display INFINITI FX35 2008 Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 415 of 3924

ATC-10

< SERVICE INFORMATION >

PRECAUTIONS

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

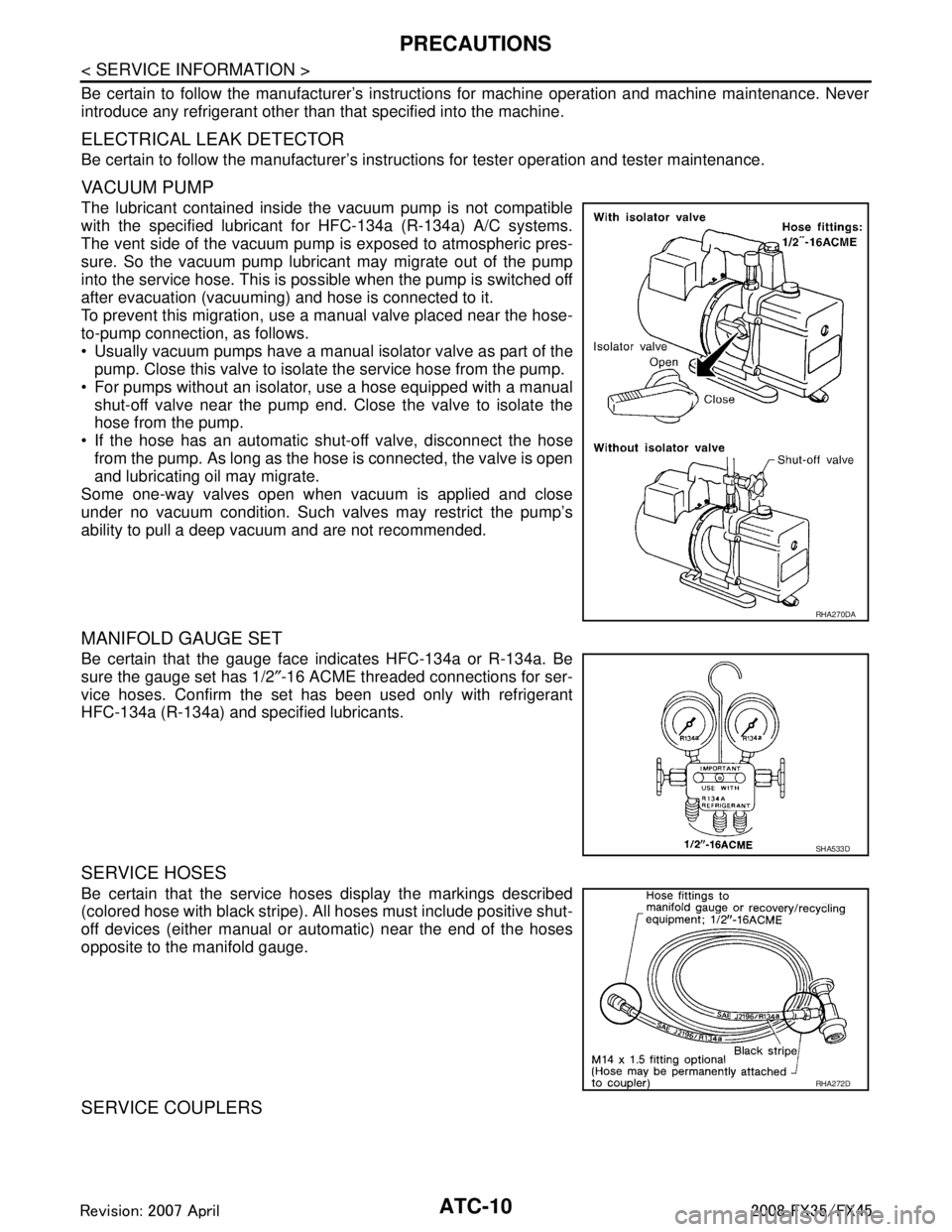

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric pres-

sure. So the vacuum pump lubricant may migrate out of the pump

into the service hose. This is pos sible when the pump is switched off

after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

Usually vacuum pumps have a manual isolator valve as part of the pump. Close this valve to isolat e the service hose from the pump.

For pumps without an isolator, use a hose equipped with a manual

shut-off valve near the pump end. Close the valve to isolate the

hose from the pump.

If the hose has an automatic shut -off valve, disconnect the hose

from the pump. As long as the hos e is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or aut omatic) near the end of the hoses

opposite to the manifold gauge.

SERVICE COUPLERS

RHA270DA

SHA533D

RHA272D

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 428 of 3924

LUBRICANTATC-23

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

*1: If the refrigerant leak is small, no addition of lubricant is needed.

LUBRICANT ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT

1. Before connecting recovery/recycling recharging equipm ent to vehicle, check recovery/recycling recharg-

ing equipment gauges. No refrigerant pressure should be displayed. If NG, recover refrigerant from equip-

ment lines.

2. Connect recovery/recycling recharging equipment to vehicle. Confirm refrigerant purity in supply tank

using recovery/recycling recharging equipment and refrigerant identifier. If NG, refer to AT C - 4 , "

Precaution

for Working with HFC-134a (R-134a)".

3. Confirm refrigerant purity in vehicle A/C system us ing recovery/recycling recharging equipment and refrig-

erant identifier. If NG, refer to AT C - 4 , "

Precaution for Working with HFC-134a (R-134a)".

4. Discharge refrigerant into the refrigerant recove ry/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

5. Drain the lubricant from the old (removed) comp ressor into a graduated container and recover the amount

of lubricant drained.

6. Drain the lubricant from the new compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount drained from old compressor. Add this

lubricant to new compressor through the suction port opening.

8. Measure an amount of new lubricant equal to the am ount recovered during discharging. Add this lubricant

to new compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add another 5 m (0.2 US fl oz., 0.2 Imp fl oz.) of lubricant at

this time.

Do not add this 5 m (0.2 US fl oz., 0.2 Imp fl oz.) of lubricant when replaces the compressor only.

In case of refrigerant leak 30 (1.0, 1.1) Large leak

— Small leak*1

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m (US fl oz., Imp fl oz.)

RJIA3578E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 432 of 3924

AIR CONDITIONER CONTROLATC-27

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Description of Control SystemINFOID:0000000001328169

The control system consists of input sensors, swit ches, the unified meter and A/C amp. (microcomputer) and

outputs. The relationship of these co mponents is shown in the figure below:

Control OperationINFOID:0000000001328170

DISPLAY SCREEN

The operation status of the system is displayed on the screen.

AUTO SWITCH

The compressor, intake doors, air mix doors, mode doors and blower speed are automatically controlled so

that the in-vehicle temperature will reach, and be mainta ined at the set temperature selected by the operator.

SJIA1658E

SJIA1567E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 433 of 3924

ATC-28

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

When pressing AUTO switch, air inlet, air outlet, fan speed, and discharge air temperature are automatically

controlled.

TEMPERATURE CONTROL SWITCH (POTENTIO TEMPERATURE CONTROL) (DRIVER SIDE)

The set temperature is increased or decreased with this switch.

TEMPERATURE CONTROL SWITCH (POTENTIO TEMPERATURE CONTROL) (PASSENGER

SIDE)

The set temperature is increased or decreased with this switch.

When the temperature switch is pressed, the DUA L switch indicator will automatically illuminate.

INTAKE SWITCH

When intake switch is ON, REC LED turns ON, and air inlet is fixed to REC.

When press intake switch again, FRE LED turns ON, and air inlet is fixed to FRE.

When intake switch is pressed for approximately 1. 5 seconds or longer, FRE and REC LEDs blink twice.

Then, automatic control mode is entered. Inlet status is displayed by LED even during automatic controlled.

When FRE LED is turned ON, shifting mode position to D/ F or DEF, or when compressor is turned from ON

to OFF, intake switch is automatically turned OFF (fixed to FRE mode). REC mode can be re-entered by

pressing intake switch again, and then compressor is turned ON. (Except D/F or DEF position)

DEFROSTER (DEF) SWITCH

Mode doors are set to the defrost position with this switch . Also, intake doors are set to the outside air position,

and compressor turns ON.

REAR WINDOW DEFOGGER SWITCH

When illumination is ON, rear window is defogged.

OFF SWITCH

Compressor and blower are OFF, the intake door s and the mode doors are automatically controlled.

A/C SWITCH

Compressor is ON or OFF with this switch.

(Pressing the A/C switch when the A/C switch is ON will turn OFF the A/C switch and compressor.)

MODE SWITCH

The air discharge outlets is controlled with this switch.

FAN SWITCH

The blower speed is manually controlled with this swit ch. Seven speeds are available for manual control (as

shown on the display screen).

DUAL SWITCH

When the DUAL switch indicator is illuminated, the driver side and passenger side temperature can each be set independently.

When the DUAL switch indicator is not illuminated, t he driver side setting temperature is applied to both

sides.

Fail-Safe FunctionINFOID:0000000001328171

If a communication error exists between the unified meter and A/C amp., and the A/C and AV switch for 30

seconds or longer, air conditioner is controlled under following conditions:

Compressor : ON

Air outlet : AUTO

Air inlet : FRE (Fresh)

Blower fan speed : AUTO

Set temperature : Setting befo re communication error occurs

Display : OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 437 of 3924

ATC-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

CONSULT-III FunctionINFOID:0000000001328175

CONSULT-III can display each diagnosis item using the diagnosis test modes shown following.

DATA MONITOR

Display Item List

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000001328176

WORK FLOW

SYMPTOM TABLE

System part Check item, diagnosis mode Description

BCM Data monitor Displays BCM input data in real time.

Monitor item name “operation or unit” Contents

IGN ON SW “On/Off” Displays “IGN position (On)/OFF, ACC position (Off)” status as judged from ignition switch signal.

FAN ON SIG “On/Off” Displays “FAN (On)/FAN (Off)” status as judged from blower fan motor switch signal.

AIR COND SW “On/Off” Di splays “COMP (On)/COMP (Off)” status as judged from air conditioner switch signal.

*1AT C - 5 0 , "Operational Check"

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System. AT C - 5 2 , "

Power

Supply and Ground

Circuit for Auto

Amp"

A/C system cannot be controlled.

Go to Integrated Display System.

Go to Navigation System. AV- 7 9 , "

Unable to

Operate System

with A/C and AV

Switch" (Without

navigation system)

or AV- 1 2 7 , "

Unable

to Operate System

with A/C and AV

Switch" (With navi-

gation system)

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door Motor. (LAN) AT C - 5 7 , "

Mode

Door Motor Circuit"Mode door motor does not operate normally.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. (LAN) AT C - 5 9 , "

Air Mix

Door Motor Circuit"Air mix door motor does not operate normal-

ly.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 449 of 3924

ATC-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

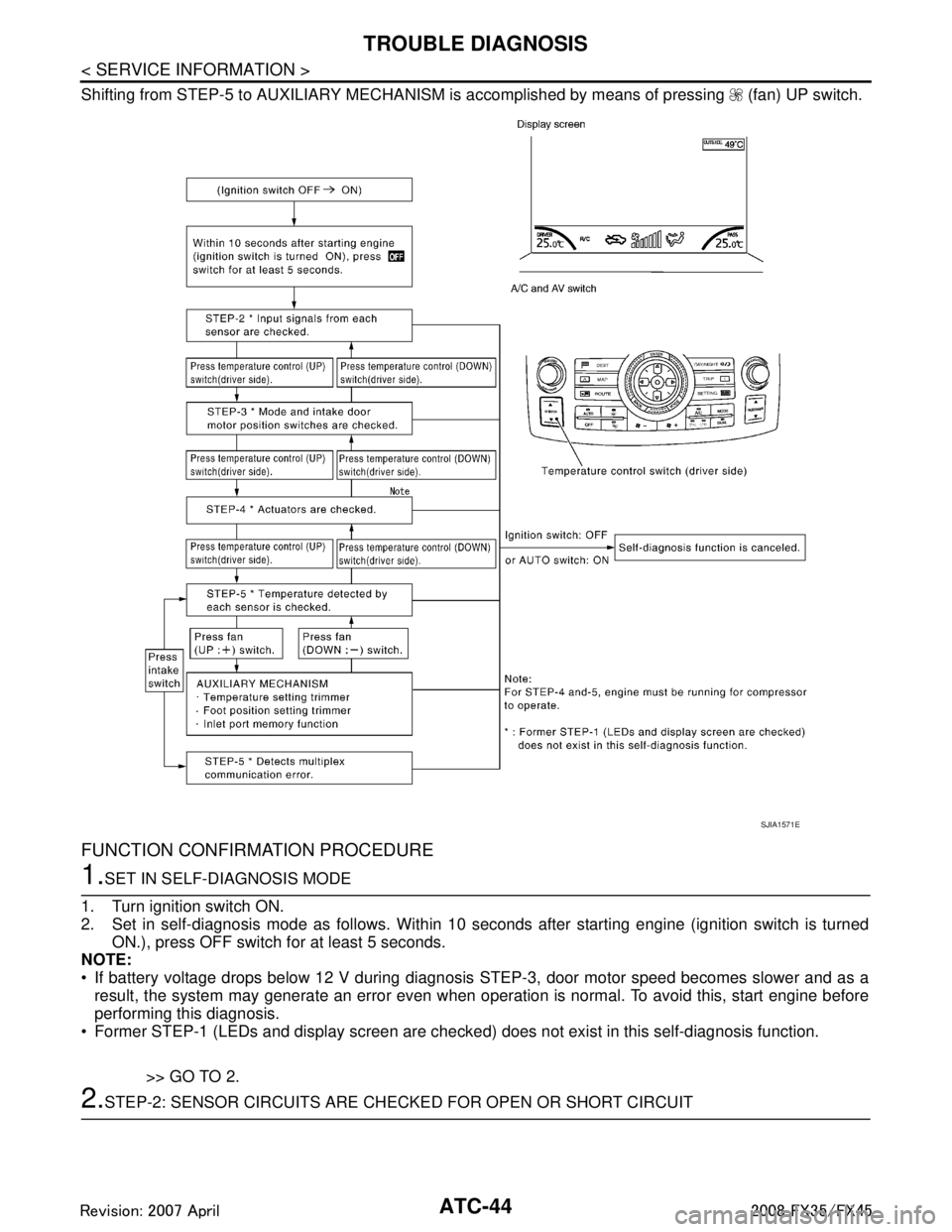

Shifting from STEP-5 to AUXILIARY MECHANISM is accomplished by means of pressing (fan) UP switch.

FUNCTION CONFIRMATION PROCEDURE

1.SET IN SELF-DIAGNOSIS MODE

1. Turn ignition switch ON.

2. Set in self-diagnosis mode as follows. Within 10 seconds after starting engine (ignition switch is turned ON.), press OFF switch for at least 5 seconds.

NOTE:

If battery voltage drops below 12 V during diagnosis STEP-3, door motor speed becomes slower and as a

result, the system may generate an error even when operation is normal. To avoid this, start engine before

performing this diagnosis.

Former STEP-1 (LEDs and display screen are checked) does not exist in this self-diagnosis function.

>> GO TO 2.

2.STEP-2: SENSOR CIRCUITS ARE CHECK ED FOR OPEN OR SHORT CIRCUIT

SJIA1571E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 450 of 3924

TROUBLE DIAGNOSISATC-45

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Does code No. 20 appear on the display?

YES >> GO TO 3.

NO >> GO TO 13.

3.CHECK TO ADVANCE SELF-DIAGNOSIS STEP-3

Press temperature control (UP) switch (driver side).

Advance to self

-diagnosis STEP-3?

YES >> GO TO 4.

NO >> Replace A/C and AV switch. (Temperat ure control switch is malfunctioning.)

4.CHECK TO RETURN SELF-DIAGNOSIS STEP-2

Press temperature control (DOWN) switch (driver side).

Return to self

-diagnosis STEP-2?

YES >> GO TO 5.

NO >> Malfunctioning A/C and AV switch or unified meter and A/C amp. Refer to ATC-84, "

Self-Diagno-

sis".

5.STEP-3: MODE DOOR AND INTAKE DOOR POSITIONS ARE CHECKED

Press temperature control (UP) switch (driver side).

Does code No. 30 appear on the display?

YES >> GO TO 6.

NO >> GO TO 14.

6.STEP-4: OPERATION OF EA CH DOOR MOTOR IS CHECKED

1. Press temperature control (UP) switch (driver side).

2. Press (DEF) switch. Code No. of each door motor test is indicated on the display.

>> GO TO 7.

7.CHECK ACTUATORS

SJIA1778E

SJIA1779E

SJIA1780E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 451 of 3924

ATC-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Refer to the following chart and check discharge air flow, air temper-

ature, blower motor duty ratio and compressor operation.

Checks must be made visually, by listening the sound, or by touching air outlets with hand, etc. for improper

operation.

*1: FOOT position during automatic control. Refer to "AUXILIARY MECHANISM: FOOT POSITION SETTING

TRIMMER".

OK or NG

OK >> GO TO 8.

NG >> Air outlet does not change.

Go to Mode Door Motor Circuit. Refer to ATC-57, "

Mode Door Motor Circuit".

Intake door does not change. Go to Intake Door Motor Circuit. Refer to ATC-62, "

Intake Door Motor Circuit".

Discharge air temperature does not change. Go to Air Mix Door Motor Circuit. Refer to ATC-59, "

Air Mix Door Motor Circuit".

Blower motor operation is malfunctioning.

Go to Blower Motor Circuit. Refer to ATC-64, "

Blower Motor Circuit".

Magnet clutch does not engage. Go to Magnet Clutch Circuit. Refer to ATC-69, "

Magnet Clutch Circuit".

8.STEP-5: TEMPERATURE OF EACH SENSOR IS CHECKED

1. Press temperature control (UP) switch (driver side).

2. Code No. 51 appears on the display.

>> GO TO 9.

9.CHECK AMBIENT SENSOR

Press (DEF) switch one time. Temperature detected by ambient

sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 10.

NG >> Go to Ambient Sensor Circuit. Refer to ATC-86, "

Ambi-

ent Sensor Circuit".

SJIA0302E

Code No. 414243444546

Mode door position VENT B/L 1 B/L 2

FOOT

*1D/F DEF

Intake door position REC REC 20% FRE FRE FRE FRE

Air mix door position FULL COLD FULL COLD FULL HOT FULL HOT FULL HOT FULL HOT

Blower motor duty ratio 37% 91% 65% 65% 65% 91%

Compressor ON ON OFF OFF ON ON

Electronic control valve

(ECV) duty ratio 100% 100% 0% 0% 50% 100%

PJIA0151E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 452 of 3924

TROUBLE DIAGNOSISATC-47

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

10.CHECK IN-VEHICLE SENSOR

Press (DEF) switch for the second time. Temperature detected

by in-vehicle sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 11.

NG >> Go to In-vehicle Sensor Circuit. Refer to ATC-88, "

In-

vehicle Sensor Circuit".

11 .CHECK INTAKE SENSOR

Press (DEF) switch for the third time. Temperature detected by

intake sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 12.

NG >> Go to Intake Sensor Circuit. Refer to ATC-94, "

Intake

Sensor Circuit".

12.CHECK CAN COMMUNICATION ERROR

1. Press intake switch.

2. CAN communication error between the unified meter and A/C amp. and the display control unit can be detected as self-diag-

nosis results. (If plural errors occur, the display of each error will

blink twice for 0.5 second intervals.)

OK or NG

OK >> 1. Turn ignition switch OFF or AUTO switch ON. 2. INSPECTION END

NG >> Go to CAN communication. Refer to BCS-11, "

CON-

SULT-III Function (BCM)".

Unified meter and A/C amp. - Display control unit

13.CHECK MALFUNCTIONING SENSOR AND DOOR MOTOR

Refer to the following chart for malfunctioning code No.

(If two or more sensors and door motors malfuncti on, corresponding code Nos. indicates 1 second each.)

*1: Perform self-diagnosis STEP-2 under sunshine.

PJIA0152E

PJIA0153E

SJIA1611E

Code No. Malfunctioning sensor and door motor (Including circuits) Reference page 21 / −21 Ambient sensor ATC-86, "

Ambient Sensor Circuit"

22 / −22 In-vehicle sensor AT C - 8 8 , "In-vehicle Sensor Circuit"

24 / −24 Intake sensor AT C - 9 4 , "Intake Sensor Circuit"

25 / −25

Sunload sensor*1AT C - 9 1 , "Sunload Sensor Circuit"

26 / −26 Air mix door motor PBR (Driver side)

AT C - 6 2 , "Air Mix Door Motor PBR Circuit"27 / −27 Air mix door motor PBR (Passenger side)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 453 of 3924

ATC-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

When performing indoors, aim a light (more than 60 W) at sunload sensor, otherwise code No. 25 will indicate

despite that sunload sensor is functioning properly.

>> INSPECTION END

14.CHECK MALFUNCTIONING DOOR MOTOR POSITION SWITCH

Mode and/or intake door motor PBR(s) is/are malfunctioning.

(If two or more mode or intake door motors malfunc tion, corresponding code Nos. indicates 1 second each.)

*1: If mode door motor harness c onnector is disconnected, the following display pattern will appear.

31 →32 →33 →34 →35 →36 →Return to 31

*2: If intake door motor harness connector is disconnected, the following display pattern will appear.

37 →38 →39 →Return to 37

*3: FOOT position during automatic control. Refer to "AUXILIARY MECHANISM: FOOT POSITION SETTING

TRIMMER".

>> INSPECTION END

AUXILIARY MECHANISM: TEMPERATURE SETTING TRIMMER

The trimmer compensates for differences in range of ±3 °C ( ±6 °F) between temperature setting (displayed dig-

itally) and temperature felt by customer.

Operating procedures for this trimmer are as follows:1. Begin self-diagnosis STEP-5 mode. Refer to "Self-diagnosis Function".

2. Press (fan) UP switch to set system in auxiliary mode.

3. Display shows “61” in auxiliary mechanism. It ta kes approximately 3 seconds to enable setting operation.

SJIA1781E

Code No. *1 *2Mode or intake door position Reference page

31 VENT

Mode door motorAT C - 5 7 , "

Mode Door Motor Circuit"

32 B/L 1

33 B/L 2

34

FOOT

*3

35 D/F

36 DEF

37 FRE

Intake door motorATC-62, "

Intake Door Motor Circuit"38 20% FRE

39 REC

SJIA1782E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C