INFINITI FX35 2005 Service Manual

Manufacturer: INFINITI, Model Year: 2005, Model line: FX35, Model: INFINITI FX35 2005Pages: 4731, PDF Size: 60.13 MB

Page 1051 of 4731

BL-236

INTEGRATED HOMELINK TRANSMITTER

Revision: 2005 July 2005 FX

Trouble DiagnosesAIS004PV

DIAGNOSTIC PROCEDURE

SYMPTOM: Transmitter Does Not Activate Receiver.

Before conducting the procedure given below, make sure that system receiver (garage door opener, etc.)

operates with original, hand-held transmitter. If NG, receiver or hand-held transmitter is malfunctioning, not

vehicle related.

1. CHECK ILLUMINATION

1. Turn ignition switch “OFF”.

2. Does red light (LED) of transmitter illuminate when any transmit- ter button is pressed?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2. CHECK TRANSMITTER

Check transmitter with Tool*.

*:For details, refer to Technical Service Bulletin.

OK or NG

OK >> Receiver or hand-held transmitter malfunction, not vehicle related.

NG >> Replace inside mirror assembly.

3. CHECK BCM OUTPUT POWER SUPPLY

Does room lamp come on when driver side door opened. Refer to LT- 1 5 9

.

Does room lamp illumination?

YES >> GO TO 4.

NO >> Repair or replace the malfunction part.

4. CHECK POWER SUPPLY

1. Disconnect transmitter connector.

2. Turn ignition switch “OFF”.

3. Check voltage between auto anti-dazzling inside mirror (homelink universal transceiver) connector R4 ter- minal 5 (B/W) and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness between BCM and anti-daz- zling inside mirror (homelink universal transceiver).

PIIA6142E

5 (B/W) – Ground : Battery voltage

PIIA2370E

Page 1052 of 4731

INTEGRATED HOMELINK TRANSMITTER BL-237

C

D E

F

G H

J

K L

M A

B

BL

Revision: 2005 July 2005 FX

5. CHECK GROUND CIRCUIT

Check continuity between anti-dazzling inside mirror (homelink uni-

versal transceiver) connector R4 terminal 8 (B) and ground.

OK or NG

OK >> Replace inside mirror assembly.

NG >> Harness for open or short between anti-dazzling inside mirror (homelink universal transceiver) ground.

8 (B) – Ground :Continuity should exist.

PIIA2368E

Page 1053 of 4731

BL-238

BODY REPAIR

Revision: 2005 July2005 FX

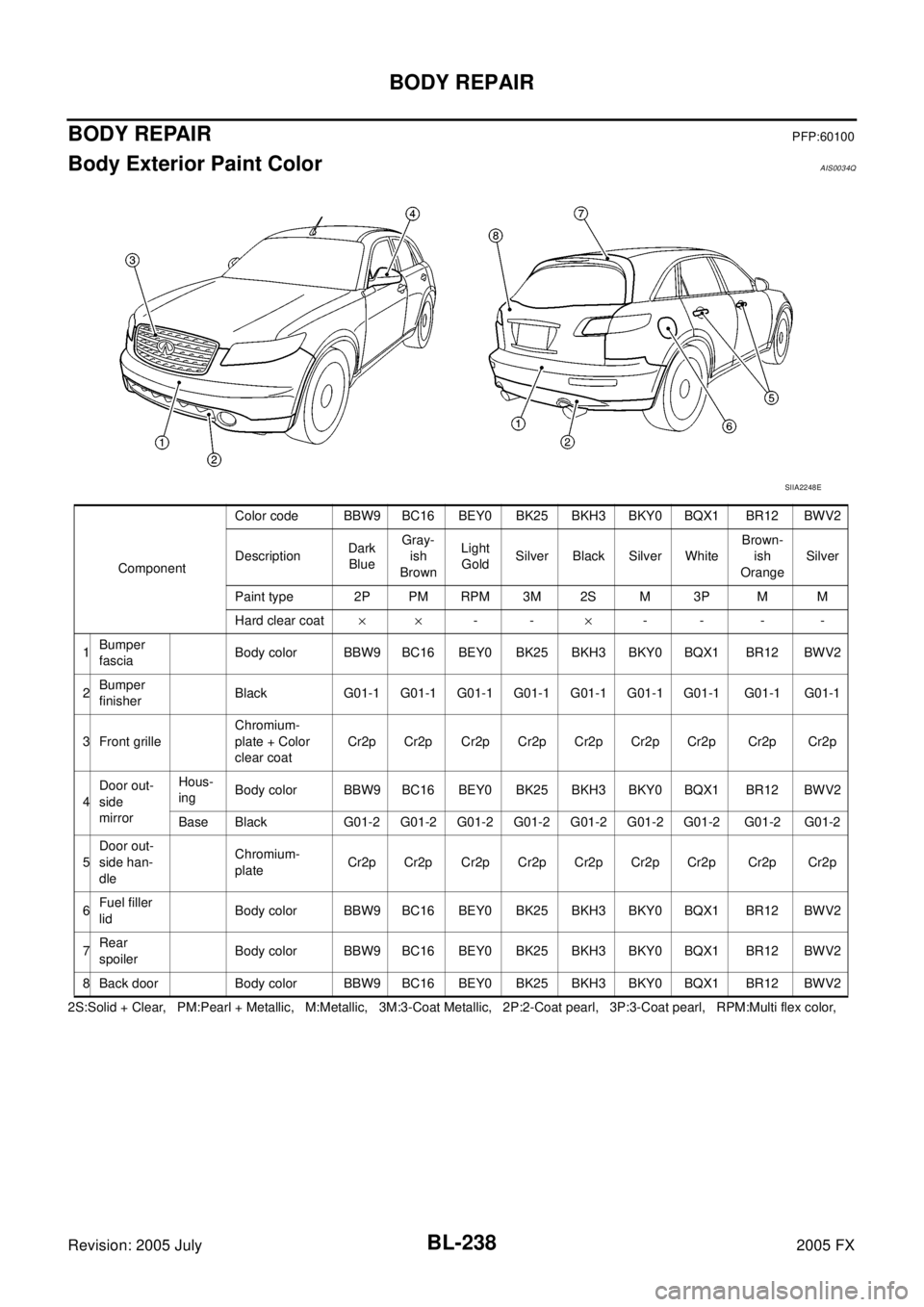

BODY REPAIRPFP:60100

Body Exterior Paint ColorAIS0034Q

2S:Solid + Clear, PM:Pearl + Metallic, M:Metallic, 3M:3-Coat Metallic, 2P:2-Coat pearl, 3P:3-Coat pearl, RPM:Multi flex color,

SIIA2248E

ComponentColor code BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

DescriptionDark

BlueGray-

ish

BrownLight

GoldSilver Black Silver WhiteBrown-

ish

OrangeSilver

Paint type 2P PM RPM 3M 2S M 3P M M

Hard clear coat´´--´-- - -

1Bumper

fasciaBody color BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

2Bumper

finisherBlack G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1 G01-1

3 Front grilleChromium-

plate + Color

clear coatCr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p

4Door out-

side

mirrorHous-

ingBody color BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

Base Black G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2 G01-2

5Door out-

side han-

dleChromium-

plateCr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p Cr2p

6Fuel filler

lidBody color BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

7Rear

spoilerBody color BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

8 Back door Body color BBW9 BC16 BEY0 BK25 BKH3 BKY0 BQX1 BR12 BWV2

Page 1054 of 4731

BODY REPAIR

BL-239

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2005 July2005 FX

Body Component PartsAIS0034R

UNDERBODY COMPONENT PARTS

SIIA2386E

Page 1055 of 4731

BL-240

BODY REPAIR

Revision: 2005 July2005 FX

1. Hoodledge assembly 16. Rear floor rear

2. Upper front hoodledge 17. Rear floor seat belt anchor reinforcement

3. Hoodledge reinforcement 18. Rear floor side

4. Upper hoodledge 19. Spare tire clamp bracket

5. Upper dash extension 20. Front side member

6. Upper dash crossmember assembly 21. Front side member rear reinforcement

7. Upper dash assembly 22. Front side member front extension

8. Front cowl top assembly 23. Front side member closing plate

9. Lower dash 24. Front side member outrigger assembly (RH&LH)

10. Front floor center 25. Front crossmember

11. Front floor 26. 2ND rear crossmember

12. Front floor reinforcement 27. Rear side member assembly

13. Inner sill 28. Rear side member extension

14. Lower rear seat crossmember 29. Rear center crossmember assembly

15. Rear floor front 30. Rear end crossmember assembly

Page 1056 of 4731

BODY REPAIR

BL-241

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2005 July2005 FX

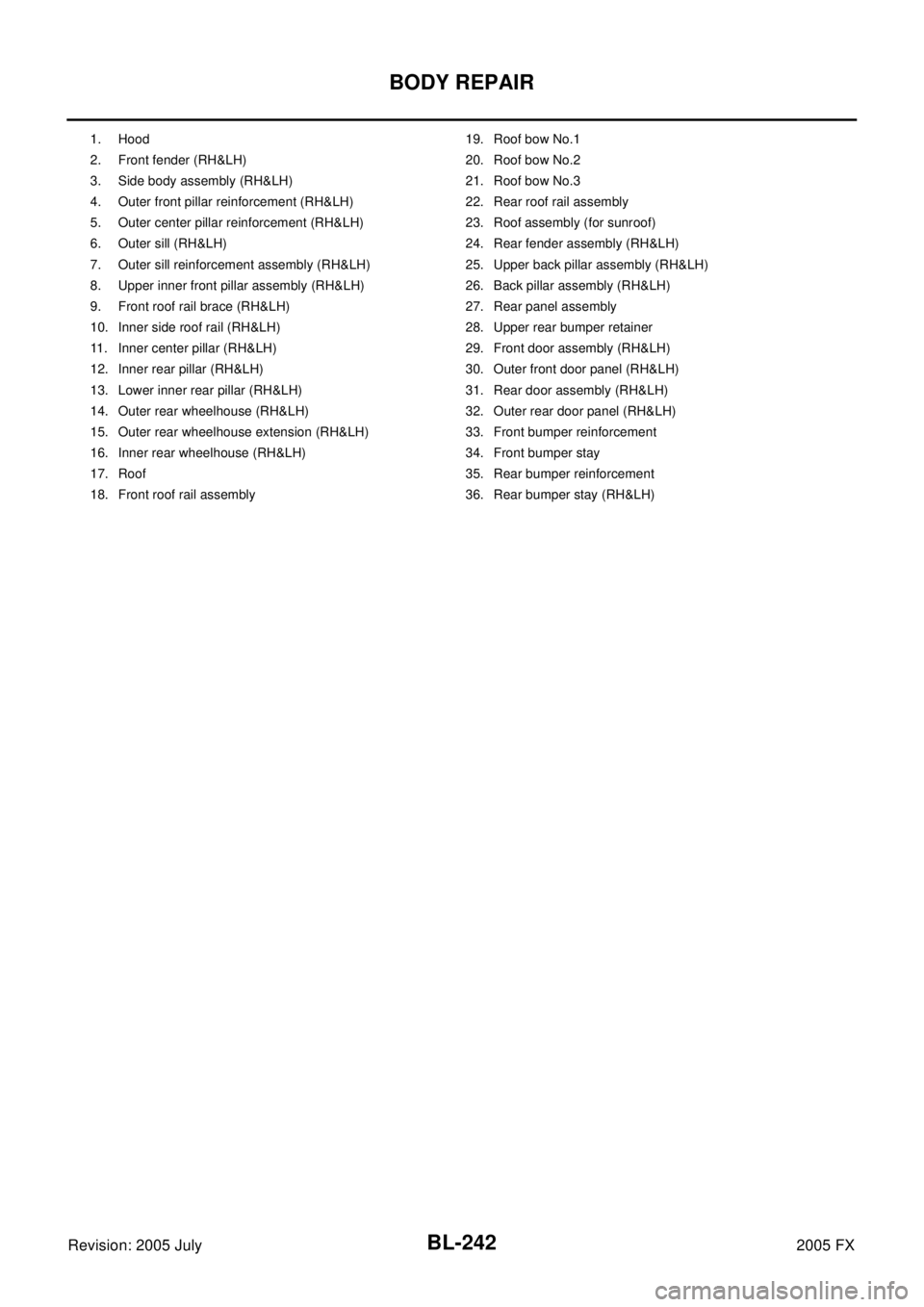

BODY COMPONENT PARTS

SIIA2387E

Page 1057 of 4731

BL-242

BODY REPAIR

Revision: 2005 July2005 FX

1. Hood 19. Roof bow No.1

2. Front fender (RH&LH) 20. Roof bow No.2

3. Side body assembly (RH&LH) 21. Roof bow No.3

4. Outer front pillar reinforcement (RH&LH) 22. Rear roof rail assembly

5. Outer center pillar reinforcement (RH&LH) 23. Roof assembly (for sunroof)

6. Outer sill (RH&LH) 24. Rear fender assembly (RH&LH)

7. Outer sill reinforcement assembly (RH&LH) 25. Upper back pillar assembly (RH&LH)

8. Upper inner front pillar assembly (RH&LH) 26. Back pillar assembly (RH&LH)

9. Front roof rail brace (RH&LH) 27. Rear panel assembly

10. Inner side roof rail (RH&LH) 28. Upper rear bumper retainer

11. Inner center pillar (RH&LH) 29. Front door assembly (RH&LH)

12. Inner rear pillar (RH&LH) 30. Outer front door panel (RH&LH)

13. Lower inner rear pillar (RH&LH) 31. Rear door assembly (RH&LH)

14. Outer rear wheelhouse (RH&LH) 32. Outer rear door panel (RH&LH)

15. Outer rear wheelhouse extension (RH&LH) 33. Front bumper reinforcement

16. Inner rear wheelhouse (RH&LH) 34. Front bumper stay

17. Roof 35. Rear bumper reinforcement

18. Front roof rail assembly 36. Rear bumper stay (RH&LH)

Page 1058 of 4731

BODY REPAIR

BL-243

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2005 July2005 FX

Corrosion ProtectionAIS005A1

DESCRIPTION

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodeposition primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during welding operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built

into the vehicle at the factory.

SIIA2294E

PIIA0095E

Page 1059 of 4731

BL-244

BODY REPAIR

Revision: 2005 July2005 FX

ANTI-CORROSIVE WAX

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sec-

tions. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of

the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf

life.

SIIA2251E

Page 1060 of 4731

BODY REPAIR

BL-245

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2005 July2005 FX

UNDERCOATING

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1. Do not apply undercoating to any place unless specified (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

5. After putting seal on the vehicle, put undercoating on it.

SIIA2252E