ignition INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 60 of 5621

![INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diag INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diag](/img/42/57023/w960_57023-59.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

11 . CHECK HARNESS BETWEEN ICC SENSOR INTEGRATED UNIT AND ICC BRAKE HOLD RELAY

1. Turn ignition switch OFF.

2. Disconnect ICC sensor integrated unit connector and ICC brake hold relay.

3. Check continuity between ICC sensor integrated unit harness

connector (A) and ICC brake hold relay harness connector (B).

4. Check continuity between ICC sensor integrated unit harness

connector (A) and ground.

OK or NG

OK >> GO TO 12.

NG >> 1. Repair harness between ICC sensor integrated unit and ICC brake hold relay.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

12. CHECK ICC BRAKE HOLD RELAY GROUND CIRCUIT

Check continuity between ICC brake hold relay harness connector

and ground.

OK or NG

OK >> GO TO 13.

NG >> 1. Repair or replace harness between ICC brake hold

relay and ground.

2. Erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

AB

Continuity

Connector Terminal Connector Terminal

E61 2 E80 2 Yes

A

GroundContinuity

Connector Terminal

E61 2 No

PKIB9338E

ICC brake hold relay

connectorTerminal

GroundContinuity

E80 1 Yes

PKIB9341E

Page 61 of 5621

![INFINITI M35 2006 Factory Owners Manual ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated uni INFINITI M35 2006 Factory Owners Manual ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated uni](/img/42/57023/w960_57023-60.png)

ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated unit connector.

2. Turn ignition switch ON.

3. Perform “ACTIVE TEST” (“STOP LAMP”: “STP LMP DRIVE

ON”) with CONSULT-II, check voltage between ICC brake hold

relay harness connector and ground.

OK or NG

OK >> GO TO 14.

NG >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

14. CHECK ICC BRAKE HOLD RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between ICC brake hold relay harness connector

and ground.

OK or NG

OK >> GO TO 15.

NG >> 1. Repair or replace harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Terminals

ConditionVoltage

(Approx.) (+)

(–)

ICC brake hold

relay connectorTerminal

E80 2 GroundDuring

“ACTIVE TEST”12 V

PKIB9342E

Terminals

Voltage

(Approx.) (+)

(–)

ICC brake hold relay

connectorTe r m i n a l

E80 3 Ground Battery voltage

PKIB9343E

Page 62 of 5621

![INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

15. CHECK HARNESS BETWEEN ICC BRAKE HOLD RELAY AND ECM

1. Turn ignition switch OF INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

15. CHECK HARNESS BETWEEN ICC BRAKE HOLD RELAY AND ECM

1. Turn ignition switch OF](/img/42/57023/w960_57023-61.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-53

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

15. CHECK HARNESS BETWEEN ICC BRAKE HOLD RELAY AND ECM

1. Turn ignition switch OFF.

2. Disconnect ECM connector.

3. Check continuity between ICC brake hold relay harness connec-

tor (A) and ECM harness connector (B).

4. Check continuity between ICC brake hold relay harness connec-

tor (A) and ground.

OK or NG

OK >> GO TO 16.

NG >> 1. Repair harness between ICC brake hold relay and ECM.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

16. CHECK ICC BRAKE HOLD RELAY

With CONSULT-II

1. Connect ECM connector and ICC brake hold relay.

2. Disconnect stop lamp switch connector.

3. Perform “ACTIVE TEST” (“STOP LAMP”) with CONSULT-II, and make sure that stop lamp is illuminated.

OK or NG

OK >> GO TO 17.

NG >> 1. Replace ICC brake hold relay.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

17. CHECK STOP LAMP SWITCH WITH ABS DATA MONITOR

With CONSULT-II

With “ABS” “DATA MONITOR”, check if “STOP LAMP SW” are operates normally.

OK or NG

OK >> GO TO 18.

NG >> GO TO 20.

18. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE”self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 19.

AB

Continuity

Connector Terminal Connector Terminal

E80 5 M71 101 Yes

A

GroundContinuity

Connector Terminal

E80 5 No

PKIB9344E

Page 63 of 5621

![INFINITI M35 2006 Factory Owners Manual ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS� INFINITI M35 2006 Factory Owners Manual ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS�](/img/42/57023/w960_57023-62.png)

ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS” self-diagnosis. Refer to BRC-22, "

CONSULT-II Functions (ABS)" .

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

20. CHECK STOP LAMP SWITCH INSTALLATION AND ADJUSTMENT

Check stop lamp switch for proper installation, and adjust the switch if necessary. Refer to BR-6, "

BRAKE

PEDAL" .

OK or NG

OK >> GO TO 21.

NG >> 1. Adjust stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

21. CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to ACS-68, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 22.

NG >> 1. Replace stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

22. CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Turn ignition switch ON.

4. Check voltage between stop lamp switch harness connector and

ground.

OK or NG

OK >> GO TO 23.

NG >> 1. Repair or replace harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Te r m i n a l s

Voltage

(Approx.) (+)

(–)

Stop lamp switch

connectorTerminal

E124 3 Ground Battery voltage

PKIC0833E

Page 64 of 5621

![INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(C INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(C](/img/42/57023/w960_57023-63.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT)

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) connector.

3. Check continuity between stop lamp switch harness connector

(A) and ABS actuator and electric unit (control unit) harness

connector (B).

4. Check continuity between stop lamp switch harness connector

(A) and ground.

OK or NG

OK >> 1. Perform “ABS” self-diagnosis. Refer to BRC-22, "CONSULT-II Functions (ABS)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NG >> 1. Repair or replace harness between stop lamp switch and ABS actuator and electric unit (control

unit).

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 14 ECM CIRCUITNKS004D8

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “CAN COMM CIRCUIT [U1000]” (DTC 100) other than “ECM CIRCUIT [C1A14]” (DTC 14) is indi-

cated in self-diagnosis item in the display.

Is it indicated?

YES >> 1. CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

AB

Continuity

Connector Terminal Connector Terminal

E124 4 E30 30 Yes

A

GroundContinuity

Connector Terminal

E124 4 No

PKIC0834E

Page 71 of 5621

![INFINITI M35 2006 Factory Owners Manual ACS-62

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 1: MAIN Switch Does Not Turn ON*1 , MAIN Switch Does Not Turn

OFF

*2NKS004DK

NOTE:

*1: The MAIN switch indicator INFINITI M35 2006 Factory Owners Manual ACS-62

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 1: MAIN Switch Does Not Turn ON*1 , MAIN Switch Does Not Turn

OFF

*2NKS004DK

NOTE:

*1: The MAIN switch indicator](/img/42/57023/w960_57023-70.png)

ACS-62

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 1: MAIN Switch Does Not Turn ON*1 , MAIN Switch Does Not Turn

OFF

*2NKS004DK

NOTE:

*1: The MAIN switch indicator lamp in the combination meter does not illuminate.

*2: The MAIN switch indicator lamp in the combination meter remains powered.

1. CHECK MAIN SWITCH

With CONSULT-II

With “ICC” “DATA MONITOR”, check if “MAIN SW” and “CRUISE LAMP” operate normally.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK UNIFIED METER AND A/C AMP.

With CONSULT-II

With “METER A/C AMP” “DATA MONITOR”, check if “CRUISE IND” operates normally.

OK or NG

OK >> 1. Perform “METER A/C AMP”self-diagnosis. Refer toDI-18, "CONSULT-II Function (METER A/C

AMP)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NG >> GO TO 3.

3. CHECK CONNECTOR ICC SENSOR INTEGRATED UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC sensor integrated unit connector, and connect it securely again.

3. Check if the malfunction is improved.

Is it improved?

YES >> Poor connector connection

1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-

minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 4.

4. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

With CONSULT-II

1. Perform self-diagnosis.

2. Check if “DTC 100 CAN COMM CIRCUIT” is indicated.

Is it indicated?

YES >> CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

NO >> ICC steering switch inspection. Refer to ACS-47, "

DTC 6 OPERATION SW CIRC" .

Page 86 of 5621

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NCS001JC

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for On Board Diagnostic (OBD) System of A/T and EngineNCS001JD

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative termi-

nal before any repair or inspection work. The open/short circuit of related switches, sensors, sole-

noid valves, etc. will cause the MIL to light up.

Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Page 87 of 5621

AT-8

PRECAUTIONS

Revision: 2006 January2006 M35/M45

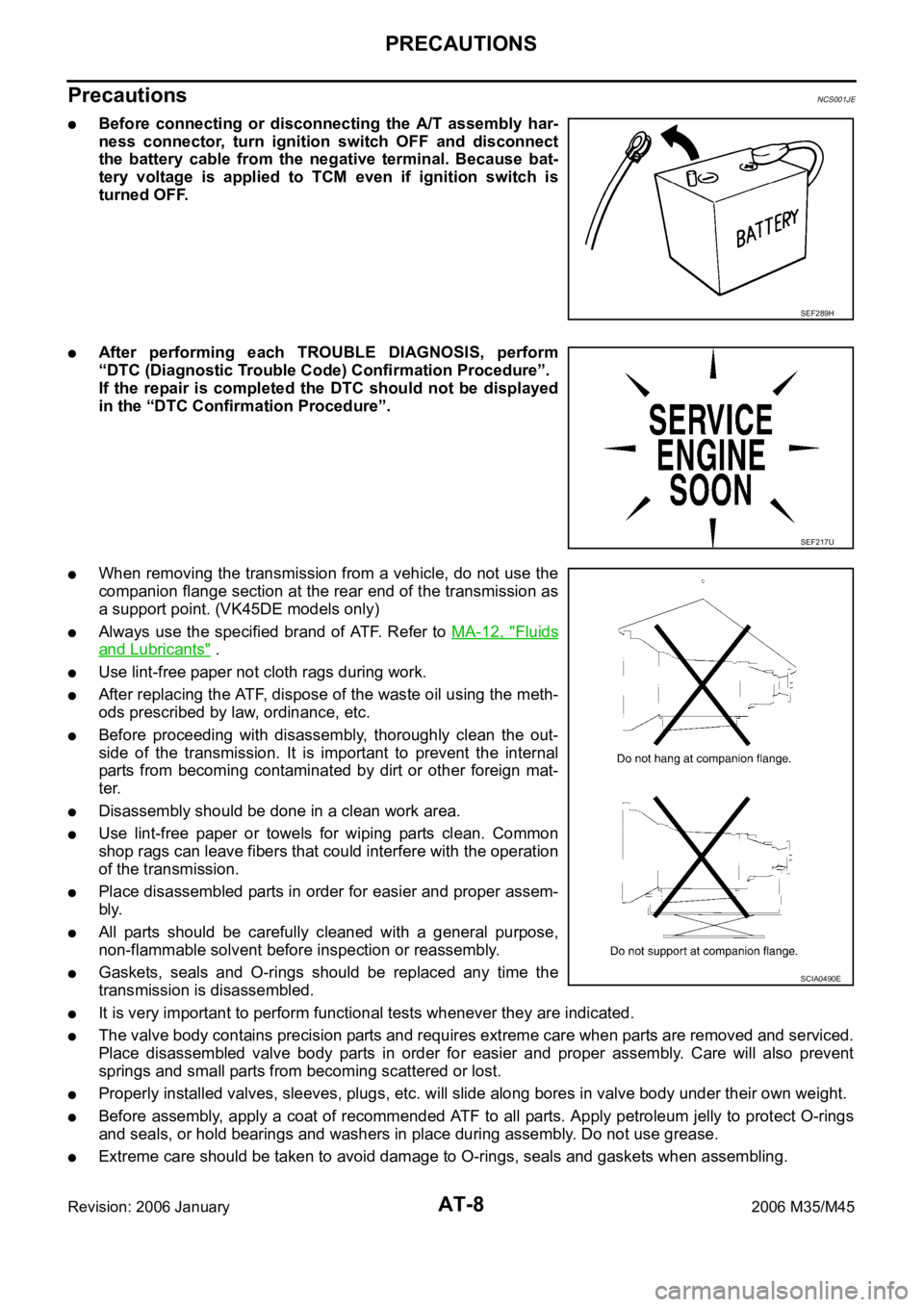

Precautions NCS001JE

Before connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch OFF and disconnect

the battery cable from the negative terminal. Because bat-

tery voltage is applied to TCM even if ignition switch is

turned OFF.

After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) Confirmation Procedure”.

If the repair is completed the DTC should not be displayed

in the “DTC Confirmation Procedure”.

When removing the transmission from a vehicle, do not use the

companion flange section at the rear end of the transmission as

a support point. (VK45DE models only)

Always use the specified brand of ATF. Refer to MA-12, "Fluids

and Lubricants" .

Use lint-free paper not cloth rags during work.

After replacing the ATF, dispose of the waste oil using the meth-

ods prescribed by law, ordinance, etc.

Before proceeding with disassembly, thoroughly clean the out-

side of the transmission. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign mat-

ter.

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transmission.

Place disassembled parts in order for easier and proper assem-

bly.

All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

Gaskets, seals and O-rings should be replaced any time the

transmission is disassembled.

It is very important to perform functional tests whenever they are indicated.

The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

SEF289H

SEF217U

SCIA0490E

Page 121 of 5621

AT-42

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-55, "

Emission-Related Diagnostic Information" (for VQ35DE

engine), EC-765, "

Emission-Related Diagnostic Information" (for VK45DE engine).

Diagnostic trouble codes (DTC)

1st trip diagnostic trouble codes (1st trip DTC)

Freeze frame data

1st trip freeze frame data

System readiness test (SRT) codes

Te s t v a l u e s

HOW TO ERASE DTC (WITH CONSULT-II)

If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-II ON and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

SCIA5671E

Page 122 of 5621

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-43

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with GST (Generic Scan Tool). For details, refer to EC-146, "

Generic Scan Tool (GST)

Function" (for VQ35DE engine), EC-859, "Generic Scan Tool (GST) Function" (for VK45DE engine).

HOW TO ERASE DTC (NO TOOLS)

The A/T CHECK indicator lamp is located on the instrument panel.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-67, "

How to Erase DTC"

(for VQ35DE engine), EC-778, "How to Erase DTC" (for VK45DE engine).

Malfunction Indicator Lamp (MIL)NCS001K1

DESCRIPTION

The MIL is located on the combination meters.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "WARNING LAMPS" ,

or see EC-722, "

MIL AND DATA LINK CONNECTOR" (for

VQ35DE engine), EC-1459, "

MIL AND DATA LINK CONNEC-

TOR" (for VK45DE engine).

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U