INFINITI FX35 2004 Service Manual

Manufacturer: INFINITI, Model Year: 2004, Model line: FX35, Model: INFINITI FX35 2004Pages: 4449, PDF Size: 99.66 MB

Page 3661 of 4449

LT-106

TURN SIGNAL AND HAZARD WARNING LAMPS

Revision: 2004 November 2004 FX35/FX45

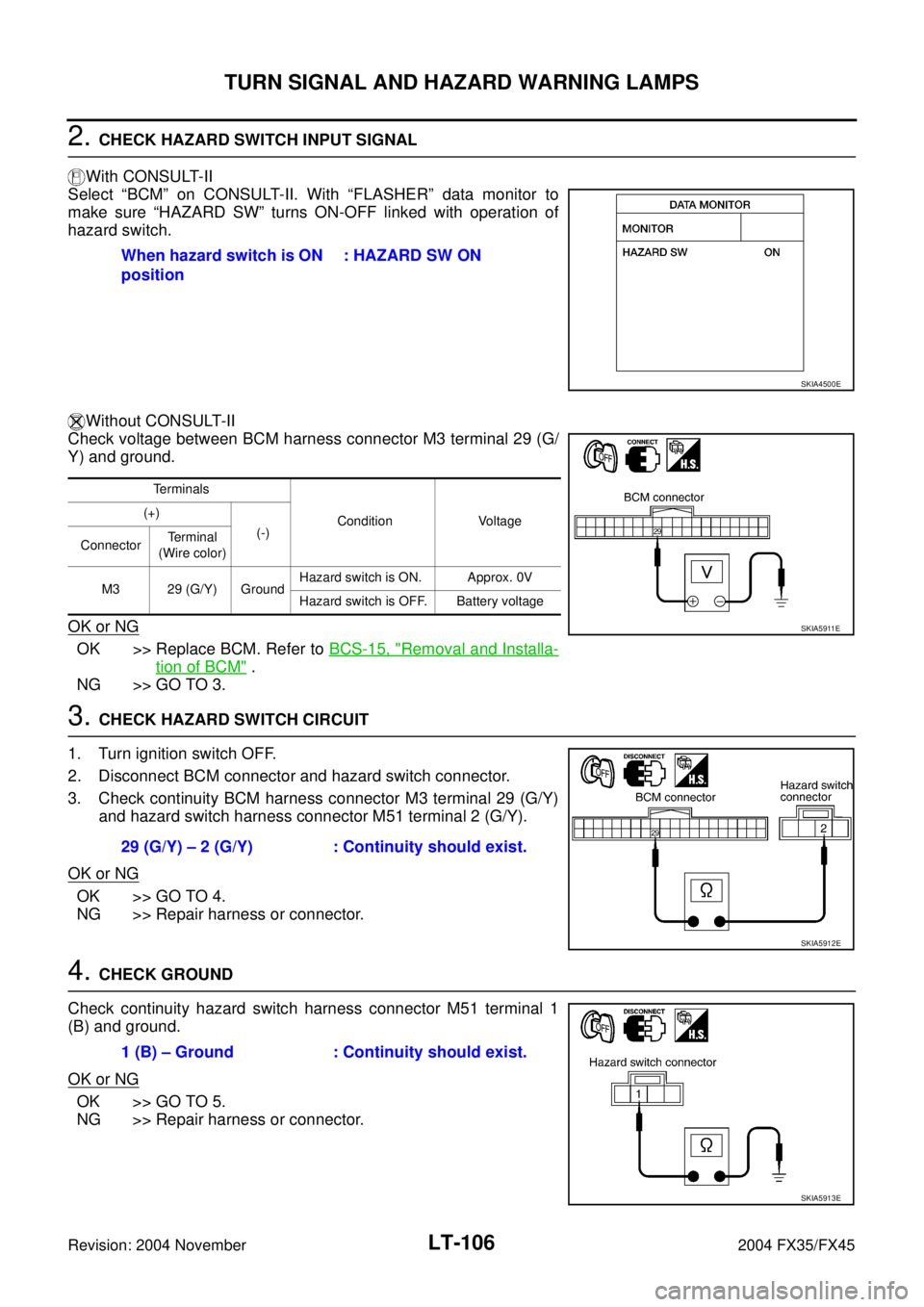

2. CHECK HAZARD SWITCH INPUT SIGNAL

With CONSULT-II

Select “BCM” on CONSULT-II. With “FLASHER” data monitor to

make sure “HAZARD SW” turns ON-OFF linked with operation of

hazard switch.

Without CONSULT-II

Check voltage between BCM harness connector M3 terminal 29 (G/

Y) and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-15, "Removal and Installa-

tion of BCM" .

NG >> GO TO 3.

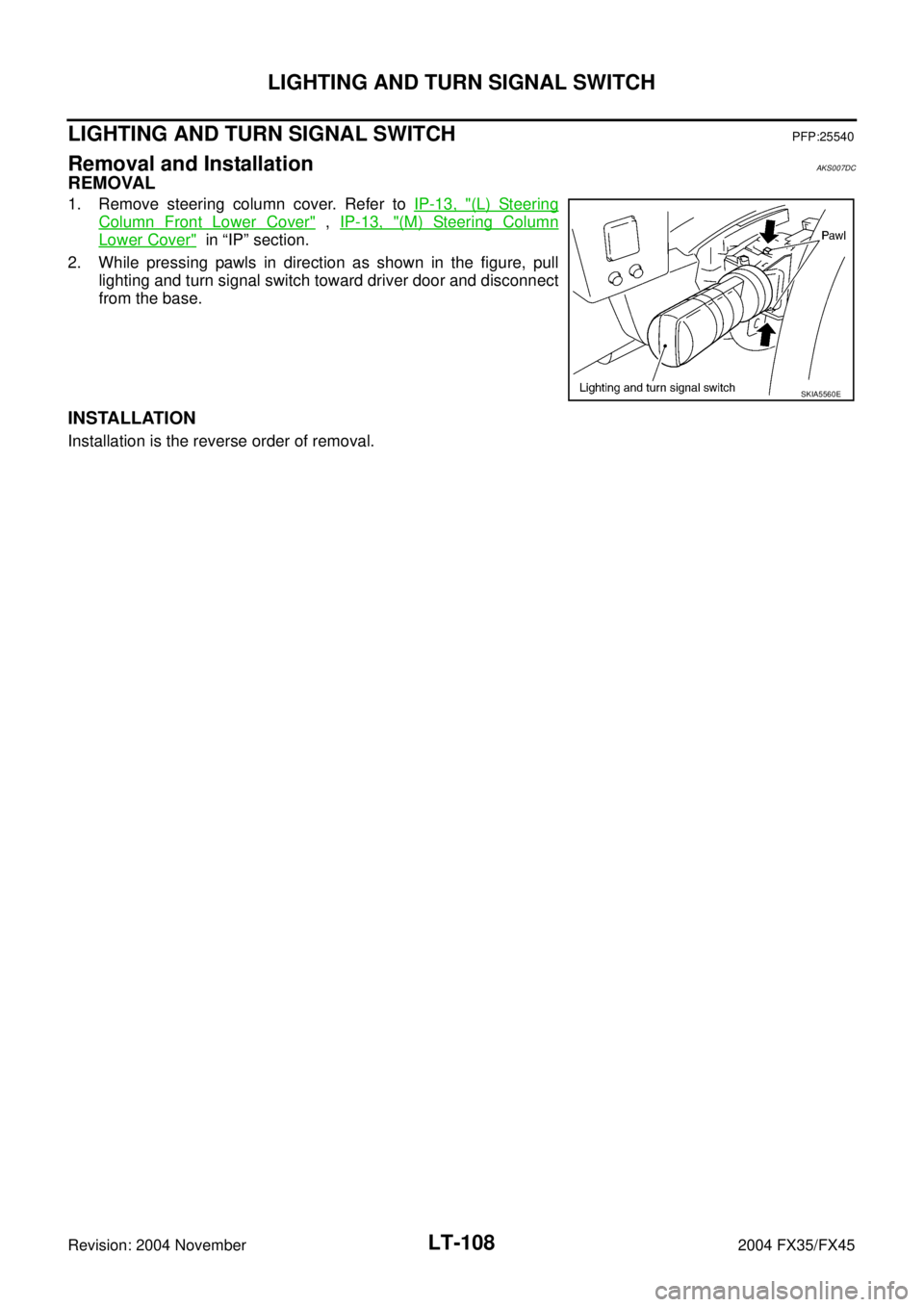

3. CHECK HAZARD SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and hazard switch connector.

3. Check continuity BCM harness connector M3 terminal 29 (G/Y)

and hazard switch harness connector M51 terminal 2 (G/Y).

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK GROUND

Check continuity hazard switch harness connector M51 terminal 1

(B) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.When hazard switch is ON

position : HAZARD SW ON

SKIA4500E

Terminals

Condition Voltage (+)

(-)

ConnectorTerminal

(Wire color)

M3 29 (G/Y) GroundHazard switch is ON. Approx. 0V

Hazard switch is OFF. Battery voltage

SKIA5911E

29 (G/Y) – 2 (G/Y) : Continuity should exist.

SKIA5912E

1 (B) – Ground : Continuity should exist.

SKIA5913E

Page 3662 of 4449

TURN SIGNAL AND HAZARD WARNING LAMPS

LT-107

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2004 November 2004 FX35/FX45

5. CHECK HAZARD SWITCH

1. Disconnect hazard switch connector.

2. Check continuity hazard switch.

OK or NG

OK >> Replace BCM if turn signal lamps does not work after

setting the connector again. Refer to BCS-15, "

Removal

and Installation of BCM" .

NG >> Replace hazard switch.

Turn Signal Indicator Lamp Does Not OperateAKS007D7

1. CHECK BULB

Check bulb of turn signal indicator lamp in combination meter.

OK or NG

OK >> Replace combination meter.

NG >> Replace indicator bulb.

Bulb Replacement (Front Turn Signal Lamp)AKS007D8

Refer to LT- 3 5 , "Bulb Replacement" in “HEADLAMP -XENON TYPE-”.

Bulb Replacement (Rear Turn Signal Lamp)AKS007D9

Refer to LT- 1 4 7 , "Bulb Replacement" in “REAR COMBINATION LAMP”.

Removal and Installation of Front Turn Signal LampAKS007DA

Refer to LT- 3 6 , "Removal and Installation" in “HEADLAMP -XENON TYPE-”.

Removal and Installation of Rear Turn Signal Lamp AKS007DB

Refer to LT- 1 4 7 , "Removal and Installation" in “REAR COMBINATION LAMP”.

Removal and Installation of Rear Combination Lamp Control UnitAKS007NX

REMOVAL

1. Remove luggage side finisher assembly (left). Refer to EI-44,

"Removal and Installation" in “EI” section.

2. Remove nuts (2), and remove rear combination lamp control

unit.

INSTALLATION

Install in the reverse order of removal.

Te r m i n a l

Condition Continuity

Hazard switch

12Hazard switch is ON. Yes

Hazard switch is OFF. No

PKIA5221E

SKIA6185E

Page 3663 of 4449

LT-108

LIGHTING AND TURN SIGNAL SWITCH

Revision: 2004 November 2004 FX35/FX45

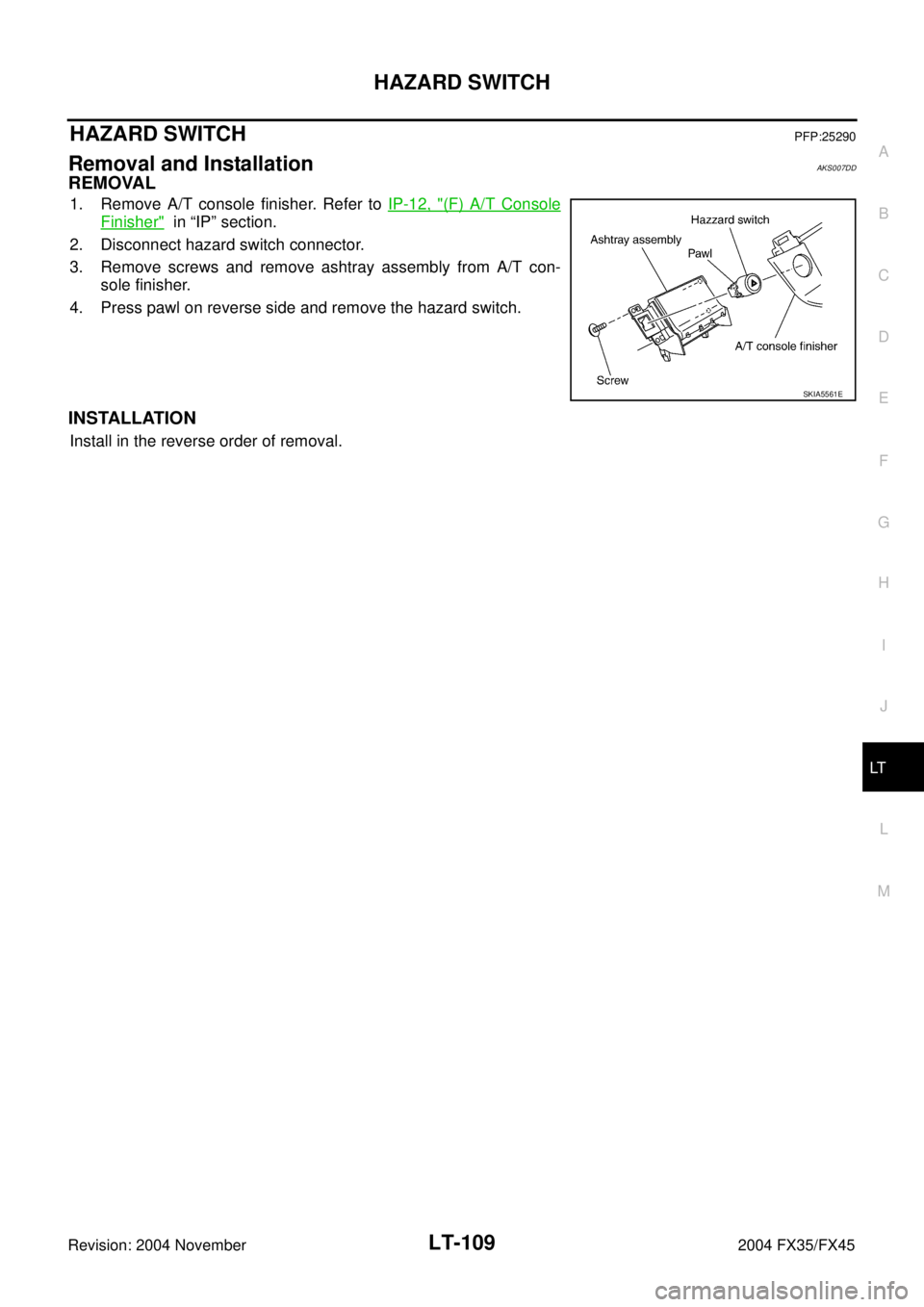

LIGHTING AND TURN SIGNAL SWITCHPFP:25540

Removal and InstallationAKS007DC

REMOVAL

1. Remove steering column cover. Refer to IP-13, "(L) Steering

Column Front Lower Cover" , IP-13, "(M) Steering Column

Lower Cover" in “IP” section.

2. While pressing pawls in direction as shown in the figure, pull

lighting and turn signal switch toward driver door and disconnect

from the base.

INSTALLATION

Installation is the reverse order of removal.

SKIA5560E

Page 3664 of 4449

HAZARD SWITCH

LT-109

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2004 November 2004 FX35/FX45

HAZARD SWITCHPFP:25290

Removal and InstallationAKS007DD

REMOVAL

1. Remove A/T console finisher. Refer to IP-12, "(F) A/T Console

Finisher" in “IP” section.

2. Disconnect hazard switch connector.

3. Remove screws and remove ashtray assembly from A/T con-

sole finisher.

4. Press pawl on reverse side and remove the hazard switch.

INSTALLATION

Install in the reverse order of removal.

SKIA5561E

Page 3665 of 4449

LT-110

COMBINATION SWITCH

Revision: 2004 November 2004 FX35/FX45

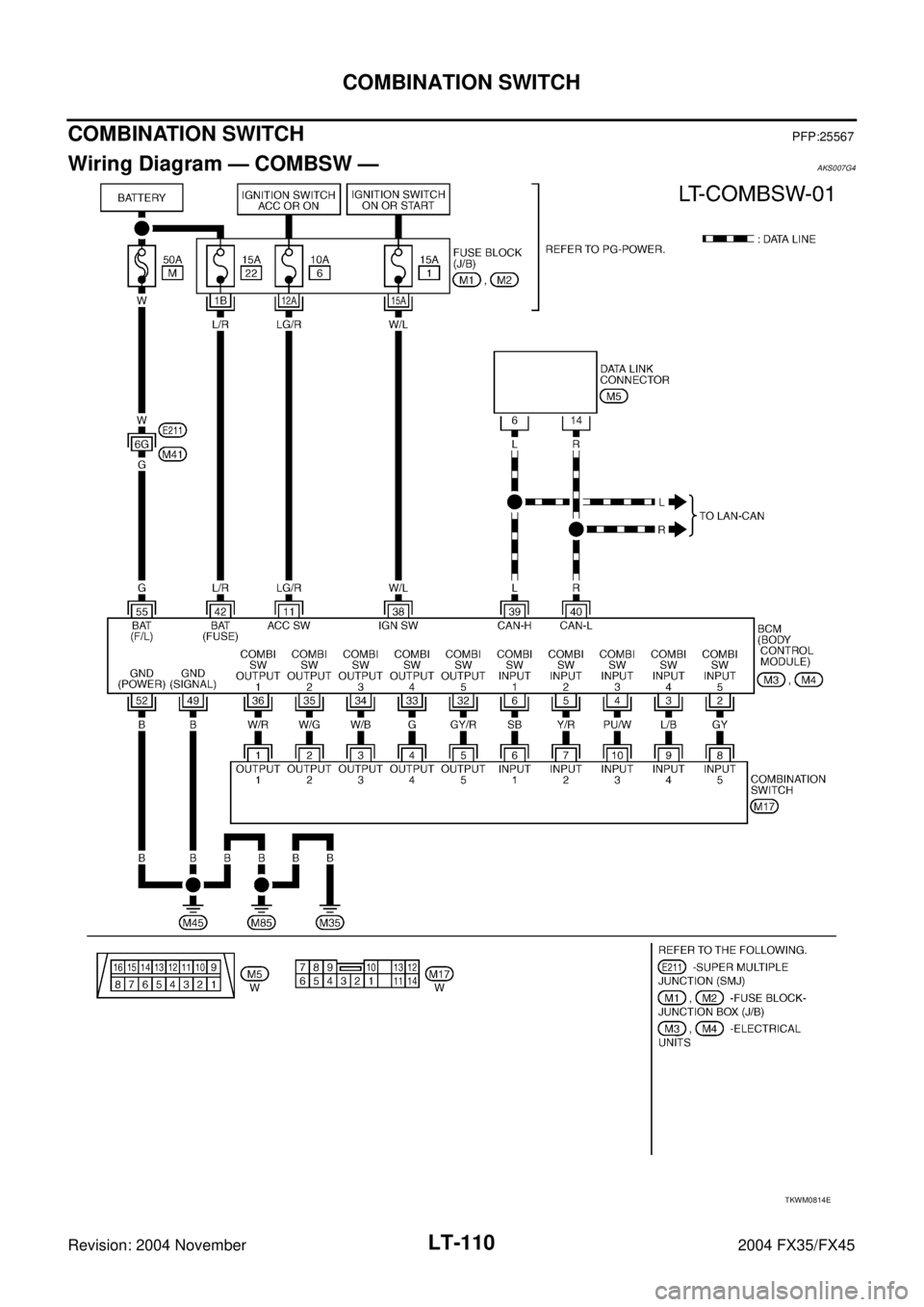

COMBINATION SWITCHPFP:25567

Wiring Diagram — COMBSW —AKS007G4

TKWM0814E

Page 3666 of 4449

COMBINATION SWITCH

LT-111

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2004 November 2004 FX35/FX45

Combination Switch Reading FunctionAKS007G5

For details, refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" in “BCS” section.

CONSULT-II FunctionAKS007G6

CONSULT-II has a display function for work support, self-diagnosis, data monitor, and active test for each part

by combining data receiving and sending via the communication line from BCM.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, then turn igni-

tion switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, refer to GI-40, "

CONSULT-II Data Link

Connector (DLC) Circuit" .

BCM diagnosis part Check item, diagnosis mode Description

Combination switch Data monitor Displays BCM input data in real time.

PBIB1503E

SKIA3098E

PKIA5222E

Page 3667 of 4449

LT-112

COMBINATION SWITCH

Revision: 2004 November 2004 FX35/FX45

4. Touch “COMB SW”.

DATA MONITOR

Operation Procedure

1. Touch “COMB SW” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “DATA MONITOR” screen.

4. Touch “START”.

5. When “SELECTION FROM MENU” is selected, touch items to be monitored. When “ALL SIGNALS” is

selected, all the signals will be monitored.

6. Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

PKIA5223E

ALL SIGNALS Monitors all the signals.

SELECTION FROM MENU Selects and monitors individual signal.

Monitor item name

“OPERATION OR UNIT”Contents

TURN SIGNAL R “ON/OFF” Displays “Turn Right (ON)/Other (OFF)” status, determined from lighting switch signal.

TURN SIGNAL L “ON/OFF” Displays “Turn Left (ON)/Other (OFF)” status, determined from lighting switch signal.

HI BEAM SW “ON/OFF”Displays status (high beam switch: ON/Others: OFF) of high beam switch judged from lighting

switch signal.

HEAD LAMP SW 1 “ON/OFF” Displays “Headlamp switch 1 (ON)/Other (OFF)” status, determined from lighting switch signal.

HEAD LAMP SW 2 “ON/OFF”Displays status (headlamp switch 2: ON/Others: OFF) of headlamp switch 2 judged from lighting

switch signal.

TAIL LAMP SW “ON/OFF”Displays status (lighting switch 1st position: ON/Others: OFF) of lighting switch judged from light-

ing switch signal.

PASSING SW “ON/OFF”Displays status (flash-to-pass switch: ON/Others: OFF) of flash-to-pass switch judged from light-

ing switch signal.

AUTO LIGHT SW “ON/OFF” Displays “Auto light switch (ON)/Other (OFF)” status, determined from lighting switch signal.

FR FOG SW “ON/OFF” Displays “Front fog lamp switch (ON)/Other (OFF)” status, determined from lighting switch signal.

FR WIPER HI “ON/OFF” Displays “Front Wiper HI (ON)/Other (OFF)” status, determined from wiper switch signal.

FR WIPER LOW “ON/OFF” Displays “Front Wiper LOW (ON)/Other (OFF)” status, determined from wiper switch signal.

FR WIPER INT “ON/OFF” Displays “Front Wiper INT (ON)/Other (OFF)” status, determined from wiper switch signal.

FR WASHER SW “ON/OFF” Displays “Front Washer Switch (ON)/Other (OFF)” status, determined from wiper switch signal.

INT VOLUME [1 - 7] Displays intermittent operation knob setting (1 - 7), determined from wiper switch signal.

RR WIPER ON “ON/OFF” Displays “rear Wiper (ON)/Other (OFF)” status as judged from wiper switch signal.

RR WIPER INT “ON/OFF” Displays “rear Wiper INT (ON)/Other (OFF)” status as judged from wiper switch signal.

RR WASHER SW “ON/OFF” Displays “rear Washer Switch (ON)/Other (OFF)” status as judged from wiper switch signal.

Page 3668 of 4449

COMBINATION SWITCH

LT-113

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2004 November 2004 FX35/FX45

Combination Switch InspectionAKS007G7

1. SYSTEM CHECK

1. Referring to table below, check which system malfunctioning switch belongs to.

>> Check the system to which malfunctioning switch belongs, and GO TO 2.

2. SYSTEM CHECK

With CONSULT-II

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect CONSULT-II, and select “COMB SW” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in malfunction-

ing system operate normally.

Example: When auto light switch is malfunctioning, confirm that

“FRONT WIPER LOW” and “FRONT WIPER INT” in System 3,

to which the auto light switch belongs, turn ON-OFF normally.

Without CONSULT-II

Operating combination switch, confirm that other switches in malfunctioning system operate normally.

Example: When auto light switch is malfunctioning, confirm that FRONT WIPER LOW and FRONT WIPER

INT in System 3, to which the auto light switch belongs, operate normally.

Check results

Other switches in malfunctioning system operate normally.>>Replace lighting switch or wiper switch.

Other switches in malfunctioning system do not operate normally.>>GO TO 3.

System 1 System 2 System 3 System 4 System 5

— FR WASHER FR WIPER LO TURN LH TURN RH

FR WIPER HI — FR WIPER INT PASSING HEAD LAMP1

INT VOLUME 1 RR WASHER — HEAD LAMP2 HI BEAM

RR WIPER INT INT VOLUME 3 AUTO LIGHT — LIGHT SW 1ST

INT VOLUME 2 RR WIPER ON — FR FOG —

PKIA5224E

Page 3669 of 4449

LT-114

COMBINATION SWITCH

Revision: 2004 November 2004 FX35/FX45

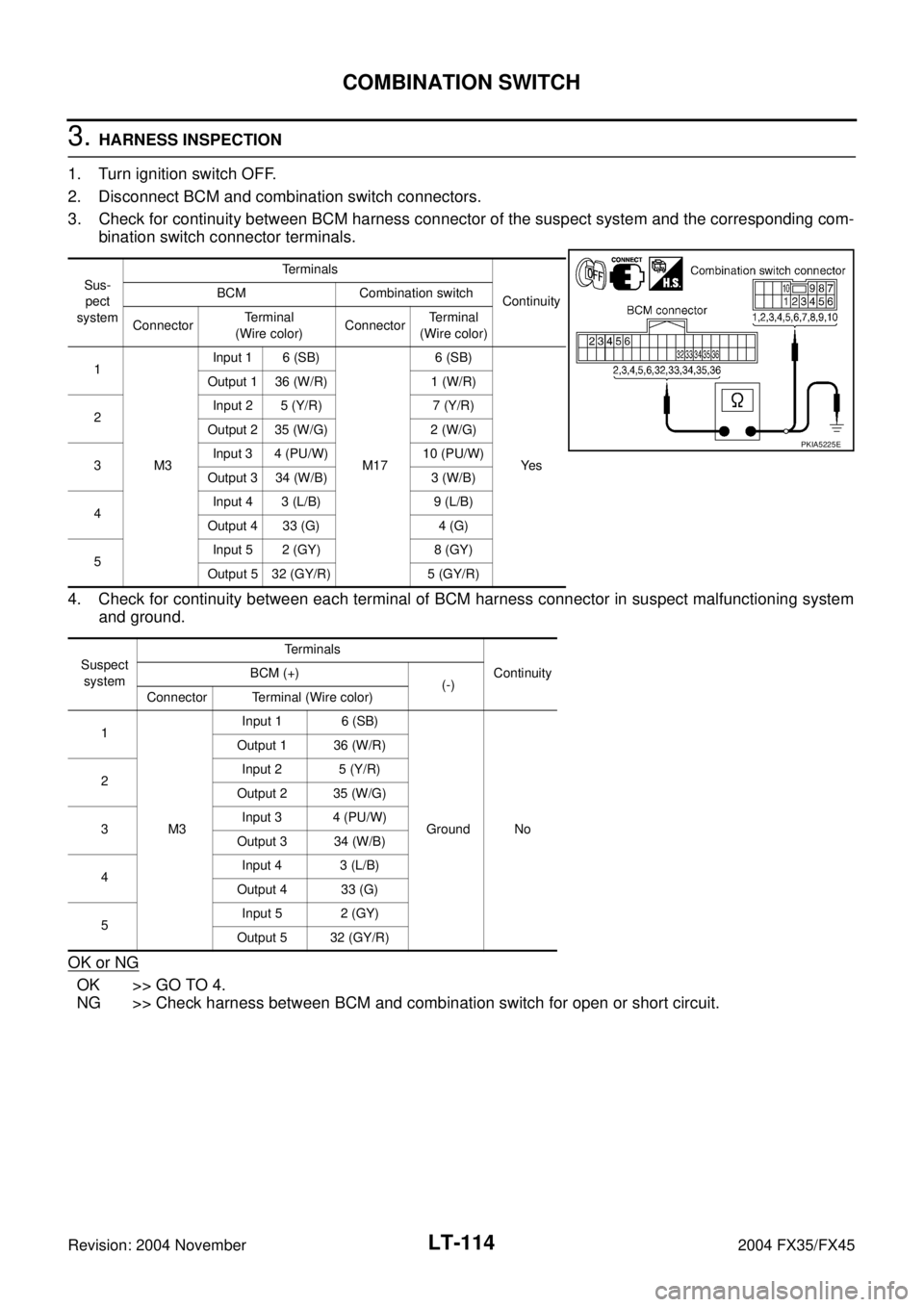

3. HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check for continuity between BCM harness connector of the suspect system and the corresponding com-

bination switch connector terminals.

4. Check for continuity between each terminal of BCM harness connector in suspect malfunctioning system

and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

Sus-

pect

systemTerminals

Continuity BCM Combination switch

ConnectorTerminal

(Wire color)ConnectorTe r m i n a l

(Wire color)

1

M3Input 1 6 (SB)

M176 (SB)

Ye s Output 1 36 (W/R) 1 (W/R)

2Input 2 5 (Y/R) 7 (Y/R)

Output 2 35 (W/G) 2 (W/G)

3Input 3 4 (PU/W) 10 (PU/W)

Output 3 34 (W/B) 3 (W/B)

4Input 4 3 (L/B) 9 (L/B)

Output 4 33 (G) 4 (G)

5Input 5 2 (GY) 8 (GY)

Output 5 32 (GY/R) 5 (GY/R)

Suspect

systemTerminals

Continuity BCM (+)

(-)

Connector Terminal (Wire color)

1

M3Input 1 6 (SB)

Ground No Output 1 36 (W/R)

2Input 2 5 (Y/R)

Output 2 35 (W/G)

3Input 3 4 (PU/W)

Output 3 34 (W/B)

4Input 4 3 (L/B)

Output 4 33 (G)

5Input 5 2 (GY)

Output 5 32 (GY/R)

PKIA5225E

Page 3670 of 4449

COMBINATION SWITCH

LT-115

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2004 November 2004 FX35/FX45

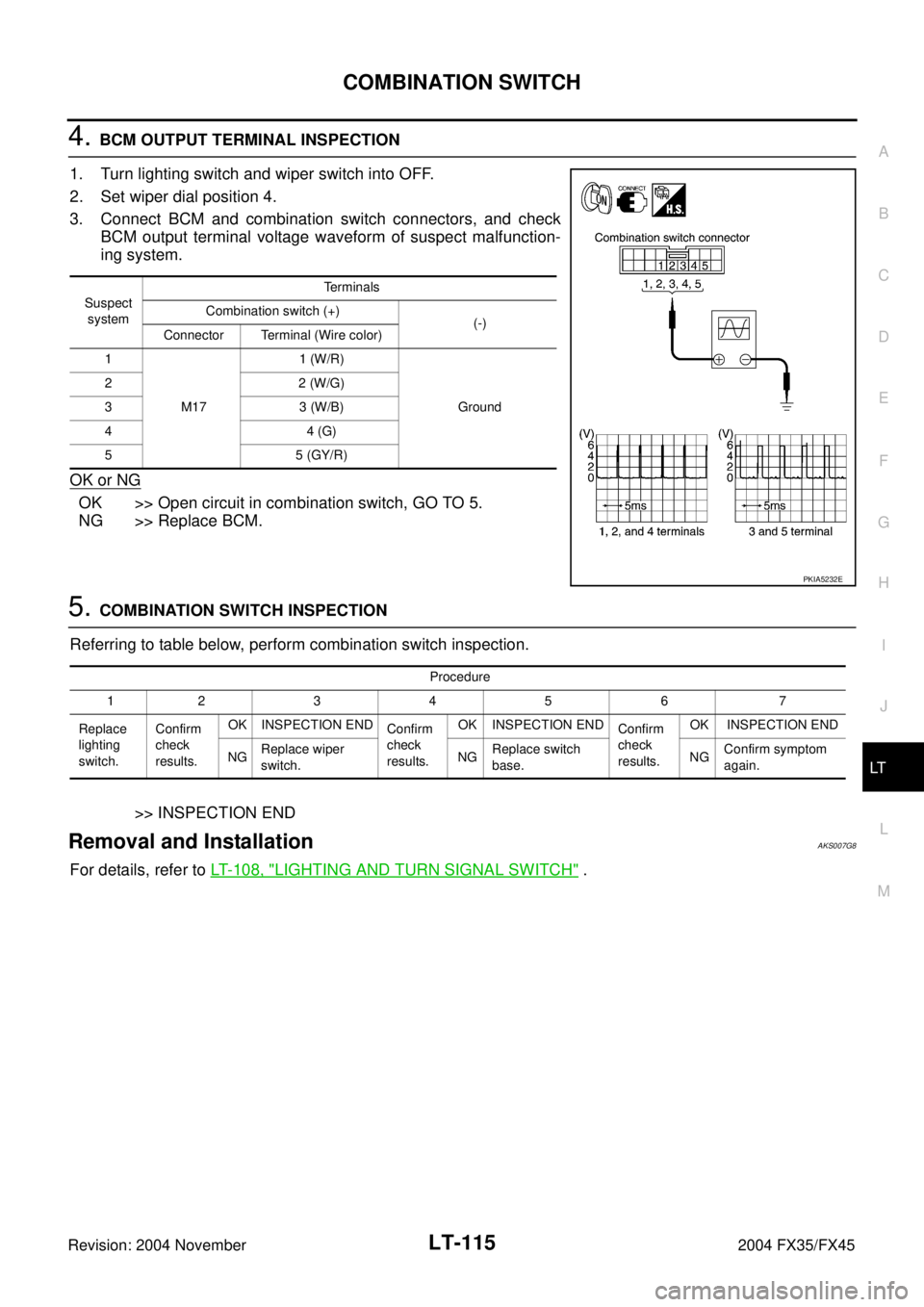

4. BCM OUTPUT TERMINAL INSPECTION

1. Turn lighting switch and wiper switch into OFF.

2. Set wiper dial position 4.

3. Connect BCM and combination switch connectors, and check

BCM output terminal voltage waveform of suspect malfunction-

ing system.

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM.

5. COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationAKS007G8

For details, refer to LT- 1 0 8 , "LIGHTING AND TURN SIGNAL SWITCH" .

Suspect

systemTerminals

Combination switch (+)

(-)

Connector Terminal (Wire color)

1

M171 (W/R)

Ground 22 (W/G)

33 (W/B)

44 (G)

55 (GY/R)

PKIA5232E

Procedure

123456 7

Replace

lighting

switch.Confirm

check

results.OK INSPECTION END

Confirm

check

results.OK INSPECTION END

Confirm

check

results.OK INSPECTION END

NGReplace wiper

switch.NGReplace switch

base.NGConfirm symptom

again.