stall INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4857 of 5621

PG-30

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Revision: 2006 January2006 M35/M45

Check IPDM E/R Power Supply and Ground CircuitNKS004EA

1. CHECK FUSE AND FUSIBLE LINK

Check for blown fuses.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link.

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between IPDM E/R and fusible link.

3. CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R harness connectors.

2. Check continuity between IPDM E/R harness connectors and

ground.

OK or NG

OK >> INSPECTION END

NG >> Check harness ground circuit.

Terminal No. Power source Fuse and fusible link No.

1

BatteryE

2C

—71

78

Terminals

Vo l ta g e (+) (-)

IPDM E/R connector Terminal

Ground

E31

Battery voltage

2

PKIB6562E

IPDM E/R connector Terminal

GroundContinuity

E8 38

E951

Ye s

54

PKIC0906E

Page 4858 of 5621

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-31

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

Inspection with CONSULT-II (Self-Diagnosis)NKS004EB

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. CHECK SELF DIAGNOSTIC RESULT

1. Connect CONSULT-II and select “IPDM E/R” on the “SELECT SYSTEM” screen.

2. Select “SELF-DIAG RESULTS” on the “SELECT DIAG MODE” screen.

3. Check display content in self diagnostic results.

NOTE:

The details for display of the period are as follows:

CRNT: Error currently detected with IPDM E/R.

PAST: Error detected in the past and memorized with IPDM E/R.

Contents displayed

NO DTC IS DETECTED.FURTHER TESTING MAY BE REQUIRED.>>INSPECTION END

CAN COMM CIRC>>After print-out of the monitor items, refer to LAN-7, "

Precautions When Using CON-

SULT-II" .

Removal and Installation of IPDM E/RNKS004EC

: Vehicle front

REMOVAL

1. Remove cowl top cover (RH). Refer to EI-18, "COWL TOP" in

“EI” section.

2. Disengage pawls (A) 4 on both side of IPDM E/R cover B (1),

remove IPDM E/R cover A (2).

3. While pushing pawl (A) on backside of IPDM E/R cover B (1)

toward vehicle front to unlock, lift up IPDM E/R (2).

CONSULT-II displayCONSULT-II

display codeTIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED.- - - No malfunction

CAN COMM CIRC U1000

Any of or several items below have errors.

TRANSMIT DIAG

ECM

BCM/SEC

SKIB4109E

SKIB4110E

Page 4859 of 5621

PG-32

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Revision: 2006 January2006 M35/M45

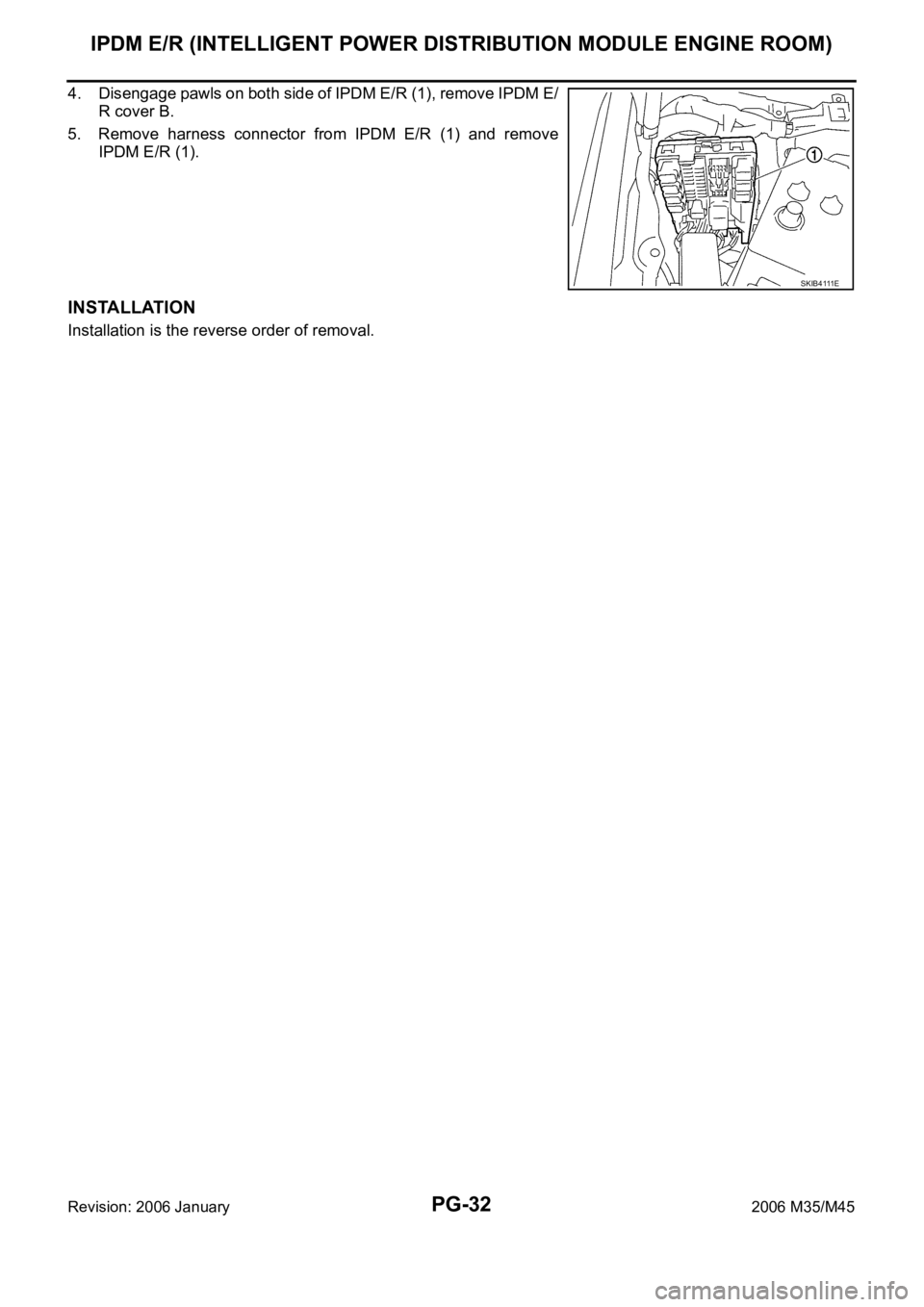

4. Disengage pawls on both side of IPDM E/R (1), remove IPDM E/

R cover B.

5. Remove harness connector from IPDM E/R (1) and remove

IPDM E/R (1).

INSTALLATION

Installation is the reverse order of removal.

SKIB4111E

Page 4861 of 5621

PG-34

PDU (POWER DISTRIBUTION UNIT)

Revision: 2006 January2006 M35/M45

*1: When the A/T selector lever position is N position, the engine start condition is different according to the vehicle speed.

At vehicle speed of 5 km/h or less, the engine can start only when the brake pedal is depressed.

At vehicle speed of 5 km/h or more, the engine can start even if the brake pedal is not depressed. (It is the same as “Engine stall

return operation while driving”.)

*2: When the A/T selector lever position is any position other than P position and when the vehicle speed is 5 km/h or more, the engine

stop condition is different.

Press and hold the push-button ignition switch for 2 seconds or more. (When the push-button ignition switch is pressed for too short

a time, the operation may be invalid, so properly press and hold to prevent the incorrect operation.)

Press the push-button ignition switch 3 times within 1.5 seconds. (Emergency stop operation) Power supply positionEngine start/stop condition Push-button ignition

switch operation fre-

quency Brake pedal operation condition A/T selector lever position

LOCK

ACCNot depressed

(When A/T selector lever is in any posi-

tion other than P or N, there will be no

effect even if it is depressed.)Any position other than P or N

(When the brake pedal is not

depressed, there will be no effect even

if the A/T selector lever is in P or N

position.)1

LOCK

ACC ONNot depressed

(When A/T selector lever is in any posi-

tion other than P or N, there will be no

effect even if it is depressed.)Any position other than P or N

(When the brake pedal is not

depressed, there will be no effect even

if the A/T selector lever is in P or N

position.)2

LOCK

ACC ON

LOCKNot depressed

(When A/T selector lever is in any posi-

tion other than P or N, there will be no

effect even if it is depressed.)Any position other than P or N

(When the brake pedal is not

depressed, there will be no effect even

if the A/T selector lever is in P or N

position.)3

LOCK

START

ACC

START

ON

START

(Engine start)Depressed P or N position (*1)1

[If the switch is

pushed once, the

engine starts from

any power supply

position (LOCK,

ACC, and ON)]

Engine start condition

LOCK

(Engine stop)— P position 1

Engine start condition

ACC

(Engine stop)— Any position other than P (*2) 1

Engine stall return

operation while driving— N position 1

Page 4872 of 5621

PDU (POWER DISTRIBUTION UNIT)

PG-45

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

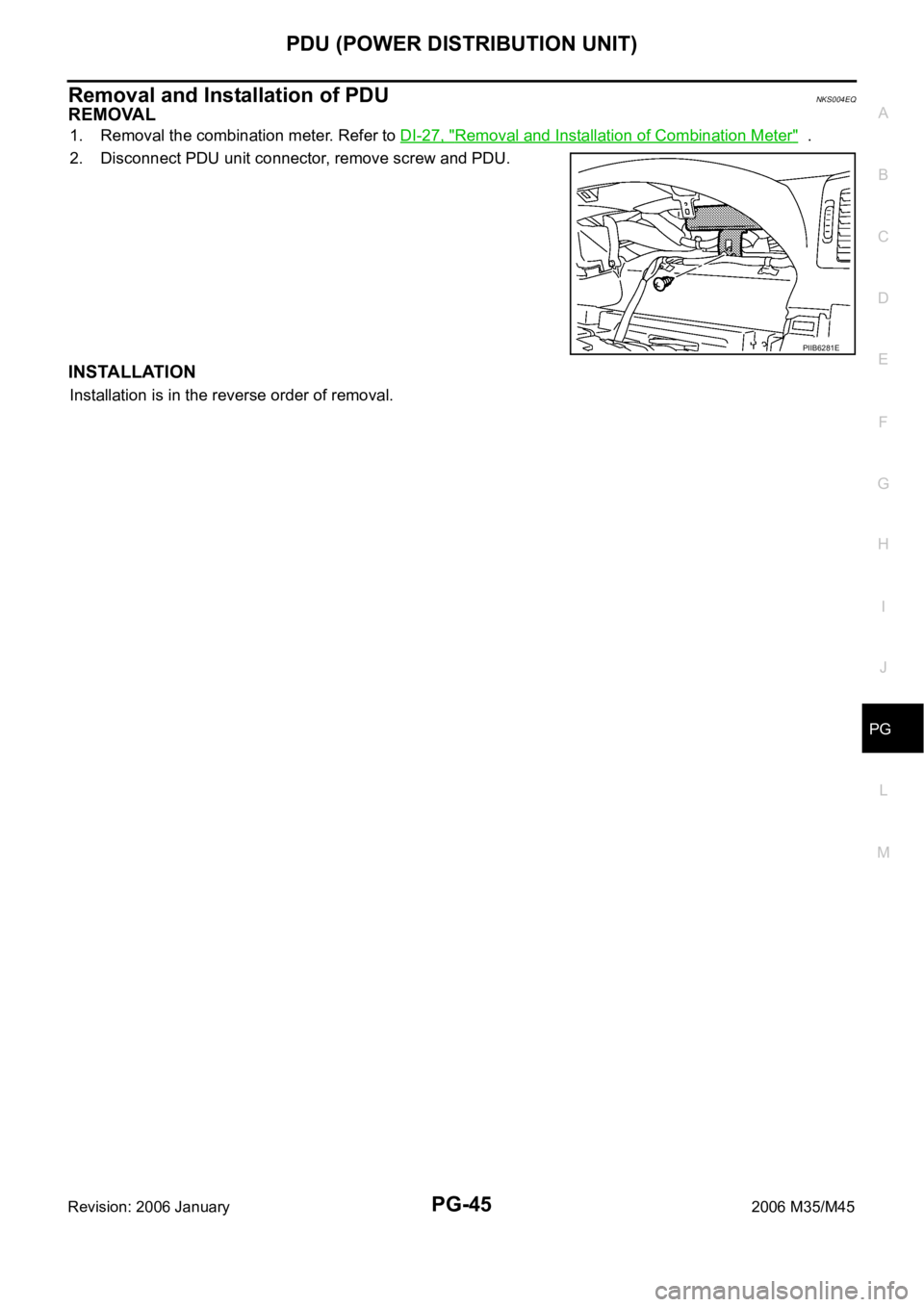

Removal and Installation of PDUNKS004EQ

REMOVAL

1. Removal the combination meter. Refer to DI-27, "Removal and Installation of Combination Meter" .

2. Disconnect PDU unit connector, remove screw and PDU.

INSTALLATION

Installation is in the reverse order of removal.

PIIB6281E

Page 4940 of 5621

PR-1

PROPELLER SHAFT

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION PR

A

B

PR

Revision: 2006 January2006 M35/M45

PROPELLER SHAFT

PREPARATION ........................................................... 2

Special Service Tools ............................................... 2

Commercial Service Tools ........................................ 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 3

NVH Troubleshooting Chart ..................................... 3

FRONT PROPELLER SHAFT .................................... 4

On-Vehicle Inspection .............................................. 4

APPEARANCE AND NOISE INSPECTION .......... 4

PROPELLER SHAFT VIBRATION ........................ 4

Components ............................................................. 4

Removal and Installation .......................................... 5

REMOVAL ........................................................

..... 5

INSPECTION ........................................................ 5

INSTALLATION ..................................................... 5

REAR PROPELLER SHAFT ...................................... 6

On-Vehicle Inspection .............................................. 6APPEARANCE AND NOISE INSPECTION .......... 6

PROPELLER SHAFT VIBRATION ........................ 6

Components ............................................................. 7

Removal and Installation .......................................... 8

REMOVAL ........................................................

..... 8

INSPECTION ........................................................ 9

INSTALLATION ................................................... 10

Disassembly and Assembly of Center Bearing (For

3S80A-1VL107 and 3F80A-1VL107 Type) ............. 11

DISASSEMBLY ................................................... 11

ASSEMBLY ......................................................... 12

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 13

General Specifications ......................................... ... 13

2WD MODELS .................................................... 13

AWD MODELS .................................................... 13

Journal Axial Play ................................................... 14

Propeller Shaft Runout ........................................... 14

Page 4941 of 5621

PR-2

PREPARATION

Revision: 2006 January2006 M35/M45

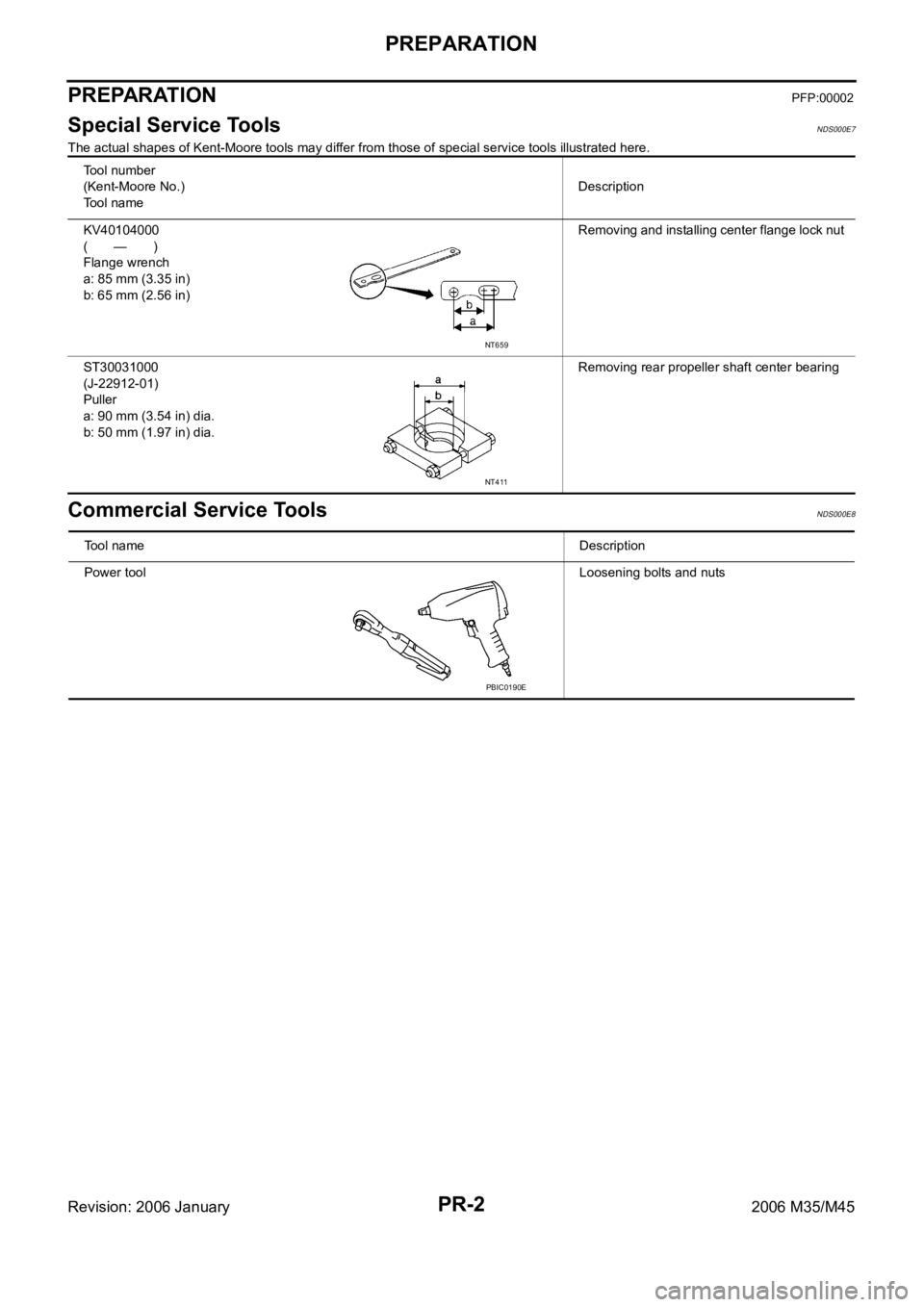

PREPARATIONPFP:00002

Special Service ToolsNDS000E7

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsNDS000E8

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40104000

(—)

Flange wrench

a: 85 mm (3.35 in)

b: 65 mm (2.56 in)Removing and installing center flange lock nut

ST30031000

(J-22912-01)

Puller

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.Removing rear propeller shaft center bearing

NT659

NT411

Tool nameDescription

Power toolLoosening bolts and nuts

PBIC0190E

Page 4942 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000E9

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: Applicable Reference pageFront

PR-4—

—

—

—

PR-4PR-5

NVH in FFD and RFD section

NVH in FAX, RAX, FSU and RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in BR section

NVH in PS section

RearPR-6PR-10—

PR-7—

PR-6PR-9

Possible cause and SUSPECTED PARTS

Uneven rotating torque

Center bearing improper installation

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomNoiseShake

Vibration

Page 4943 of 5621

PR-4

FRONT PROPELLER SHAFT

Revision: 2006 January2006 M35/M45

FRONT PROPELLER SHAFTPFP:37200

On-Vehicle InspectionNDS000EA

APPEARANCE AND NOISE INSPECTION

Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

PROPELLER SHAFT VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1. Measure propeller shaft runout at runout measuring point by

rotating final drive companion flange with hands. For measuring

point, refer to PR-4, "

Propeller Shaft Runout Measuring Point" .

2. If runout still exceeds specifications, separate propeller shaft at

final drive companion flange; then rotate companion flange 90,

180, 270 degrees and install propeller shaft.

3. Check runout again. If runout still exceeds specifications,

replace propeller shaft assembly.

4. Check the vibration by driving vehicle.

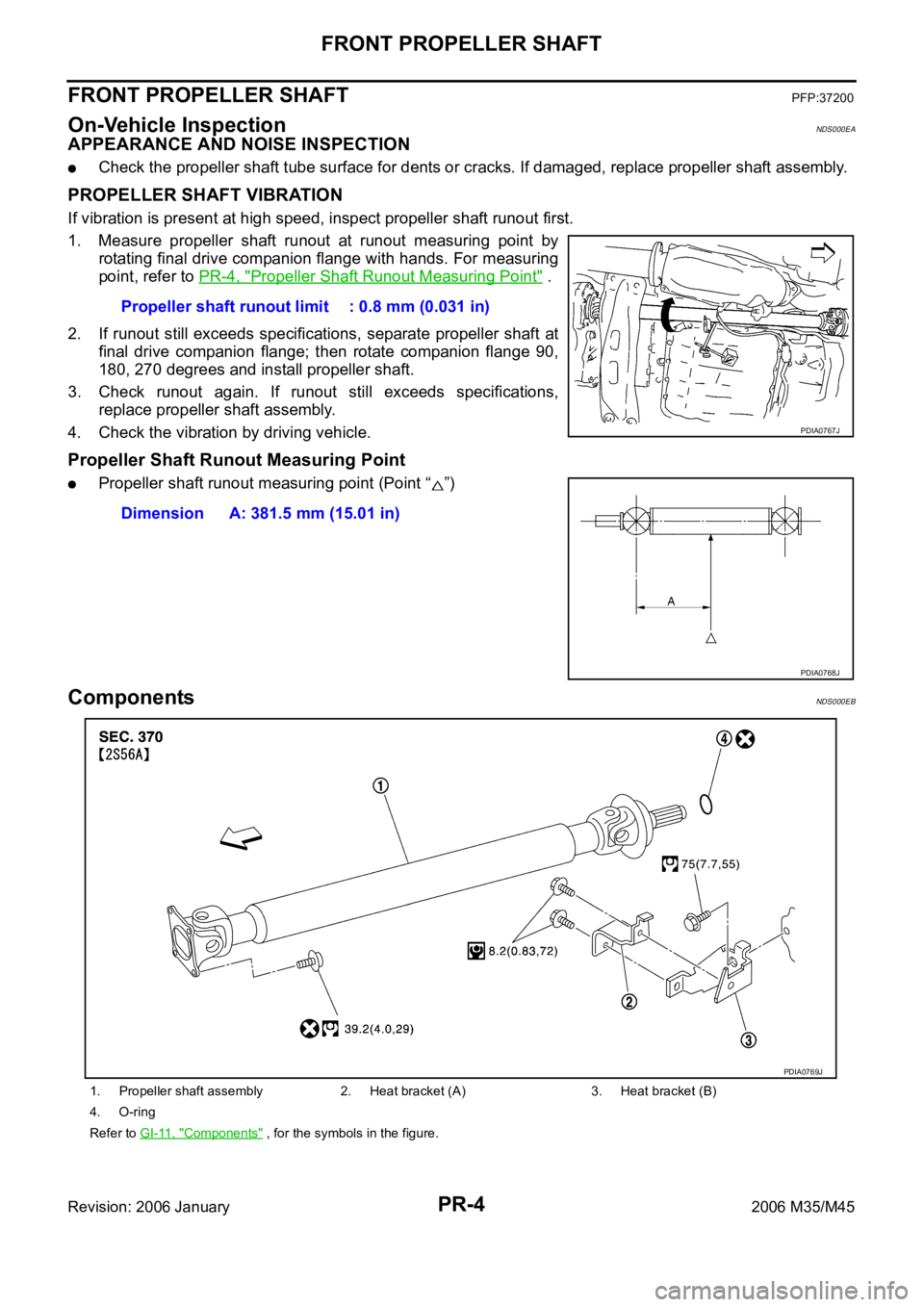

Propeller Shaft Runout Measuring Point

Propeller shaft runout measuring point (Point “ ”)

ComponentsNDS000EB

Propeller shaft runout limit : 0.8 mm (0.031 in)

PDIA0767J

Dimension A: 381.5 mm (15.01 in)

PDIA0768J

1. Propeller shaft assembly 2. Heat bracket (A) 3. Heat bracket (B)

4. O-ring

Refer to GI-11, "

Components" , for the symbols in the figure.

PDIA0769J

Page 4944 of 5621

FRONT PROPELLER SHAFT

PR-5

C

E

F

G

H

I

J

K

L

MA

B

PR

Revision: 2006 January2006 M35/M45

Removal and InstallationNDS000EC

REMOVAL

1. Remove engine undercover with a power tool.

2. If necessary, remove heat bracket.

3. Remove the three way catalyst (right bank) with a power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

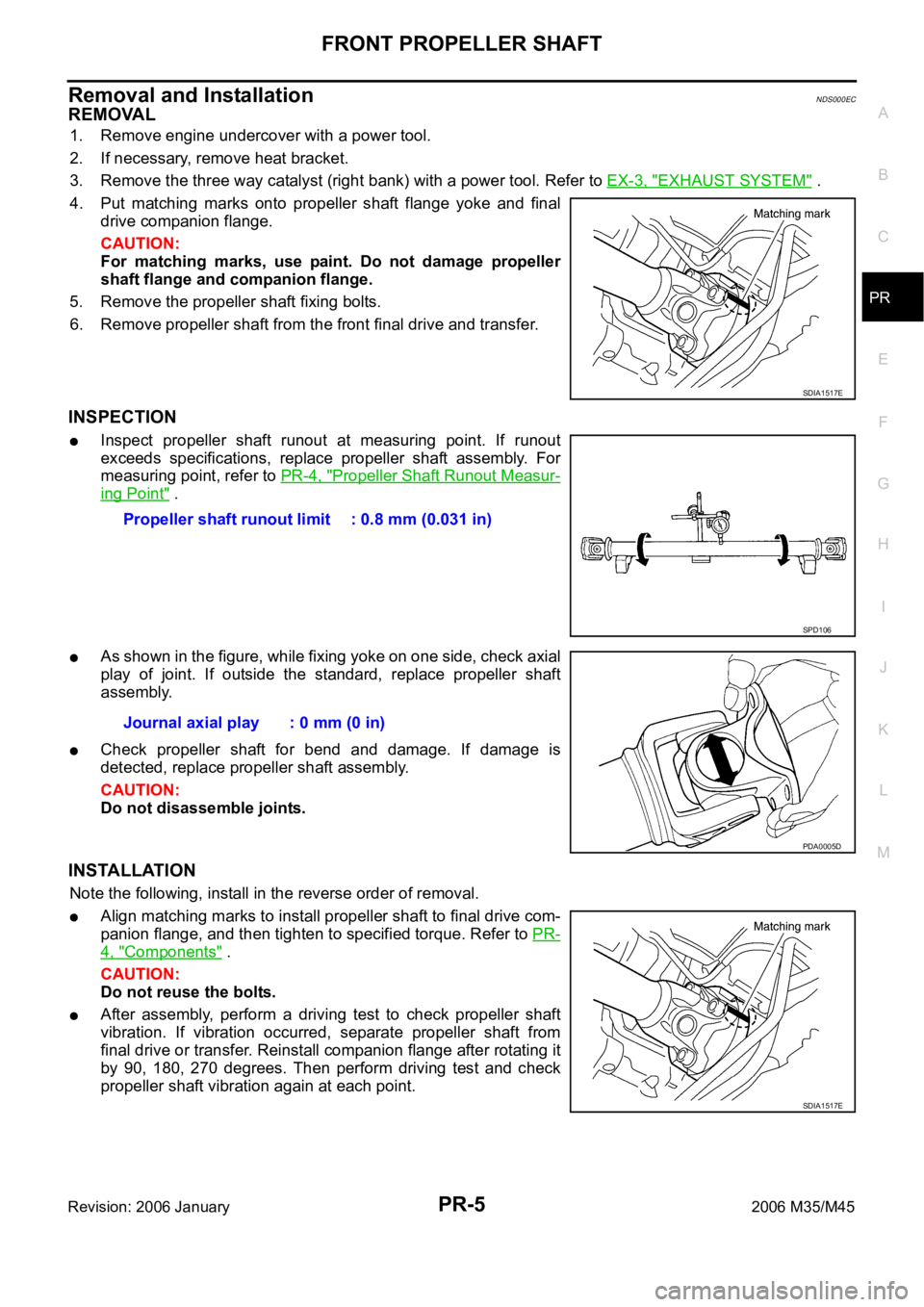

4. Put matching marks onto propeller shaft flange yoke and final

drive companion flange.

CAUTION:

For matching marks, use paint. Do not damage propeller

shaft flange and companion flange.

5. Remove the propeller shaft fixing bolts.

6. Remove propeller shaft from the front final drive and transfer.

INSPECTION

Inspect propeller shaft runout at measuring point. If runout

exceeds specifications, replace propeller shaft assembly. For

measuring point, refer to PR-4, "

Propeller Shaft Runout Measur-

ing Point" .

As shown in the figure, while fixing yoke on one side, check axial

play of joint. If outside the standard, replace propeller shaft

assembly.

Check propeller shaft for bend and damage. If damage is

detected, replace propeller shaft assembly.

CAUTION:

Do not disassemble joints.

INSTALLATION

Note the following, install in the reverse order of removal.

Align matching marks to install propeller shaft to final drive com-

panion flange, and then tighten to specified torque. Refer to PR-

4, "Components" .

CAUTION:

Do not reuse the bolts.

After assembly, perform a driving test to check propeller shaft

vibration. If vibration occurred, separate propeller shaft from

final drive or transfer. Reinstall companion flange after rotating it

by 90, 180, 270 degrees. Then perform driving test and check

propeller shaft vibration again at each point.

SDIA1517E

Propeller shaft runout limit : 0.8 mm (0.031 in)

SPD106

Journal axial play : 0 mm (0 in)

PDA0005D

SDIA1517E