indicator HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1181 of 1681

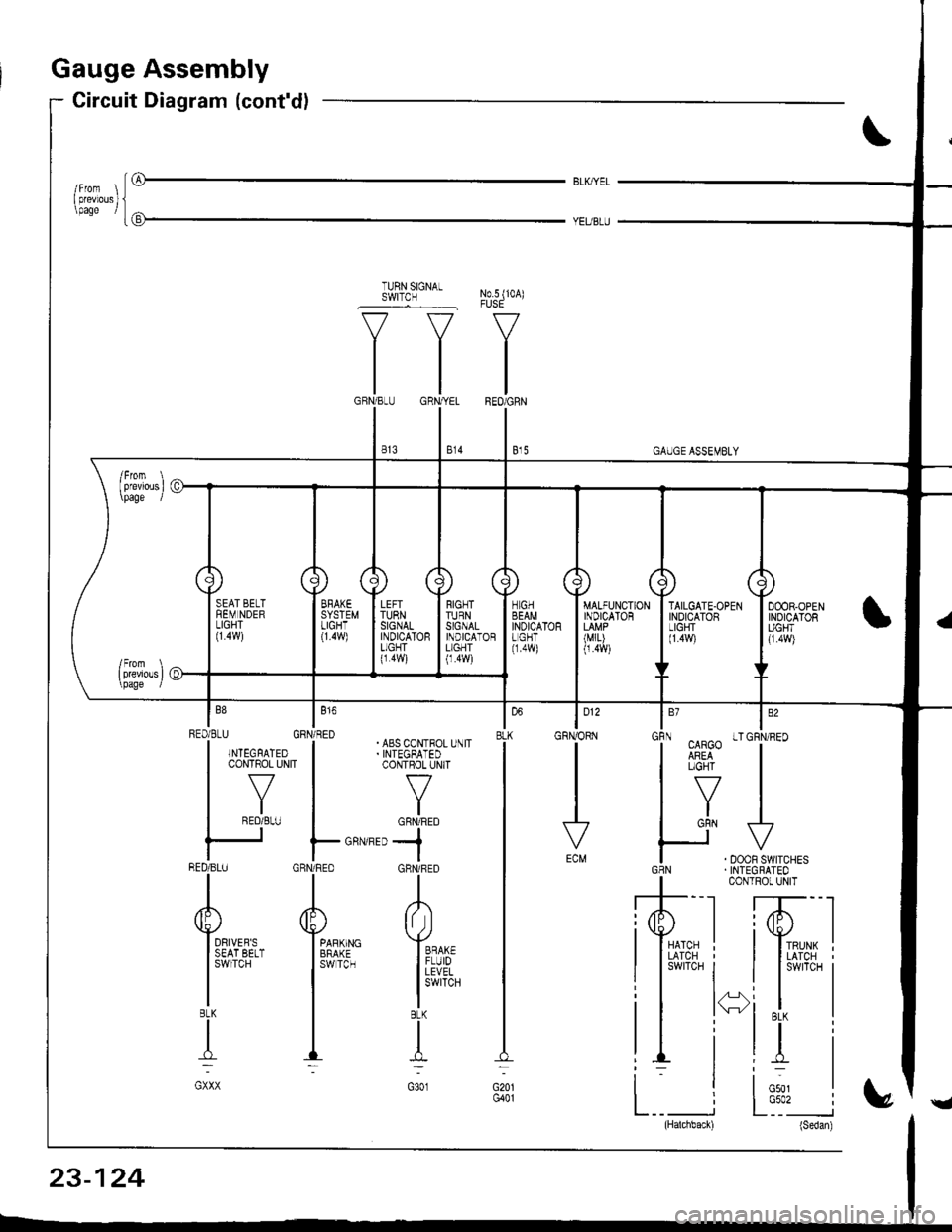

auge Assembly

Circuit Diagram (cont'dl

iG

BLK,IYEL

No.5 (10A)

V

IREO/GRN

I e,s

TURN SIGNALSWITCN

v--=v

tltl

tlGBN/BLIJ GRN,YEL

lltl

I e's I s,o

"i.uv"'T""

H^,J.**.GBN . INTEGRATEO

I coNrRor uNrT

,'T--l ffi--l

lI*ni lI*i

il i*i t i

i. li;, I

L__ i L:'�_" i(Hatchback) (Sedan)

| 012

GRNORN

vECM

louBLK

G20lG401

RIGNTTURNSIGNALINDICATORL]GHT(1.4w)

TAILGATE.OPENINDICATORLIGHT(1.4!9

RED/BLU GBN/RED| | . ABS CoN-FOL U\lTI .NTEGFATED I .INTEGBATED

|

*v^"

|

-'v*

| .roL-" I or*frro

ts Fo.''-,,-jBED/BLU GRN/RED GHNi RED

rrl

AAA

Yu'**- Y*,,r" Y**

l3$i;.?.'' 13ffi3- ll#,

| | l!i,Iib'.

TIT:-_:

GXXX G3O1

23-124

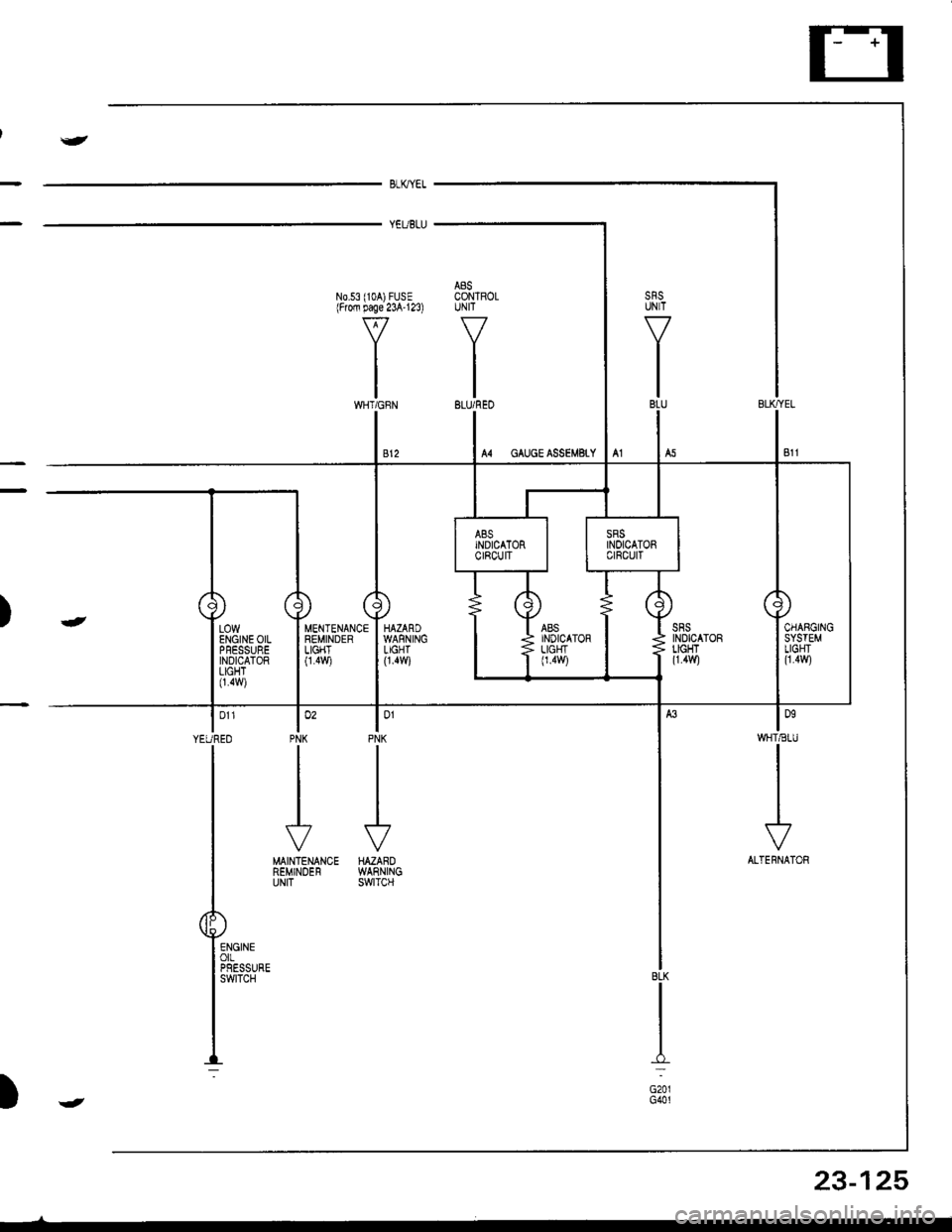

Page 1182 of 1681

J

BLKYEL

YEUBLU

A8SN0.53 (104) FUSE CONTROLlFrofi page 23A'123) UNIT

VV

II

tltlWHT/GFN BLU/REO

lonWHT€IU

I

I

I

\?

ALTERNATOR

lo'PNK

J

HAZAROWARNINGswtTcH

MENTENANCEREMINDERLIGHT0.4v,/i

lo'PNK

II

I

J

MAINTENANCEREMINDERUNIT

| 011

YEUREO

I

T

P"-:

)-

BLK

I:

G201G401

LOWENGINE OILPFESSUREINDICATORLIGHT0.4w)

23-125

)J

Page 1190 of 1681

I

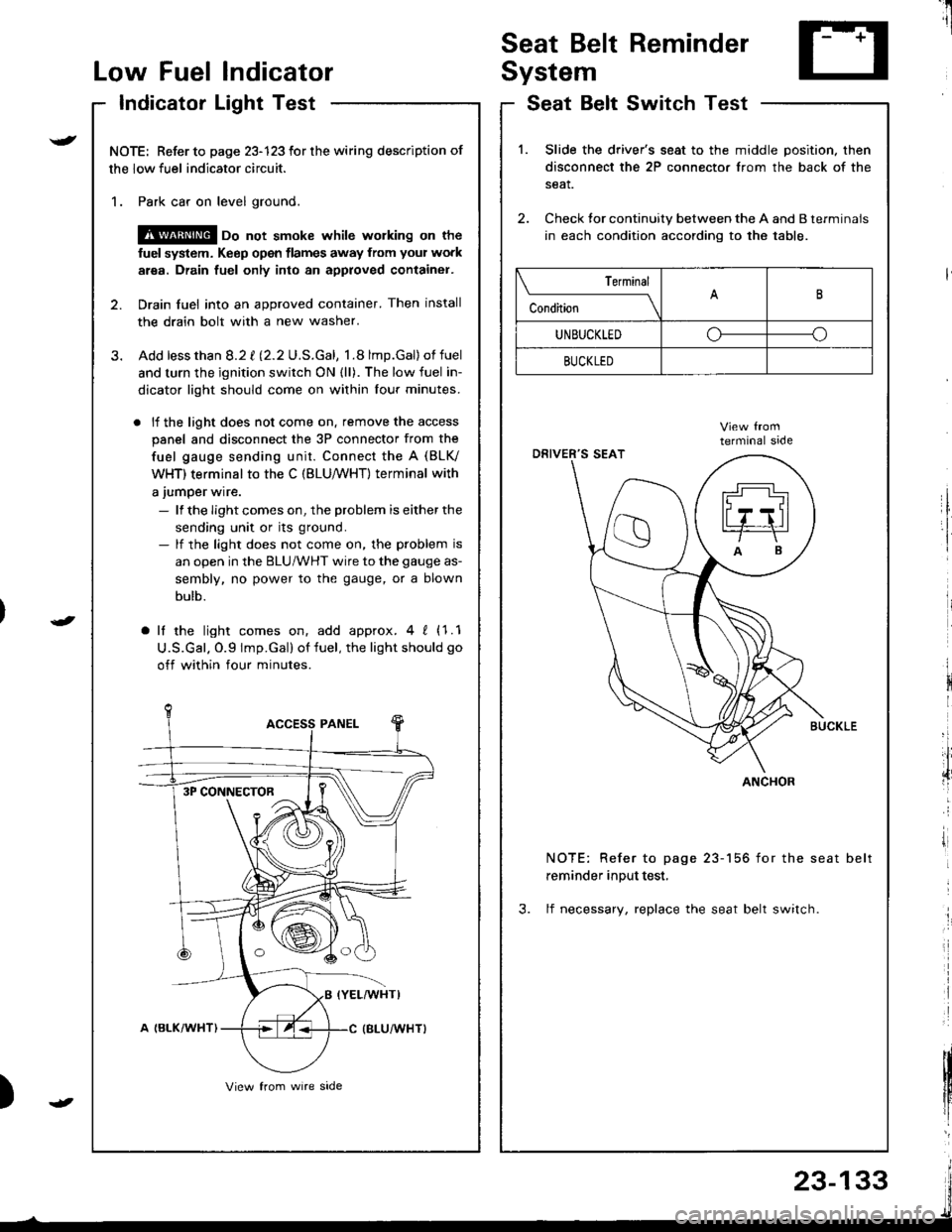

Seat Belt Reminder

SystemLow Fuel lndicator

Indicator Light Test

NOTE: Refer to page 23-123 for the wiring description of

the low fuel indicator circuit.

1. Park car on level ground.

@ oo not smoke whilc wolking on the

fuel system. Keep open tlames away from your work

area. Drain fuel only into an approved container.

2. Drain fuel into an approved container. Then install

the drain bolt with a new washer.

3. Add lessthan 8.2 t l2.2U.S.Gal, 1.8 lmp.Gal)of fuel

and turn the ignition switch ON {ll). The low fuel in-

dicator light should come on within lour minutes.

. lf the light does not come on. remove the access

panel and disconnect the 3P connector from the

fuel gauge sending unit. Connect the A (BLV

WHT) terminal to the C (BLU,/WHT) terminal with

a jumper wire.

- lf the Iight comes on, the problem is either the

sending unit or its ground.- lf the light does not come on, the problem is

an open in the BLU/WHT wire to the gauge as-

sembly, no power to the gauge, or a blown

bulb.

a lf the light comes on, add approx.4 ! (1.1

U.S.Gal. O.9 lmp.Gal) of fuel, the light should go

off within four minutes.

I

i

)

SeatSwitchTestBelt

1.Slide the driver's seat to the middle position. then

disconnect the 2P connector from the back of the

seat.

Check tor continuity between the A and B terminals

in each condition according to the table.

NOTE: Refer to page 23-156 for the seat belt

reminder input test,

3. lf necessary, replace the seat belt switch.

Terminal

c""dil----lB

UNBUCKLEDoo

BUCKLED

ANCHOR3P CONNECTOR

23-133

Page 1192 of 1681

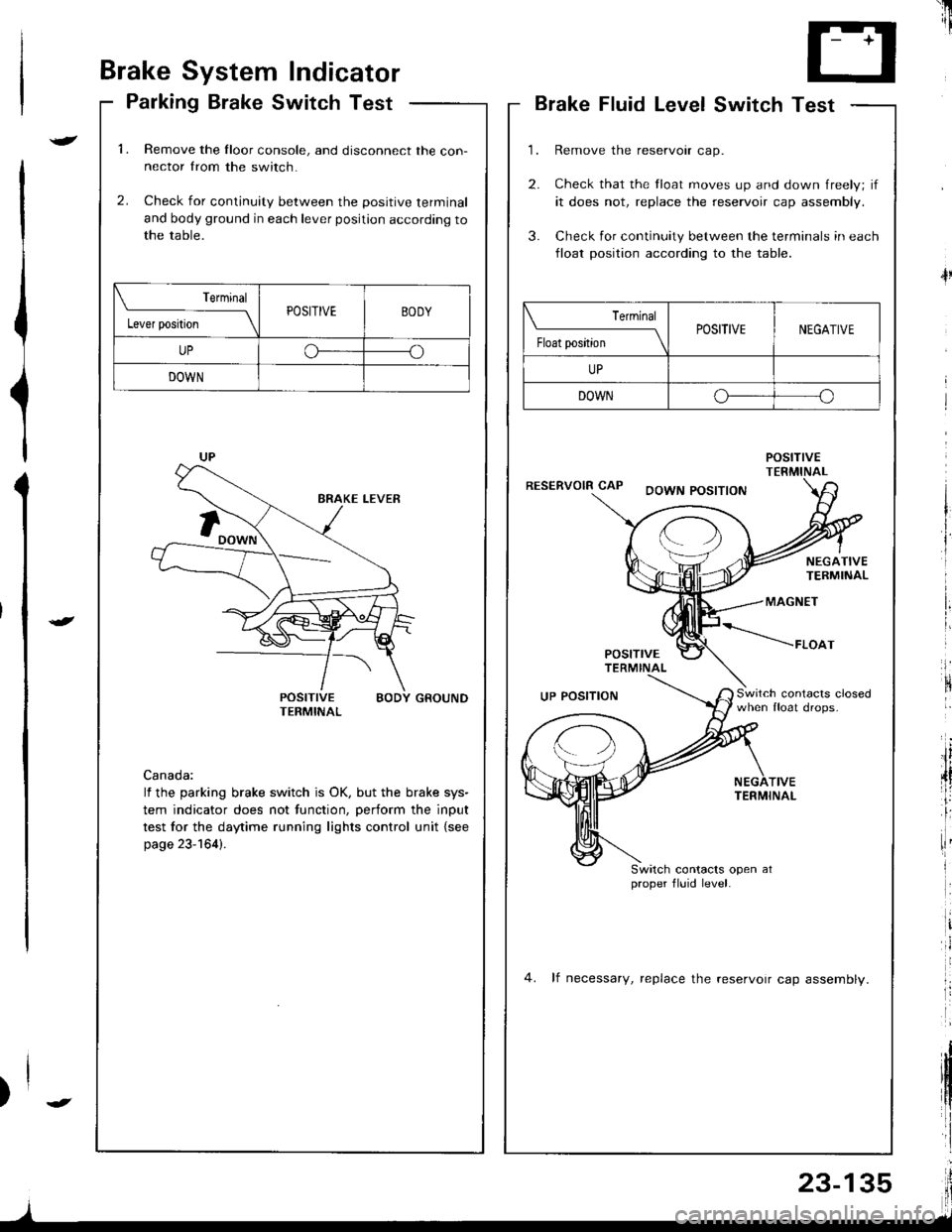

Brake System Indicator

Parking Brake Switch Test

1.Remove the Iloor console, and disconnect the con-nector from the switch.

Check for continuity between the positive terminal

and body ground in each lever position according tothe table.

2.

POSITIVE BODY GROUNDTERMINAL

Canada:

lf the parking brake switch is OK, but the brake sys-

tem indicator does not function, perform the input

test for the daytime running lights control unit {see

page 23-164).

Terminal

l"*rr*ril---ltPOSITIVEBODY

UPoo

DOWN

'il

--r '1i

T- +T

L.J

Brake Fluid LevelSwitch Test

Remove the reservoir cap.

Check that the float moves up and down freely; if

it does not, replace the reservoir cap assembly.

Check for continuity between the terminals in each

lloat position according to the table.

POStnVETERMINALRESERVOIR CAPDOWN POSITION

4l

NEGATIVETERMINAL

MAGNET

POSITTVETERMINAL

*----raoo,

Switch contacrs closedwhen float drops.UP POSITION

TIVETERMINAL

Switch contacts open atproper fluid level.

4. lf necessary, replace the reservoir cap assemblv.

| ermrnal

Float position \POSITIVENEGATIVE

UP

DOWNo--o

I

Page 1197 of 1681

![HONDA INTEGRA 1998 4.G Manual PDF A/T Gear Position Indicator

Component Location Index

GAUGE ASSEMALYRemoval, page 23-126Disassembly, page 23-127Bulb Locations, page 23-122INTERLOCK SYSTEMDescription, page 23-147A/T GEAR POS]TIONINDI HONDA INTEGRA 1998 4.G Manual PDF A/T Gear Position Indicator

Component Location Index

GAUGE ASSEMALYRemoval, page 23-126Disassembly, page 23-127Bulb Locations, page 23-122INTERLOCK SYSTEMDescription, page 23-147A/T GEAR POS]TIONINDI](/img/13/6069/w960_6069-1196.png)

A/T Gear Position Indicator

Component Location Index

GAUGE ASSEMALYRemoval, page 23-126Disassembly, page 23-127Bulb Locations, page 23-122INTERLOCK SYSTEMDescription, page 23-'147A/T GEAR POS]TIONINDICATORInput Test, page 23-142

A/T GEAR POSTTION SWITCHTest, page 23-144R6olacement, section 14

:S

23-140

Page 1199 of 1681

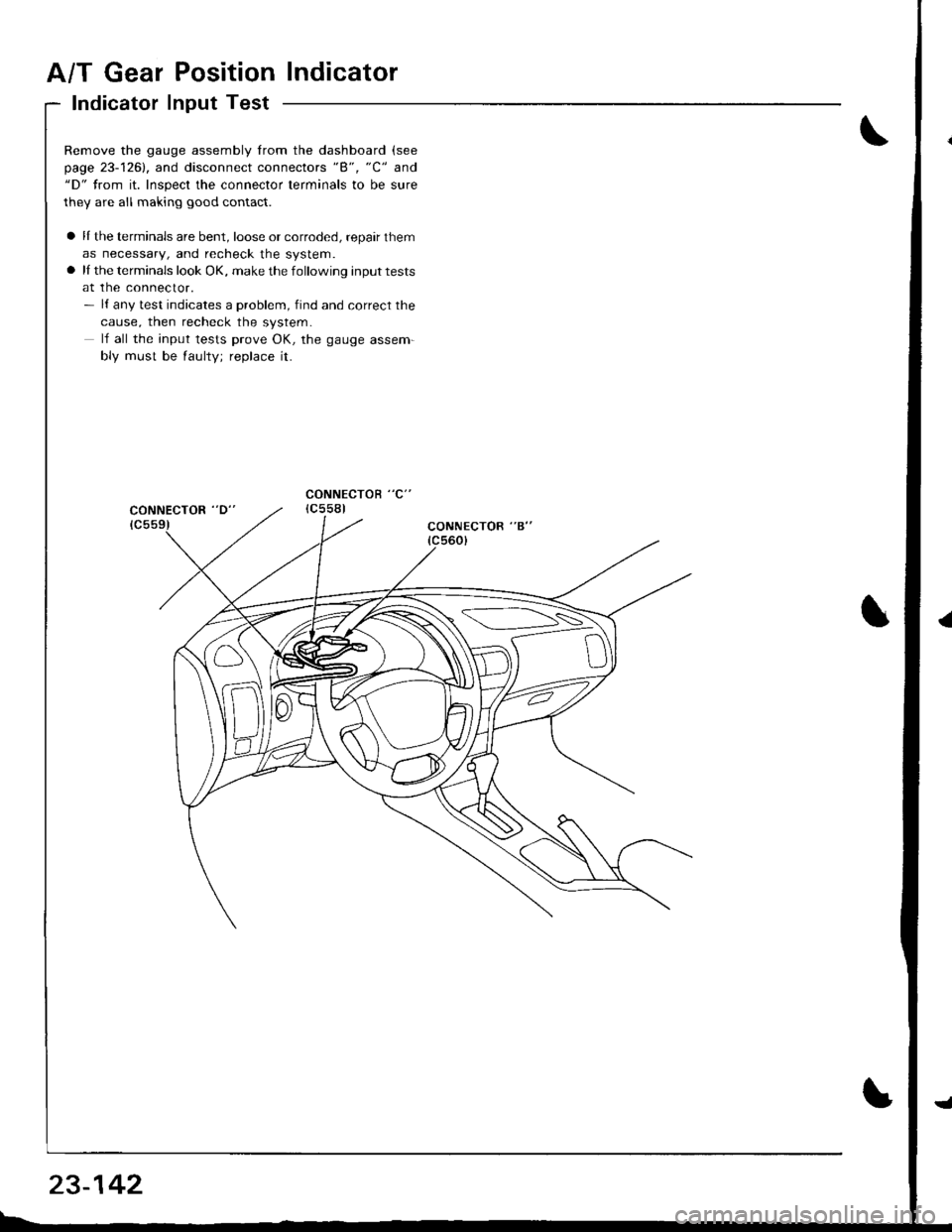

A/T Gear Position Indicator

Indicator Input Test

Remove the gauge assembly from the dashboard (see

page 23-1261, and disconnect connectors "8", "C" and"D" from it. Inspect the connector terminals to be sure

they are all making good contact.

a lI the terminals are bent, loose or corroded, repair them

as necessary, and recheck the system.a lI the terminals look OK, make the following input tests

at the connector.- l{ any test indicates a problem, find and correct the

cause, then recheck the system.

lf all the input tests prove OK, the gauge assem-

bly must be faulty; replace it.

CONNECTOR "B"

=------'\-\-\\---- =

23-142

Page 1201 of 1681

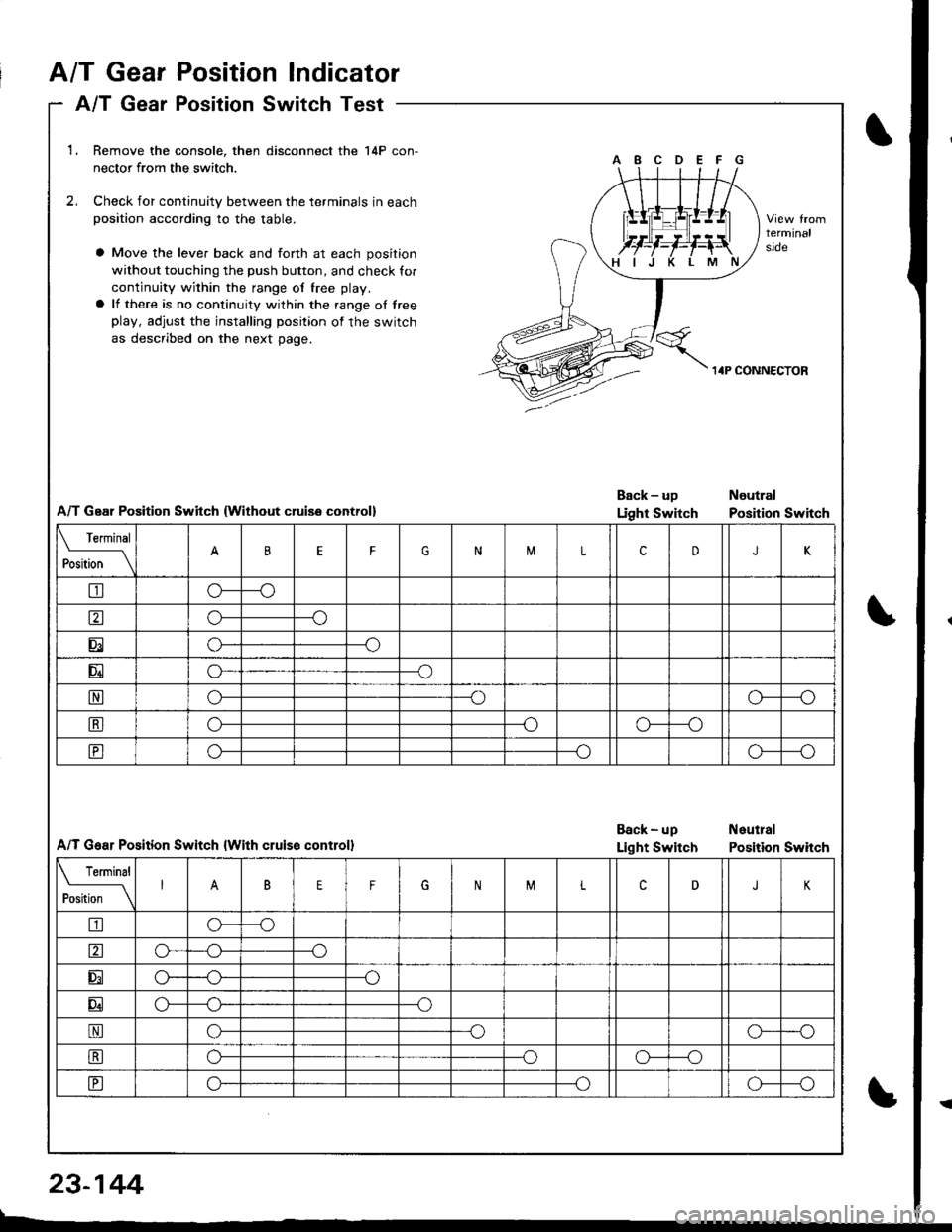

1.Remove the console, then disconnect the 14P con-

nector from the switch.

Check for continuity between the terminals in eachposition according to the table.

2.

Move the lever back and forth at each position

without touching the push button, and check fof

continuity within the range of free play.

lf there is no continuity within the range of freeplay, adjust the installing position of the switch

as described on the next page.

terminalsroe

A/T Geal Position Switch lwithout cluise control)

Back-uD Noutral

Light Switch Position Switch

A/T G€ar Position Switch lwith cluise controll

Back - up Neutlal

Light Switch Position Switch

Terminal

P*m""

_\BFGNiTLcDJK

tro---o

ao---o

Eo---o

Eo---o

No--_o--o

tro---oo---o

Eo--_oo---o

rermrnal

t]"t-

_\BEFGNMLcDJ

tro----o

o---o

EG_--o

Eo---o

No---oo---o

tro--oo---o

EG---oo---o

A/T GearPosition Indicator

A/T GearPosition Switch Test

23-144

I

Page 1209 of 1681

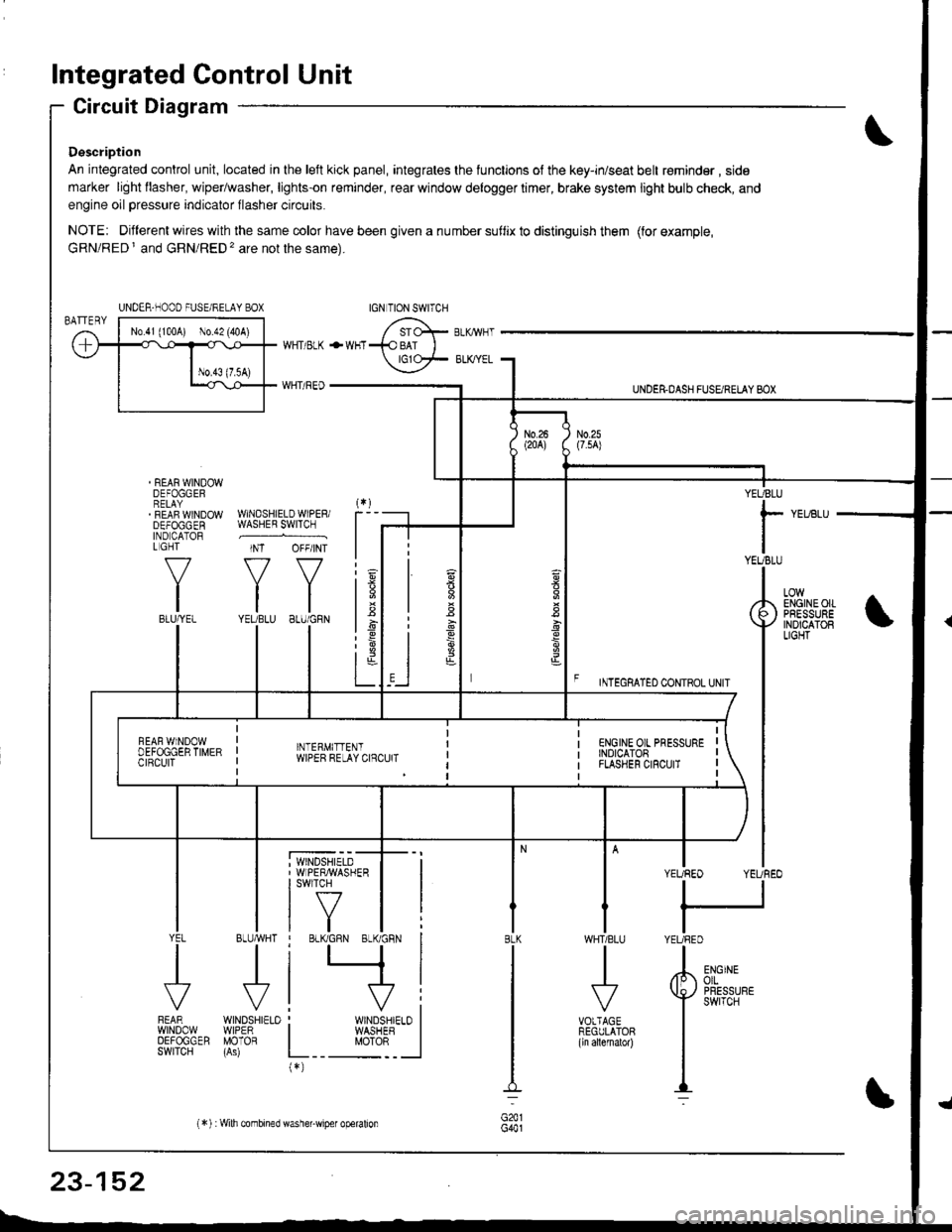

Integrated Control Unit

Circuit Diagram

Description

An integrated control unit, located in lhe left kick panel, integrates the lunctions of the key-in/seat belt r€minder , side

marker light llasher, wiper/washer, lights-on reminder, rear window delogger timer, brake system light bulb check, and

engine oil pressure indicator flasher circuits.

NOTE: Different wires with the same color have been given a nu mber suflix to distinguish them (for example,

GRN/RED I and GRN/RED'� are not the same).

REAR WINDOWDEFOGGERRELAYREAF WINDOWDEFOGGENIND CATORL GHT

f-7

IIBLU/YEL

WHT/ BLK

WHT/ REO

+WHT

WNDSHIELDWIPERiWASHER SWITCH

INT OFF/INT

f7 f7

tltlYEUBLU 8LU/GRN

BLUMHT

J

wtN0sHr€10WIPERMOTOR

UNDER.DASH FUSARETAY BOX

F rmecnlleo counoL ultr

YEUBLU

rYEUBLU

YEUREO YEUREO

tl

IYEURED

LOWENGINEOIIPRESSUREINOICATOBLIGHT

; WINDSHIELD' WIPERMASHERI swlTcH

tf7IVtlYEL

J

FEARwtN00wOEFOGGERSWITCH

WHTIBLU

J

VOTTAGEREGULATOR(ln allernatol)

BLK

G441

ENGINEolLPRESSUREswrTcH

UNDER-NOOO FUSE/RELAY BOX

1.6

:6

t;t-L

i

"'i'- 'i*-

|

I Il

I vi: WINDSHIELO II WASHEB I

L__ "oto: _ __l(*)

n

s

s

,]

23-152

(*) :Wilh combined washer-wiper operalion

Page 1213 of 1681

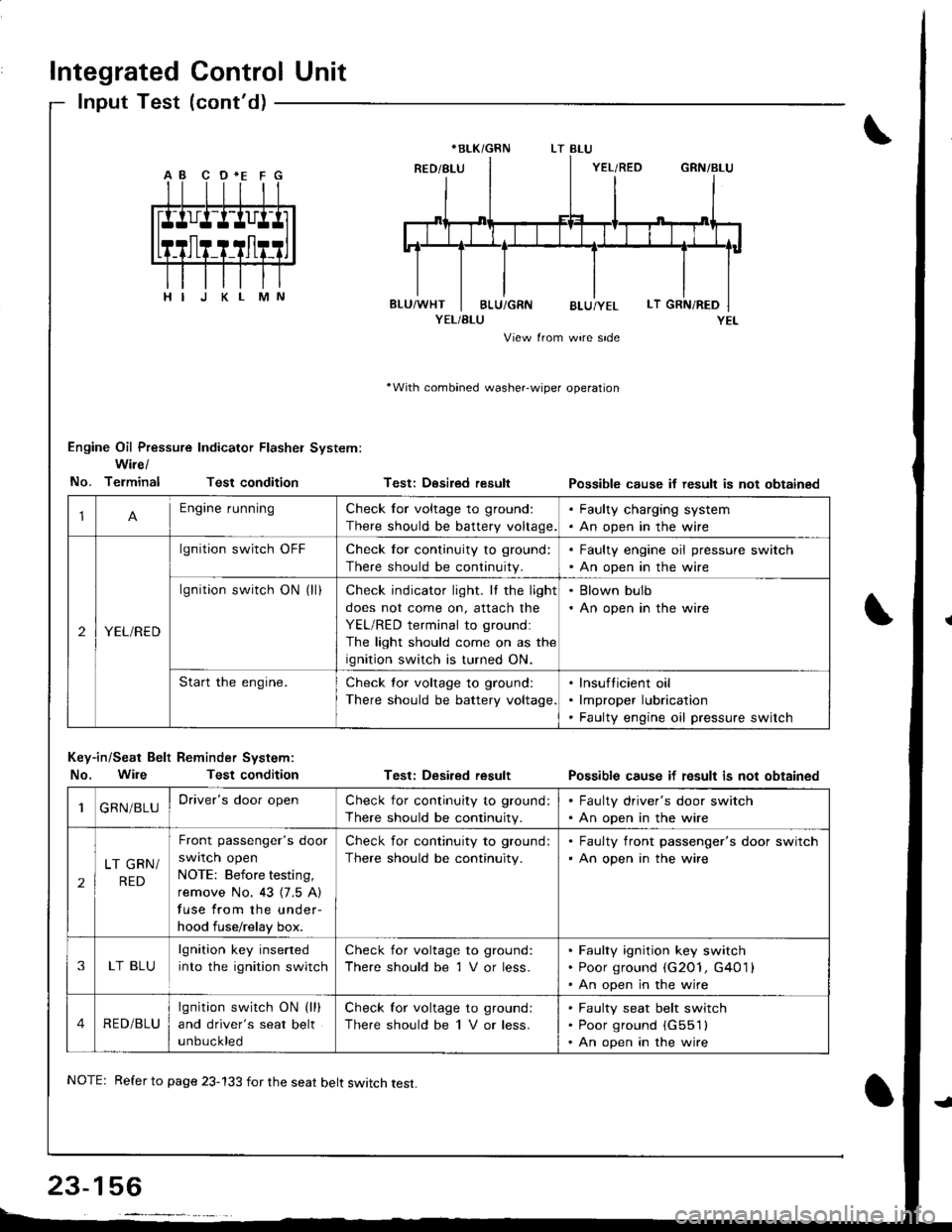

Integrated Control Unit

lnput Test (cont'd)

YEL/BLU

View from wire side

'With combined washer-wiper operation

Engine Oil Pressure Indicator Flasher System:

Wire/

No. TerminalTest condition

Key-in/Seat Belt Reminder System:

No. WileTest condition

Testi Desired result

Test: Desired result

Possible cause if result is not obtainsd

Possible cause if fesult is not obtained

*BLK/GRN

1Engine runningCheck for voltage to ground:

There should be battery voltage.

. Faulty charging system. An open in the wire

2YEL/RED

lgnition switch OFFCheck for continuity to ground:

There should be continuity.

. Faulty engine oil pressure switch. An open in the wire

lgnition switch ON (ll)Check indicator light. It the light

does not come on, attach the

YEL/RED terminal to groundl

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the wire

Start the engine.Check tor voltage to ground:

There should be battery voltage

lnsufticient oil

lmproper lubrication

Faulty engine oil pressure switch

1GRN/BLUDriver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An open in the wire

2

LT GRN/

RED

Front passenger's door

swrlcn open

NOTE: Before testing,

remove No. 43 {7.5 A)

fuse from the under-

hood fuse/relay box.

Check for continuity to ground:

There should be continuity.

. Faulty front passenger's door switch'An open in the wire

3LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G2O1, G401 l

An open in the wire

4RED/BLU

lgnition switch ON (lll

and driver's seat belt

unbuckled

Check for voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground (G551l

An open in the wire

NOTE: Refer to page 23-133 for the seat belt switch test.

Page 1216 of 1681

)

Engine Oil Pressure

Indicator System

Description

NOTE: Refer to page 23-152 for the circuit diagram ofthe engine oil pressure indicator flasher. and to page 23

156 for the input test of the flasher circuit.

The low engine oil pressure indicator light works in twoways. lt will flash continuously following a momentaryloss ol oil pressure, or it will go on and stay on wath a

complete loss of oil pressure.

When the engine first starts, before oil pressure rises

above 29.4 kPa (O.3 kgf/cmr, 4.3 psi), current flows

through the low engine oil pressure indicator light andthe oil pressure switch to ground. This tests the circuit.

With the engine running, voltage is applied to the Ilash-er circuit of the integrated control unit. With normal oilpressure, the oil pressure switch is open and the low en-gine oil pressure indicator light does not operate. lf the

oil pressure switch closes momentarily (more than O.5

seconds). but then opens again, terminal "YEL/RED" will

sense ground through the switch- The integrated con-trol unit will then provide and remove ground tor the low

engine oil pressure indicator light through terminal"YEL/RED". The light will flash on and off untilthe igni

tion switch is turned to "OFF".

lf engine oil pressure talls below 29.4 kPa (O.3 kgf/cmr,

4.3 psi) and does not increase, the oil pressure switchwill stay closed. The low engine oil pressure indicator light

will go on and stay on.

NOTE: Refer to page 23-130 for the engine oil pressure

switch test.

I

23-159