ECO mode INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3030 of 3924

![INFINITI FX35 2008 Service Manual

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m INFINITI FX35 2008 Service Manual

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support m](/img/42/57017/w960_57017-3029.png)

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000001451950

CAN Diagnostic Support MonitorINFOID:0000000001451951

CONSULT-III and CAN diagnostic support monitor (on-boar d diagnosis function) are used for detecting root

cause.

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTC

Self-diagnosis item

(CONSULT-III indication) DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Refer to LAN-13

.

When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMM When a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less. Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit.

U1010 CONTROL UNIT [CAN] When an error is detected during the initial diag-

nosis for CAN controller of each control unit. Replace the control unit

indicating “U1010”.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3031 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISLAN-11

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSISLAN-11

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)](/img/42/57017/w960_57017-3030.png)

TROUBLE DIAGNOSISLAN-11

< SERVICE INFORMATION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

L

M A

B

LAN

N

O P

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

For some models, CAN communication diagnosis result is received from the vehicle monitor. (CONSULT-III

is not available.)

Refer to LAN-39, "

CAN Diagnostic Support Monitor" for the details.

PKID1075E

Item PRSNT Description

Initial diagnosis OK Normal at present

NG Control unit error (Except for some control units)

Transmission diagnosis OK Normal at present

UNKWN Unable to transmit signals for 2 seconds or more.

Diagnosis not performed

Control unit name

(Reception diagnosis) OK Normal at present

UNKWN Unable to receive signals for 2 seconds or more.

Diagnosis not performed

No control unit for receiving signals. (No applicable optional parts)

Item PRSNT PAST Description

Transmission diagnosis OKOK Normal at present and in the past

1 – 39 Normal at present, but unable to transmit signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to transmit signals for 2 seconds or more at present.

Control unit name

(Reception diagnosis) OK

OK Normal at present and in the past

1 – 39 Normal at present, but unable to receive signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to receive signals for 2 seconds or more at present.

–– Diagnosis not performed.

No control unit for receiving signals. (No applicable optional parts)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3150 of 3924

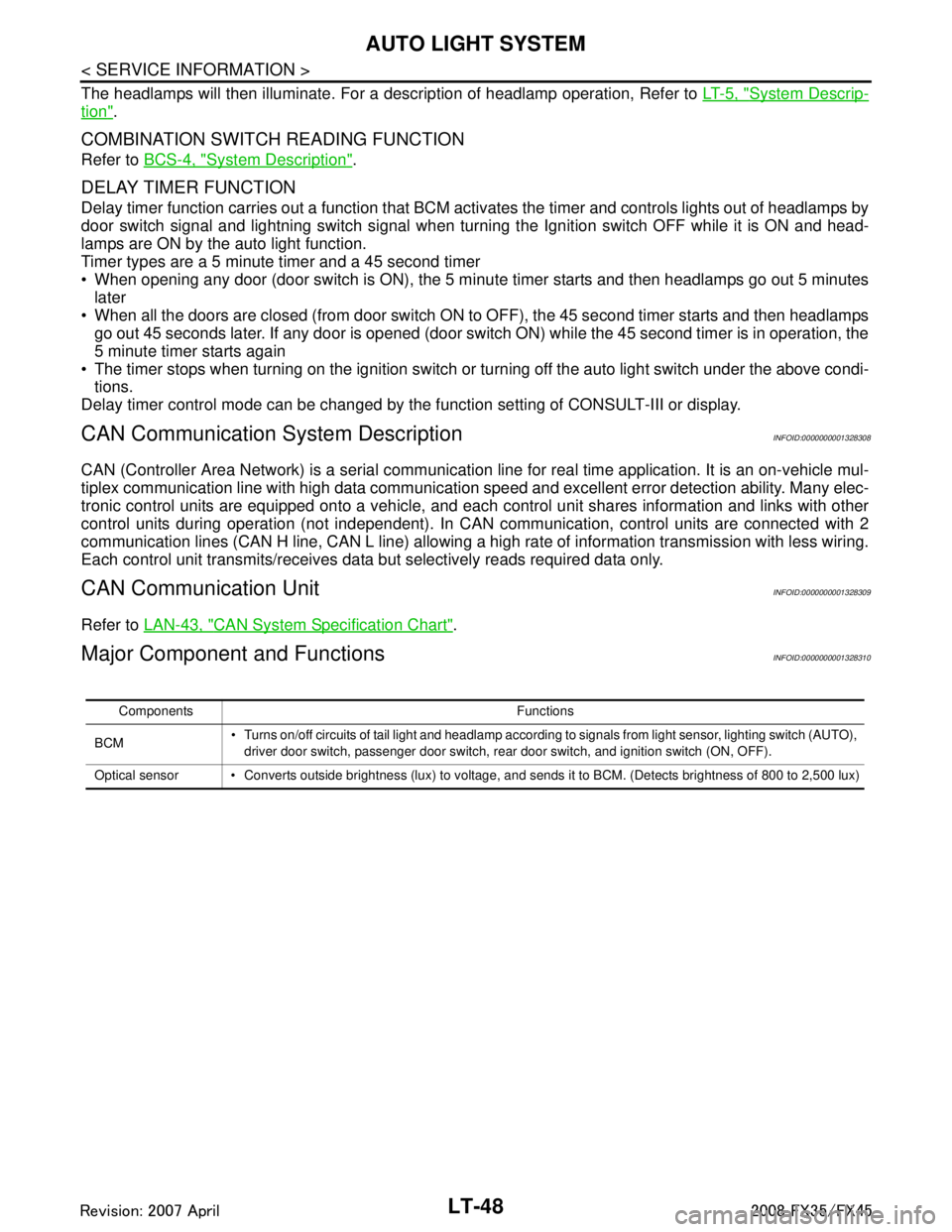

LT-48

< SERVICE INFORMATION >

AUTO LIGHT SYSTEM

The headlamps will then illuminate. For a description of headlamp operation, Refer to LT- 5 , "System Descrip-

tion".

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

DELAY TIMER FUNCTION

Delay timer function carries out a function that BCM ac tivates the timer and controls lights out of headlamps by

door switch signal and lightning switch signal when turn ing the Ignition switch OFF while it is ON and head-

lamps are ON by the auto light function.

Timer types are a 5 minute timer and a 45 second timer

When opening any door (door switch is ON), the 5 mi nute timer starts and then headlamps go out 5 minutes

later

When all the doors are closed (from door switch ON to OFF), the 45 second timer starts and then headlamps go out 45 seconds later. If any door is opened (door switch ON) while the 45 second timer is in operation, the

5 minute timer starts again

The timer stops when turning on the ignition switch or turning off the auto light switch under the above condi-

tions.

Delay timer control mode can be changed by the f unction setting of CONSULT-III or display.

CAN Communication System DescriptionINFOID:0000000001328308

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328309

Refer to LAN-43, "CAN System Specification Chart".

Major Component and FunctionsINFOID:0000000001328310

Components Functions

BCM Turns on/off circuits of tail light and headlamp according to signals from light sensor, lighting switch (AUTO),

driver door switch, passenger door switch, rear door switch, and ignition switch (ON, OFF).

Optical sensor Converts outside brightness (lux) to voltage, and sends it to BCM. (Detects brightness of 800 to 2,500 lux)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3257 of 3924

INTERIOR ROOM LAMPLT-155

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

CONSULT-III Functions (BCM)INFOID:0000000001328413

CONSULT-III can display each diagnostic item using the diagnostic test mode shown following.

CONSULT-III BASIC OPERATION

Refer to GI-34, "Description".

WORK SUPPORT (INT LAMP)

Display Item List

Reference between “MODE” and “TIME” for “TURN ON/OFF”

DATA MONITOR (INT LAMP)

Display Item List

BCM connector Terminal

GroundContinuity

M4 49

Ye s

52

SKIA5294E

BCM diagnosis part Diagnosis mode Description

INT LAMP WORK SUPPORT Changes setting for each function.

DATA MONITOR Displays BCM input data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending driving signal to them.

BATTERY SAVER WORK SUPPORT Changes the setting for each function.

DATA MONITOR Displays BCM input data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending driving signal to them.

Item Description CONSULT-III

SET I/L D −UNLCK INTCON The 30 seconds glowing function interior room lamps and ignition keyhole illu-

mination can be selected when driver door is released (unlocked).

ON/OFF

ROOM LAMP ON TIME SET The time in order to escalate illumination can be adjusted when interior room

lamps and ignition keyhole illumination is turned on. MODE 1 – 7

ROOM LAMP OFF TIME SET The time in order to diminish illumination can be adjusted when interior room

lamps and ignition keyhole illumination is turned off. MODE 1 – 7

MODE 123 4 5 6 7

Time (sec.) 0.5 1 2 3 4 5 0

Monitor item Contents

IGN ON SW “ON/OFF” Displays “IGN position (ON)/OFF, ACC position (OFF)” judged from the ignition switch sig-

nal.

KEY ON SW “ON/OFF” Displays “Key inse rted (ON)/key removed (OFF)” status judged from the key switch signal.

DOOR SW - DR “ON/OFF” Displays status of the driver door as judged from the driver door switch signal. (Door is open:

ON/Door is closed: OFF)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3290 of 3924

![INFINITI FX35 2008 Service Manual

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally an INFINITI FX35 2008 Service Manual

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally an](/img/42/57017/w960_57017-3289.png)

ENGINE OILLU-5

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

ENGINE OIL

InspectionINFOID:0000000001325813

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check

the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and make sure the engine oil level is within the range shown in the figure.

3. If it is out of range, adjust it.

NOTE:

When checking the engine oil level, insert oil level gauge with its

tip aligned with oil level gauge guide on cylinder head. (In figure,

air cleaner case and air duct are removed.)

ENGINE OIL APPEARANCE

Check engine oil for white turbidity or heavy contamination.

If engine oil becomes turbid and white, it is highl y probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following areas:

Oil pans (lower and upper)

Oil pan drain plug

Oil pressure switch

Oil filter

Oil filter bracket (AWD models)

Oil cooler

Water pump cover

Chain tensioner cover

Intake valve timing control cover and intake valve timing control solenoid valve

Mating surface between cylinder head and rocker cover

Mating surface between front timing chain case and rear timing chain case

Mating surface between rear timing chain case and cylinder head

Mating surface between rear timing chain case and cylinder block

Mating surface between rear timing chain case and oil pan (upper)

Mating surface between cylinder block and cylinder head

Crankshaft oil seals (front and rear)

Camshaft position sensor (PHASE)

OIL PRESSURE CHECK

PBIC3101E

KBIA1343E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3325 of 3924

MA-8

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) Maintenance-free item. For service procedures, refer to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

NOTE:

(1) Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

(2) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section.

Engine coolant NOTE (3) R*

MA-12

, MA-19

Engine oil R R R R R R R R MA-15, MA-22

Engine oil filter (Use genuine

NISSAN engine oil filter or equiv-

alent.) RRRR R RRR

MA-16

, MA-23

Spark plugs (PLATINUM-

TIPPED type) Replace every 105,000 miles (169,000 km).

MA-17, MA-24

Intake & exhaust valve clear-

ance* NOTE (4)

EM-91, EM-218

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Brake lines & cables IIIIMA-32

Brake pads & rotors

IIIIMA-32

Automatic transmission & trans-

fer fluid & differential gear oilNOTE (1) IIII MA-26,

MA-28,

MA-29

Steering gear, linkage & transfer

gear, axle & suspension parts I I MA-33,

MA-34

Tire rotation NOTE (2) MA-3,

MA-31

Drive shaft boots and propeller

shaft (AWD models) IIII

MA-34, MA-29

Exhaust system

IIMA-26

In-cabin microfilter

RRRRAT C - 1 0 7

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3381 of 3924

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

PG

N

O P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

System DescriptionINFOID:0000000001328870

IPDM E/R (Intelligent Power Distribution Module Engi ne Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It c ontrols integrated relay via IPDM E/R control circuit.

IPDM E/R-integrated control circuit performs ON-OFF operation of relay, CAN communication control, oil

pressure switch signal, and hood switch signal reception, etc.

It controls operation of each electrical pa rt via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R-integr ated relays can be removed.

SYSTEMS CONTROLLED BY IPDM E/R

IPDM E/R receives a request signal fr om each control unit with CAN communication. It controls each system.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control uni t using two communication lines (CAN-L line, CAN-H

line), it is possible to transmit maximum amount of in formation with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

Fail- Safe Control

When CAN communication with other control units is impos sible, IPDM E/R performs fail-safe control. After

CAN communication recovers normally, it also returns to normal control.

Operation of control parts by IPDM E/R during fail-safe mode is as follows:

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status CAN communication is normally performed with other control units.

Individual unit control by IPDM E/R is normally performed.

When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status Process to stop CAN communication is activated.

Control system Transmit control unit Control part

Lamp control BCM Headlamps (HI, LO)

Front fog lamps

Parking, license plate, side marker and tail lamps

Wiper control BCM Front wipers

Rear window defogger control BCM Rear window defogger

A/C compressor control ECM A/C compressor (magnet clutch)

Cooling fan control ECM Cooling fan

Horn control BCM Horn

Controlled system Fail-safe mode

Headlamp With the ignition switch ON, the headlamp (low) is ON.

With the ignition switch OFF, the headlamp (low) is OFF.

Parking, license plate side marker, and

tail lamps With the ignition switch ON, the parking, license plate, side marker and tail lamps is ON.

With the ignition switch OFF, the parking, license plate, side marker and tail lamps is OFF.

Cooling fan With the ignition switch ON, the cooling fan HI operates.

With the ignition switch OFF, the cooling fan stops.

Front wiper Until the ignition switch is turned OFF, the front wiper LO and HI remains in the same status

it was in just before fail-safe control was initiated.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C compressor OFF

Front fog lamps Front fog lamp relay OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3382 of 3924

PG-18

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

All systems controlled by IPDM E/R are stopped. When 3 seconds have elapsed after CAN communica-

tion with other control units is st opped, mode switches to sleep status.

3. Sleep status IPDM E/R operates in low power mode.

CAN communication is stopped.

When a change in CAN communication line is detected, mode switches to CAN communication status.

When a change hood switch or ignition switch signal is detected, mode switches to CAN communication

status.

CAN Communication System DescriptionINFOID:0000000001328871

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Modern

vehicles are equipped with many electronic control units and each control unit shares information and links

with other control units during operation (not independent ). In CAN communication, control units are con-

nected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/recei ves data but selectively reads required data only.

CAN Communication UnitINFOID:0000000001328872

Refer to LAN-43, "CAN System Specification Chart".

Function of Detecting I gnition Relay MalfunctionINFOID:0000000001328873

When contact point of integrated ignition relay is st uck and cannot be turned OFF, IPDM E/R turns ON park-

ing, license plate, side marker and tail lamps for 10 minutes to indicate ignition relay malfunction.

When a state of ignition relay having built-in does not agr ee with a state of ignition switch signal input by a

CAN communication from BCM, IPDM E/R lets tail lamp relay operate.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

CONSULT-III Function (IPDM E/R)INFOID:0000000001328874

CONSULT-III can display each diagnostic item using the diagnostic test mode shown following.

Self Diagnostic Result

Display Item List

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF — ON OFF —

OFF ON ON (10 minutes)

Inspection Item, Diagnosis Mode Description

Self Diagnostic Result The IPDM E/R performs diagnosis of the CAN communication and self-diagnosis.

Data Monitor The input/output data of the IPDM E/R is displayed in real time.

CAN Diag Support Monitor The result of transmit/receive diagnosis of CAN communication can be read.

Active test The IPDM E/R sends a drive signal to electronic components to check their operation.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3384 of 3924

PG-20

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

NOTE:

This item is displayed, but cannot be tested.

Auto Active TestINFOID:0000000001328875

DESCRIPTION

In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems:

Rear window defogger

Front wipers

Parking, license plate, side marker and tail lamps

Front fog lamps

Headlamps (Hi, Lo)

A/C compressor (magnetic clutch)

Cooling fan

OPERATION PROCEDURE

1. Close hood and front door (passenger side), and then lift wiper arms away from windshield (to prevent

glass damage by wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON, and within 20 seconds, pre ss drivers door switch 10 times (close other doors).

Then turn ignition switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, horn chir ps once oil pressure warning lamp starts blinking.

6. After a series of operations is repeated three times, auto active test is completed. NOTE:

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

CAUTION:

Be sure to inspect BL-38, "

Check Door Switch" when the auto active t est cannot be performed.

INSPECTION IN AUTO ACTIVE TEST MODE

When auto active test mode is actuated, the following eight steps are repeated three times.

Front wiper (HI, LO) operation FRONT WIPER With a certain operation (Off, Hi, Lo),

the front wiper relay (Lo, Hi) can

be operated.

Cooling fan operation MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan can be operated.

Lamp (HI, LO, FOG) opera-

tion LAMPSWith a certain operation (Off, Hi, Lo, Fog), the lamp relay (Lo, Hi, Fog)

can be operated.

Cornering lamp operation CORNERING LAMP

NOTE—

Horn operation HORN With a certain On-Off operation, the horn relay can be operated. Test item CONSULT-III screen display Description

PKIB6583E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3457 of 3924

PS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612911

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000001612914

NOTE:

This Procedure is applied only to models with In telligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the ″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS /IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for Steering SystemINFOID:0000000001327705

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehicle

condition, and then check wheel alignment.

Observe the following precautions when disassembling.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C