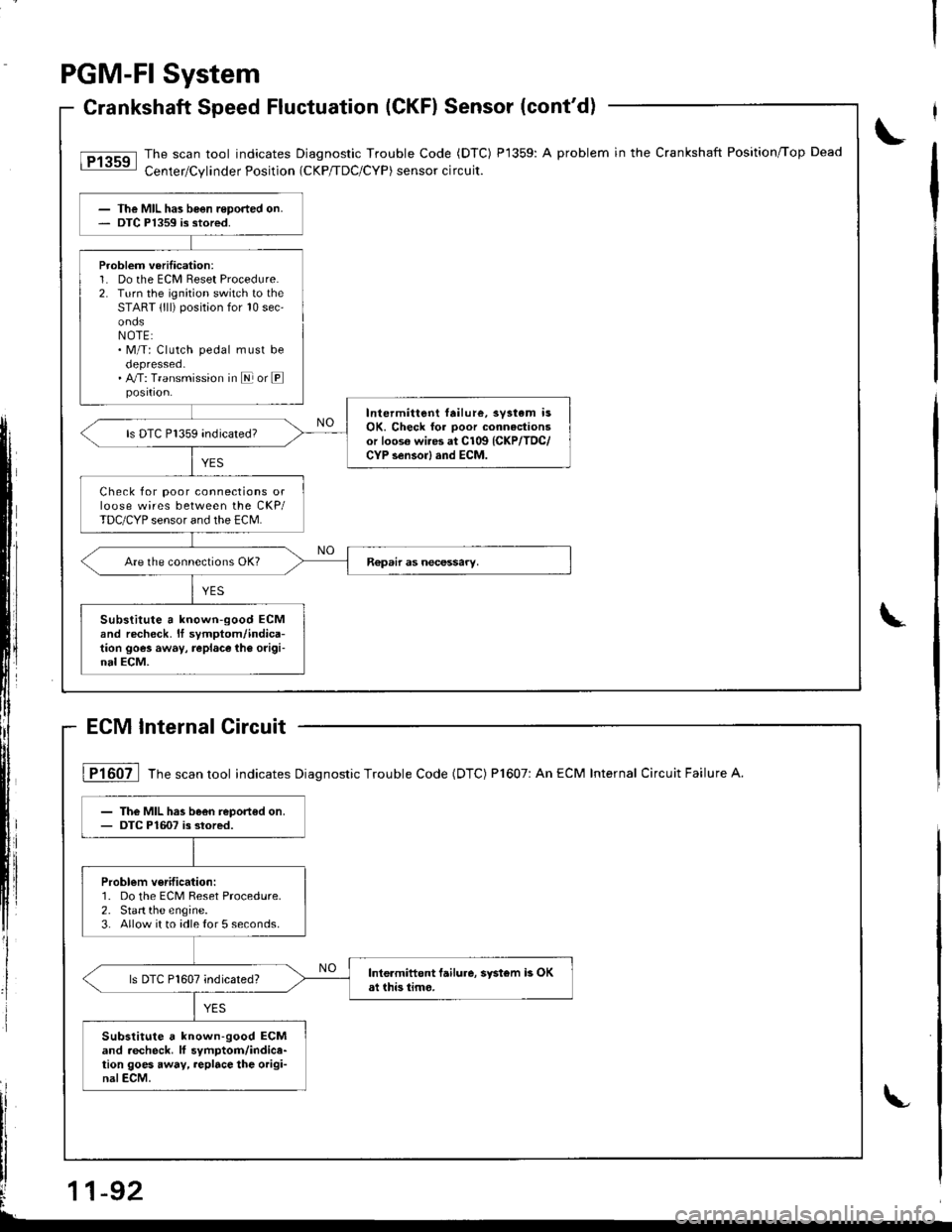

The scan tool indicates Diagnostic Trouble Code (DTC) P1359: A problem in the Crankshaft Position,Top Dead

Cenler/Cylinder Position (cKP/TDC/CYP) sensor circuit.tPr3ssl

The MIL has been reported on.DTC P1359 is stored.

Problem verilication:1. Do the ECM Reset Procedure.2. Turn the ignition switch to theSTART {lll) positaon for 10 sec'

NOTE:. M/T: Clutch pedal must be

. A/T: Transmission in E or E

Intermittent failure, svstem isOK. Check for ooor connactionsor loos€ wi.es at C109 {CKP/TDC/CYP sensorl and ECM.

ls DTC P1359 indicated?

Check for poor connections orloose wires between the CKP/TDC/CYP sensor and the ECM.

Substitute a known-good ECMand recheck. It symptom/indica-tion goes away, replace ih6 origi-nal ECM.

PGM-FI System

Crankshaft Speed Fluctuatio(CKFI Sensor (cont'd)

ECM lnternal Circuit

\

L

I P1607 Tfre scan tool indicates Diagnostic Trouble Code (DTC) Pl607: An ECM Internal Circuit Failure A.

The MIL has been reported on.DTC P16O7 is stored.

Problem verification:1. Do the ECM Reset Procedure.2. Start the engine.3. Allow it to idle {or 5 seconds.

Inte.miftent failure, systom L OKst this iimo.ls DTC P1607 indicated?

Substitute a known-good ECMand .echeck. lf symptom/indica-tion goes away, replace the origi-nalECM.

-92