Intake Manifold INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 448 of 5621

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION AT C

A

B

AT C

Revision: 2006 January2006 M35/M45

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 5

OPERATION PROCEDURE ................................. 5

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions for Working with HFC-134a (R-134a) ..... 6

CONTAMINATED REFRIGERANT ....................... 7

General Refrigerant Precautions .............................. 7

Precautions for Refrigerant Connection ................... 7

ABOUT ONE-TOUCH JOINT ................................ 7

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION .................................................... 10

O-RING AND REFRIGERANT CONNECTION ... 10

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 13

RECOVERY/RECYCLING EQUIPMENT ............ 13

ELECTRICAL LEAK DETECTOR ....................... 13

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 14

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 15

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment ... 17

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 20Variable Displacement Compressor ....................... 21

GENERAL INFORMATION ................................. 21

DESCRIPTION .................................................... 22

Component Layout ................................................. 25

LUBRICANT .............................................................. 26

Maintenance of Lubricant Quantity in Compressor ... 26

LUBRICANT ........................................................ 26

LUBRICANT RETURN OPERATION .................. 26

LUBRICANT ADJUSTING PROCEDURE FOR

COMPONENTS REPLACEMENT EXCEPT

COMPRESSOR .................................................. 27

LUBRICANT ADJUSTING PROCEDURE FOR

COMPRESSOR REPLACEMENT ....................... 27

AIR CONDITIONER CONTROL ............................... 29

Description of Air Conditioner LAN Control System ... 29

System Construction .............................................. 29

OPERATION ........................................................ 30

TRANSMISSION DATA AND TRANSMISSION

ORDER ............................................................... 30

AIR MIX DOOR CONTROL (AUTOMATIC TEM-

PERATURE CONTROL) ..................................... 31

FAN SPEED CONTROL ...................................... 31

INTAKE DOOR CONTROL ................................. 31

MODE DOOR CONTROL ................................... 31

UPPER VENTILATOR DOOR CONTROL .......... 31

MAGNET CLUTCH CONTROL ........................... 32

SELF-DIAGNOSIS SYSTEM .............................. 32

Description of Control System ................................ 33

Control Operation ................................................... 33

DISPLAY SCREEN .............................................. 33

MULTIFUNCTION SWITCH ................................ 34

DISPLAY SCREEN .............................................. 34

MODE SWITCH (DRIVER SIDE) ........................ 34

MODE SWITCH (PASSENGER SIDE) ................ 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (DRIVER

SIDE) ................................................................... 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (PASSEN-

GER SIDE) .......................................................... 34

Page 582 of 5621

HEATER & COOLING UNIT ASSEMBLY

ATC-135

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

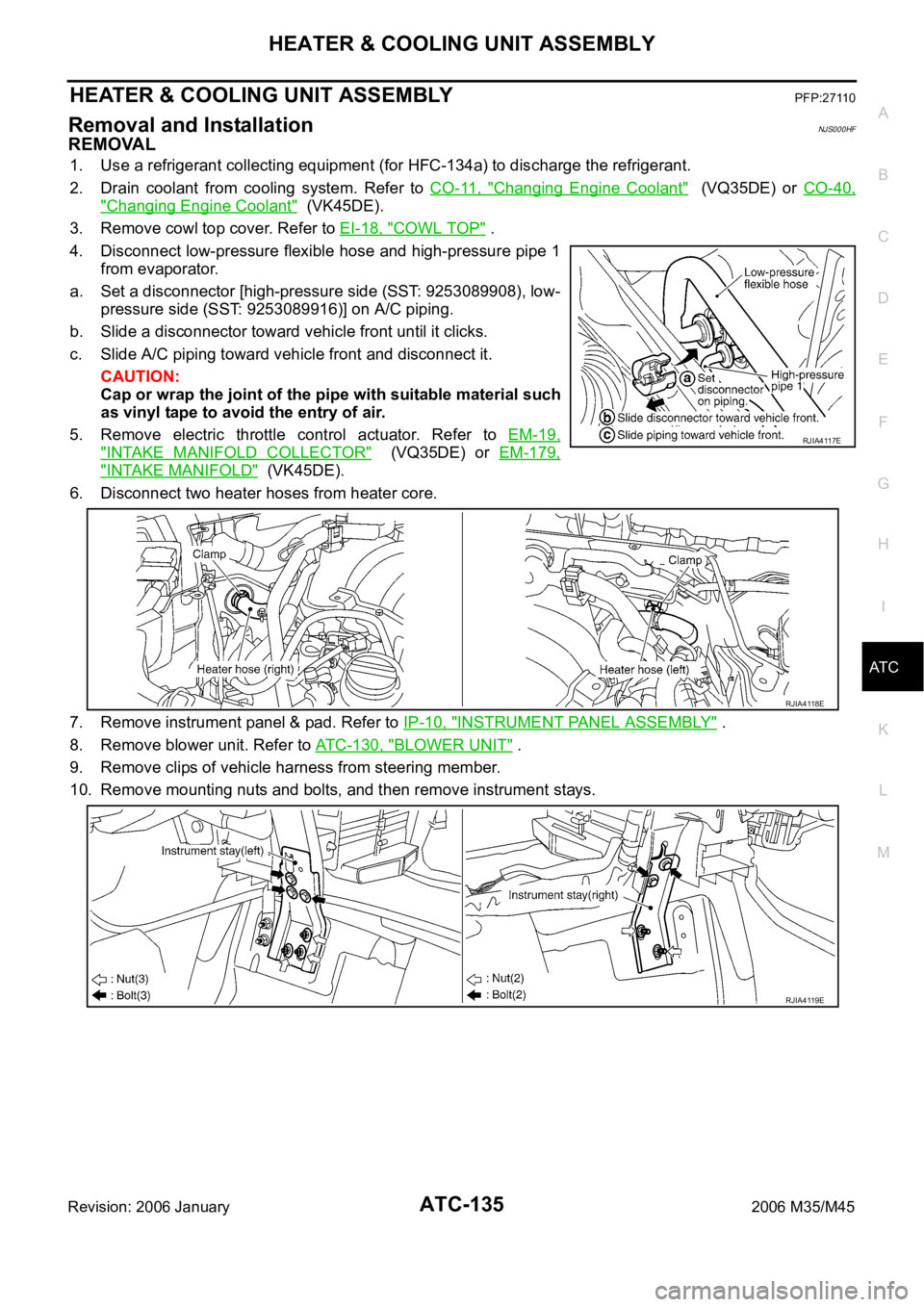

HEATER & COOLING UNIT ASSEMBLYPFP:27110

Removal and InstallationNJS000HF

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Drain coolant from cooling system. Refer to CO-11, "

Changing Engine Coolant" (VQ35DE) or CO-40,

"Changing Engine Coolant" (VK45DE).

3. Remove cowl top cover. Refer to EI-18, "

COWL TOP" .

4. Disconnect low-pressure flexible hose and high-pressure pipe 1

from evaporator.

a. Set a disconnector [high-pressure side (SST: 9253089908), low-

pressure side (SST: 9253089916)] on A/C piping.

b. Slide a disconnector toward vehicle front until it clicks.

c. Slide A/C piping toward vehicle front and disconnect it.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

5. Remove electric throttle control actuator. Refer to EM-19,

"INTAKE MANIFOLD COLLECTOR" (VQ35DE) or EM-179,

"INTAKE MANIFOLD" (VK45DE).

6. Disconnect two heater hoses from heater core.

7. Remove instrument panel & pad. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

8. Remove blower unit. Refer to ATC-130, "

BLOWER UNIT" .

9. Remove clips of vehicle harness from steering member.

10. Remove mounting nuts and bolts, and then remove instrument stays.

RJIA4117E

RJIA4118E

RJIA4119E

Page 619 of 5621

ATC-172

REFRIGERANT LINES

Revision: 2006 January2006 M35/M45

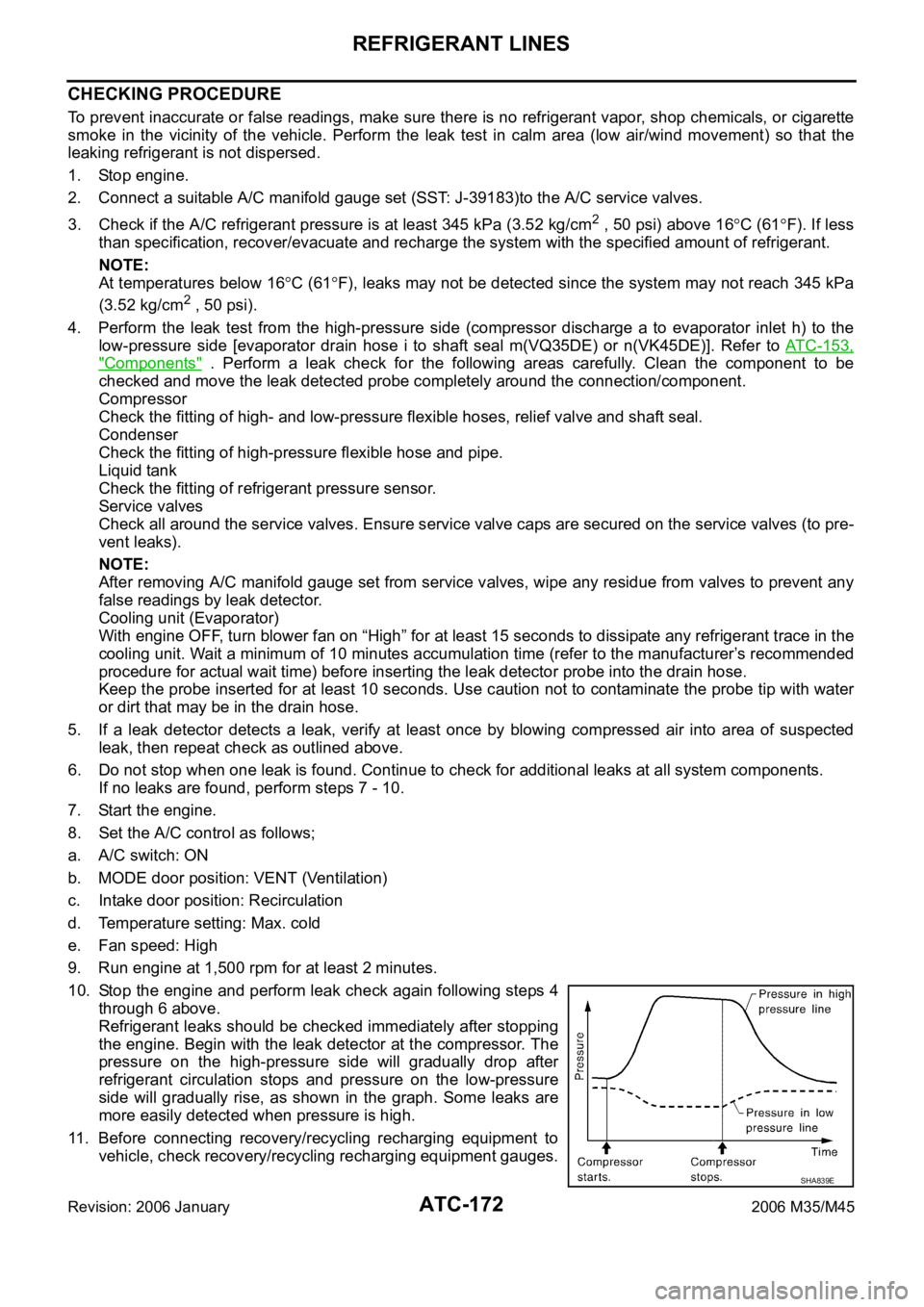

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Stop engine.

2. Connect a suitable A/C manifold gauge set (SST: J-39183)to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2 , 50 psi) above 16C (61F). If less

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16

C (61F), leaks may not be detected since the system may not reach 345 kPa

(3.52 kg/cm

2 , 50 psi).

4. Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet h) to the

low-pressure side [evaporator drain hose i to shaft seal m(VQ35DE) or n(VK45DE)]. Refer to ATC-153,

"Components" . Perform a leak check for the following areas carefully. Clean the component to be

checked and move the leak detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Condenser

Check the fitting of high-pressure flexible hose and pipe.

Liquid tank

Check the fitting of refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start the engine.

8. Set the A/C control as follows;

a. A/C switch: ON

b. MODE door position: VENT (Ventilation)

c. Intake door position: Recirculation

d. Temperature setting: Max. cold

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Stop the engine and perform leak check again following steps 4

through 6 above.

Refrigerant leaks should be checked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

11. Before connecting recovery/recycling recharging equipment to

vehicle, check recovery/recycling recharging equipment gauges.

SHA839E

Page 1296 of 5621

VACUUM LINES

BR-21

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

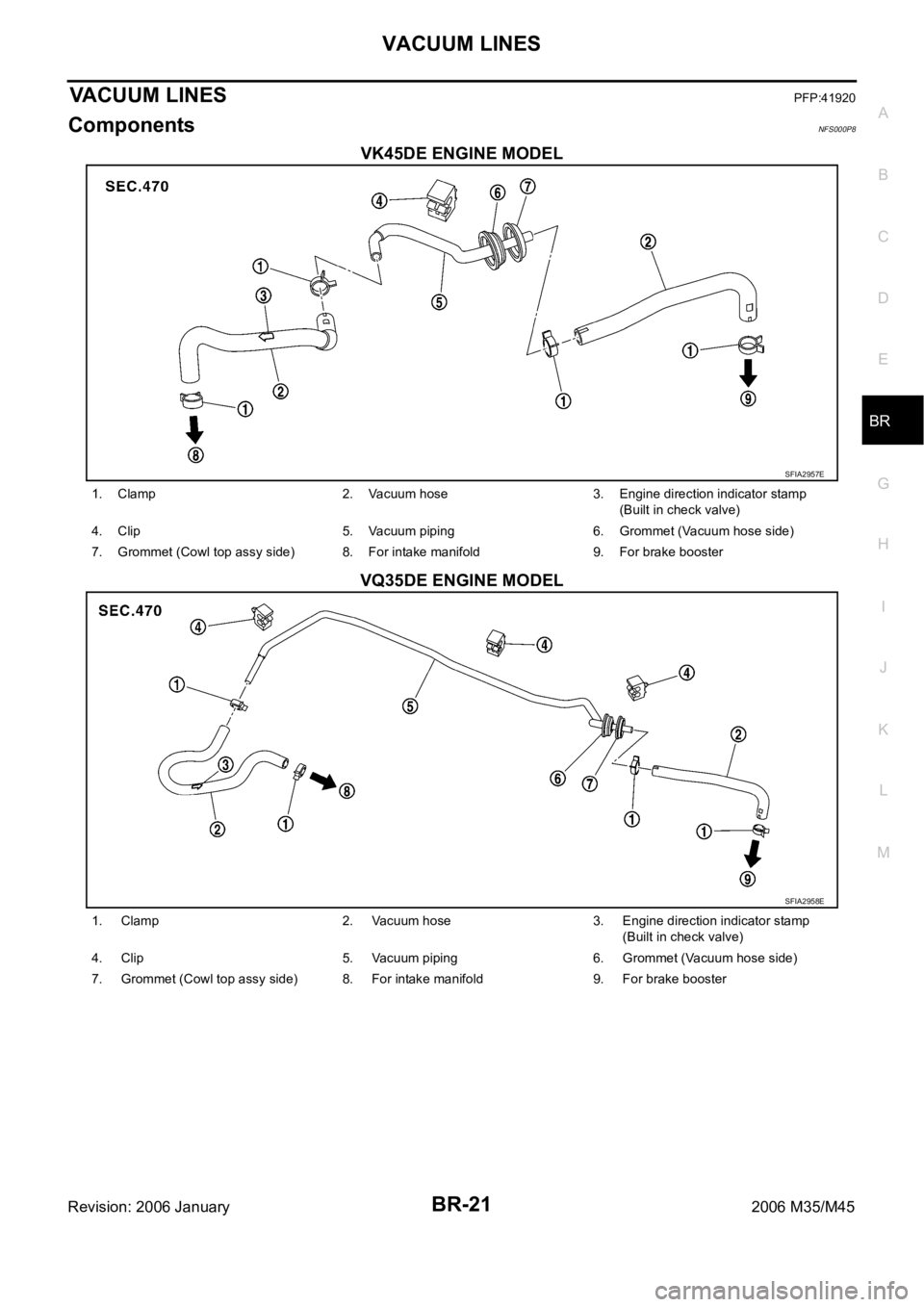

VACUUM LINESPFP:41920

ComponentsNFS000P8

VK45DE ENGINE MODEL

VQ35DE ENGINE MODEL

SFIA2957E

1. Clamp 2. Vacuum hose 3. Engine direction indicator stamp

(Built in check valve)

4. Clip 5. Vacuum piping 6. Grommet (Vacuum hose side)

7. Grommet (Cowl top assy side) 8. For intake manifold 9. For brake booster

SFIA2958E

1. Clamp 2. Vacuum hose 3. Engine direction indicator stamp

(Built in check valve)

4. Clip 5. Vacuum piping 6. Grommet (Vacuum hose side)

7. Grommet (Cowl top assy side) 8. For intake manifold 9. For brake booster

Page 1406 of 5621

![INFINITI M35 2006 Factory Service Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM INFINITI M35 2006 Factory Service Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM](/img/42/57023/w960_57023-1405.png)

WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-19, "

INTAKE MANIFOLD COLLECTOR" .

3. Remove air duct (inlet) and air cleaner case assembly. Refer to EM-17, "

AIR CLEANER AND AIR DUCT"

.

4. Remove front engine undercover with power tool.

5. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-11, "

Changing Engine Coolant" and CO-24, "WATER PUMP" .

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

6. Remove radiator hose (upper) and heater hose.

7. Remove the following parts, when remove water outlet.

A/T fluid charging pipe: Refer to AT-271, "TRANSMISSION ASSEMBLY" .

Intake manifold collectors (upper and lower): Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Rocker cover (right bank): Refer to EM-51, "ROCKER COVER" .

8. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

1. Harness bracket 2. Water hose 3. Water bypass hose

4. Engine coolant temperature sensor 5. Gasket 6. Water outlet

7. Heater hose 8. Water pipe 9. Radiator hose (upper)

10. Heater pipe 11. Washer 12. O-ring

SBIA0484E

Page 1415 of 5621

![INFINITI M35 2006 Factory Service Manual CO-40

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004RE

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the

“MIN� INFINITI M35 2006 Factory Service Manual CO-40

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004RE

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the

“MIN�](/img/42/57023/w960_57023-1414.png)

CO-40

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004RE

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the

“MIN” to “MAX” when engine is cool.

Adjust the engine coolant level as necessary.

LEAK CHECK

To check for leaks, apply pressure to the cooling system with

radiator cap tester (commercial service tool) and radiator cap

tester adapter (SST).

WA R N I N G :

Do not remove radiator cap when engine is hot. Serious

burns could occur from high-pressure engine coolant

escaping from thermostat housing.

CAUTION:

Higher testing pressure than specified may cause radiator

damage.

NOTE:

In a case engine coolant decreases, replenish radiator with engine coolant.

If anything is found, repair or replace damaged parts.

Changing Engine CoolantNBS004RF

WAR NING :

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

DRAINING ENGINE COOLANT

1. Remove engine room cover (RH and LH). Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-179, "

INTAKE MANIFOLD" .

3. Open radiator drain plug at the bottom of radiator, and then remove radiator cap.

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to EM-250, "

DISASSEMBLY" .

4. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

SMA412B

Testing pressure : 157 kPa (1.6 kg/cm2 , 23 psi)

PBIC1528E

1 : Radiator drain plug hole

2 : Front engine undercover

: Engine front

PBIC3395E

Page 1428 of 5621

![INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-53

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WAT E R PU M PPFP:21020

ComponentsNBS004RP

Refer to GI-11, "Components" for symbol marks in the figure. INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-53

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WAT E R PU M PPFP:21020

ComponentsNBS004RP

Refer to GI-11, "Components" for symbol marks in the figure.](/img/42/57023/w960_57023-1427.png)

WATER PUMP

CO-53

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WAT E R PU M PPFP:21020

ComponentsNBS004RP

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and InstallationNBS004RQ

CAUTION:

When removing water pump, be careful not to get engine coolant on drive belts.

Water pump can not be disassembled and should be replaced as a unit.

After installing water pump, connect hose and clamp securely, then check for leaks using radiator

cap tester (commercial service tool) and radiator cap tester adapter [SST: EG17650301 (J33984-

A)].

REMOVAL

1. Remove following parts:

Front engine undercover (power tool)

Engine cover: Refer to EM-179, "INTAKE MANIFOLD" .

Engine room cover (RH and LH): Refer to EM-173, "ENGINE ROOM COVER" .

Air duct (inlet): Refer to EM-177, "AIR CLEANER AND AIR DUCT" .

Alternator, water pump and A/C compressor belt: Refer to EM-174, "DRIVE BELTS" .

2. Drain engine coolant from drain plugs on radiator and both side of cylinder block. Refer to CO-40, "

Chang-

ing Engine Coolant" and EM-250, "DISASSEMBLY" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Remove water pump pulley.

4. Remove water pump.

Engine coolant will leak from cylinder block, so have a receptacle ready under vehicle.

CAUTION:

Handle the water pump vane so that it does not contact any other parts.

Do not disassemble water pump.

1. Water pump 2. Water pump pulley 3. Gasket

PBIC3396E

Page 1430 of 5621

![INFINITI M35 2006 Factory Service Manual THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Compo INFINITI M35 2006 Factory Service Manual THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Compo](/img/42/57023/w960_57023-1429.png)

THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and InstallationNBS004RS

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-179, "

INTAKE MANIFOLD" .

3. Remove air duct (inlet). Refer to EM-177, "

AIR CLEANER AND AIR DUCT" .

4. Drain engine coolant from drain plugs on radiator and both side of cylinder block. Refer to CO-40, "

Chang-

ing Engine Coolant" and EM-250, "DISASSEMBLY" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

1. Water connector 2. O-ring 3. Rubber ring

4. Heater hose 5. Water control valve 6. Water outlet

7. Gasket 8. O-ring 9. Water outlet pipe

10. Thermostat housing 11. Radiator cap 12. Radiator hose (upper)

13. Thermostat 14. Rubber ring 15. Water inlet

16. Water suction hose 17. Water suction pipe 18. Radiator hose (lower)

19. Gasket 20. O-ring 21. Heater pipe

22. Heater hose

A. To radiator B. To intake manifold adapter C. To cylinder block

D. To cylinder head (right bank) E. To cylinder head (left bank) F.To heater core

PBIC3306E

Page 1431 of 5621

![INFINITI M35 2006 Factory Service Manual CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassembl INFINITI M35 2006 Factory Service Manual CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassembl](/img/42/57023/w960_57023-1430.png)

CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassemble thermostat.

7. Remove intake manifolds (upper and lower). Refer to EM-179, "

INTAKE MANIFOLD" .

8. Disconnect radiator hose (upper) from thermostat housing.

9. Disconnect heater hoses from water outlet and heater pipe.

10. Remove thermostat housing, water outlet pipe, water connector, water control valve, water outlet and

heater pipe.

CAUTION:

Do not disassemble water control valve.

INSPECTION AFTER REMOVAL

Make sure that valves both in thermostat and water control valve are completely closing at normal tempar-

ature.

Place a thread so that it is caught in the valves of the thermostat

and water control valve. Immerse fully in a container filled with

water. Heat while stirring. (The example in the figure shows ther-

mostat.)

The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

Continue heating. Check the maximum valve lift.

NOTE:

The maximum valve lift standard temperature for water control

valve is the reference value.

After checking the maximum valve lift, lower the water tempera-

ture and check the valve closing temperature.

Standard values:

If the malfunctioning condition, when closing valve at normal temperature, or measured values are out of

the standard, replace thermostat and/or water control valve.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over engine room. Use rag to absorb engine coolant.

Thermostat and Water Control Valve

Install thermostat and water control valve with the whole circum-

ference of each flange part fit securely inside rubber ring. (The

example in the figure shows thermostat.)

SLC252B

Thermostat Water control valve

Valve opening temperature 80 - 84

C (176 - 183F) 93.5 - 96.5C (200 - 206F)

Maximum valve liftMore than 10 mm/ 95

C

(0.39 in/ 203

F)More than 8 mm/ 108

C

(0.315 in/ 226

F)

Valve closing temperature 77

C (171F) 90C (194F)

PBIC0157E

Page 1582 of 5621

![INFINITI M35 2006 Factory Service Manual EVAPORATIVE EMISSION SYSTEM

EC-39

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

EVAPORATIVE EMISSION SYSTEMPFP:14950

DescriptionNBS004SB

SYSTEM DESCRIPTION

The evaporative emis INFINITI M35 2006 Factory Service Manual EVAPORATIVE EMISSION SYSTEM

EC-39

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

EVAPORATIVE EMISSION SYSTEMPFP:14950

DescriptionNBS004SB

SYSTEM DESCRIPTION

The evaporative emis](/img/42/57023/w960_57023-1581.png)

EVAPORATIVE EMISSION SYSTEM

EC-39

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

EVAPORATIVE EMISSION SYSTEMPFP:14950

DescriptionNBS004SB

SYSTEM DESCRIPTION

The evaporative emission system is used to reduce hydrocarbons emitted into the atmosphere from the fuel

system. This reduction of hydrocarbons is accomplished by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into the EVAP canister which contains activated carbon and the

vapor is stored there when the engine is not operating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the

engine is operating. EVAP canister purge volume control solenoid valve is controlled by ECM. When the

engine operates, the flow rate of vapor controlled by EVAP canister purge volume control solenoid valve is

proportionally regulated as the air flow increases.

EVAP canister purge volume control solenoid valve also shuts off the vapor purge line during decelerating and

idling.

PBIB1631E