INFINITI FX35 2008 Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 471 of 3924

ATC-66

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the unified meter and A/C amp. based on the

input from the PBR, in-vehicle sensor, sunl oad sensor, intake sensor and ambient sensor.

When the air flow is increased, the duty ratio of the blower fan motor’s drive signal is changed at 8%/sec. to

prevent a sudden increase in air flow.

In addition to manual air flow control and the usual automat ic air flow control, starting air flow control, low

water temperature starting control and high passenger co mpartment temperature starting control are avail-

able.

Starting Fan Speed Control

Start up from COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56 °C (133 °F), the blower will not

operate for a short period of time (up to 150 seconds ). The exact start delay time varies depending on the

ambient and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at lo w speed until the engine coolant temperature rises above

56 °C (133 °F), and then the blower speed will increase to the objective speed.

Start up from usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the AU TO switch is pressed. The blower speed will gradu-

ally rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. Du ring conditions of low or no sunload, the blower

speed is at duty ratio 25%. During high sunload conditi ons, the unified meter and A/C amp. raise the blower

speed (duty ratio 49%).

Fan Speed Control Specification

RJIA1995E

RJIA1996E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 472 of 3924

TROUBLE DIAGNOSISATC-67

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

COMPONENT DESCRIPTION

Brush-Less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point of contact and the coil rotated.

DIAGNOSIS PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

1.CHECK POWER SUPPLY FOR BLOWER MOTOR

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector M78 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> Check power supply circuit and 15A fuses [Nos. 10 and 11, located in the fuse block (J/B)]. Refer to PG-

77.

If fuses are OK, check harness for open circuit. Repair or replace if necessary.

If fuses are NG, check harness fo r short circuit and replace fuse.

2.CHECK BLOWER MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between blower motor harness connector M78 terminal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK CIRCUIT CONTINUITY BETWEEN BLOWER MOTOR AND UNIFIED METER AND A/C AMP.

1. Disconnect unified meter and A/C amp. connector.

ZHA152H

SJIA0266E

1 – Ground : Battery voltage

RJIA1997E

3 – Ground : Continuity should exist.

RJIA1998E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 473 of 3924

ATC-68

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

2. Check continuity between blower motor harness connector M78terminal 2 and unified meter and A/C amp. harness connector

M57 terminal 53.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK UNIFIED METER AND A/C AMP. OUTPUT SIGNAL

1. Reconnect blower motor connector and unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Change the fan speed from Lo to Hi, and check the duty ratios between blower motor harness connector M78 terminal 2 and

ground using an oscilloscope. Normal terminal 2 drive signal

duty ratios are shown in the table below.

OK or NG

OK >> Replace blower motor after conf irming the fan air flow does not change.

NG >> Replace unified meter and A/C amp.

COMPONENT INSPECTION

Blower Motor

2 – 53 : Continuity should exist.

RJIA1999E

RJIA2000E

SJIA1802E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 474 of 3924

TROUBLE DIAGNOSISATC-69

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Confirm smooth rotation of the blower motor.

Ensure that there are no foreign particles inside the blower unit.

Magnet Clutch CircuitINFOID:0000000001328190

SYMPTOM: Magnet clutch does not engage.

INSPECTION FLOW

RJIA0905E

*1 AT C - 9 4 , "Intake Sensor Circuit"*2AT C - 8 6 , "Ambient Sensor Circuit"*3 AT C - 4 3 , "Self-Diagnosis Function",

see No. 13.

SJIA1590E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 475 of 3924

ATC-70

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

SYSTEM DESCRIPTION

Unified meter and A/C amp. controls compressor operation by ambient temperature, intake air temperature

and signal from ECM.

Low Temperature Protection Control

Unified meter and A/C amp. will turn the compressor ON or OFF as determined by a signal detected by ambi-

ent sensor and intake sensor.

When ambient temperature is higher than −2 °C (28 °F), the compres-

sor turns ON. The compressor turns OFF when ambient temperature

is lower than −5 °C (23 °F).

When intake air temperature is higher than 1 °C (34 °F), the compres-

sor turns ON. The compressor turns OFF when intake air tempera-

ture is lower than −5 °C (23 °F).

DIAGNOSIS PROCEDURE FOR MAGNET CLUTCH

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

1.CHECK AMBIENT SENSOR AND INTAKE SENSOR CIRCUIT

Check ambient sensor and intake sensor. Refer to ATC-43, "

Self-Diagnosis Function", see No. 9 and 11.

*4 "DIAGNOSIS PROCEDURE FOR

MAGNET CLUTCH" *5

AT C - 7 5 , "Insufficient Cooling"*6AT C - 5 0 , "Operational Check"

*7AT C - 4 3 , "Self-Diagnosis Function",

see No. 4 to 6. *8

AT C - 3 2 , "How to Perform Trouble Di-

agnosis for Quick and Accurate Re-

pair"

RHA094GB

SJIA0267E

SJIA1608E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 476 of 3924

TROUBLE DIAGNOSISATC-71

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

OK or NG

OK >> GO TO 2.

NG >> Malfunctioning ambient sensor: Refer to ATC-86, "

Ambient Sensor Circuit".

Malfunctioning intake sensor: Refer to ATC-94, "

Intake Sensor Circuit".

2.PERFORM IPDM E/R AUTO ACTIVE TEST

Perform “IPDM E/R auto active test”. Refer to PG-20, "

Auto Active Test".

Does the magnet clutch operate?

YES >> WITH CONSULT-III: GO TO 5 WITHOUT CONSULT-III: GO TO 6.

NO >> Check 10A fuse (No. 79, located in IPDM E/R). Refer to PG-23, "

IPDM E/R Terminal Arrange-

ment", and GO TO 3.

3.CHECK CIRCUIT CONTINUITY BETWEEN IPDM E/R AND COMPRESSOR

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and compressor connector.

3. Check continuity between IPDM E/R harness connector E8 ter- minal 33 and compressor harness connector F2 terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK MAGNET CLUTCH CIRCUIT

Check for operation sound when applying battery voltage direct cur-

rent to terminal.

OK or NG

OK >> 1. Replace IPDM E/R. 2. Go to self-diagnosis procedure ATC-43, "

Self-Diag-

nosis Function" and perform self-diagnosis STEP-4.

Confirm that magnet clutch operation normal.

NG >> 1. Replace magnet clutch.

2. Go to self-diagnosis procedure ATC-43, "

Self-Diag-

nosis Function" and perform self-diagnosis STEP-4.

Confirm that magnet clutch operation normal.

5.CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

Check compressor ON/OFF signal in “Data monitor”. Refer to ATC-32, "

CONSULT-III Function".

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6.CHECK CIRCUIT CONTINUITY BETWEEN BC M AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect BCM connector and unified meter and A/C amp. connector.

33 – 1 : Continui ty should exist.

RJIA2004E

RJIA2005E

A/C SW ON : AIR COND SW ON

A/C SW OFF : AIR COND SW OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 477 of 3924

ATC-72

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

3. Check continuity between BCM harness connector M3 terminal27 and unified meter and A/C amp. harness connector M57 ter-

minal 42.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK VOLTAGE FOR UNIFIED METER AND A/C AMP. (COMPRESSOR ON SIGNAL)

1. Reconnect BCM connector and unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Check voltage between unified meter and A/C amp. harness connector M57 terminal 42 and ground using an oscilloscope.

OK or NG

OK >> GO TO 8.

NG-1 >> If the voltage is approx. 5 V when A/C switch is ON: Replace unified meter and A/C amp.

NG-2 >> If the voltage is approx. 0 V w hen A/C switch is OFF: Replace BCM.

8.CHECK REFRIGERANT PRESSURE SENSOR

WITH CONSULT-III

1. Start the engine.

2. Check voltage of refrigerant pressure sensor in “Data monitor”. Refer to EC-127, "

CONSULT-III Reference

Value in Data Monitor Mode" (VQ35DE) or EC-705, "CONSULT-III Reference Value in Data Monitor

Mode" (VK45DE).

WITHOUT CONSULT-III

1. Start the engine. 27 – 42 : Continuity should exist.

RJIA2006E

RJIA2007E

Te r m i n a l s

Condition Voltage

(+)

(− )

Unified meter

and A/C amp.

connector Te r m i n a l

No.

M57 42 Ground A/C switch: ON

(Blower motor operates.)

Approx. 0 V

OFF switch: ON

(A/C system: OFF)

SJIA1423J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 478 of 3924

TROUBLE DIAGNOSISATC-73

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

2. Check voltage between ECM harness connector F101 terminal 70 and ground.

OK or NG

OK >> WITH CONSULT-III: GO TO 9. WITHOUT CONSULT-III: GO TO 10.

NG >> Refer to EC-581

(VQ35DE) or EC-1177 (VK45DE).

9.CHECK BCM INPUT (FAN ON) SIGNAL

Check FAN ON/OFF signal in “Data monitor”. Refer to ATC-32, "

CONSULT-III Function".

OK or NG

OK >> GO TO 12.

NG >> GO TO 10.

10.CHECK CIRCUIT CONTINUITY BETWEEN BC M AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect BCM connector and unified meter and A/C amp. connector.

3. Check continuity between BCM harness connector M3 terminal 28 and unified meter and A/C amp. harness connector M57 ter-

minal 57.

OK or NG

OK >> GO TO 11.

NG >> Repair harness or connector.

11 .CHECK VOLTAGE FOR UNIFIED METER AND A/C AMP. (FAN ON SIGNAL)

1. Reconnect BCM connector and unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Check voltage between unified meter and A/C amp. harness connector M57 terminal 57 and ground using an oscilloscope.

Te r m i n a l s

Condition Voltage

(+)

(− )

ECM

connec- tor Te r m i n a l

No.

F101 70 Ground A/C switch: ON

(Blower motor operates.)Approx. 1.0 - 4.0

V

PBIB1188E

FAN SW ON : FAN ON SIG ON

FAN SW OFF : FAN ON SIG OFF

28 – 57 : Continuity should exist.

RJIA2009E

RJIA2010E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 479 of 3924

ATC-74

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 12.

NG-1 >> If the voltage is approx. 5 V when blower motor is ON: Replace unified meter and A/C amp.

NG-2 >> If the voltage is approx. 0 V when blower motor is OFF: Replace BCM.

12.CHECK CAN COMMUNICATION

Check CAN communication. Refer to BCS-13, "

U1000 CAN Communication Circuit".

BCM – ECM

ECM – IPDM E/R

ECM – Unified meter and A/C amp.

OK or NG

OK >> Replace ECM

NG >> Repair or replace malfunctioning part(s).

COMPONENT INSPECTION

Refrigerant Pressure Sensor

The refrigerant pressure sensor is attached to the condenser.

Make sure that the A/C refrigerant pressure and the sensor output

voltage are within the specified r ange as shown in the A/C operating

condition figure. Refer to EC-581

(VQ35DE) or EC-1177 (VK45DE).

Te r m i n a l s

Condition Voltage

(+)

(− )

Unified meter

and A/C amp.

connector Te r m i n a l N o .

M57 57 Ground A/C switch: ON

(Blower motor operates.)

Approx. 0 V

OFF switch: ON

(A/C system: OFF)

SJIA1474J

RJIA2011E

RJIA2954E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 480 of 3924

TROUBLE DIAGNOSISATC-75

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

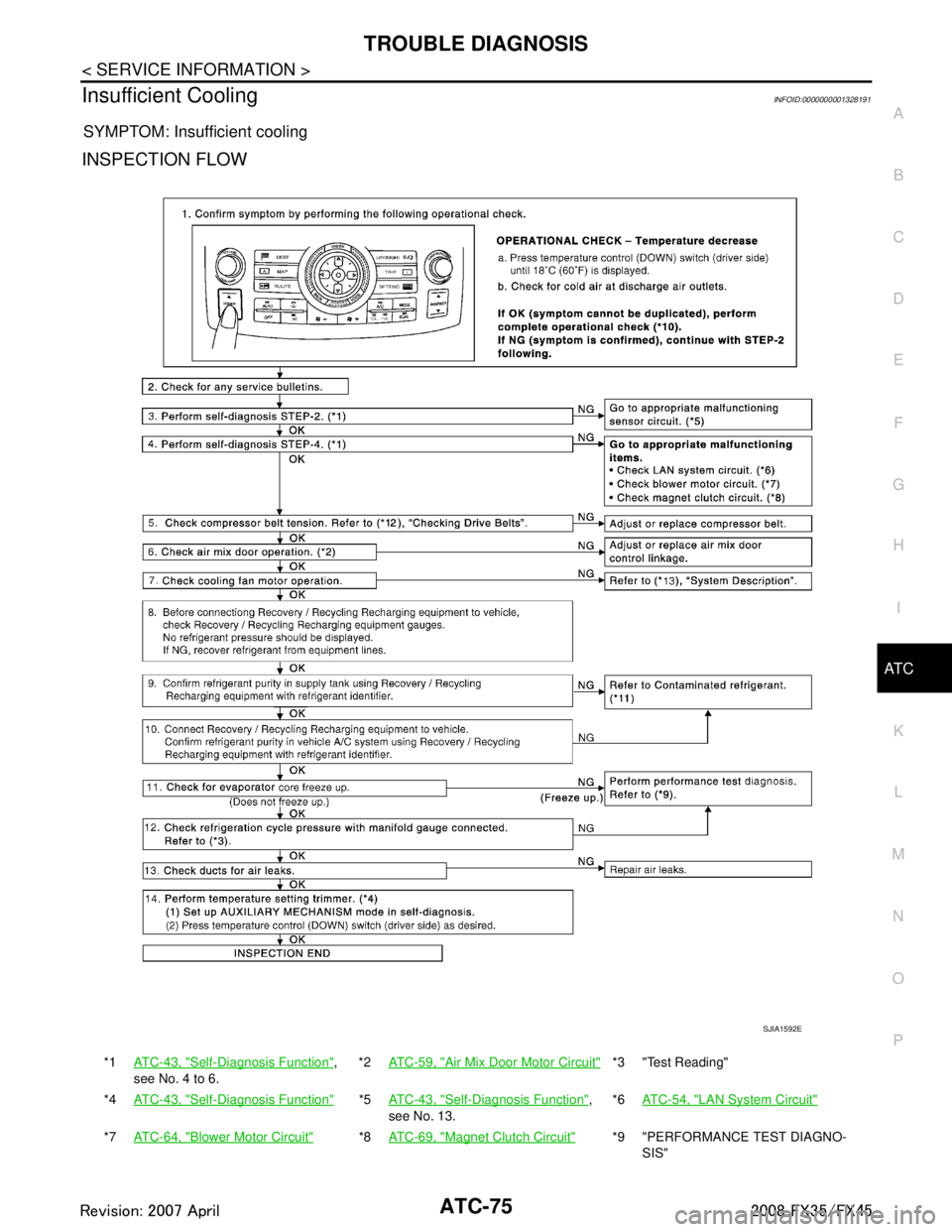

Insufficient CoolingINFOID:0000000001328191

SYMPTOM: Insufficient cooling

INSPECTION FLOW

*1 AT C - 4 3 , "Self-Diagnosis Function",

see No. 4 to 6. *2

AT C - 5 9 , "Air Mix Door Motor Circuit"*3 "Test Reading"

*4 AT C - 4 3 , "

Self-Diagnosis Function"*5 AT C - 4 3 , "Self-Diagnosis Function",

see No. 13. *6

AT C - 5 4 , "LAN System Circuit"

*7AT C - 6 4 , "Blower Motor Circuit"*8 AT C - 6 9 , "Magnet Clutch Circuit"*9 "PERFORMANCE TEST DIAGNO-

SIS"

SJIA1592E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C