brake Hyundai Matrix 2003 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 256 of 312

DRIVING YOUR HYUNDAI

2- 14 YC200E2-E Trailer or Vehicle Towing Tips

1. Before towing, check hitch and safety chain

connections as well as proper operation of the trailer running lights, brake lights, andturn signals.

2. Always drive your vehicle at a moderate speed (Less than 62 MPH)

3. Trailer towing requires more fuel than nor- mal conditions.

4. To maintain engine braking efficiency and electrical charging performance, do not usefifth gear (manual transaxle) or overdrive(automatic transaxle). Towing Bracket Attachment Location

NOTE:

o The total gross vehicle weight with trailer must not exceed the Gross Vehicle Weight Rating (GVWR) shown on thevehicle identification plate (see page 8-1). The total gross vehicle weight is thecombined weight of the vehicle, driver,all passengers and their luggage, cargo,hitch, trailer tongue load and other op-tional equipment.

o The front or rear axle weight must not exceed the Gross Axle Weight Rating(GAWR) shown on the vehicle identifi-cation plate (see page 8-1). it is possiblethat your towing package does not ex-ceed the GVWR but exceeds the GAWR.Improper trailer loading and/or too muchluggage in the trunk can overload therear axle. Redistribute the load andcheck the axle weight again. MANUAL

TRANSAXLE

AUTO

TRANSAXLE Trailer

1,300 1,100 550 Tongue

52

kg

Maximum Towable Weight

With BrakeType

1.5 Diesel 1.6/1.8 L

1.6/1.8 L

Without Brake Type

o The maximum permissible static verti- cal load on the coupling device : 52kg

o The maximum permissible overhang of the coupling point : 760 mm.

C190E01FC

will assist with braking performance when long down hill gradients are encountered.Improved acceleration performance will beavailable by selecting "Overdrive Off","2", or"1" depending upon road speed if it is foundthat the transmission unit makes an undesir-able upshift whilst hill climbing or overtaking.The transmission unit should be operated in"D" with the Overdrive "On" under normalcircumstances to enhance fuel economy andreduce noise and engine wear.

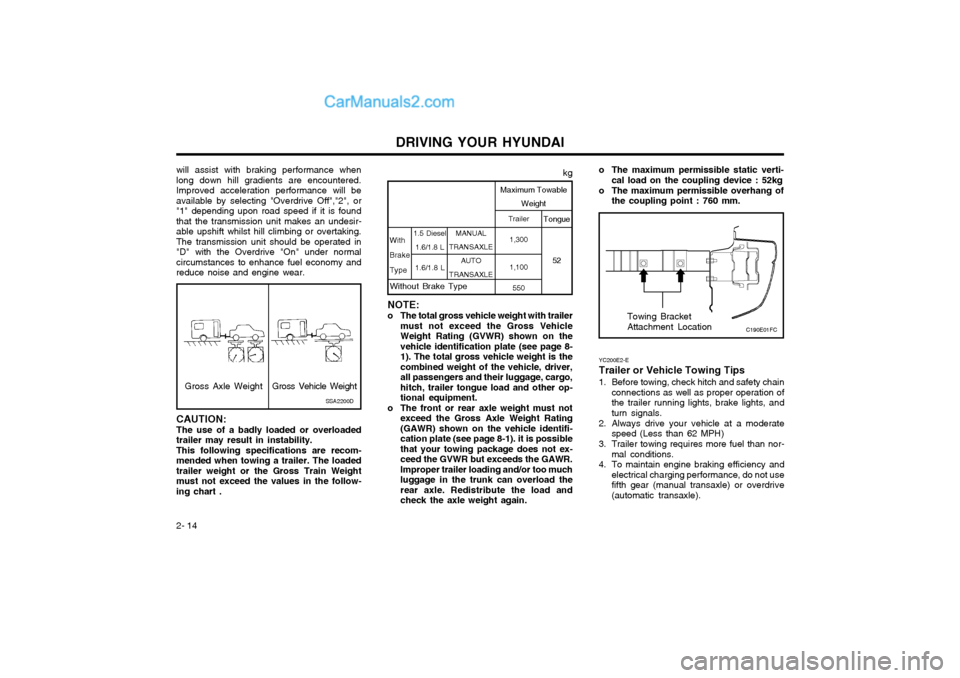

Gross Axle Weight

CAUTION: The use of a badly loaded or overloaded trailer may result in instability.This following specifications are recom-mended when towing a trailer. The loadedtrailer weight or the Gross Train Weightmust not exceed the values in the follow-ing chart . SSA2200DGross Vehicle Weight

Page 257 of 312

DRIVING YOUR HYUNDAI 2- 15

5. Always secure items in the trailer to pre-

vent load shift while driving.

6. Check the condition and air pressure of all tyres on the trailer and your car. Low tyre pressure can seriously affect the handling.Also check the spare tyre.

7. The vehicle/trailer combination is more af- fected by crosswind and buffeting. When being passed by a large vehicle, keep a constant speed and steer straightahead. If there is too much wind buffetingslow down to get out of the other vehicle'sair turbulence.

8. When parking your car and trailer, espe- cially on a hill, be sure to follow all thenormal precautions. Turn your front wheelinto the curb, set the parking brake firmly,and put the transaxle in 1st or Reverse(manual) or Park (automatic). In addition,place wheel chocks at each of the trailer'styres.

9. If the trailer has electric brakes, start your vehicle and trailer moving, and then applythe trailer brake controller by hand to besure the brakes are working. This lets youcheck your electrical connection at thesame time.

10.During your trip, check occasionally to be sure that the load is secure, and that thelights and any trailer brakes are still work-ing. 11.Avoid jerky starts, sudden acceleration or

sudden stops.

12.Avoid sharp turns and rapid lane changes.

13.Avoid holding the brake pedal down too long or too frequently. This could cause the brakes to overheat, resulting in re-duced braking efficiency.

14.When going down a hill, shift into a lower gear and use the engine braking effect. When ascending a long grade, downshift the transaxle to a lower gear and reducespeed to reduce chances of engine over-loading and/or overheating.

15.If you have to stop while going uphill, do not hold the vehicle in place by pressing onthe accelerator. This can cause the auto-matic transaxle to overheat. Use the park-ing brake or footbrake.

NOTE: When towing check transaxle fluid more frequently. CAUTION: If overheating should occur when towing,(temperature gauge reads near red zone),taking the following action may reduce oreliminate the problem.

1. Turn off the air conditioner.

2. Reduce highway speed.

3. Select a lower gear when going uphill.

4. While in stop and go traffic, place the gear selection in park or neutral and idle the engine at a higher speed.

Page 259 of 312

IN CASE OF EMERGENCY

3-2

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not per- formed correctly. If any doubt exists as tohow this operation should be performed,seek assistance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective clothing should be worn and care exer-cised to prevent the acid from coming intocontact with skin or clothing and the ve-hicle. Naked lights should not be permittedin the vicinity of the battery. Care shouldbe exercised to prevent sparks occurringduring connection. If acid accidentallycomes into contact with skin or eyes, theaffected area should immediately be flushed ponents such as the Fuel Injection system

computer and the Automatic Transaxlecomputer. The battery must never be dis-connected whilst the engine is running. SD040A2-E IF THE ENGINE OVERHEATS If the temperature gauge indicates overheat- ing:

1. Pull off the road and stop as soon as it is

safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle) and set the parking brake. If the air condition-ing is on, turn it off.

3. If coolant is running out under the car or steam is coming out from under the bonnetstop the engine. Do not open the bonnetuntil the coolant has stopped running orthe steaming has stopped. If there is novisible loss of coolant and no steam, leavethe engine running and check to be surethe engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see that it is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioning had been in use, it isnormal for cold water to be draining fromit).

SD030A1-E JUMP STARTING

with copious amounts of water and medi- cal assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed inanother vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle pro- viding the jump start is running prior toconnection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedischarged battery.

5. Attach the black jump cable to the nega- tive (-) terminal of the booster battery, andthe other end to a ground point within theengine compartment of the vehicle withthe flat battery. Do not connect to thenegative battery terminal of the flat batterysince sparks may be generated with thesubsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Remove jump cables in the reverse order of installation (black cable first).

CAUTION:If the jump cable is incorrectly installed,damage to the vehicle electrical systemmay occur, in particular the electronic com-

HFC4002

Booster battery Discharged battery

Page 261 of 312

IN CASE OF EMERGENCY

3-4

SD070A1-E

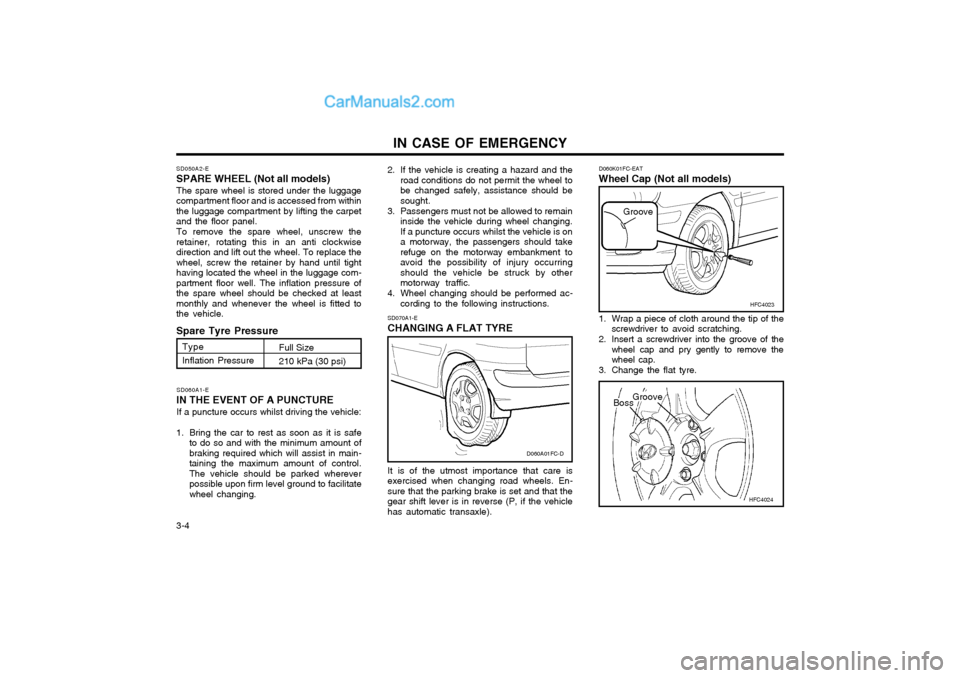

CHANGING A FLAT TYRE

It is of the utmost importance that care is exercised when changing road wheels. En-sure that the parking brake is set and that thegear shift lever is in reverse (P, if the vehiclehas automatic transaxle).

D060A01FC-D

D060K01FC-EAT

Wheel Cap (Not all models)

HFC4024

1. Wrap a piece of cloth around the tip of the

screwdriver to avoid scratching.

2. Insert a screwdriver into the groove of the wheel cap and pry gently to remove the wheel cap.

3. Change the flat tyre. HFC4023

Groove

BossGroove

SD060A1-E

IN THE EVENT OF A PUNCTURE If a puncture occurs whilst driving the vehicle:

1. Bring the car to rest as soon as it is safe to do so and with the minimum amount of braking required which will assist in main-taining the maximum amount of control.The vehicle should be parked whereverpossible upon firm level ground to facilitatewheel changing.

SD050A2-E SPARE WHEEL (Not all models) The spare wheel is stored under the luggage compartment floor and is accessed from withinthe luggage compartment by lifting the carpetand the floor panel. To remove the spare wheel, unscrew the retainer, rotating this in an anti clockwisedirection and lift out the wheel. To replace thewheel, screw the retainer by hand until tighthaving located the wheel in the luggage com-partment floor well. The inflation pressure ofthe spare wheel should be checked at leastmonthly and whenever the wheel is fitted tothe vehicle.

Spare Tyre Pressure

Type Inflation Pressure Full Size210 kPa (30 psi)

2. If the vehicle is creating a hazard and the

road conditions do not permit the wheel to be changed safely, assistance should besought.

3. Passengers must not be allowed to remain inside the vehicle during wheel changing.If a puncture occurs whilst the vehicle is ona motorway, the passengers should takerefuge on the motorway embankment toavoid the possibility of injury occurringshould the vehicle be struck by othermotorway traffic.

4. Wheel changing should be performed ac- cording to the following instructions.

Page 265 of 312

IN CASE OF EMERGENCY

3-8 The vehicle may be towed by the conven-

tional method using the towing eye at the front of the vehicle as an attachment point. Inaddition, a suspended tow with or without anambulance may be used with either the frontor the rear wheels being suspended, providedthe above caution is observed. In addition, the following points must be noted:

o If towing by conventional means, the ignition key must be at the "ACC" posi- tion, otherwise the steering lock will beactivated.

o Because the brake system and steering system power assistance is derived fromthe engine, the amount of effort re-quired to stop or steer the vehicle willbe greater than normal. o If a suspended tow is being given to the

rear, the ignition key must be at the"ACC" position since the steering lockis not designed to withstand the forcerequired to hold the front wheels straightduring the tow.

o The vehicle must not be towed with the front wheels on the ground for morethan thirty miles.

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE

SD100A2-E

Automatic Transaxle Vehicle

o NOT OK FOR AUTOMATIC TRANSAXLE EQUIPPED VEHICLE

o OK FOR MANUAL TRANSAXLE

The vehicle may be towed by the conven- tional method using the towing eye at the frontof the vehicle as an attachment point. In addition, a suspended tow may be given to the front of the vehicle without an ambulance.In the event of a suspended tow being givento the rear of the vehicle, the use of anambulance is imperative. D120A01A-EAT

IF YOU LOSE YOUR KEYS

Information about the key of immobilizer sys-tem will be found on page 1-2.

CAUTION: The following restriction must be observed in order to avoid serious damage to thetransaxle . The vehicle must never be towed from the rear with the front wheels on the ground. The vehicle must not be towed until transaxle fluid has been added to bringthe level up to the "HOT" marking on thedipstick. (The level will need to be reducedagain after towing). The vehicle must not be towed at speeds faster than 25 mph. or distances greaterthan fifty miles. The general points regard-ing the steering lock etc. described in thepreceding section (Manual transaxle ve-hicle) should be observed.

SD090A1-E

Manual Transaxle Vehicle

o OK FOR AUTOMATIC OR MANUAL TRANSAXLE EQUIPPED VEHICLE WITH NO DAMAGE

D080C01FC

D080B01FC

D080C02FC

Page 267 of 312

APPEARANCE CARE

4-2

Plastic wheel covers should be cleaned using a sponge and water. Cast alloy wheels shouldbe cleaned using a mild soap or neutral deter-gent. Abrasive compounds must not be usedsince in the event of these damaging the lac-quer coating, oxidization of the aluminium wheelwill occur, spoiling the appearance.The use of an a toothbrush will facilitate cleaningbetween the wheel "spokes".

ensure that accidental spillages are immediatelyflushed with water.Do not use abrasive cleaning materials whichmay damage the bumpers.Avoid subjecting the bumpers to high tempera-tures such as may be encountered in high bakepaint ovens.

SE040B1-E STAIN/SPOT REMOVALShould tree sap, dead insects or tar prove to be difficult to remove from the paint film, turpentineor a proprietary paint cutting compound may beused. Ensure that the area to be cleaned is notrubbed intensively to prevent breaking throughthe colour coat and exposing the under coat. SE040C1-E POLISHINGThe exterior paint work should be polished with a proprietary wax polish when water no longercollects in bead form on the paint work. Theinstructions of the product manufacturer shouldbe adhered to. SE040E1-E BUMPER MAINTENANCE The special material from which the bumpers are manufactured warrants special attention to pre-serve the appearance of the bumpers. Avoidcontact with battery electrolyte or brake fluid and SE040F1-E ACCIDENT REPAIRS In the event of the body work sustaining damage, the following points should be noted prior torepairs being undertaken.If body panels are replaced or repaired, anticorrosion treatment must be applied to the repairarea. The product used must be compatible withthose used in manufacture. It is recommendedthat repairs are entrusted to a Hyundai dealer toensure that replacement parts used are of thesame high quality as those used in manufactureof the vehicle and that the correct repair methodsand materials will ensure adequate levels ofcorrosion protection and the continued validity ofthe Anti Perforation Warranty. SE050A1-E INTERIOR During the winter period, it is possible that the passenger compartment flooring may becomewet from damp footwear or quantities of snowadhering to footwear. The carpet should not beallowed to remain in this condition since thecarpet may begin to create musty smells and will

SE050D1-E SEAT BELTSSeat belts should be cleaned only with a mild soap solution. Strong detergents, solvens orbleaches may damage the belt webbing andtherefore reduce the effectiveness of the belt.Belts which display signs of fraying, wear of cutshould be replaced. SE050E1-E WINDOWS A proprietary glass cleaner should be used to clean the inside of the windows. However, therear heated windshield must only be cleanedusing a light horizontal cleaning action. Careshould be exercised to avoid the use of abrasivecleaners or contact with items of jewellery whichmay damage the heating elements.

promote corrosion of the floor pan in addition tothe carpet and under felt beginning to rot. SE050C1-E INTERIOR VALETINGThe soft trim and carpets should be maintained with the regular use of a vacuum cleaner. Heavysoiling should be removed with a dry cleaningagent recommended for this purpose followingthe instructions of the product manufacturer.Paint thinner, solvents or other such cleaningmaterials should not be used since damage tothe upholstery may result.

Page 268 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-1

SF020A1-E

MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety

of the vehicle, certain routine maintenance operations are required at specific mileage ortime intervals.

It is the responsibility of the vehicle owner to

ensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.

The new vehicle warranty may be invalidated

if the routine maintenance operations are notperformed in line with the recommendationsoutlined and the safety and durability of thevehicle adversely affected.

It is recommended that all maintenance op-

erations with the exception of the daily oper-ating checks are entrusted to a Hyundaidealer to ensure that the latest repair and maintenance procedures and specializedservicing tools are employed. In addition, theuse of genuine Hyundai replacement parts willensure that the vehicle safety and perfor-mance will not be compromised. NOTE:

The inspection and testing of certain elec-

tronic fuel injection/engine management and automatic transmission control sys-tems require specialised electronic equip-ment specifically designed for Hyundaivehicles. The use of general purpose elec-trical test equipment may result in dam-age to the control unit microprocessors.

SF000A1-E

5. VEHICLE

MAINTENANCE REQUIREMENTS

SF020C1-E

Specified Scheduled Procedures The Specified scheduled procedures are listed

in the maintenance charts beginning at page 5-2. The operations specified must be per-formed at the time or mileage intervals shownirrespective of whether the mileage intervalhas been reached before the specified timeinterval.

Certain lubricants and components degrade

with both time and mileage (e.g. engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended thatthe maintenance operations are performed bythe factory-trained or distributor-trained tech-nicians at your Hyundai dealer because of the need for specialized knowledge and toolingand to ensure that no possibility of invalidatingthe manufacturers warranty exists.

The maintenance schedules relate to ve-

hicles operated under normal conditions, ve-hicles which are operated under adverseconditions will require more frequent mainte-nance which is described at page 5-5.

SF030B1-E

SERVICE HISTORY It is important that all scheduled maintenance

services are recorded in the warranty andservice passport to ensure that proof of main-tenance is available when warranty service isrequired.

5

Page 271 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 4 F030C01E-EAT

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT GASOLINE ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

50 60

4048

I

R R

I I

R I

R R I I II

R

IIIII I

I I IIII I I I I

R I III I I

I

R IIII

R R I I I I

R I III I I

30 36

2024

I

R

I IIII I I II

R IIIIII

I

R IIII

R R I I I I

R I III I I

10 12

I I IIII I I I I

R I III I I

MILES X 1,000 MONTHS

NO. DESCRIPTION

1 2 3 456789

10111213141516171819

Page 272 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-5

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the

appropriate maintenance intervals.

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

F040A04E-EAT

SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas ENGINE OIL AND FILTER AIR CLEANER FILTERSPARK PLUGSTIMING BELT BRAKE PADS REAR BRAKE LININGS AND CYLINDERSSUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(IN FRONT OF BLOWER UNIT)

EVERY 4,500MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000MILES OR 48 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY MORE FREQUENTLY EVERY 60,000MILESEVERY 27,000MILES MORE FREQUENTLY

MAINTENANCE OPERATIONMAINTENANCE ITEM

R R R RII I

R R R A, B, C, F, H C, E B, H D, E, F, GC, D, G, HC, D, G, H C, D, E, F A, C, D, E, F, G, H, I, JA, C, E, F, G, H, I C,E

MAINTENANCE INTERVALS

DRIVING

CONDITION

F - More than 50% driving in heavy city traffic during hot weather above 90°F (32°C)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car, taxi, commercial car or vehicle towing

J - Driving over 100MPH

Page 274 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/ parking brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake pads, calipers and rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust pipe and muffler Visually inspect the exhaust pipes, mufflerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range

of the dipstick, after engine and transaxle areat normal operating temperature. Check theAutomatic Transaxle Fluid level with the en-gine running and the transaxle in neutral, withthe parking brake properly applied. Use DIA-MOND ATF SP- III or SK ATF SP- III when

adding or changing fluid. 6ZF070F1-A

o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling system Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N01E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Valve Clearance

Intake valves: 0.0067 ~ 0.0091 in. (0.17 ~ 0.23mm)

Exhaust valves: 0.0098 ~ 0.0122 in. (0.25 ~ 0.31mm)