stall INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5517 of 5621

TF-52

TRANSFER ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLY

Front Drive Shaft and Drive Chain

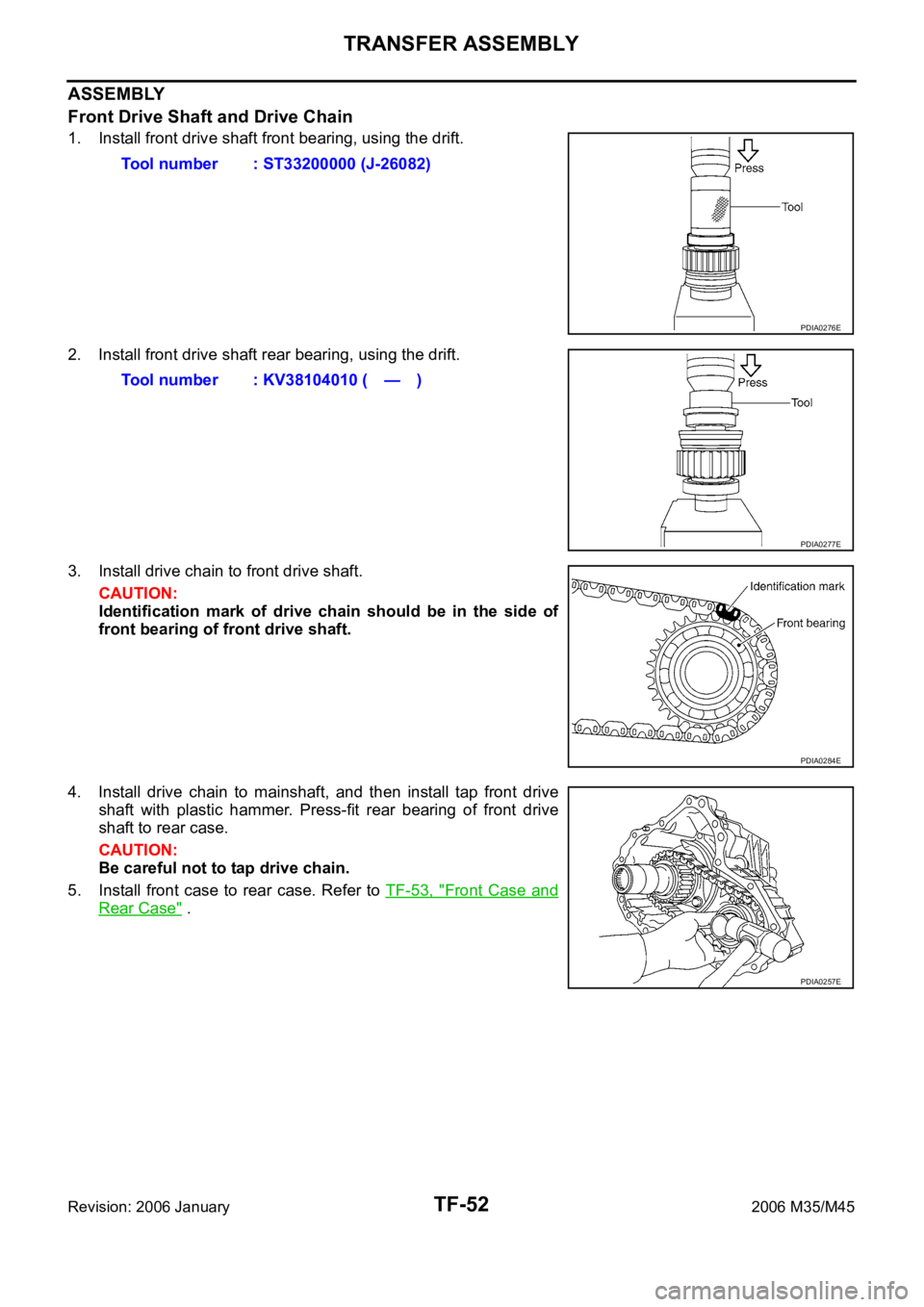

1. Install front drive shaft front bearing, using the drift.

2. Install front drive shaft rear bearing, using the drift.

3. Install drive chain to front drive shaft.

CAUTION:

Identification mark of drive chain should be in the side of

front bearing of front drive shaft.

4. Install drive chain to mainshaft, and then install tap front drive

shaft with plastic hammer. Press-fit rear bearing of front drive

shaft to rear case.

CAUTION:

Be careful not to tap drive chain.

5. Install front case to rear case. Refer to TF-53, "

Front Case and

Rear Case" . Tool number : ST33200000 (J-26082)

PDIA0276E

Tool number : KV38104010 ( — )

PDIA0277E

PDIA0284E

PDIA0257E

Page 5518 of 5621

TRANSFER ASSEMBLY

TF-53

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

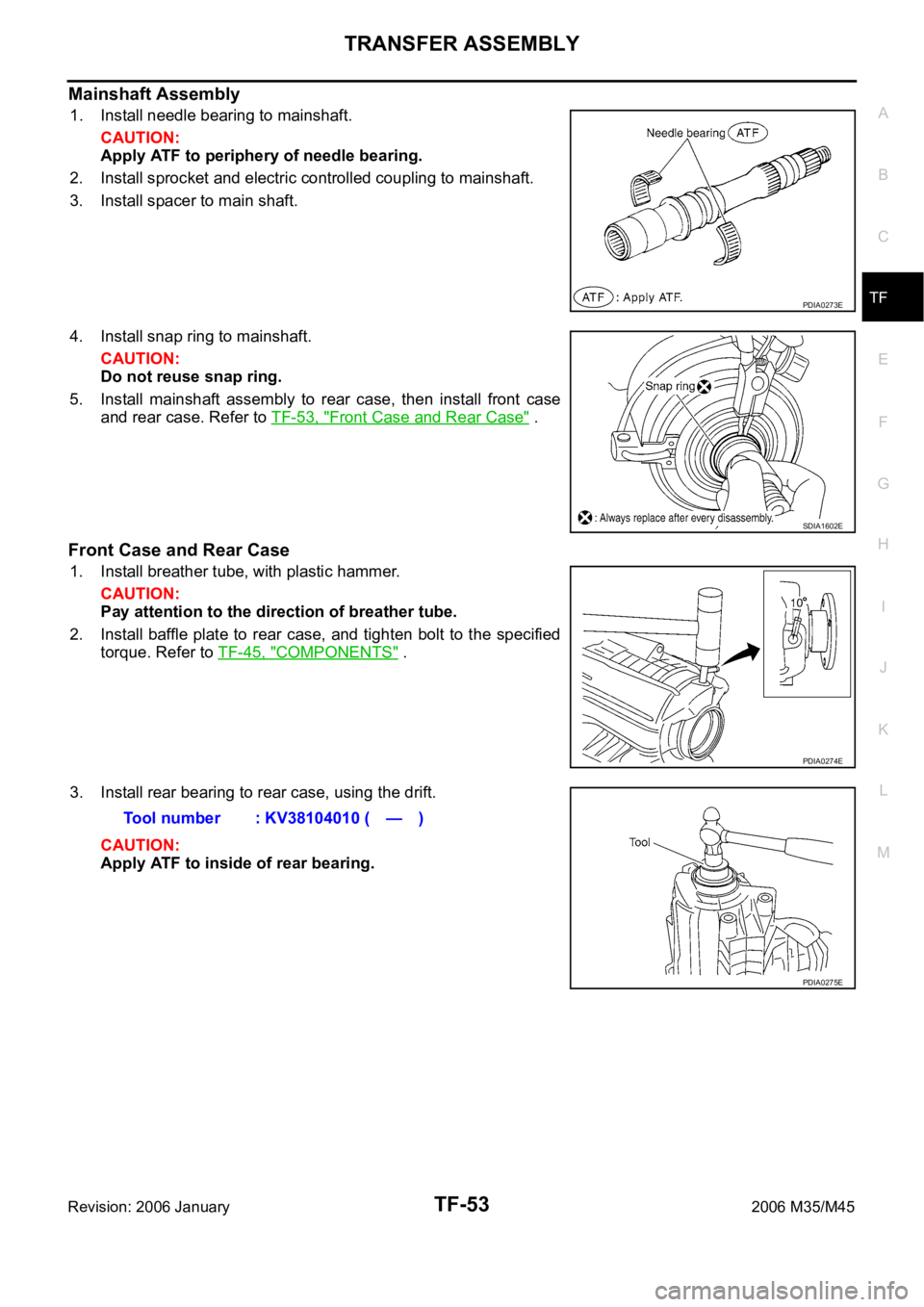

Mainshaft Assembly

1. Install needle bearing to mainshaft.

CAUTION:

Apply ATF to periphery of needle bearing.

2. Install sprocket and electric controlled coupling to mainshaft.

3. Install spacer to main shaft.

4. Install snap ring to mainshaft.

CAUTION:

Do not reuse snap ring.

5. Install mainshaft assembly to rear case, then install front case

and rear case. Refer to TF-53, "

Front Case and Rear Case" .

Front Case and Rear Case

1. Install breather tube, with plastic hammer.

CAUTION:

Pay attention to the direction of breather tube.

2. Install baffle plate to rear case, and tighten bolt to the specified

torque. Refer to TF-45, "

COMPONENTS" .

3. Install rear bearing to rear case, using the drift.

CAUTION:

Apply ATF to inside of rear bearing.

PDIA0273E

SDIA1602E

PDIA0274E

Tool number : KV38104010 ( — )

PDIA0275E

Page 5519 of 5621

TF-54

TRANSFER ASSEMBLY

Revision: 2006 January2006 M35/M45

4. Install snap ring to rear case.

CAUTION:

Do not reuse snap ring.

5. Install mainshaft assembly to rear case, using the drift.

CAUTION:

ATF should be applied to contact surface of mainshaft and

rear bearing.

6. Install O-ring to transfer assembly harness connector.

CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

7. Install transfer assembly harness connector into rear case.

8. Install retainer to transfer assembly harness connector.

9. Set temperature sensor and tighten bolt to the specified torque.

Refer to TF-45, "

COMPONENTS" .

10. Hold electric controlled coupling harness with oil cover hold

plate, install oil cover to rear case, and tighten bolt to the speci-

fied torque. Refer to TF-45, "

COMPONENTS" .

CAUTION:

The harness should be guided by a cut portion.

PDIA0263E

Tool number : ST35321000 ( — )

SDIA2368E

SDIA1597E

SDIA2404E

Page 5520 of 5621

TRANSFER ASSEMBLY

TF-55

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

11. Install oil gutter to rear case.

CAUTION:

The tip of oil gutter should be put into rear case groove.

12. Install drive chain to front drive shaft.

CAUTION:

Identification mark of drive chain should be in the side of

front bearing of front drive shaft.

13. Install drive chain to mainshaft, and then install tap front drive

shaft with plastic hammer. Press-fit rear bearing of front drive

shaft to rear case.

CAUTION:

Be careful not to tap drive chain.

14. Install mainshaft bearing to front case, using the drift.

15. Install snap ring to front case.

CAUTION:

Do not reuse snap ring.

PDIA0261E

PDIA0284E

PDIA0257E

Tool number : ST30621000 (J-25742-5)

PDIA0283E

PDIA0267E

Page 5521 of 5621

TF-56

TRANSFER ASSEMBLY

Revision: 2006 January2006 M35/M45

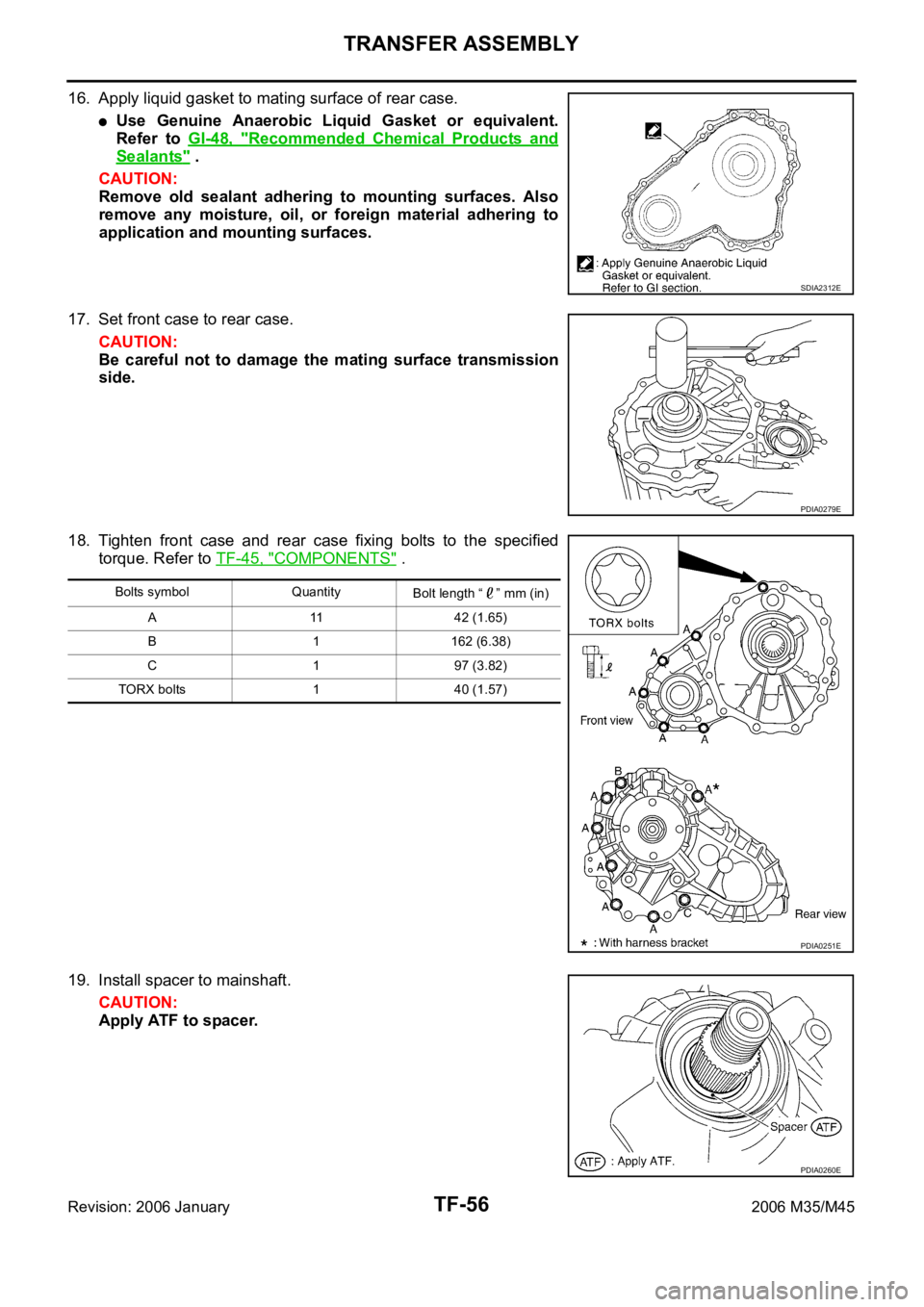

16. Apply liquid gasket to mating surface of rear case.

Use Genuine Anaerobic Liquid Gasket or equivalent.

Refer to GI-48, "

Recommended Chemical Products and

Sealants" .

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

17. Set front case to rear case.

CAUTION:

Be careful not to damage the mating surface transmission

side.

18. Tighten front case and rear case fixing bolts to the specified

torque. Refer to TF-45, "

COMPONENTS" .

19. Install spacer to mainshaft.

CAUTION:

Apply ATF to spacer.

SDIA2312E

PDIA0279E

Bolts symbol Quantity

Bolt length “ ” mm (in)

A 11 42 (1.65)

B 1 162 (6.38)

C 1 97 (3.82)

TORX bolts 1 40 (1.57)

PDIA0251E

PDIA0260E

Page 5522 of 5621

TRANSFER ASSEMBLY

TF-57

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

20. Install rear oil seal to rear case, using the drifts.

CAUTION:

Do not reuse rear oil seal.

Apply ATF to rear oil seal.

When installing, do not incline rear oil seal.

21. Install companion flange while align the matching mark of main-

shaft with the mark of companion flange.

22. Tighten self-lock nut to the specified torque, with flange wrench.

Refer to TF-45, "

COMPONENTS" .

CAUTION:

Do not reuse self-lock nut.

23. Install mainshaft oil seal until it is flush with end face of front

case, using the drift.

CAUTION:

Do not reuse mainshaft oil seal.

Apply ATF to mainshaft oil seal.

When installing, do not incline mainshaft oil seal.

24. Install front oil seal until it is flush with end face of front case,

using the drift.

CAUTION:

Do not reuse front oil seal.

Apply ATF to front oil seal.

When installing, do not incline front oil seal.

25. Apply sealant to threads of drain plug. Then install it to rear case

and tighten to the specified torque. Refer to TF-45, "

COMPO-

NENTS" . Dimension A : 6.7 - 7.3 mm (0.264 - 0.287 in)

Tool number A: ST30720000 (J-25405)

B: KV40104830 ( — )

PDIA0281E

SDIA2378E

SDIA2369E

Tool number : ST30720000 (J-25405)

PDIA0282E

Tool number : ST27862000 ( — )

PDIA0287E

Page 5523 of 5621

TF-58

TRANSFER ASSEMBLY

Revision: 2006 January2006 M35/M45

Use Genuine Silicone RTV or equivalent. Refer to GI-48, "Recommended Chemical Products and

Sealants" .

CAUTION:

Remove old sealant and oil adhering to threads.

26. Set gasket to filler plug. Install it to rear case and tighten to the specified torque. Refer to TF-45, "

COM-

PONENTS" .

CAUTION:

Do not reuse gasket.

After oil is filled, tighten filler plug to specified torque.

Page 5527 of 5621

WT-2Revision: 2006 January2006 M35/M45 MALFUNCTION CODE NO. 52 ........................... 34

Inspection 8: CAN Communication System Mal-

function ................................................................... 34

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 35

Inspection 1: Warning Lamp Does Not Come On

When Ignition Switch Is Turned On ........................ 35

Inspection 2: Warning Lamp Stays On When Ignition

Switch Is Turned On ............................................ ... 36

Inspection 3: Warning Lamp Blinks When Ignition

Switch Is Turned On ............................................ ... 37

Inspection 4: Turn Signal Lamp Blinks When Ignition

Switch Is Turned On ............................................ ... 37

Inspection 5: ID Registration Can Not Be Completed ... 38REMOVAL AND INSTALLATION .............................. 39

Transmitter .............................................................. 39

REMOVAL ............................................................ 39

INSTALLATION .................................................... 39

Low Tire Pressure Warning Control Unit ................. 40

REMOVAL ............................................................ 40

INSTALLATION .................................................... 40

Receiver .................................................................. 40

REMOVAL ............................................................ 40

INSTALLATION .................................................... 40

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 41

Road Wheel ............................................................ 41

Tire .......................................................................... 41

Page 5530 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

WT-5

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNES000JN

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

FAX-5

, FSU-6WT-6WT-7WT-41WT-8—

—

WT-41

NVH in PR section.

NVH in RFD section.

NVH in FAX and FSU sections.

NVH in RAX and RSU sections.

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

NVH in FAX, RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

SymptomTIRESNoise

Shake

Vibration

Shimmy

Judder

Poor quality ride or

handling

ROAD

WHEELNoiseShake

Shimmy, Judder

Poor quality ride or

handling

Page 5532 of 5621

ROAD WHEEL TIRE ASSEMBLY

WT-7

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

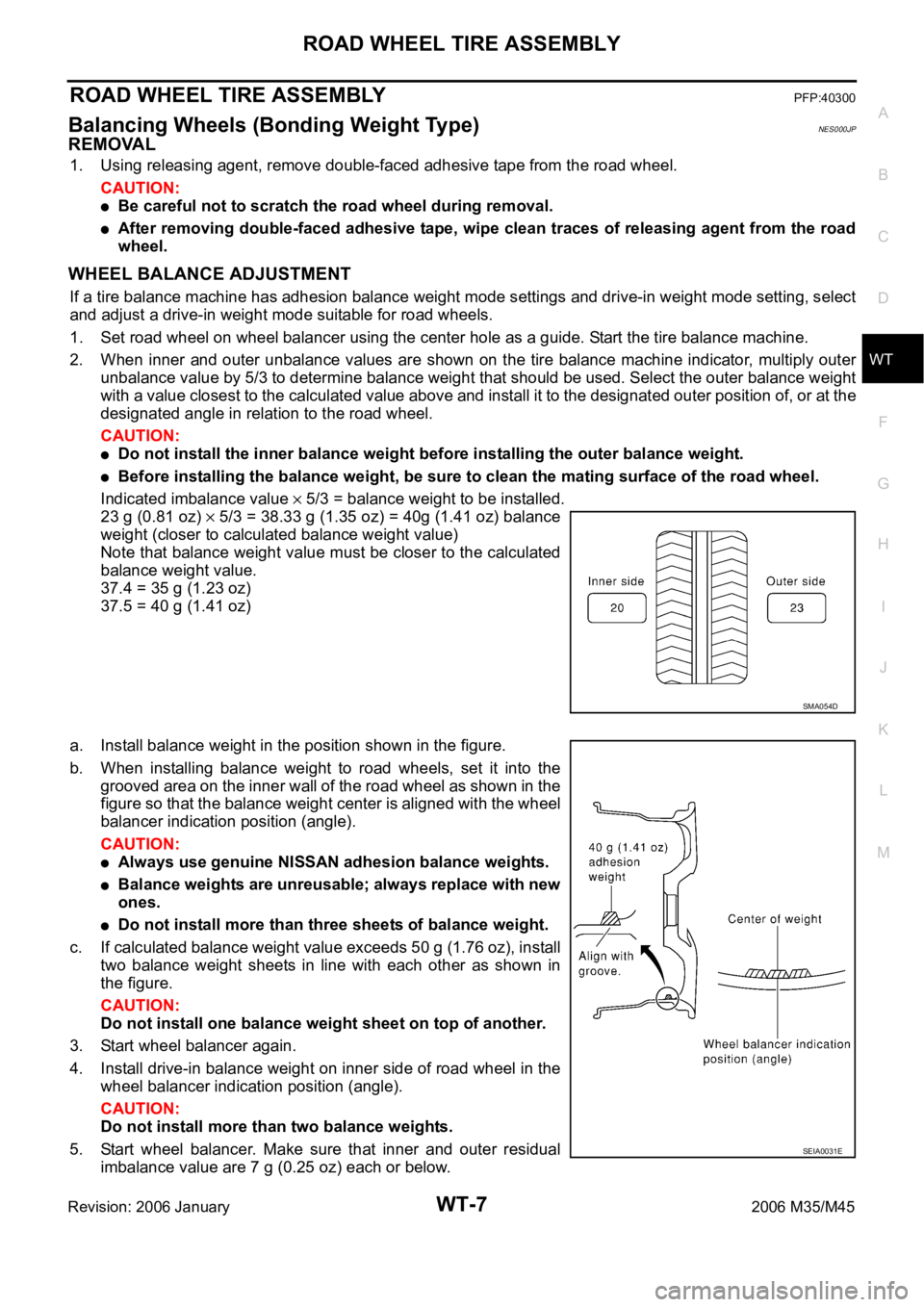

ROAD WHEEL TIRE ASSEMBLYPFP:40300

Balancing Wheels (Bonding Weight Type)NES000JP

REMOVAL

1. Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

WHEEL BALANCE ADJUSTMENT

If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting, select

and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer

unbalance value by 5/3 to determine balance weight that should be used. Select the outer balance weight

with a value closest to the calculated value above and install it to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Do not install the inner balance weight before installing the outer balance weight.

Before installing the balance weight, be sure to clean the mating surface of the road wheel.

Indicated imbalance value

5/3 = balance weight to be installed.

23 g (0.81 oz)

5/3 = 38.33 g (1.35 oz) = 40g (1.41 oz) balance

weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated

balance weight value.

37.4 = 35 g (1.23 oz)

37.5 = 40 g (1.41 oz)

a. Install balance weight in the position shown in the figure.

b. When installing balance weight to road wheels, set it into the

grooved area on the inner wall of the road wheel as shown in the

figure so that the balance weight center is aligned with the wheel

balancer indication position (angle).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are unreusable; always replace with new

ones.

Do not install more than three sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

imbalance value are 7 g (0.25 oz) each or below.

SMA054D

SEIA0031E