window INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 617 of 5621

ATC-170

REFRIGERANT LINES

Revision: 2006 January2006 M35/M45

Checking for Refrigerant LeaksNJS000HY

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electrical leak detector or fluorescent dye leak

detector (SST: J-42220).

If dye is observed, confirm the leak with an electrical leak detector. It is possible a prior leak was repaired and

not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electrical leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electrical leak detector probe slower and closer to the suspected leak area will improve the

chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorNJS000HZ

1. Check A/C system for leaks using the UV lamp and safety goggles (SST: J-42220) in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (SST: J-43872) to prevent future

misdiagnosis.

4. Perform a system performance check and verify the leak repair with an approved electrical leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionNJS000I0

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.52 kg/cm

2 , 50 psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (SST: J-41459).

3. Connect the injector tool to the A/C low-pressure side service valve.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool (SST: J-41459) (refer to the manufacture’s

operating instructions).

6. With the engine still running, disconnect the injector tool from the service valve.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

8. Attach a blue label as necessary.

Page 745 of 5621

![INFINITI M35 2006 Factory User Guide AV-124

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggested.If there are restric INFINITI M35 2006 Factory User Guide AV-124

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggested.If there are restric](/img/42/57023/w960_57023-744.png)

AV-124

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggested.If there are restrictions (such as one way streets)

on roads close to the starting point or destination,

the system may suggest an indirect route.Adjust the location of the starting point or

destination.

The system may suggest an indirect route because

route calculation does not take into consideration

some areas such as narrow streets (gray roads).Reset the destination to a main or ordinary

road, and recalculate the route.

The landmark information does not

correspond to the actual informa-

tion.This may caused by insufficient or incorrect data on

the DVD-ROM.This is not a malfunction.

The suggested route does not

exactly connect to the starting

point, waypoints, or destination.There is no data for route calculation closer to

these locations.Set the starting point, waypoints and desti-

nation on main road, and perform route cal-

culation. Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

The voice guidance is not avail-

able.Voice guidance is only available at certain intersec-

tions. In some cases, voice guidance is not avail-

able even when the vehicle should make a turn.This is not a malfunction.

The vehicle has deviated from the suggested

route.Go back to the suggested route or request

route calculation again.

Voice guidance is set to off. Turn on the voice guidance.

Route guidance is set to off. Turn on the voice guidance.

The guidance content does not

correspond to the actual condition.The content of the voice guidance may vary,

depending on the types of intersections at which

turns are made.Follow all traffic rules and regulations.

Symptom Possible cause Possible solution

The system does not recognize

the command.

The system recognizes the com-

mand incorrectly.The interior of the vehicle is too noisy.Close the windows or have other occu-

pants be quiet.

The volume of the voice is too low. Speak louder.

Pronunciation is unclear. Speak clearly.

Voice recognition mode is not yet ready to speak.Push the release “PTT” on the steering

switch, and speak a command after the

tone sounds.

5 seconds or more have passed after pushed and

released “PTT” on the steering switch.Make sure to speak a command within

5seconds after push and release “PTT” on

the steering switch.

Only a limited range of voice commands is usable

for each screen.Use a correct voice command appropriate

for the current screen.

Symptom Possible cause Possible solution

Rear view monitor image is not

displayedThe selector lever is not shifted in R position. Shift the selector lever in R position.

Page 900 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS

AV-279

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggest INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS

AV-279

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggest](/img/42/57023/w960_57023-899.png)

TROUBLE DIAGNOSIS

AV-279

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VOICE GUIDANCE

VOICE RECOGNITION

REAR VIEW MONITOR

An indirect route is suggested.If there are restrictions (such as one way streets)

on roads close to the starting point or destination,

the system may suggest an indirect route.Adjust the location of the starting point or

destination.

The system may suggest an indirect route because

route calculation does not take into consideration

some areas such as narrow streets (gray roads).Reset the destination to a main or ordinary

road, and recalculate the route.

The landmark information does not

correspond to the actual informa-

tion.This may caused by insufficient or incorrect data on

the DVD-ROM.This is not a malfunction.

The suggested route does not

exactly connect to the starting

point, waypoints, or destination.There is no data for route calculation closer to

these locations.Set the starting point, waypoints and desti-

nation on main road, and perform route cal-

culation. Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

The voice guidance is not avail-

able.Voice guidance is only available at certain intersec-

tions. In some cases, voice guidance is not avail-

able even when the vehicle should make a turn.This is not a malfunction.

The vehicle has deviated from the suggested

route.Go back to the suggested route or request

route calculation again.

Voice guidance is set to off. Turn on the voice guidance.

Route guidance is set to off. Turn on the voice guidance.

The guidance content does not

correspond to the actual condition.The content of the voice guidance may vary,

depending on the types of intersections at which

turns are made.Follow all traffic rules and regulations.

Symptom Possible cause Possible solution

The system does not recognize

the command.

The system recognizes the com-

mand incorrectly.The interior of the vehicle is too noisy.Close the windows or have other occu-

pants be quiet.

The volume of the voice is too low. Speak louder.

Pronunciation is unclear. Speak clearly.

Voice recognition mode is not yet ready to speak.Push the release “PTT” on the steering

switch, and speak a command after the

tone sounds.

5 seconds or more have passed after pushed and

released “PTT” on the steering switch.Make sure to speak a command within

5seconds after push and release “PTT” on

the steering switch.

Only a limited range of voice commands is usable

for each screen.Use a correct voice command appropriate

for the current screen.

Symptom Possible cause Possible solution

Rear view monitor image is not

displayedThe selector lever is not shifted in R position. Shift the selector lever in R position.

Page 929 of 5621

BCS-8

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

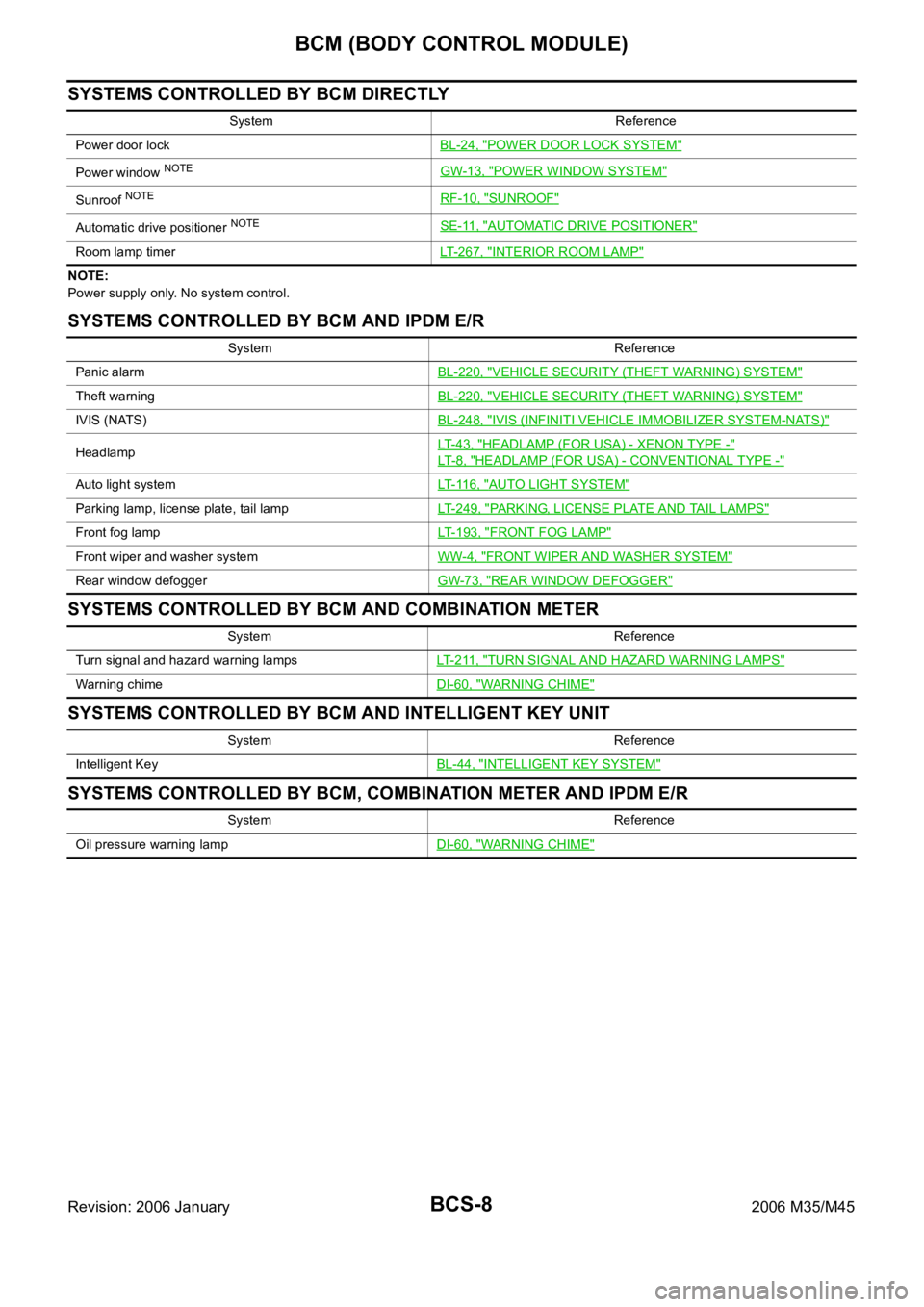

SYSTEMS CONTROLLED BY BCM DIRECTLY

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT

SYSTEMS CONTROLLED BY BCM, COMBINATION METER AND IPDM E/R

System Reference

Power door lockBL-24, "

POWER DOOR LOCK SYSTEM"

Power window NOTEGW-13, "POWER WINDOW SYSTEM"

Sunroof NOTERF-10, "SUNROOF"

Automatic drive positioner NOTESE-11, "AUTOMATIC DRIVE POSITIONER"

Room lamp timerLT-267, "INTERIOR ROOM LAMP"

System Reference

Panic alarmBL-220, "

VEHICLE SECURITY (THEFT WARNING) SYSTEM"

Theft warningBL-220, "VEHICLE SECURITY (THEFT WARNING) SYSTEM"

IVIS (NATS)BL-248, "IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)"

HeadlampLT- 4 3 , "HEADLAMP (FOR USA) - XENON TYPE -"

LT- 8 , "HEADLAMP (FOR USA) - CONVENTIONAL TYPE -"

Auto light systemLT- 11 6 , "AUTO LIGHT SYSTEM"

Parking lamp, license plate, tail lampLT-249, "PARKING, LICENSE PLATE AND TAIL LAMPS"

Front fog lampLT-193, "FRONT FOG LAMP"

Front wiper and washer systemWW-4, "FRONT WIPER AND WASHER SYSTEM"

Rear window defoggerGW-73, "REAR WINDOW DEFOGGER"

System Reference

Turn signal and hazard warning lampsLT- 2 11 , "

TURN SIGNAL AND HAZARD WARNING LAMPS"

Warning chimeDI-60, "WARNING CHIME"

System Reference

Intelligent KeyBL-44, "

INTELLIGENT KEY SYSTEM"

System Reference

Oil pressure warning lampDI-60, "

WARNING CHIME"

Page 930 of 5621

BCM (BODY CONTROL MODULE)

BCS-9

C

D

E

F

G

H

I

J

L

MA

B

BCS

Revision: 2006 January2006 M35/M45

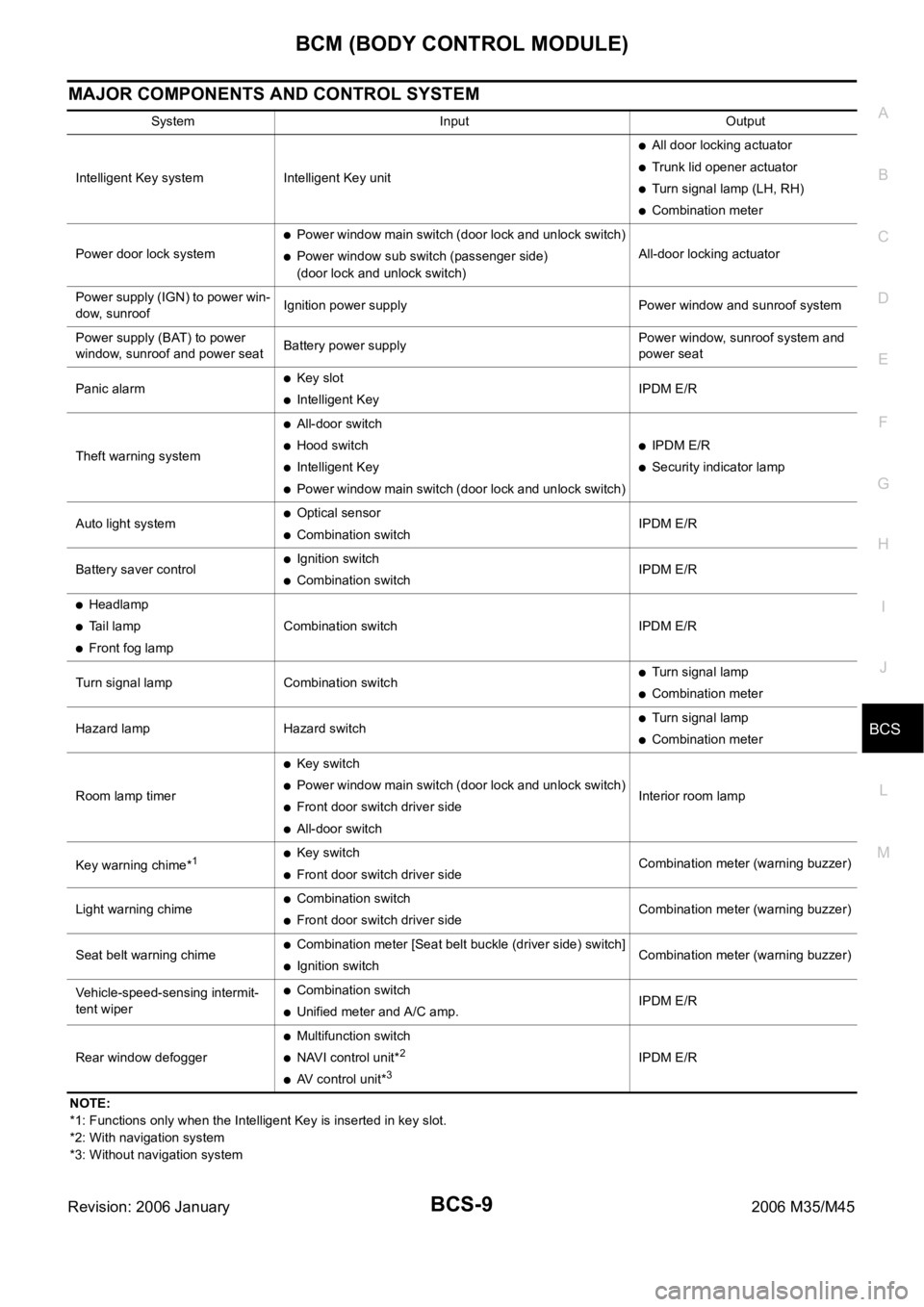

MAJOR COMPONENTS AND CONTROL SYSTEM

NOTE:

*1: Functions only when the Intelligent Key is inserted in key slot.

*2: With navigation system

*3: Without navigation systemSystem Input Output

Intelligent Key system Intelligent Key unit

All door locking actuator

Trunk lid opener actuator

Turn signal lamp (LH, RH)

Combination meter

Power door lock system

Power window main switch (door lock and unlock switch)

Power window sub switch (passenger side)

(door lock and unlock switch)All-door locking actuator

Power supply (IGN) to power win-

dow, sunroofIgnition power supply Power window and sunroof system

Power supply (BAT) to power

window, sunroof and power seatBattery power supplyPower window, sunroof system and

power seat

Panic alarm

Key slot

Intelligent KeyIPDM E/R

Theft warning system

All-door switch

Hood switch

Intelligent Key

Power window main switch (door lock and unlock switch)

IPDM E/R

Security indicator lamp

Auto light system

Optical sensor

Combination switchIPDM E/R

Battery saver control

Ignition switch

Combination switchIPDM E/R

Headlamp

Tail lamp

Front fog lampCombination switch IPDM E/R

Turn signal lamp Combination switch

Turn signal lamp

Combination meter

Hazard lamp Hazard switch

Turn signal lamp

Combination meter

Room lamp timer

Key switch

Power window main switch (door lock and unlock switch)

Front door switch driver side

All-door switchInterior room lamp

Key warning chime*

1Key switch

Front door switch driver sideCombination meter (warning buzzer)

Light warning chime

Combination switch

Front door switch driver sideCombination meter (warning buzzer)

Seat belt warning chime

Combination meter [Seat belt buckle (driver side) switch]

Ignition switchCombination meter (warning buzzer)

Vehicle-speed-sensing intermit-

tent wiper

Combination switch

Unified meter and A/C amp.IPDM E/R

Rear window defogger

Multifunction switch

NAVI control unit*2

AV control unit*3

IPDM E/R

Page 935 of 5621

BCS-14

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

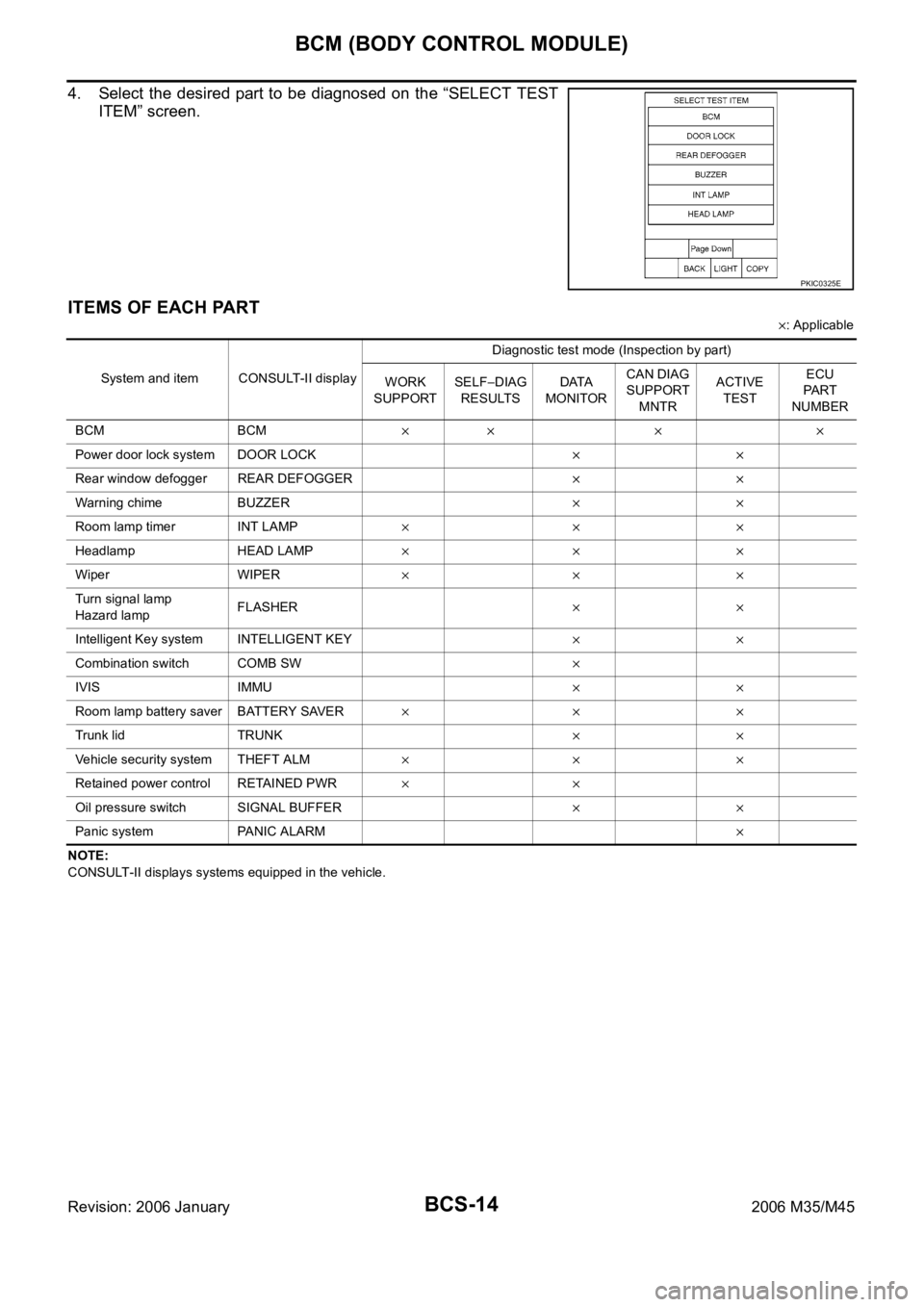

4. Select the desired part to be diagnosed on the “SELECT TEST

ITEM” screen.

ITEMS OF EACH PART

: Applicable

NOTE:

CONSULT-II displays systems equipped in the vehicle.

PKIC0325E

System and item CONSULT-II displayDiagnostic test mode (Inspection by part)

WORK

SUPPORTSELFDIAG

RESULTSDATA

MONITORCAN DIAG

SUPPORT

MNTRACTIVE

TESTECU

PA R T

NUMBER

BCM BCM

Power door lock system DOOR LOCK

Rear window defogger REAR DEFOGGER

Warning chime BUZZER

Room lamp timer INT LAMP

Headlamp HEAD LAMP

Wiper WIPER

Turn signal lamp

Hazard lampFLASHER

Intelligent Key system INTELLIGENT KEY

Combination switch COMB SW

IVIS IMMU

Room lamp battery saver BATTERY SAVER

Trunk lid TRUNK

Vehicle security system THEFT ALM

Retained power control RETAINED PWR

Oil pressure switch SIGNAL BUFFER

Panic system PANIC ALARM

Page 941 of 5621

BL-2Revision: 2006 January2006 M35/M45 CHANGE SETTINGS FUNCTION ....................... 60

INTELLIGENT KEY REGISTRATION .................. 60

STEERING LOCK UNIT REGISTRATION .......... 60

CAN Communication System Description .............. 60

CAN Communication Unit ....................................... 60

Schematic ............................................................... 61

Wiring Diagram — I/KEY— .................................... 63

Terminals and Reference Value for Intelligent Key

Unit ......................................................................... 74

Terminals and Reference Value for BCM ................ 77

Terminals and Reference Value for IPDM E/R ........ 77

Trouble Diagnosis Procedure ................................. 78

WORK FLOW ...................................................... 78

CONSULT-II Functions (INTELLIGENT KEY) ........ 80

CONSULT-II Inspection Procedure ......................... 80

BASIC OPERATION ............................................ 80

CONSULT-II Application Items ............................... 81

SELF-DIAGNOSTIC RESULTS ........................... 81

DATA MONITOR .................................................. 82

WORK SUPPORT ............................................... 83

ACTIVE TEST ..................................................... 84

Trouble Diagnosis Symptom Chart ......................... 86

ALL FUNCTIONS OF INTELLIGENT KEY SYS-

TEM DOES NOT OPERATE ............................... 86

DOOR LOCK/UNLOCK FUNCTION MALFUNC-

TION .................................................................... 86

REMOTE KEYLESS ENTRY FUNCTION MAL-

FUNCTION .......................................................... 87

TRUNK OPEN FUNCTION MALFUNCTION ...... 88

HAZARD AND BUZZER REMINDER FUNC-

TION MALFUNCTION ......................................... 89

HAZARD AND HORN REMINDER FUNCTION

MALFUNCTION ................................................... 89

POWER WINDOW DOWN FUNCTION MAL-

FUNCTION .......................................................... 90

WARNING FUNCTION MALFUNCTION ............. 90

Check CAN Communication System ...................... 92

Check Power Supply and Ground Circuit ............... 93

Check Key Slot ....................................................... 94

Check Door Switch ..............................................

... 96

Check Trunk Room Lamp Switch ........................... 99

Check Door Request Switch .................................101

Check Trunk Opener Request Switch ..................103

Check Unlock Sensor ...........................................105

Check Intelligent Key Warning Buzzer .................107

Check Outside Key Antenna (Driver Side and Pas-

senger Side) .........................................................108

Check Outside Key Antenna (Trunk Room) .........110

Check Inside Key Antenna ...................................112

Check Park Position Switch ..................................115

Check Ignition Switch Position .............................117

Check Remote Keyless Entry Receiver ................117

Check Trunk Lid Opener Cancel Switch ...............121

Check Key Slot Illumination ..................................123

Check Horn Function ............................................124

Check Combination Meter Display Function .........124

Check Warning Chime Function ...........................125

Removal and Installation of Intelligent Key Unit ...125

REMOVAL ........................................................

.125INSTALLATION ..................................................125

Intelligent Key Battery Replacement .....................126

DISASSEMBLY AND ASSEMBLY OF INTELLI-

GENT KEY .........................................................126

INTELLIGENT KEY BATTERY INSPECTION ...126

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION ..............................................................127

Component Parts and Harness Connector Location .127

System Description ...............................................128

PRECAUTIONS FOR INTELLIGENT KEY SYS-

TEM ...................................................................129

Operation Description ...........................................129

SYSTEM DIAGRAM ..........................................129

OPERATION WHEN INTELLIGENT KEY IS

CARRIED ...........................................................129

OPERATION WHEN KEY SLOT IS USED ........130

PUSH-BUTTON IGNITION SWITCH OPERA-

TION PROCEDURE ..........................................130

CAN Communication System Description ............131

CAN Communication Unit .....................................131

Schematic .............................................................132

Wiring Diagram —ENG/ST— ................................134

Terminals and Reference Value for Intelligent Key

Unit ........................................................................143

Terminals and Reference Value for Steering Lock

Unit ........................................................................146

Terminals and Reference Value for BCM ..............147

Terminals and Reference Value for IPDM E/R ......147

Terminals and Reference Value for PDU ..............148

Work Flow .............................................................149

CONSULT-II Functions (INTELLIGENT KEY) .......151

CONSULT-II Inspection Procedure .......................151

BASIC OPERATION ..........................................151

CONSULT-II Application Items ..............................152

SELF-DIAGNOSTIC RESULTS .........................152

DATA MONITOR ................................................153

WORK SUPPORT .............................................154

ACTIVE TEST ....................................................155

DTC B2013 STRG COMM 1 .................................157

DIAGNOSIS DESCRIPTION .............................157

TERMINALS AND REFERENCE VALUE FOR

INTELLIGENT KEY UNIT ..................................157

SELF-DIAGNOSTIC LOGIC ..............................157

DIAGNOSTIC PROCEDURE .............................157

DTC B2551 STEERING LOCK UNIT ....................159

DIAGNOSIS DESCRIPTION .............................159

TERMINALS AND REFERENCE VALUE ..........159

SELF-DIAGNOSTIC LOGIC .............................

.160

DIAGNOSTIC PROCEDURE .............................160

DTC B2552 INTELLIGENT KEY ...........................163

DIAGNOSIS DESCRIPTION .............................163

DTC B2553 IGN POWER CIRCUIT ......................163

DIAGNOSIS DESCRIPTION .............................163

TERMINAL AND REFERENCE VALUE FOR

INTELLIGENT KEY UNIT ..................................163

CONSULT-II DATA MONITOR STANDARD

VALUE ...............................................................163

SELF-DIAGNOSTIC LOGIC ..............................164

DIAGNOSTIC PROCEDURE .............................164

Page 963 of 5621

BL-24

POWER DOOR LOCK SYSTEM

Revision: 2006 January2006 M35/M45

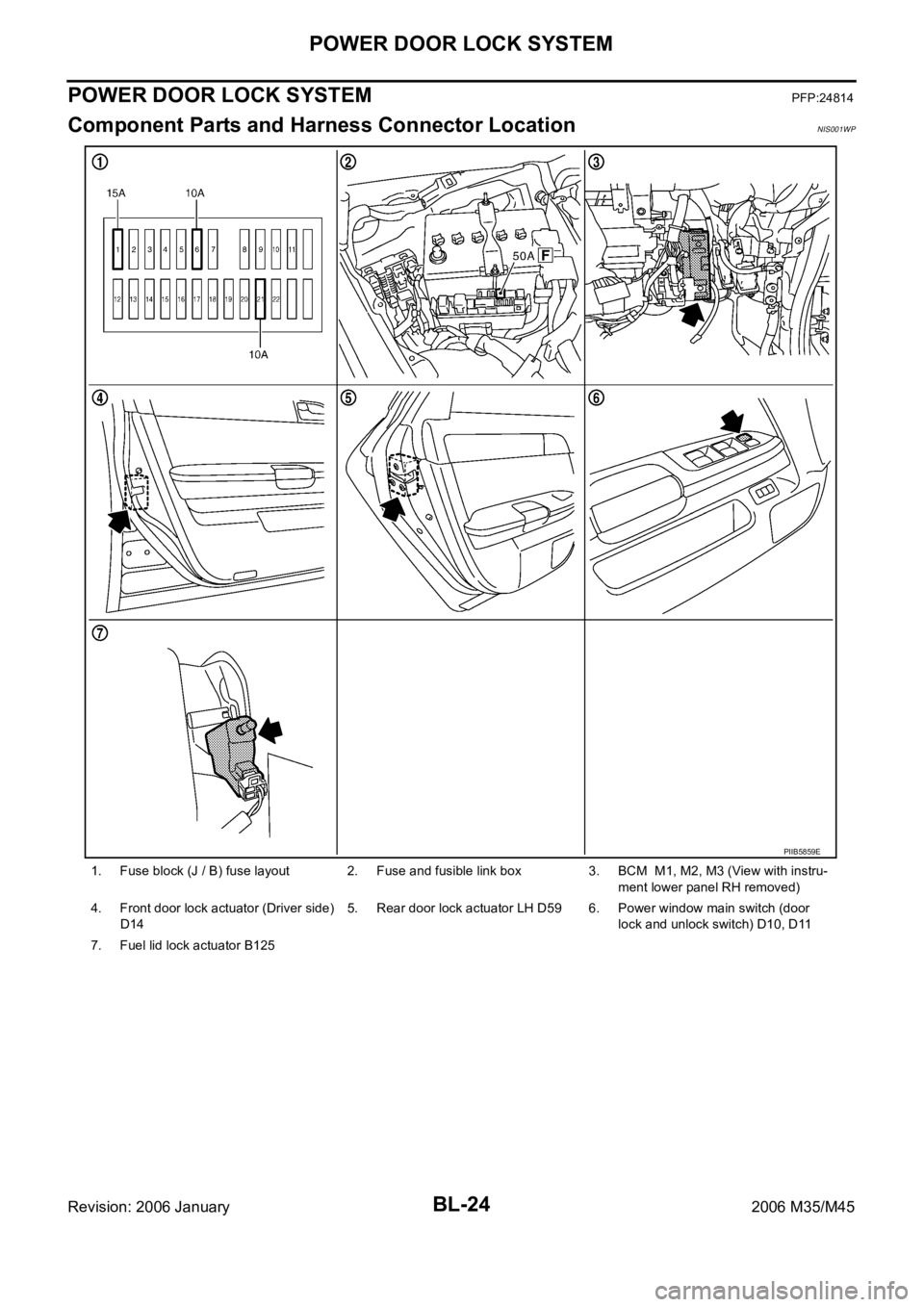

POWER DOOR LOCK SYSTEMPFP:24814

Component Parts and Harness Connector LocationNIS001WP

1. Fuse block (J / B) fuse layout 2. Fuse and fusible link box 3. BCM M1, M2, M3 (View with instru-

ment lower panel RH removed)

4. Front door lock actuator (Driver side)

D145. Rear door lock actuator LH D59 6. Power window main switch (door

lock and unlock switch) D10, D11

7. Fuel lid lock actuator B125

PIIB5859E

Page 964 of 5621

POWER DOOR LOCK SYSTEM

BL-25

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

System DescriptionNIS001WQ

Power is supplied at all times

through 50A fusible link (letter F , located in the fuse and fusible link box).

to BCM terminal 55,

through 10A fuse [No. 21, located in the fuse block (J/B)]

to BCM terminal 42.

When ignition switch is in ACC or ON position, power is supplied

through 10A fuse [No. 6, located in fuse block (J/B)]

to BCM terminal 11.

When ignition switch is in ON or START position, power is supplied

through 15A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38.

Ground is supplied

to BCM terminal 52

through body grounds M16 and M70.

When the door is locked or unlocked with power window main switch (door lock and unlock switch), ground is

supplied

to CPU of power window main switch

through power window main switch (door lock and unlock switch) terminal 17

through grounds M16 and M70.

Then power window main switch (door lock and unlock switch) operation signal is sent.

to BCM terminal 22

from power window main switch (door lock and unlock switch) terminal 14

When the door is locked or unlocked with power window sub-switch (front passenger side) (door lock and

unlock switch), ground is supplied

to CPU of power window sub-switch

through power window sub-switch (front passenger side) (door lock and unlock switch) terminal 11

through grounds M16 and M70.

Then power window sub-switch (front passenger side) (door lock and unlock switch) operation signal is sent

to BCM terminal 22

from power window sub-switch (front passenger side) (door lock and unlock switch) terminal 16.

When the door is locked with front door key cylinder switch (driver side), ground is supplied

to CPU of power window main switch

through power window main switch (door lock and unlock switch) terminal 4

through front door key cylinder switch (driver side) terminals 6 and 4

through grounds M16 and M70.

Then front door key cylinder switch (driver side) operation signal (lock) is sent

to BCM terminal 22

from power window main switch (door lock and unlock switch) terminal 14

When the door is unlocked with front door key cylinder switch (driver side), ground is supplied

to CPU of power window main switch

through power window main switch (door lock and unlock switch) terminal 6

through front door key cylinder switch (driver side) terminals 5 and 4

through grounds M16 and M70.

Then front door key cylinder switch (driver side) operation signal (unlock) is sent

to BCM terminal 22

from power window main switch (door lock and unlock switch) terminal 14

BCM is connected to power window main switch and power window sub-switch as serial link.

Page 970 of 5621

POWER DOOR LOCK SYSTEM

BL-31

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Terminals and Reference Value of BCMNIS001WV

Work FlowNIS001WW

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-25, "

System Description" .

3. According to the trouble diagnosis chart by symptom, repair or replace the cause of the malfunction.

Refer to BL-34, "

Trouble Diagnosis Chart by Symptom" .

4. Does power door lock system operate normally?

YES: GO TO 5.

NO: GO TO 3.

5. INSPECTION END

Termi-

nalWire

colorItem ConditionVoltage [V]

(Approx.)

11 V Ignition switch (ACC) Ignition switch is in ACC position Battery voltage

22 G Power window serial link Ignition switch ON

38 W Ignition switch (ON)Ignition switch is in ON or START posi-

tionBattery voltage

39 L CAN H — —

40 P CAN L — —

42 P Battery source (Fuse) — Battery voltage

44 GRDriver door lock actuator

(unlock) signalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

50 V Door lock actuator (lock) signalDoor lock / unlock switch

(Free

Lock)0 Battery voltage 0

51 GRear doors lock actuator and

fuel lid lock actuator (unlock) sig-

nalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

52 B Ground — 0

55 W Power source (Fusible link) — Battery voltage

70 GFront door lock actuator (pas-

senger side) lock signalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

PIIA2344J