INFINITI FX35 2008 Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3691 of 3924

SE-52

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check Passenger Side Mirror Motor Circuit

INFOID:0000000001328118

1.CHECK DOOR MIRROR FUNCTION

Check the following.

Operation malfunction caused by a foreign object caught in door mirror face edge.

OK or NG

OK >> GO TO 2 (With CONSULT-III). GO TO 3 (WIthout CONSULT-III).

NG >> Repair the malfunctioning parts, and check the symptom again.

2.CHECK MIRROR MOTOR

With CONSULT-III

Check the operation with “MIRROR MOTOR RH” in the ACTIVE TEST.

OK or NG

OK >> Passenger side mirror motor circuit is OK.

NG >> GO TO 3.

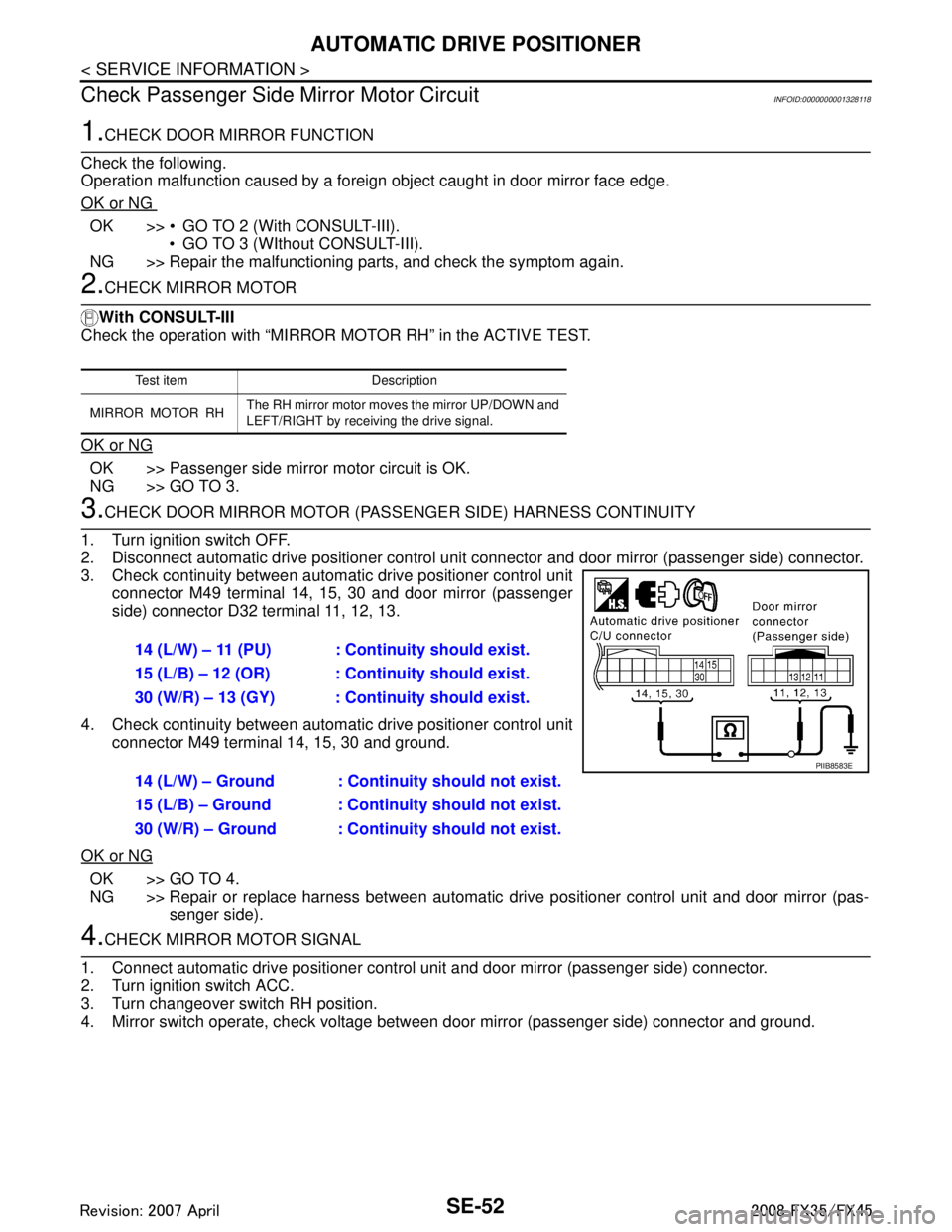

3.CHECK DOOR MIRROR MOTOR (PASSE NGER SIDE) HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control uni t connector and door mirror (passenger side) connector.

3. Check continuity between automat ic drive positioner control unit

connector M49 terminal 14, 15, 30 and door mirror (passenger

side) connector D32 terminal 11, 12, 13.

4. Check continuity between automat ic drive positioner control unit

connector M49 terminal 14, 15, 30 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas-

senger side).

4.CHECK MIRROR MOTOR SIGNAL

1. Connect automatic drive positioner control unit and door mirror (passenger side) connector.

2. Turn ignition switch ACC.

3. Turn changeover switch RH position.

4. Mirror switch operate, check voltage between door mirror (passenger side) connector and ground.

Te s t i t e m D e s c r i p t i o n

MIRROR MOTOR RH The RH mirror motor moves

the mirror UP/DOWN and

LEFT/RIGHT by receiving the drive signal.

14 (L/W) – 11 (PU) : Co ntinuity should exist.

15 (L/B) – 12 (OR) : Cont inuity should exist.

30 (W/R) – 13 (GY) : Cont inuity should exist.

14 (L/W) – Ground : Continuity should not exist.

15 (L/B) – Ground : Continuity should not exist.

30 (W/R) – Ground : Continuity should not exist.

PIIB8583E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3692 of 3924

AUTOMATIC DRIVE POSITIONERSE-53

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

OK or NG

OK >> Replace door mirror motor (passenger side).

NG >> Check the condition of the harness and connector.

Check Sliding Sensor CircuitINFOID:0000000001328119

1.CHECK FUNCTION

With CONSULT-III

Check operation with “SLIDE PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK >> Sliding sensor circuit is OK.

NG >> GO TO 2.

2.CHECK SLIDING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and sliding motor connector.

Connector Terminals (Wire color)

Mirror switch condition Voltage (V)

(Approx.)

(+) (–)

D32 11 ( P U )

Ground UP Battery voltage

Other than above 0

12 (OR) LEFT Battery voltage

Other than above 0

13 (G/Y) DOWN or RIGHT Battery voltage

Other than above 0

PIIB8582E

Monitor item

[OPERATION or

UNIT] Contents

SLIDE PULSE The seat sliding position (pulse) judged from the sliding sensor

signal is displayed.

Connector Te r m i n a l s

(Wire color) Condition Signal

(Reference value)

(+) (–)

B152 18 (G/L) Ground Sliding

motor op-

eration

PIIA6105E

PIIA3277E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3693 of 3924

SE-54

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

2. Check continuity between driver seat control unit connector

B152 terminals 18, 28C and sliding motor connector B161 termi-

nals 18, 28.

3. Check continuity between driv er seat control unit connector

B152 terminals 18, 28C and ground.

OK or NG

OK >> Replace sliding motor.

NG >> Repair or replace harness between driver seat control unit and sliding motor.

Check Reclining Sensor CircuitINFOID:0000000001328120

1.CHECK FUNCTION

With CONSULT-III

Check operation with “RECLINING PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check signal between driver seat contro l unit connector and ground, with oscilloscope.

OK or NG

OK >> Reclining sensor circuit is OK.

NG >> GO TO 2.

2.CHECK RECLINING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and reclining motor connector. 18 (G/L) – 18 (G/L) : Cont

inuity should exist.

28C (B/W) – 28 (B/W) : Continuity should exist.

18 (G/L) – Ground : Continuity should not exist.

28C (B/W) – Ground : Continuity should not exist.

PIIA6106E

Monitor item [PO-

ERATION or UNIT] Contents

RECLN PULSE The seat reclining position (pulse) judged from the reclining

sensor is displayed

Connector Te r m i n a l s

(Wire color) Condition Signal

(Reference value)

(+) (–)

B152 29 (G) Ground Reclining

motor op-

eration

PIIA6107E

SIIA0692J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3694 of 3924

AUTOMATIC DRIVE POSITIONERSE-55

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

2. Check continuity between driver seat control unit connector B152 terminals 28C, 29 and reclining motor connector B166 ter-

minals 28, 29.

3. Check continuity between driver seat control unit connector B152 terminals 28C, 29 and ground.

OK or NG

OK >> Replace reclining motor.

NG >> Repair or replace harness between connectors driver seat control unit and reclining motor.

Check Front Lifting Sensor CircuitINFOID:0000000001328121

1.CHECK FUNCTION

With CONSULT-III

Check operation with “LIFT FR PULSE” on the DA TA MONITOR to make sure the pulse changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK >> Front lifting sensor circuit is OK.

NG >> GO TO 2.

2.CHECK FRONT LIFTING SE NSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and front lifting motor connector. 28C (B/W) – 28 (B/W) : Continuity should exist.

29 (G) – 29 (G) : Continuity should exist.

28C (B/W) – Ground : Continuity should not exist.

29 (G) – Ground : Continuity should not exist.

PIIA6108E

Monitor item [OP-

ERATION or UNIT] Contents

LIFT FR PULSE The front lifting position (pulse) judged from the front lifting

sensor is displayed

Connector Te r m i n a l s

(Wire color) Condition Signal

(Reference value)

(+) (–)

B152 19 (G/R) Ground Front lift-

ing motor

operation

PIIA6109E

SIIA0691J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3695 of 3924

SE-56

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

2. Check continuity between driver seat control unit connector

B152 terminals 19, 28C and front lifting motor connector B164

terminals 19, 28A.

3. Check continuity between driv er seat control unit connector

B152 terminals 19, 28C and ground.

OK or NG

OK >> Replace front lifting motor.

NG >> Repair or replace harness between driver seat control unit and front lifting motor.

Check Rear Lifting Sensor CircuitINFOID:0000000001328122

1.CHECK REAR LIFTING SENSOR INPUT/OUTPUT SIGNAL

With CONSULT-III

Check operation with “LIFT RP PULSE” on the DATA MONITOR to make sure pulse changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector ground, with oscilloscope.

OK or NG

OK >> Rear lifting sensor circuit is OK.

NG >> GO TO 2.

2.CHECK REAR LIFTING SE NSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and rear lifting motor connector. 19 (G/R) – 19 (G/R) : Cont

inuity should exist.

28C (B/W) – 28A (B/W) : Co ntinuity should exist.

19 (G/R) – Ground : Continuity should not exist.

28C (B/W) – Ground : Continuity should not exist.

PIIA6110E

Monitor item [OP-

ERATION or UNIT Contents

LIFT RR PULSE The rear lifting position (pulse) judged from the rear lifting

sensor is displayed.

Connector Te r m i n a l s

(Wire color) Condition Signal

(Reference value)

(+) (–)

B152 30 (R/W) Ground Rear lift-

ing motor

operation

PIIA6111E

SIIA0693J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3696 of 3924

AUTOMATIC DRIVE POSITIONERSE-57

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

2. Check continuity between driver seat control unit connector B152 terminals 28C, 30 and rear lifting motor connector B162

terminals 28B, 30.

3. Check continuity between driver seat control unit connector B152 terminals 28C, 30 and ground.

OK or NG

OK >> Replace rear lifting motor.

NG >> Repair or replace harness between driver seat control unit and rear lifting motor.

Check Telescopic Sensor CircuitINFOID:0000000001328123

1.CHECK FUNCTION

With CONSULT-III

Operate the telescopic switch with “TELESCO SEN” on the DATA MONITOR to make sure the voltage

changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Telescopic sensor circuit is OK.

NG >> GO TO 2.

2.CHECK HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit c onnector and tilt sensor and telescopic sensor connec-

tor. 28C (B/W) – 28B (B/W) : Co

ntinuity should exist.

30 (R/W) – 30 (R/W) : Cont inuity should exist.

28C (B/W) – Ground : Continuity should not exist.

30 (R/W) – Ground : Continuity should not exist.

PIIA6112E

Monitor item

[OPERATION or UNIT] Contents

TELESCO

SEN “V”The telescoping position (voltage) judged from the tele-

scoping sensor signal is displayed.

Connector Te r m i n a l s

(Wire color) ConditionVoltage (V)

(Approx.)

(+) (–)

M49 23 (Y/B) Ground Telescopic

top position

1

Telescopic

bottom position 4

PIIA5070E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3697 of 3924

SE-58

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

2. Check continuity harness between automatic drive positionercontrol unit connector M49 terminals 23 and tilt sensor and tele-

scopic sensor connector M28 terminals 3.

3. Check continuity harness between automatic drive positioner control unit connector M49 terminals 23 and ground.

OK or NG

OK >> Replace tilt sensor and telescopic sensor.

NG >> Repair or replace harness between automatic driv e positioner control unit and tilt sensor and tele-

scopic sensor.

Check Tilt Sensor CircuitINFOID:0000000001328124

1.CHECK TILT SENSOR

With CONSULT-III

With “TILT SEN” on the DATA MONITOR, operate the tilt switch to make sure voltage changes.

Without CONSULT-III

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Tilt sensor circuit is OK.

NG >> GO TO 2.

2.CHECK HARNESS

1. Disconnect automatic drive positioner control unit connector and tilt sensor and telescopic sensor connec-

tor.

2. Check continuity harness between automatic drive positioner control unit connector M49 terminals 7 and tilt sensor and tele-

scopic sensor connector M28 terminals 2.

3. Check continuity harness between automatic drive positioner control unit connector M49 terminals 7 and ground.

OK or NG

OK >> Replace tilt sensor and telescopic sensor.

NG >> Repair or replace harness between automatic driv e positioner control unit and tilt sensor and tele-

scopic sensor.

23 (Y/B) – 3 (Y/B) : Continuity should exist.

23 (Y/B) – Ground : Continuity should not exist.

PIIA5079E

Monitor item

[OPERATION or UNIT] Contents

TILT SEN “V” The tilt position (voltage) judged from the tilt sensor sig-

nal is displayed.

Connector Te r m i n a l s

(Wire color) ConditionVoltage (V)

(Approx.)

(+) (–)

M49 7 (Y/R) Ground Tilt top position 2

Tilt bottom position 4

PIIA5069E

7 (Y/R) – 2 (Y/R) : Continuity should exist.

7 (Y/R) – Ground : Continuity should not exist.

PIIA5080E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3698 of 3924

AUTOMATIC DRIVE POSITIONERSE-59

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

Check Driver Side Mirror Sensor CircuitINFOID:0000000001328125

1.CHECK DOOR MIRROR FUNCTION

Check the following.

Operation malfunction in memory control

NOTE:

If a door mirror face position is set to an impl ausible angle, the set position may not be reproduced.

OK or NG

OK >> GO TO 2.

NG >> Repair the malfunctioning parts, and check the symptom again.

2.CHECK MIRROR SENSOR INSPECTION

With CONSULT-III

Make sure “ON” is displayed on “MIR/SE L H R–L, MIR/SE LH U–D” in the DATA MONITOR.

Without CONSULT-III

1. Turn ignition switch to ACC position.

2. Check voltage between door mirror (driver side) connector and ground.

OK or NG

OK >> Driver side mirror sensor circuit is OK.

NG >> GO TO 3.

3.CHECK HARNESS CONTINUITY 1

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mirror (driver side) connector.

3. Check continuity between automat ic drive positioner control unit

connector M50 terminals 33, 41 and door mirror (driver side)

connector D2 terminals 1, 9.

4. Check continuity between automat ic drive positioner control unit

connector M49 terminals 33, 41 and ground.

OK or NG

OK >> GO TO 3.

Monitor item

[OPERATION or UNIT] Contents

MIR/SE LH R–L “V” Voltage output from LH door mirror sensor

(LH/RH) is displayed.

MIR/SE LH U–D “V” Voltage output from LH door mirror sensor

(UP/DOWN) is

displayed.

Con-

nector Terminals (Wire color)

ConditionVoltage (V)

(Approx,)

(+) (–)

D2 2 (W)

Ground When motor is

UP or DOWN

operation

Changes between

3 (close to perk) –

1 (close to valley)

10 (LG) When motor is

LEFT or RIGHT op-

eration Changes between

3 (close to right edge) – 1 (close to left edge)

PIIB8585E

33 (G/W) – 1 (OR) : Continuity should exist.

41 (B/Y) – 9 (BR) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8586E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3699 of 3924

SE-60

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (driver

side).

4.CHECK HARNESS CONTINUITY 2

1. Check continuity between automat ic drive positioner control unit

connector M49 terminal 6, 22 and door mirror (driver side) con-

nector D2 terminal 2, 10.

2. Check continuity between automat ic drive positioner control unit

connector M49 terminal 6, 22 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic dr ive positioner control unit and door mirror (driver

side).

Check Passenger Side Mi rror Sensor CircuitINFOID:0000000001328126

1.CHECK DOOR MIRROR FUNCTION

Check the following.

Operation malfunction in memory control

NOTE:

If a door mirror face position is set to an impl ausible angle, the set position may not be reproduced.

OK or NG

OK >> GO TO 2.

NG >> Repair the malfunctioning parts, and check the symptom again.

2.CHECK MIRROR SENSOR INSPECTION

With CONSULT-III

Make sure “ON” is displayed on “MIR/SE RH R–L, MIR/SE RH U–D” in the DATA MONITOR.

Without CONSULT-III

1. Turn ignition switch to ACC position.

2. Check voltage between door mirror (passenger side) connector and ground.

OK or NG

OK >> Passenger side mirror sensor circuit is OK. 6 (P/L) – 2 (W) : Cont

inuity should exist.

22 (L/Y) – 10 (LG) : Cont inuity should exist.

6 (P/L) – Ground : Continuity should not exist.

22 (L/Y) – Ground : Continuity should not exist.

PIIB8584E

Monitor item

[OPERATION or UNIT] Contents

MIR/SE RH R–L “V” Voltage output from RH door mirror sensor

(LH/RH) is displayed.

MIR/SE RH U–D “V” Voltage output from RH door mirror sensor

(UP/DOWN) is

displayed.

Con-

nector Terminals (W

ire color)

Condition Voltage (V)

(Approx.)

(+) (–)

D32 2 (LG)

GroundWhen motor is

UP or DOWN

operation

Changes between

3 (close to perk) – 1 (close to valley)

10 (P) When motor is

LEFT or RIGHT op-

eration Changes between

1 (close to left edge) – 3 (close to right edge)

PIIB8585E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3700 of 3924

AUTOMATIC DRIVE POSITIONERSE-61

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

NG >> GO TO 3.

3.CHECK HARNESS CONTINUITY 1

1. Disconnect automatic drive positioner contro l unit and door mirror (passenger side) connector.

2. Check continuity between automat ic drive positioner control unit

connector M50 terminal 33, 41 and door mirror (passenger side)

connector D32 terminal 1, 9.

3. Check continuity between automat ic drive positioner control unit

connector M50 terminals 33, 41 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas-

senger side).

4.CHECK HARNESS CONTINUITY 2

1. Check continuity between automat ic drive positioner control unit

connector M49 terminal 5, 21 and door mirror (passenger side)

connector D32 terminal 2, 10.

2. Check continuity between automat ic drive positioner control unit

connector M49 terminal 5, 21 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas-

senger side).

Check Steering and Door Mirror Sensor Power Supp ly and Ground CircuitINFOID:0000000001328127

1.CHECK STEERING AND DOOR MIRROR SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit

connector M50 terminal 33 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace automatic drive positioner control unit.

2.CHECK STEERING AND DOOR MIRROR SENSOR GROUND CIRCUIT

33 (G/W) – 1 (BR) : Continuity should exist.

41 (B/Y) – 9 (G) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8586E

5 (OR) – 2 (LG) : Continuity should exist.

21 (G/Y) – 10 (P) : Cont

inuity should exist.

5 (OR) – Ground : Continuity should not exist.

21 (G/Y) – Ground : Contin uity should not exist.

PIIB8587E

33 (G/W) – Ground : Approx. 5V

PIIA4778E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C