check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 564 of 5621

TROUBLE DIAGNOSIS

ATC-117

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

DIAGNOSIS PROCEDURE FOR IN-VEHICLE SENSOR

SYMPTOM: In-vehicle sensor circuit is open or shorted. (22 or 22 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN IN-VEHICLE SENSOR AND GROUND

1. Disconnect in-vehicle sensor connector.

2. Turn ignition switch ON.

3. Check voltage between in-vehicle sensor harness connector

M54 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector

M54 terminal 2 and unified meter and A/C amp. harness con-

nector M65 terminal 60.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK IN-VEHICLE SENSOR

Refer to AT C - 11 8 , "

In-vehicle Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace in-vehicle sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

RJIA4094E

1 – Ground : Approx. 5 V

RJIA2022E

2 – 60 : Continuity should exist.

RJIA4095E

Page 565 of 5621

ATC-118

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

4. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector

M54 terminal 1 and unified meter and A/C amp. harness con-

nector M65 terminal 44.

4. Check continuity between in-vehicle sensor harness connector

M54 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

In-vehicle Sensor

After disconnecting in-vehicle sensor connector M54, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace in-vehicle sensor.1 – 44 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4096E

Temperature C (F) Resistance k

15 (5) 12.73

10 (14) 9.92

5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

RJIA4097E

Page 566 of 5621

TROUBLE DIAGNOSIS

ATC-119

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

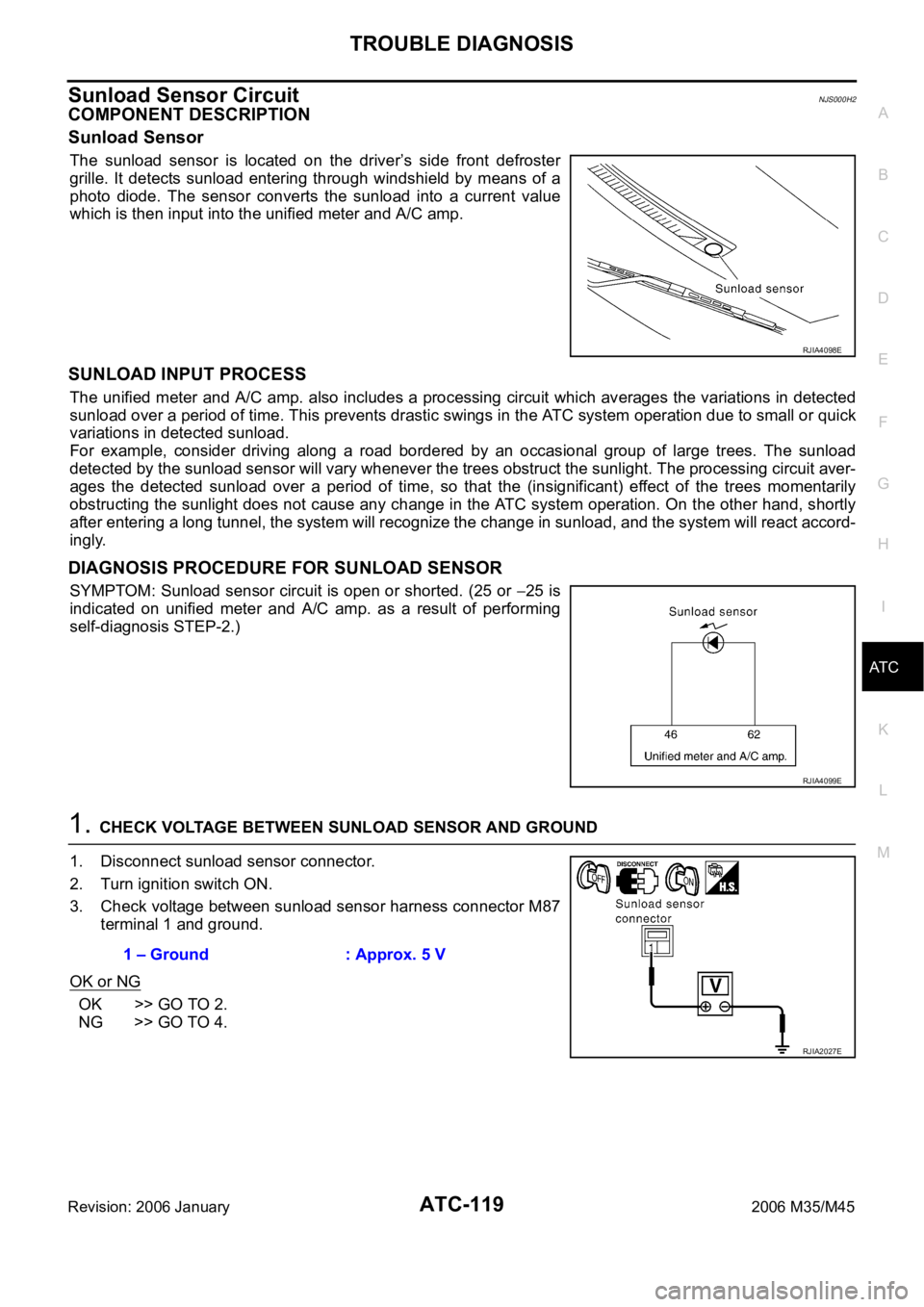

Sunload Sensor CircuitNJS000H2

COMPONENT DESCRIPTION

Sunload Sensor

The sunload sensor is located on the driver’s side front defroster

grille. It detects sunload entering through windshield by means of a

photo diode. The sensor converts the sunload into a current value

which is then input into the unified meter and A/C amp.

SUNLOAD INPUT PROCESS

The unified meter and A/C amp. also includes a processing circuit which averages the variations in detected

sunload over a period of time. This prevents drastic swings in the ATC system operation due to small or quick

variations in detected sunload.

For example, consider driving along a road bordered by an occasional group of large trees. The sunload

detected by the sunload sensor will vary whenever the trees obstruct the sunlight. The processing circuit aver-

ages the detected sunload over a period of time, so that the (insignificant) effect of the trees momentarily

obstructing the sunlight does not cause any change in the ATC system operation. On the other hand, shortly

after entering a long tunnel, the system will recognize the change in sunload, and the system will react accord-

ingly.

DIAGNOSIS PROCEDURE FOR SUNLOAD SENSOR

SYMPTOM: Sunload sensor circuit is open or shorted. (25 or 25 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN SUNLOAD SENSOR AND GROUND

1. Disconnect sunload sensor connector.

2. Turn ignition switch ON.

3. Check voltage between sunload sensor harness connector M87

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

RJIA4098E

RJIA4099E

1 – Ground : Approx. 5 V

RJIA2027E

Page 567 of 5621

ATC-120

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 2 and unified meter and A/C amp. harness con-

nector M65 terminal 62.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK SUNLOAD SENSOR

1. Reconnect sunload sensor connector and unified meter and A/C amp. connector.

2. Refer to ATC-121, "

Sunload Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace sunload sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 1 and unified meter and A/C amp. harness con-

nector M65 terminal 46.

4. Check continuity between sunload sensor harness connector

M87 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.2 – 62 : Continuity should exist.

RJIA4100E

1 – 46 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4101E

Page 568 of 5621

TROUBLE DIAGNOSIS

ATC-121

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

COMPONENT INSPECTION

Sunload Sensor

Measure voltage between unified meter and A/C amp. harness con-

nector M65 terminal 46 and ground.

When checking sunload sensor, select a place where sun shines directly on it.

If NG, replace sunload sensor.

RJIA4102E

SHA930E

Page 569 of 5621

ATC-122

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Intake Sensor CircuitNJS000H3

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit assembly. It

converts temperature of air after it passes through the evaporator

into a resistance value which is then input to the unified meter and A/

C amp.

DIAGNOSIS PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (24 or 24 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M82

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M82

terminal 2 and unified meter and A/C amp. harness connector

M65 terminal 59.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

RJIA4103E

RJIA4104E

1 – Ground : Approx. 5 V

RJIA4215E

2 – 59 : Continuity should exist.

RJIA4106E

Page 570 of 5621

TROUBLE DIAGNOSIS

ATC-123

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

3. CHECK INTAKE SENSOR

Refer to ATC-123, "

Intake Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace intake sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M82

terminal 1 and unified meter and A/C amp. harness connector

M65 terminal 43.

4. Check continuity between intake sensor harness connector M82

terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

Intake Sensor

After disconnecting intake sensor connector M82, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace intake sensor.1 – 43 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4105E

Temperature C (F) Resistance k

15 (5) 12.34

10 (14) 9.62

5 (23) 7.56

0 (32) 6.00

5 (41) 4.80

10 (50) 3.87

15 (59) 3.15

20 (68) 2.57

25 (77) 2.12

30 (86) 1.76

35 (95) 1.47

40 (104) 1.23

45 (113) 1.04

RJIA4107E

Page 576 of 5621

INTAKE SENSOR

ATC-129

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

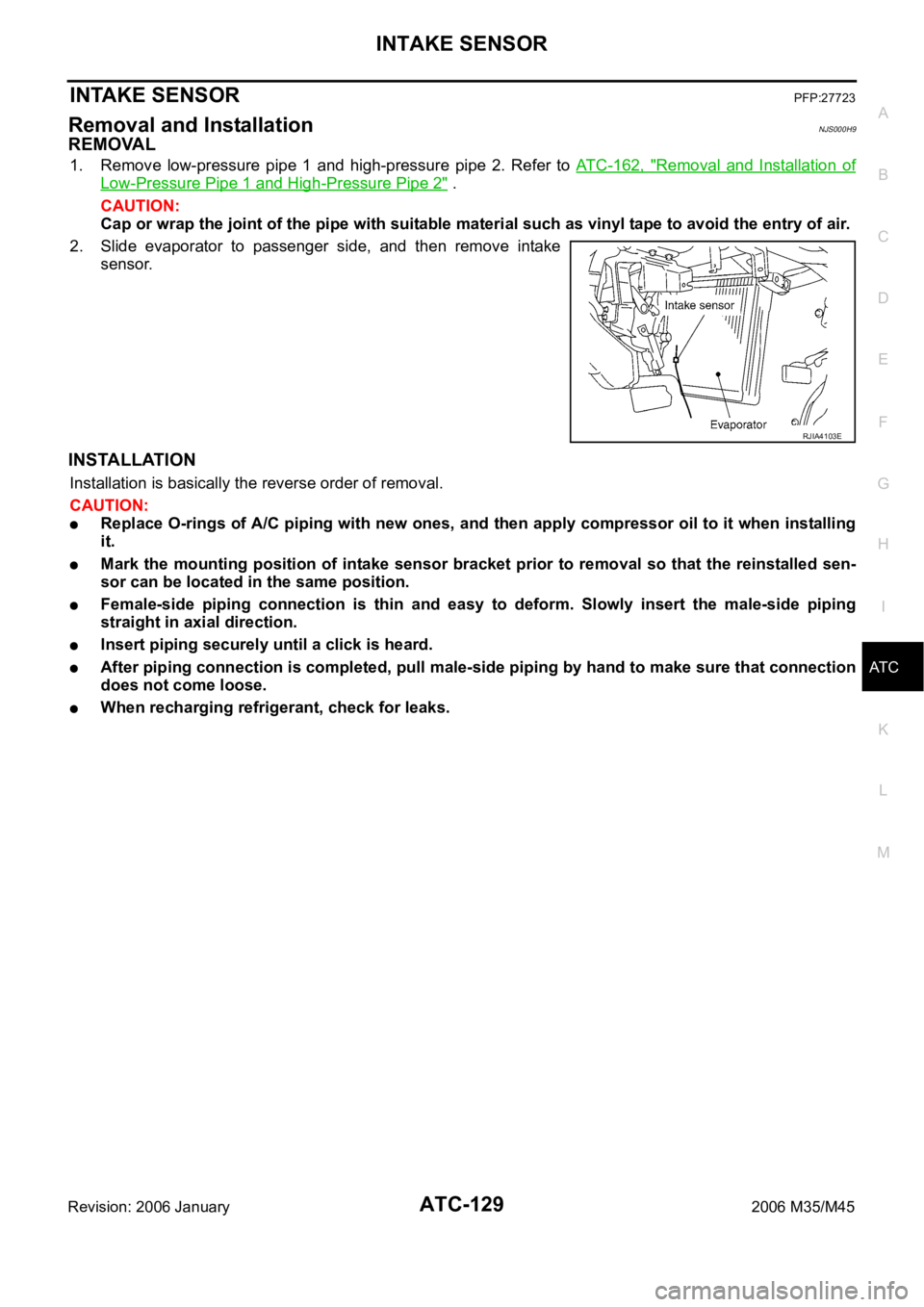

INTAKE SENSORPFP:27723

Removal and InstallationNJS000H9

REMOVAL

1. Remove low-pressure pipe 1 and high-pressure pipe 2. Refer to ATC-162, "Removal and Installation of

Low-Pressure Pipe 1 and High-Pressure Pipe 2" .

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

2. Slide evaporator to passenger side, and then remove intake

sensor.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of A/C piping with new ones, and then apply compressor oil to it when installing

it.

Mark the mounting position of intake sensor bracket prior to removal so that the reinstalled sen-

sor can be located in the same position.

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

RJIA4103E

Page 584 of 5621

HEATER & COOLING UNIT ASSEMBLY

ATC-137

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

CAUTION:

Replace O-rings of A/C piping with new ones, and then apply compressor oil to it when installing

it.

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

NOTE:

When filling radiator with coolant, refer to CO-11, "Changing Engine Coolant" (VQ35DE) or CO-40,

"Changing Engine Coolant" (VK45DE).

Recharge the refrigerant.

Heater & cooling unit assembly mounting bolt

: 6.9 Nꞏm (0.7 kg-m, 61 in-lb)

Instrument stay mounting nut and bolt

: 12 Nꞏm (1.25 kg-m, 9 ft-lb)

Page 599 of 5621

ATC-152

REFRIGERANT LINES

Revision: 2006 January2006 M35/M45

*1ATC-26, "LUBRICANT RETURN

OPERATION"

*2ATC-170, "Checking for Refrigerant

Leaks"

*3ATC-172, "CHECKING PROCE-

DURE"

*4ATC-101, "PERFORMANCE TEST

DIAGNOSIS"

*5AT C - 7 , "CONTAMINATED REFRIG-

ERANT"

SJIA1275E