Motor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5116 of 5621

![INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NO INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NO](/img/42/57023/w960_57023-5115.png)

PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NOTE:

Refer to SB-3, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK IGNITION POWER SUPPLY CIRCUIT

1. Disconnect pre-crash seat belt control unit connector.

2. Turn ignition switch ON.

3. Check voltage between pre-crash seat belt control unit harness

connector and ground.

OK or NG

OK >> Ignition power supply circuit is OK.

NG >> Check pre-crash seat belt control unit ignition power supply circuit harness.

Motor Power Supply and Ground Circuit Check [B2454]NHS0008A

1. CHECK FUSE

Check 30A fusible link (letter G , located in the fuse and fusible link box).

NOTE:

Refer to SB-3, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

Terminal

Voltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B142 13 Ground Battery voltage

PHIA1126E

Page 5117 of 5621

SB-18

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

2. CHECK MOTOR POWER SUPPLY CIRCUIT 1

With CONSULT-II

Select “SELF-DIAG RESULTS” and then make sure the “MOTOR

PWR SUP CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 3.

Displayed B2454?

Yes >> GO TO 3.

No >> Motor power supply system is normal.

3. CHECK MOTOR POWER SUPPLY CIRCUIT 2

1. Disconnect pre-crash seat belt control unit connector.

2. Check voltage between pre-crash seat belt control unit harness

connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK PRE-CRASH SEAT BELT CONTROL UNIT GROUND CIRCUIT

1. Disconnect pre-crash seat belt control unit connector.

2. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> Motor power supply and ground circuit is OK.

NG >> Repair or replace harness.

CONSULT-II display CONSULT-II display code

NO DTC –

MOTOR PWR SUP CIRC B2454

PHIA0770E

Terminal

Voltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B142 2 Ground Battery voltage

PHIA1127E

Terminal

Continuity Pre-crash seat

belt control unit

connectorTerminal

Ground

B1425

Ye s

26

PHIA1128E

Page 5124 of 5621

PRE-CRASH SEAT BELT

SB-25

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

5. CHECK BRAKE PEDAL STROKE SENSOR

Check continuity between brake pedal stroke sensor while perform-

ing brake operation.

OK or NG

OK >> Check harness connection.

If it is OK, replace pre-crash seat belt control unit.

If it is NG, repair or replace malfunction part.

NG >> Replace brake pedal stroke sensor.

Pre-Crash Seat Belt Motor LH Circuit Check [B2452]NHS0008E

1. CHECK LH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

Select “SELF-DIAG RESULTS” of CONSULT-II, and then make sure

that “SB MOTOR LH CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2452?

Ye s > > G O T O 2 .

No >> Pre-crash seat belt motor LH circuit is OK.

Brake pedal stroke

sensor connectorTerminal ConditionResistance

(K)

(Approx.)

E125 21

Brake released

depressed1.0 0.2

30.2

1.0

PHIA1137E

CONSULT-II display CONSULT-II display code

NO DTC –

SB MOTOR LH CIRC B2452

PHIA0768E

Page 5125 of 5621

SB-26

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

2. CHECK LH SEAT BELT MOTOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect pre-crash seat belt control unit connector and pre-crash seat belt motor LH connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and pre-crash seat belt motor LH harness con-

nector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3. CHECK SEAT BELT MOTOR

Check continuity between pre-crash seat belt motor LH.

OK or NG

OK >> Replace pre-crash seat belt control unit.

NG >> Replace pre-crash seat belt motor LH.

AB

Continuity Pre-crash seat

belt control unit

connectorTe r m i n a lPre-crash seat

belt motor LH

connectorTerminal

B1424

B321

Ye s

62

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B1424

No

6

PHIA1138E

Pre-crash seat belt

motor LH connectorTerminal Continuity

B32 1 2 Yes

PHIA1139E

Page 5126 of 5621

![INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

S INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

S](/img/42/57023/w960_57023-5125.png)

PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

Select SELF-DIAG RESULTS” of CONSULT-II, and then make sure

that “SB MOTOR RH CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2451?

Ye s > > G O T O 2 .

No >> Pre-crash seat belt motor RH circuit is OK.

2. CHECK RH SEAT BELT MOTOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect pre-crash seat belt control unit connector and pre-crash seat belt motor RH connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and pre-crash seat belt motor RH harness con-

nector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

CONSULT-II display CONSULT-II display code

NO DTC –

SB MOTOR RH CIRC B2451

PHIA0767E

AB

Continuity Pre-crash seat

belt control unit

connectorTerminalPre-crash seat

belt motor RH

connectorTerminal

B1421

B82

Ye s

3 1

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B1421

No

3

PHIA1140E

Page 5127 of 5621

SB-28

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

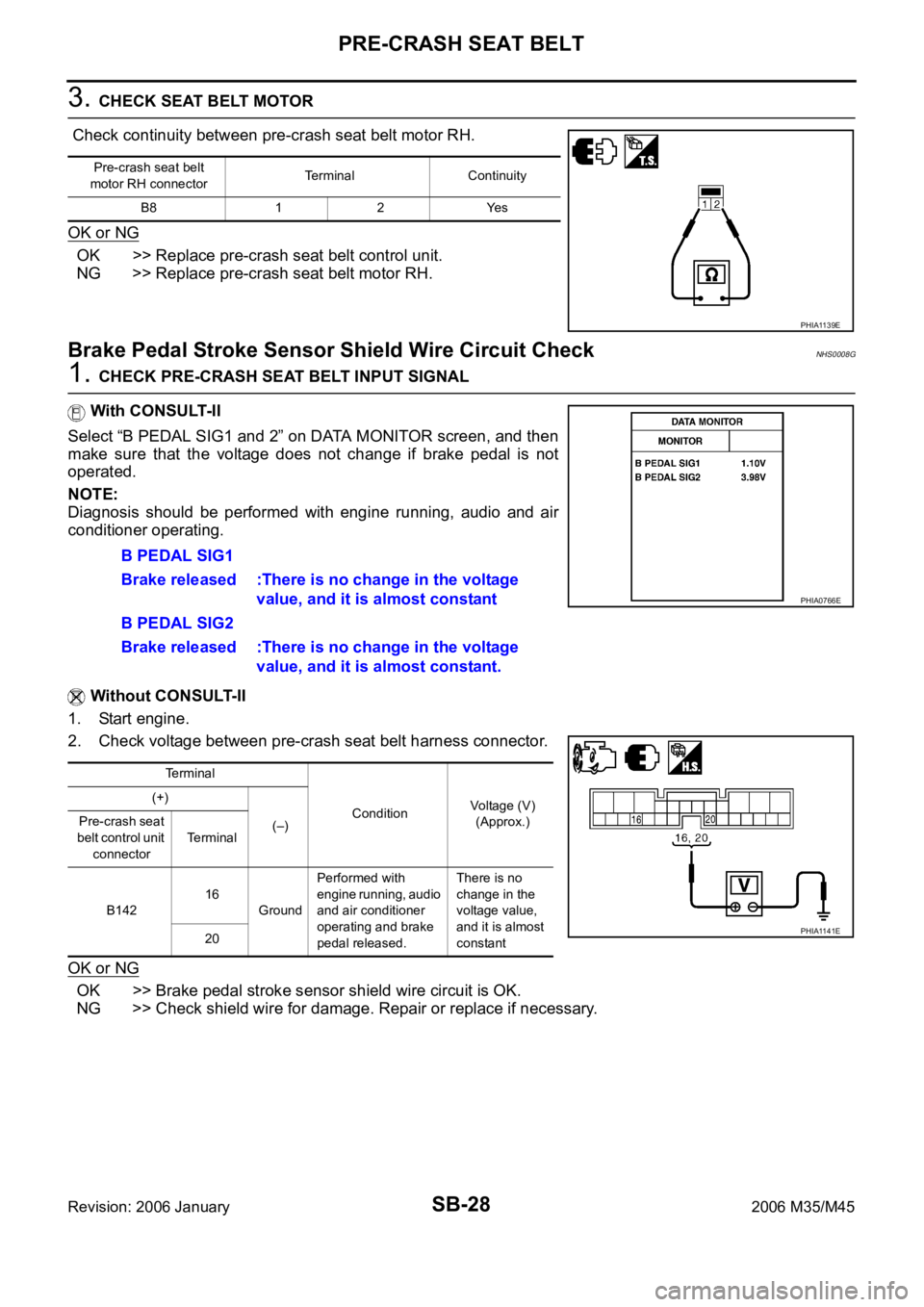

3. CHECK SEAT BELT MOTOR

Check continuity between pre-crash seat belt motor RH.

OK or NG

OK >> Replace pre-crash seat belt control unit.

NG >> Replace pre-crash seat belt motor RH.

Brake Pedal Stroke Sensor Shield Wire Circuit CheckNHS0008G

1. CHECK PRE-CRASH SEAT BELT INPUT SIGNAL

With CONSULT-II

Select “B PEDAL SIG1 and 2” on DATA MONITOR screen, and then

make sure that the voltage does not change if brake pedal is not

operated.

NOTE:

Diagnosis should be performed with engine running, audio and air

conditioner operating.

Without CONSULT-II

1. Start engine.

2. Check voltage between pre-crash seat belt harness connector.

OK or NG

OK >> Brake pedal stroke sensor shield wire circuit is OK.

NG >> Check shield wire for damage. Repair or replace if necessary.

Pre-crash seat belt

motor RH connectorTerminal Continuity

B8 1 2 Yes

PHIA1139E

B PEDAL SIG1

Brake released :There is no change in the voltage

value, and it is almost constant

B PEDAL SIG2

Brake released :There is no change in the voltage

value, and it is almost constant.

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B14216

GroundPerformed with

engine running, audio

and air conditioner

operating and brake

pedal released.There is no

change in the

voltage value,

and it is almost

constant 20

PHIA0766E

PHIA1141E

Page 5147 of 5621

SC-10

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

STARTING SYSTEM PFP:00011

System Description NKS003NI

Power is supplied at all times

through 15A fuse (No. 78, located in the IPDM E/R)

to CPU of IPDM E/R,

through 15A fuse (No. 71, located in the IPDM E/R)

to CPU of IPDM E/R.

Ground is supplied

to IPDM E/R terminals 38 and 51

from grounds E22 and E43.

When the selector lever in the P or N position, power is supplied

from TCM, and through A/T assembly terminal 9

to IPDM E/R terminal 53.

And then provided that IPDM E/R receives a starter relay ON signal with CAN communication, starter relay is

energized.

With the ignition switch in the START position, power is supplied

through IPDM E/R terminal 3

to starter motor terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

Page 5152 of 5621

STARTING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

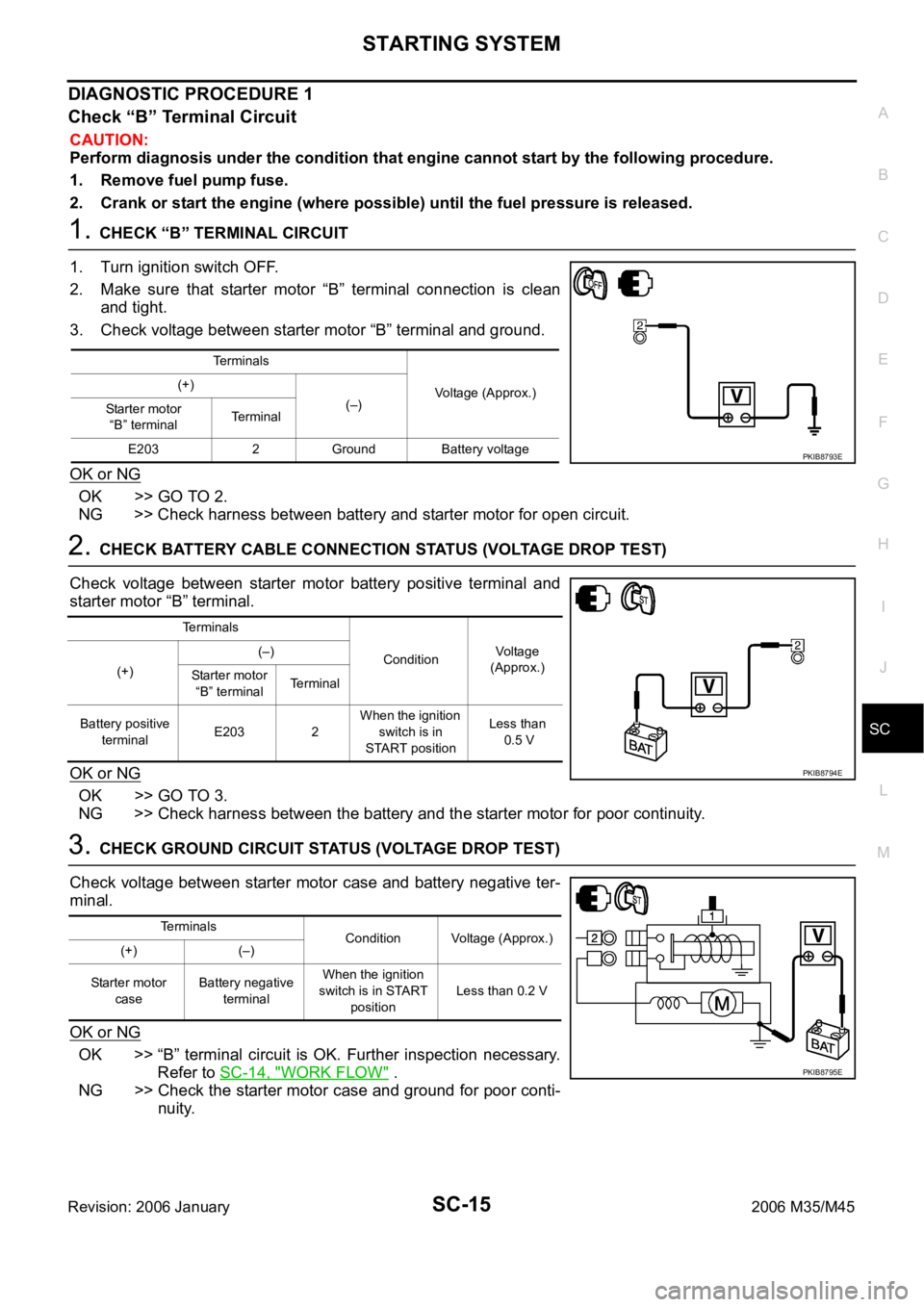

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Make sure that starter motor “B” terminal connection is clean

and tight.

3. Check voltage between starter motor “B” terminal and ground.

OK or NG

OK >> GO TO 2.

NG >> Check harness between battery and starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor battery positive terminal and

starter motor “B” terminal.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3. CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal.

OK or NG

OK >> “B” terminal circuit is OK. Further inspection necessary.

Refer to SC-14, "

WORK FLOW" .

NG >> Check the starter motor case and ground for poor conti-

nuity.

Terminals

Voltage (Approx.) (+)

(–)

Starter motor

“B” terminalTerminal

E203 2 Ground Battery voltage

PKIB8793E

Terminals

ConditionVoltage

(Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive

terminalE203 2 When the ignition

switch is in

START positionLess than

0.5 V

PKIB8794E

Terminals

Condition Voltage (Approx.)

(+) (–)

Starter motor

caseBattery negative

terminalWhen the ignition

switch is in START

positionLess than 0.2 V

PKIB8795E

Page 5153 of 5621

SC-16

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

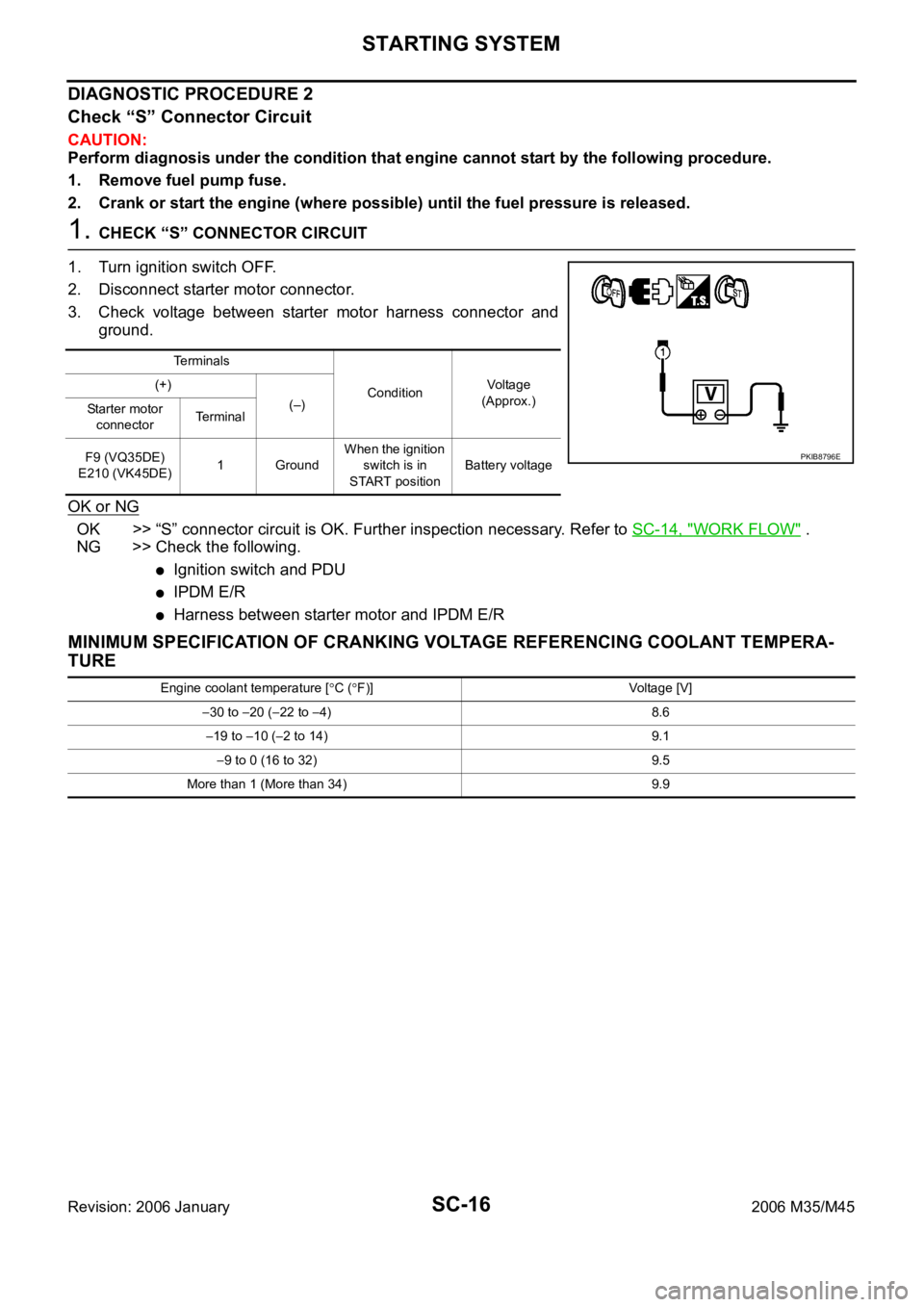

DIAGNOSTIC PROCEDURE 2

Check “S” Connector Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Check voltage between starter motor harness connector and

ground.

OK or NG

OK >> “S” connector circuit is OK. Further inspection necessary. Refer to SC-14, "WORK FLOW" .

NG >> Check the following.

Ignition switch and PDU

IPDM E/R

Harness between starter motor and IPDM E/R

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Te r m i n a l s

ConditionVoltage

(Approx.) (+)

(–)

Starter motor

connectorTe r m i n a l

F9 (VQ35DE)

E210 (VK45DE)1 GroundWhen the ignition

switch is in

START positionBattery voltage

PKIB8796E

Engine coolant temperature [C (F)] Voltage [V]

30 to 20 (22 to 4) 8.6

19 to 10 (2 to 14) 9.1

9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Page 5154 of 5621

STARTING SYSTEM

SC-17

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

Removal and Installation NKS003NL

VQ35DE ENGINE MODELS (2WD)

Removal

1. Disconnect the battery cable from the negative terminal.

2. Remove engine front and rear undercover, using power tools.

3. Remove “B” terminal nut (1).

4. Disconnect “S” connector (2).

5. Remove starter motor mounting bolts (A), using power tools.

6. Remove starter motor downward from the vehicle.

Installation

Installation is the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1. Starter motor mounting bolt 2. Harness clip bracket 3. “S” connector

4. “B” terminal nut 5. “B” terminal harness 6. Starter motor

7. Oil pan : Nꞏm (kg-m, ft-lb) : Nꞏm (kg-m, in-lb)

: Engine front

PKIB8799E

PKIB8800E