coolant level INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1433 of 5621

![INFINITI M35 2006 Factory User Guide CO-58

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004RT

ENGINE COOLANT CAPACITY (APPROXIMATE)

INFINITI M35 2006 Factory User Guide CO-58

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004RT

ENGINE COOLANT CAPACITY (APPROXIMATE)](/img/42/57023/w960_57023-1432.png)

CO-58

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004RT

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

RADIATOR

Unit: kPa (kg/cm2 , psi)

THERMOSTAT

WATER CONTROL VALVE

Engine coolant capacity (With reservoir tank at “MAX” level) 10.4 (11, 9-1/8)

Reservoir tank engine coolant capacity (at “MAX” level) 0.6 (5/8, 1/2)

Radiator cap relief pressureStandard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 (0.6, 9)

Leakage testing pressure 157 (1.6, 23)

ThermostatStandard

Valve opening temperature 80 - 84

C (176 - 183F)

Maximum valve lift More than 10 mm/ 95

C (0.39 in/ 203F)

Valve closing temperature 77

C (171F)

Water control valveStandard

Valve opening temperature 93.5 - 96.5

C (200 - 206F)

Maximum valve lift More than 8 mm/ 108

C (0.315 in/ 226F)

Valve closing temperature 90

C (194F)

Page 1434 of 5621

DI-1

DRIVER INFORMATION SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION DI

A

B

DI

Revision: 2006 January2006 M35/M45

DRIVER INFORMATION SYSTEM

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Commercial Service Tools ........................................ 4

COMBINATION METERS ........................................... 5

System Description .................................................. 5

UNIFIED METER CONTROL UNIT ...................... 5

UNIFIED METER AND A/C AMP. ......................... 5

POWER SUPPLY AND GROUND CIRCUIT ........ 5

SPEEDOMETER ................................................... 6

TACHOMETER ..................................................... 6

WATER TEMPERATURE GAUGE ........................ 6

FUEL GAUGE ....................................................... 7

ODO/TRIP METER ............................................... 7

METER ILLUMINATION CONTROL ..................... 8

FAIL-SAFE ............................................................ 9

Arrangement of Combination Meter ....................... 10

Component Parts and Harness Connector Location .... 11

Internal Circuit ........................................................ 12

Wiring Diagram — METER — ................................ 13

Terminals and Reference Value for Combination

Meter ...................................................................... 15

Terminals and Reference Value for Unified Meter

and A/C Amp. ......................................................... 16

Self-Diagnosis Mode of Combination Meter ........... 17

SELF-DIAGNOSIS FUNCTION .......................... 17

OPERATION PROCEDURE ............................... 17

CONSULT-II Function (METER A/C AMP) ............. 18

Trouble Diagnosis .................................................. 18

HOW TO PERFORM TROUBLE DIAGNOSIS ... 18

PRELIMINARY CHECK ...................................... 18

Symptom Chart ...................................................... 18

Power Supply and Ground Circuit Inspection ........ 19

Vehicle Speed Signal Inspection ............................ 20

Engine Speed Signal Inspection ............................ 21

Engine Coolant Temperature Signal Inspection ..... 22

Fuel Level Sensor Signal Inspection ...................... 22

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or Varies ....................................................... 25

Fuel Gauge Does Not Move to FULL Position ....... 25

Electrical Components Inspection .......................... 26

CHECK FUEL LEVEL SENSOR UNIT ................ 26

Removal and Installation of Combination Meter ..... 27

REMOVAL ........................................................

... 27

INSTALLATION ................................................... 27

Disassembly and Assembly of Combination Meter ... 27

DISASSEMBLY ................................................... 27

ASSEMBLY ......................................................... 27

UNIFIED METER AND A/C AMP ...........................

... 28

System Description ................................................. 28

COMBINATION METER CONTROL FUNCTION ... 28

A/C AUTO AMP. FUNCTION ............................... 29

OTHER FUNCTIONS .......................................... 29

Schematic ............................................................... 30

CONSULT-II Function (METER A/C AMP) ............. 31

CONSULT-II BASIC OPERATION ....................... 31

SELF-DIAG RESULTS ........................................ 32

DATA MONITOR ................................................. 33

Power Supply and Ground Circuit Inspection ......... 35

DTC [U1000] CAN Communication Circuit ............. 36

DTC [B2202] Meter Communication Circuit ........... 36

DTC [B2205] Vehicle Speed Circuit ........................ 39

Removal and Installation of Unified Meter and A/C

Amp. ....................................................................... 39

REMOVAL ........................................................

... 39

INSTALLATION ................................................... 39

WARNING LAMPS .................................................... 40

System Description ................................................. 40

OIL PRESSURE WARNING LAMP ..................... 40

Component Parts and Harness Connector Location ... 41

Schematic ............................................................... 42

Wiring Diagram — WARN — .................................. 43

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ............................................................. 53

Oil Pressure Warning Lamp Does Not Turn Off (Oil

Pressure Is Normal) ................................................ 54

Electrical Component Inspection ............................ 55

OIL PRESSURE SWITCH ................................... 55

Page 1451 of 5621

DI-18

COMBINATION METERS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (METER A/C AMP)NKS003U3

Refer to DI-31, "CONSULT-II Function (METER A/C AMP)" in “UNIFIED METER AND A/C AMP”.

Trouble DiagnosisNKS003U4

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to DI-18, "

PRELIMINARY CHECK" .

3. According to the symptom chart, make sure the cause of the symptom and repair or replace applicable

parts. Refer to DI-18, "

Symptom Chart" .

4. Does the meter operate normally? If yes, GO TO 5. If no, GO TO 2.

5. INSPECTION END

PRELIMINARY CHECK

1. CHECK OPERATION SELF-DIAGNOSIS MODE OF COMBINATION METER

Perform self-diagnosis mode of combination meter. Refer to DI-17, "

OPERATION PROCEDURE" .

Does self

-diagnosis mode operate?

YES >> GO TO 2.

NO >> GO TO 3.

2. CHECK UNIFIED METER AND A/C AMP. (CONSULT-II)

Perform self-diagnosis of unified meter and A/C amp. Refer to DI-31, "

CONSULT-II Function (METER A/C

AMP)" .

Self

-diagnostic results content

No malfunction detected>>INSPECTION END

Malfunction detected>>Check applicable parts, and repair or replace corresponding parts.

3. CHECK POWER SUPPLY AND GROUND CIRCUIT OF COMBINATION METER

Check power supply and ground circuit of combination meter. Refer to DI-19, "

Power Supply and Ground Cir-

cuit Inspection" .

OK or NG

OK >> Replace combination meter.

NG >> Repair power supply and ground circuit of combination meter.

Symptom ChartNKS003U5

Symptom Diagnosis/Service procedure

Speedometer or odo/trip meter indication is malfunction. Refer to DI-20, "

Vehicle Speed Signal Inspection" .

Tachometer indication is malfunction. Refer to DI-21, "

Engine Speed Signal Inspection" .

Water temperature gauge indication is malfunction. Refer to DI-22, "

Engine Coolant Temperature Signal Inspection" .

Fuel gauge indication is malfunction.

Refer to DI-22, "

Fuel Level Sensor Signal Inspection" .

Low-fuel warning lamp indication is irregular.

A/T position indicator is malfunction. Refer to DI-59, "

A/T Indicator Is Malfunction" .

Page 1455 of 5621

DI-22

COMBINATION METERS

Revision: 2006 January2006 M35/M45

Engine Coolant Temperature Signal InspectionNKS003U9

Symptom: Water temperature gauge indication is malfunction.

1. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Start engine and select “METER A/C AMP” on CONSULT-II.

2. Using “W TEMP METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” to the indication of water tempera-

ture gauge of combination meter.

Is the indication of water temperature gauge same as the value in

the monitor?

OK >> GO TO 2.

NG >> Replace combination meter. [Perform self-diagnosis of ECM when the value in the monitor indi-

cates 215

C (419F). Then repair or replace the malfunction part.]

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “ENGINE” on CONSULT-II.

2. Using “COOLAN TEMP/S” on “DATA MONITOR”, print out the

CONSULT-II screen.

3. Select “METER A/C AMP” on CONSULT-II.

4. Using “W TEMP METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” to that of the “COOLAN TEMP/S”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-133, "CON-

SULT-II Function (ENGINE)" (for VQ35DE) or EC-846,

"CONSULT-II Function (ENGINE)" (for VK45DE).

NG >> Replace unified meter and A/C amp.

Fuel Level Sensor Signal InspectionNKS003UA

Symptom:

Fuel gauge indication is malfunction.

Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms are not malfunction.

Fuel level sensor unit

Depending on vehicle position or driving circumstance, the fuel level in the tank varies, and the pointer

may fluctuate.

If the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

Low-fuel warning lamp

Depending on vehicle position or driving circumstance, the fuel in the tank flows and the warning lamp ON

timing may change.

Water temperature gauge pointer Reference value of data monitor C (F)

Hot Approx. 130 (266)

Middle Approx. 70 - 105 (158 - 221)

Cold Approx. 50 (122)

PKIA2091E

SKIA4368E

Page 1461 of 5621

DI-28

UNIFIED METER AND A/C AMP

Revision: 2006 January2006 M35/M45

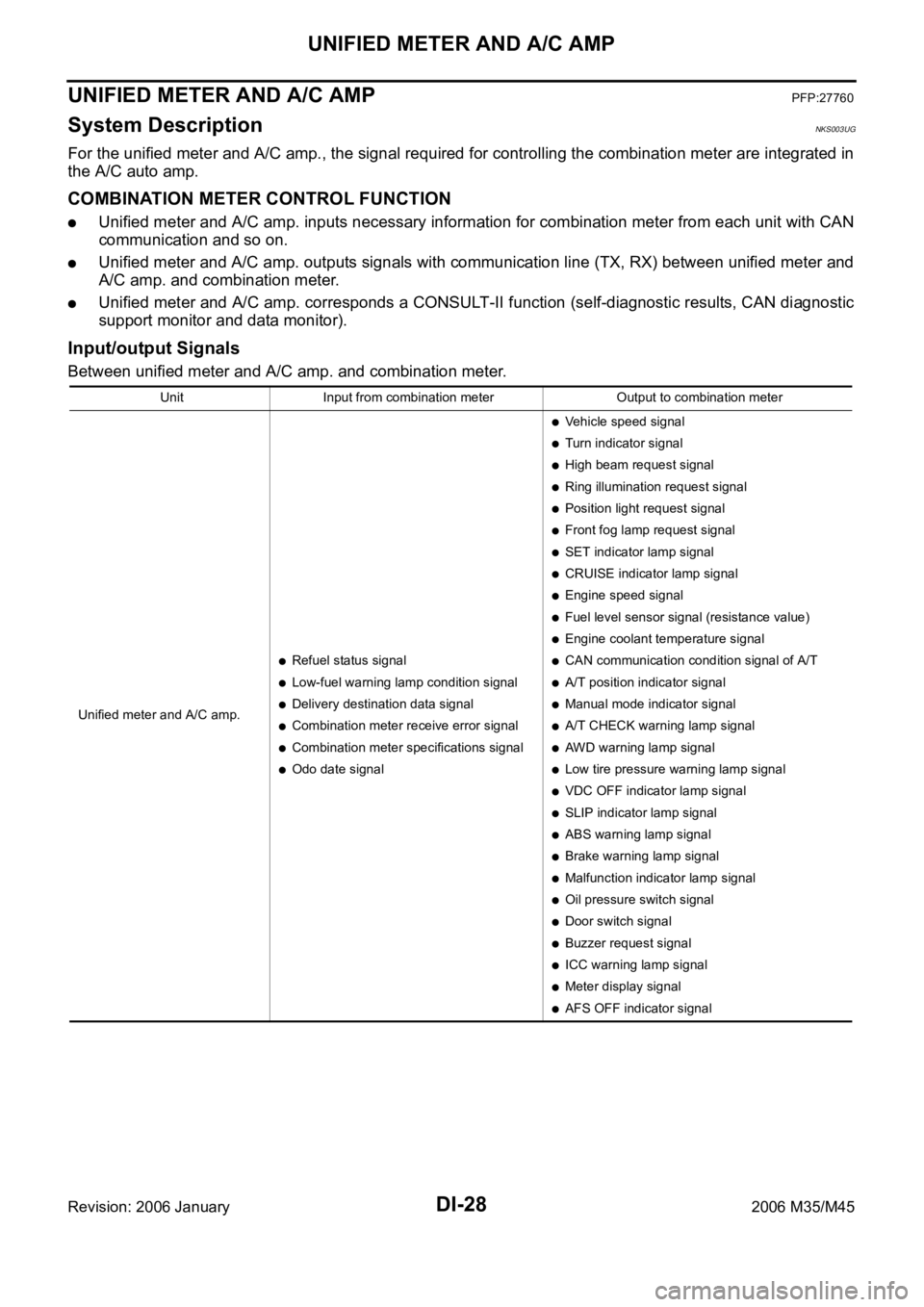

UNIFIED METER AND A/C AMPPFP:27760

System DescriptionNKS003UG

For the unified meter and A/C amp., the signal required for controlling the combination meter are integrated in

the A/C auto amp.

COMBINATION METER CONTROL FUNCTION

Unified meter and A/C amp. inputs necessary information for combination meter from each unit with CAN

communication and so on.

Unified meter and A/C amp. outputs signals with communication line (TX, RX) between unified meter and

A/C amp. and combination meter.

Unified meter and A/C amp. corresponds a CONSULT-II function (self-diagnostic results, CAN diagnostic

support monitor and data monitor).

Input/output Signals

Between unified meter and A/C amp. and combination meter.

Unit Input from combination meter Output to combination meter

Unified meter and A/C amp.

Refuel status signal

Low-fuel warning lamp condition signal

Delivery destination data signal

Combination meter receive error signal

Combination meter specifications signal

Odo date signal

Vehicle speed signal

Turn indicator signal

High beam request signal

Ring illumination request signal

Position light request signal

Front fog lamp request signal

SET indicator lamp signal

CRUISE indicator lamp signal

Engine speed signal

Fuel level sensor signal (resistance value)

Engine coolant temperature signal

CAN communication condition signal of A/T

A/T position indicator signal

Manual mode indicator signal

A/T CHECK warning lamp signal

AWD warning lamp signal

Low tire pressure warning lamp signal

VDC OFF indicator lamp signal

SLIP indicator lamp signal

ABS warning lamp signal

Brake warning lamp signal

Malfunction indicator lamp signal

Oil pressure switch signal

Door switch signal

Buzzer request signal

ICC warning lamp signal

Meter display signal

AFS OFF indicator signal

Page 1514 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-81

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

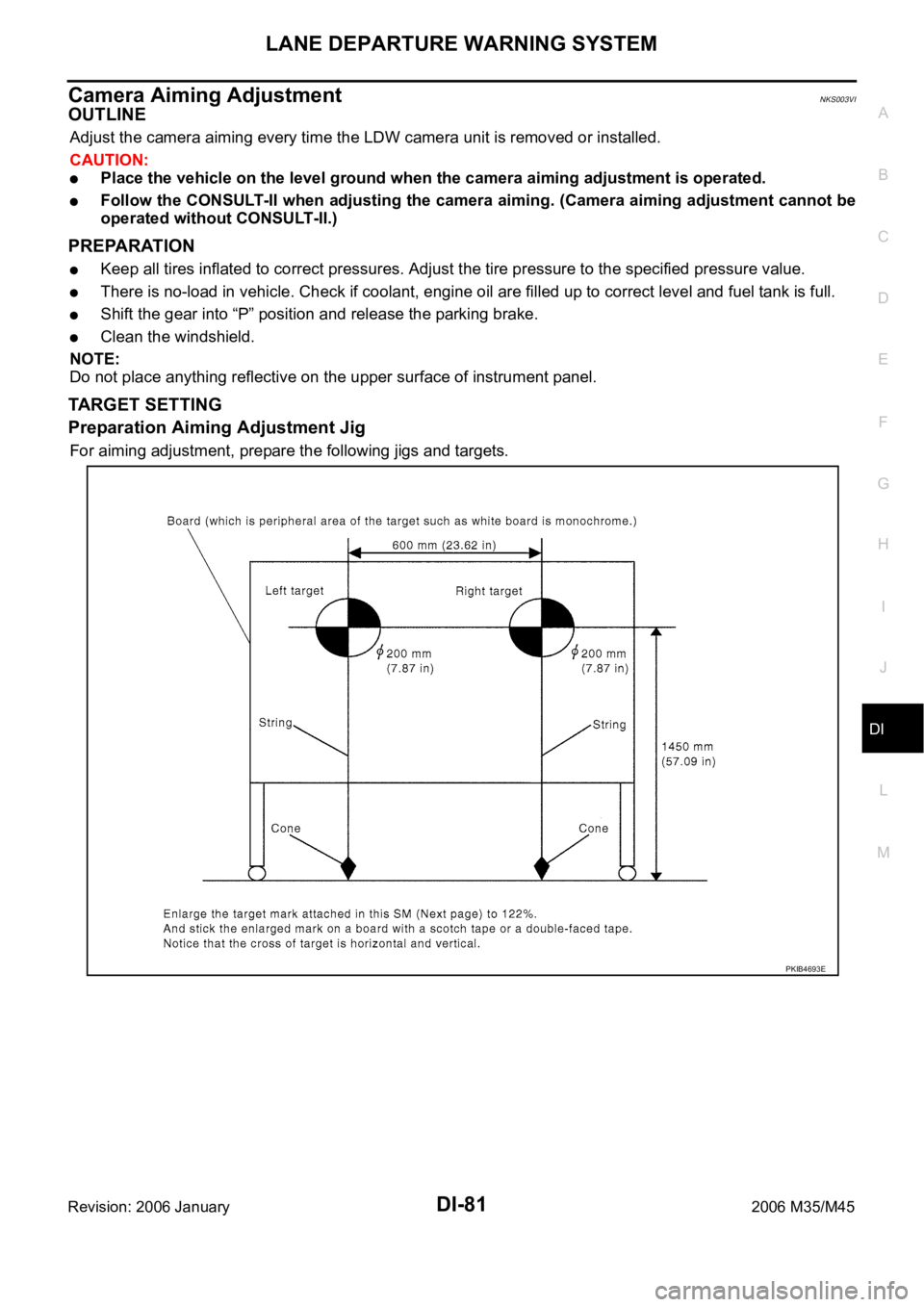

Camera Aiming AdjustmentNKS003VI

OUTLINE

Adjust the camera aiming every time the LDW camera unit is removed or installed.

CAUTION:

Place the vehicle on the level ground when the camera aiming adjustment is operated.

Follow the CONSULT-II when adjusting the camera aiming. (Camera aiming adjustment cannot be

operated without CONSULT-II.)

PREPARATION

Keep all tires inflated to correct pressures. Adjust the tire pressure to the specified pressure value.

There is no-load in vehicle. Check if coolant, engine oil are filled up to correct level and fuel tank is full.

Shift the gear into “P” position and release the parking brake.

Clean the windshield.

NOTE:

Do not place anything reflective on the upper surface of instrument panel.

TARGET SETTING

Preparation Aiming Adjustment Jig

For aiming adjustment, prepare the following jigs and targets.

PKIB4693E

Page 1608 of 5621

![INFINITI M35 2006 Factory User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-65

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

The time required for each diagnosis varies with road surface conditions, weather, altitude INFINITI M35 2006 Factory User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-65

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

The time required for each diagnosis varies with road surface conditions, weather, altitude](/img/42/57023/w960_57023-1607.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-65

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

The time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing habits, etc.

Zone A refers to the range where the time, required for the diagnosis under normal conditions*, is the

shortest.

Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not completed

within zone A.

*: Normal conditions refer to the following:

Sea level

Flat road

Ambient air temperature: 20 - 30C (68 - 86F)

Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30

C (68 - 86F)], diag-

nosis may also be performed.

Pattern 1:

The engine is started at the engine coolant temperature of 10 to 35C (14 to 95F)

(where the voltage between the ECM terminal 73 and ground is 3.0 - 4.3V).

The engine must be operated at idle speed until the engine coolant temperature is greater than

70

C (158F) (where the voltage between the ECM terminal 73 and ground is lower than 1.4V).

The engine is started at the fuel tank temperature of warmer than 0C (32F) (where the voltage

between the ECM terminal 107 and ground is less than 4.1V).

Pattern 2:

When steady-state driving is performed again even after it is interrupted, each diagnosis can be con-

ducted. In this case, the time required for diagnosis may be extended.

Pattern 3:

Operate vehicle following the driving pattern shown in the figure.

Release the accelerator pedal during decelerating vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

The accelerator pedal must be held very steady during steady-

state driving.

If the accelerator pedal is moved, the test must be conducted all

over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position

Set the selector lever in the D position with the overdrive switch turned ON.

PBIB2244E

Page 1627 of 5621

![INFINITI M35 2006 Factory User Guide EC-84

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

Idle Mixture Ratio AdjustmentNBS004SS

PREPARATION

1. Make sure that the following parts are in good order.

Battery

Ignition sy INFINITI M35 2006 Factory User Guide EC-84

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

Idle Mixture Ratio AdjustmentNBS004SS

PREPARATION

1. Make sure that the following parts are in good order.

Battery

Ignition sy](/img/42/57023/w960_57023-1626.png)

EC-84

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

Idle Mixture Ratio AdjustmentNBS004SS

PREPARATION

1. Make sure that the following parts are in good order.

Battery

Ignition system

Engine oil and coolant levels

Fuses

ECM harness connector

Vacuum hoses

Air intake system

(Oil filler cap, oil level gauge, etc.)

Fuel pressure

Engine compression

Throttle valve

Evaporative emission system

2. On air conditioner equipped models, checks should be carried out while the air conditioner is OFF.

3. Checks should be carried out while selector lever is in P or N position.

4. When measuring CO percentage, insert probe more than 40 cm (15.7 in) into tail pipe.

5. Turn off headlamp, heater blower, rear window defogger.

6. Keep front wheels pointed straight ahead.

Page 1649 of 5621

![INFINITI M35 2006 Factory User Guide EC-106

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DTC Inspection Priority ChartNBS004SZ

If some DTCs are displayed at the same time, perform inspections one by one based on the foll INFINITI M35 2006 Factory User Guide EC-106

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DTC Inspection Priority ChartNBS004SZ

If some DTCs are displayed at the same time, perform inspections one by one based on the foll](/img/42/57023/w960_57023-1648.png)

EC-106

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DTC Inspection Priority ChartNBS004SZ

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-173, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

If DTC U1010 is displayed with other DTC, first perform the trouble diagnosis for DTC U1010. Refer

to EC-176, "

DTC U1010 CAN COMMUNICATION" .

Priority Detected items (DTC)

1

U1000 U1001 CAN communication line

U1010 CAN communication

P0101 P0102 P0103 Mass air flow sensor

P0112 P0113 P0127 Intake air temperature sensor

P0117 P0118 P0125 Engine coolant temperature sensor

P0122 P0123 P0222 P0223 P1225 P1226 P2135 Throttle position sensor

P0128 Thermostat function

P0181 P0182 P0183 Fuel tank temperature sensor

P0327 P0328 Knock sensor

P0335 Crankshaft position sensor (POS)

P0340 P0345 Camshaft position sensor (PHASE)

P0460 P0461 P0462 P0463 Fuel level sensor

P0500 Vehicle speed sensor

P0643 Sensor power supply

P0605 ECM

P0700 TCM

P0705 P0850 Park/Neutral position (PNP) switch

P1550 P1551 P1552 P1553 P1554 Battery current sensor

P1610 - P1615 NATS

P2122 P2123 P2127 P2128 P2138 Accelerator pedal position sensor

Page 1655 of 5621

![INFINITI M35 2006 Factory User Guide EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat INFINITI M35 2006 Factory User Guide EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat](/img/42/57023/w960_57023-1654.png)

EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat 5CO-29

Water pumpCO-24

Water galleryCO-31

Cooling fan

5CO-22

Coolant level (Low)/Contami-

nated coolantCO-11

IVIS (INFINITI Vehicle Immobilizer System —

NATS)11EC-53 or

BL-248

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA