Motor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5155 of 5621

SC-18

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

VQ35DE ENGINE MODELS (AWD)

Removal

1. Disconnect the battery cable from the negative terminal.

2. Remove engine rear undercover, using power tools.

3. Remove exhaust mounting bracket. Refer to EM-183, "

EXHAUST MANIFOLD AND THREE WAY CATA-

LY S T" .

4. Remove “B” terminal nut (1).

5. Disconnect “S” connector (1).

6. Remove starter motor mounting bolts (A) and harness bracket

(2), using power tools.

7. Remove starter motor downward from the vehicle.

Installation

Installation is the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1. Starter motor mounting bolt 2. Oil pan 3. Starter motor

4. “B” terminal harness 5. “B” terminal nut 6. “S” connector

: Nꞏm (kg-m, ft-lb) : Engine front

PKIB8801E

PKIB8802E

PKIB8803E

Page 5156 of 5621

STARTING SYSTEM

SC-19

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

VK45DE ENGINE MODELS

Removal

1. Disconnect the battery cable from the negative terminal.

2. Remove engine front and rear undercover, using power tools.

3. Remove left engine mounting insulator and left engine mounting

bracket. Refer to EM-244, "

ENGINE ASSEMBLY" .

4. Remove “B” terminal nut (1).

5. Disconnect “S” connector (2).

6. Remove the bolt (A) and the harness bracket (3).

7. Remove starter motor mounting bolts (B), using power tools.

8. Remove starter motor forward from the vehicle.

Installation

Installation is the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1. Starter motor 2. Starter motor mounting bolt 3. “S” connector

4. “B” terminal harness 5. “B” terminal nut 6. Cylinder block

: Nꞏm (kg-m, ft-lb) : Engine front

PKIB8797E

PKIB8798E

Page 5182 of 5621

SE-1

SEAT

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION SE

A

B

SE

Revision: 2006 January2006 M35/M45

SEAT

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Service Notice .......................................................... 3

Precautions for Work ...........................................

..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

AUTOMATIC DRIVE POSITIONER ...........................11

Component Parts And Harness Connector Location

.... 11

System Description ................................................ 12

MANUAL OPERATION ....................................... 12

MEMORY OPERATION ...................................... 12

EXITING OPERATION ........................................ 14

ENTRY OPERATION .......................................... 14

INTELLIGENT KEY INTERLOCK OPERATION ... 15

FAIL-SAFE MODE .............................................. 15

INITIALIZATION PROCEDURE .......................... 16

SETTING CHANGE FUNCTION ......................... 16

CAN Communication System Description .............. 16CAN Communication Unit ....................................... 16

Schematic ............................................................... 17

Wiring Diagram—AUT/DP— .................................. 19

Terminals and Reference Values for BCM .............. 30

Terminals and Reference Value for Intelligent Key

Unit ......................................................................... 30

Terminals and Reference Values for Driver Seat

Control Unit ............................................................. 31

Terminals and Reference Values for Automatic

Drive Positioner Control Unit .................................. 33

CONSULT-II Function (AUTO DRIVE POS.) .......... 35

CONSULT-II INSPECTION PROCEDURE .......... 35

SELF-DIAGNOSIS RESULTS ............................. 36

DATA MONITOR ................................................. 37

ACTIVE TEST ..................................................... 38

WORK SUPPORT ............................................... 38

Work Flow ............................................................... 39

Symptom Chart ....................................................... 39

CAN Communication Inspection Using CONSULT-

II (Self-Diagnosis) ................................................... 41

BCM Power Supply and Ground Circuit Check ...... 41

Driver Seat Control Unit Power Supply and Ground

Circuit Check .......................................................... 42

Automatic Drive Positioner Power Supply and

Ground Circuit Check ............................................. 43

Sliding Motor Circuit Check .................................... 44

Reclining Motor LH Circuit Check ........................... 45

Front Lifting Motor Circuit Check ............................ 46

Rear Lifting Motor Circuit Check ............................. 48

Telescopic Motor Circuit Check .............................. 49

Tilt Motor Circuit Check .......................................

... 50

Sliding Sensor Circuit Check .................................. 52

Reclining Sensor Circuit Check .............................. 54

Front Lifting Sensor Circuit Check .......................... 56

Rear Lifting Sensor Circuit Check .......................... 58

Telescopic Sensor Circuit Check ............................ 60

Tilt Sensor Circuit Check ........................................ 62

Door Mirror Sensor LH Circuit Check ..................... 63

Door Mirror Sensor RH Circuit Check .................... 66

Sliding Switch Circuit Check ................................... 68

Page 5183 of 5621

SE-2Revision: 2006 January2006 M35/M45 Reclining Switch Circuit Check ............................... 70

Lifting Switch (Front) Circuit Check ........................ 72

Lifting Switch (Rear) Circuit Check ......................... 74

Power Seat Switch Ground Circuit Check .............. 75

Telescopic Switch Circuit Check ............................. 76

Tilt Switch Circuit Check ......................................

... 78

Seat Memory and Set Switch Circuit Check ........... 80

Seat Memory Indicator Lamp Circuit Check ........... 81

Door Mirror Sensor Power Supply and Ground Cir-

cuit Check ............................................................... 83

A/T Device (Detention Switch) Circuit Check ......... 85

Front Door Switch (Driver Side) Circuit Check ....... 86

UART Communication Line Circuit Check .............. 87

Lumber Support Circuit Check ............................... 89

POWER SEAT(PASSENGER SIDE) ......................... 91

Component Parts and Harness Connector Location ... 91

Wiring Diagram—SEAT—/Passenger Side ............ 92

Terminals and Reference Values for BCM .............. 94

POWER SEAT(REAR) .............................................. 95

Component Parts and Harness Connector Location ... 95

System Description ................................................. 95

REAR POWER SEAT LH AND RH OPERATION ... 95

REAR SEAT RETREAT FUNCTION ................... 96

Schematic ............................................................... 97

Wiring Diagram—R/SEAT— ................................... 98

Terminals and Reference Values for Rear Seat Con-

trol Unit .................................................................102

Work Flow .............................................................103

Trouble Diagnoses Symptom Chart ......................103

Rear Power Seat Power Supply Circuit Inspection .103

Rear Seat Control Unit Power Supply and Ground

Circuit Inspection ..................................................104

Rear Seat Sliding Motor Circuit Inspection ...........105

Rear Power Seat Switch Circuit Inspection ..........106

Automatic Return Cancel Switch Circuit Inspection .108

Automatic Return Cancel Switch Inspection .........109

Rear Door Switch Circuit Inspection .....................110

Rear Seat Sliding Sensor Circuit Inspection ..........111

CLIMATE CONTROLLED SEAT .............................113

Component Parts and Harness Connector Location .113

System Description ...............................................113

Schematic .............................................................117

Wiring Diagram—C/SEAT— .................................118

Terminal and Reference Value for Climate Con-

trolled Seat Control Unit ......................................

.123

Work Flow .............................................................124

Preliminary Check ................................................124

Trouble Diagnoses Symptom Chart .....................

.125

Climate Controlled Seat Control Unit Power Supply

Circuit Check ........................................................126

Climate Controlled Seat Control Unit Power Supply

and Ground Circuit Inspection ..............................127

Climate Controlled Seat Switch Power Supply Cir-cuit Inspection .......................................................130

Climate Controlled Seat Switch Circuit Inspection .131

Climate Controlled Seat Switch Indicator Circuit

Inspection ..............................................................133

Seat Cushion Thermal Electric Device Circuit

Inspection ..............................................................135

Seatback Thermal Electric Device Circuit Inspec-

tion ........................................................................136

Seat Cushion Thermal Electric Device Sensor Cir-

cuit Inspection .......................................................137

Seatback Thermal Electric Device Sensor Circuit

Inspection ..............................................................139

Climate Controlled Seat Blower Motor Circuit

Inspection ..............................................................140

Climate Controlled Seat Control Unit Inspection ...142

HEATED SEAT ........................................................143

Component Parts and Harness Connector Location .143

System Description ...............................................143

Schematic .............................................................145

Wiring Diagram —HSEAT— .................................146

Terminals and Reference Values for Rear Seat Con-

trol Unit ..................................................................151

Work Flow .............................................................151

Trouble Diagnoses Symptom Chart ......................151

Rear Heated Seat Power Supply and Ground Circuit

Inspection ..............................................................152

Rear Seat Control Unit Power Supply and Ground

Circuit Inspection ..................................................153

Rear Heated Seat Switch Circuit Inspection .........155

Rear Heated Seat Indicator Power Supply Circuit

Inspection ..............................................................157

Rear Heated Seat Indicator Circuit Inspection ......158

Rear Heated Seat Circuit Inspection .....................160

Rear Seatback Heater Circuit Inspection ..............161

FRONT SEAT ..........................................................163

Driver's Seat Components ....................................163

Passenger's Seat Components .............................165

Removal and Installation .......................................167

REMOVAL ..........................................................167

INSTALLATION ..................................................167

Disassembly and Assembly ..................................168

SEATBACK ........................................................168

SEAT CUSHION ................................................169

CLIMATE CONTROLLED SEAT ........................171

REAR SEAT .............................................................172

Bench Seat Components ......................................172

Power Seat (Split Type) Components ...................174Removal and Installation .......................................176

BENCH SEAT ....................................................176

POWER SEAT ...................................................176

Disassembly and Assembly ..................................177

BENCH SEAT ....................................................177

POWER SEAT ...................................................179

Page 5192 of 5621

AUTOMATIC DRIVE POSITIONER

SE-11

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

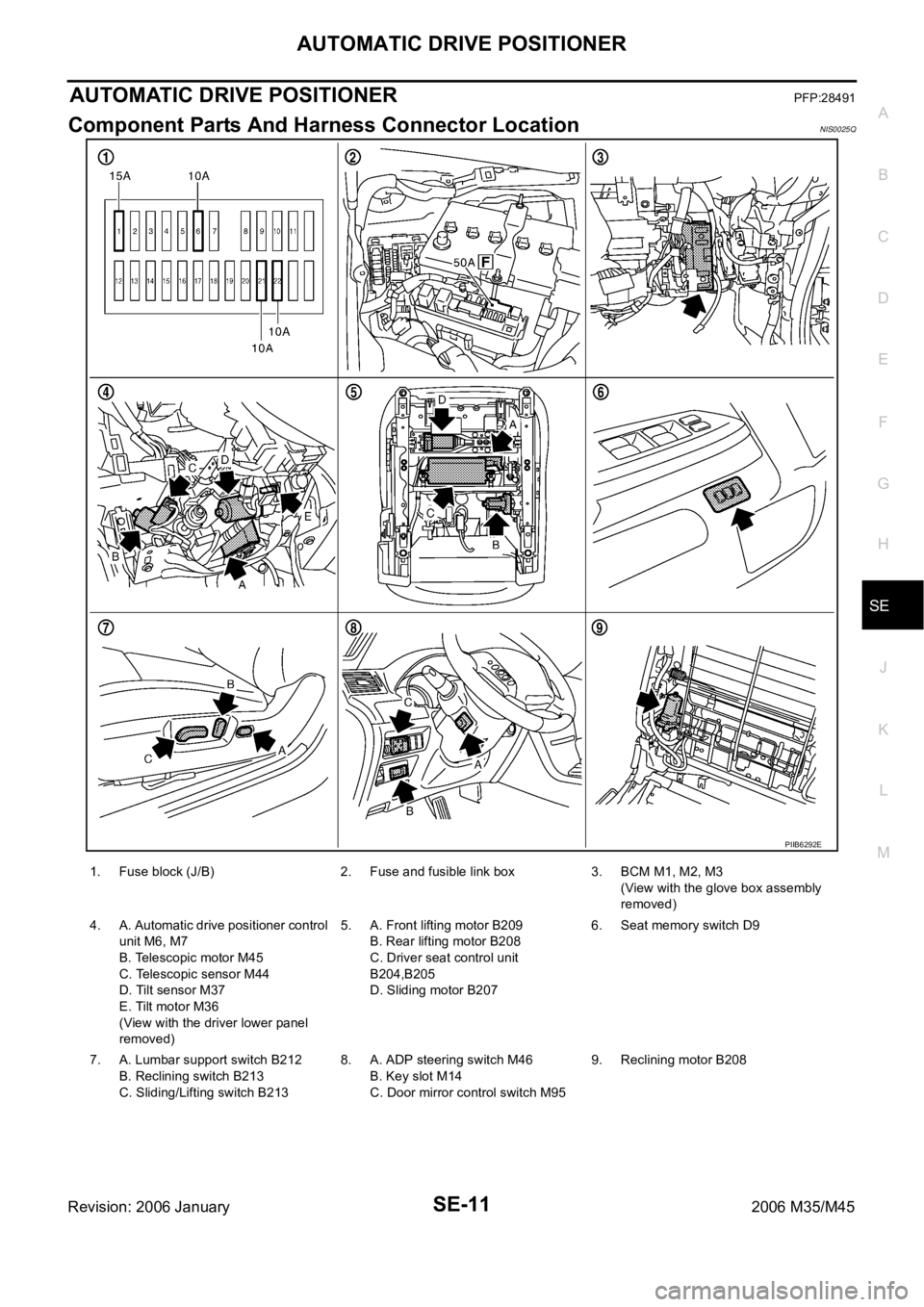

AUTOMATIC DRIVE POSITIONERPFP:28491

Component Parts And Harness Connector LocationNIS0025Q

PIIB6292E

1. Fuse block (J/B) 2. Fuse and fusible link box 3. BCM M1, M2, M3

(View with the glove box assembly

removed)

4. A. Automatic drive positioner control

unit M6, M7

B. Telescopic motor M45

C. Telescopic sensor M44

D. Tilt sensor M37

E. Tilt motor M36

(View with the driver lower panel

removed)5. A. Front lifting motor B209

B. Rear lifting motor B208

C. Driver seat control unit

B204,B205

D. Sliding motor B2076. Seat memory switch D9

7. A. Lumbar support switch B212

B. Reclining switch B213

C. Sliding/Lifting switch B2138. A. ADP steering switch M46

B. Key slot M14

C. Door mirror control switch M959. Reclining motor B208

Page 5212 of 5621

AUTOMATIC DRIVE POSITIONER

SE-31

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for Driver Seat Control UnitNIS0025Y

Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

1 P/L UART LINE (RX) Tilt switch operated

3BR/WCAN-H — —

9 W/R Reclining sensor signalON (seat reclining motor operation)

Other than above 0 or 5

10 W/G Rear lifting sensor signalON (rear lifting motor operation)

Other than above 0 or 5

11 R/W Sliding switch backward signalON (seat sliding switch backward

operation)0

Other than above Battery voltage

12 G/W Reclining switch backward signalON (seat reclining switch backward

operation)0

Other than above Battery voltage

13 Y/W Front lifting switch DOWN signalON (front lifting switch DOWN opera-

tion)0

Other than above Battery voltage

14 L/W Rear lifting switch DOWN signalON (rear lifting switch DOWN opera-

tion)0

Other than above Battery voltage

17 P/B UART LINE (TX) Tilt switch operated

19 G/O CAN-L — —

21 G/R Detention switch signalA/T selector lever is in P position. 0

A/T selector lever is in other than P

position.Battery voltage

SKIA0175E

PIIB2807E

PIIB2809E

SKIA0175E

Page 5213 of 5621

SE-32

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

24 W Seat sliding sensor signalON (seat sliding motor operation)

Other than above 0 or 5

25 W/Y Front lifting sensor signalON (front lifting motor operation)

Other than above 0 or 5

26 R/B Seat sliding switch forward signalON (seat sliding switch forward oper-

ation)0

Other than above Battery voltage

27 G/BSeat reclining switch forward sig-

nalON (seat reclining switch forward

operation)0

Other than above Battery voltage

28 Y/B Front lifting switch UP signalON (front lifting switch UP operation) 0

Other than above Battery voltage

29 L/B Rear lifting switch UP signalON (rear lifting switch UP operation) 0

Other than above Battery voltage

31 B/W Sensor ground — 0

32 W/B Ground (signal) — 0

33 W Power source (C/B) — Battery voltage

35 R/WSliding motor forward output sig-

nalSliding switch forward operation

(Motor operated)Battery voltage

Other than above 0

36 G/WReclining motor forward output

signalReclining switch forward operation

(Motor operated)Battery voltage

Other than above 0

37 Y/WFront lifting motor DOWN output

signalFront lifting switch down operation

(Motor operated)Battery voltage

Other than above 0

38 L/BRear lifting motor UP output sig-

nalRear lifting switch up operation (Motor

operated)Battery voltage

Other than above 0

39 L/WRear lifting motor DOWN output

signalRear lifting switch down operation

(Motor operated)Battery voltage

Other than above 0

40 R/B Power source (Fuse) — Battery voltage

42 R/BSliding motor backward output

signalSliding switch backward operation

(Motor operated)Battery voltage

Other than above 0 Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

SIIA0690J

SIIA0691J

Page 5214 of 5621

AUTOMATIC DRIVE POSITIONER

SE-33

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for Automatic Drive Positioner Control UnitNIS0025Z

44 G/BReclining motor backward output

signalReclining switch backward operation

(Motor operated)Battery voltage

Other than above 0

45 Y/BFront lifting motor UP output sig-

nalFront lifting switch upward operation

(Motor operated)Battery voltage

Other than above 0

48 B Ground (power) — 0 Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

Te r m i -

nal Wire

colorItem ConditionVoltage (V)

(Approx)

1 Y Tilt switch UP signalTilt switch is UP operation 0

Other than above 5

5L/RMirror sensor (RH vertical)

signalWhen mirror motor RH is UP or DOWN

operationChanges between 4.2 (close to perk)

0.5 (close to valley)

6LGMirror sensor (LH vertical)

signalWhen mirror motor LH is UP or DOWN

operationChanges between 4.2 (close to perk)

0.5 (close to valley)

7 L Tilt sensor signalTilt position : Top 1

Tilt position : Bottom 3.8

9 LG Memory switch 1 signalMemory switch 1 ON 0

Other than above 5

10 O UART LINE (TX) Tilt switch operated

11 RTelescopic switch forward

signalWhen telescopic switch is forward oper-

ation0

Other than above 5

12 R/GMemory switch indictor 1 sig-

nalWhen illuminate indictor 1 1

Other than above Battery voltage

13 PMemory switch indictor 2 sig-

nalWhen illuminate indictor 2 1

Other than above Battery voltage

14 L Mirror motor RH UP signalWhen mirror motor RH UP operation Battery voltage

Other than above 0

15 G Mirror motor RH LEFT signalWhen mirror motor RH LEFT operation Battery voltage

Other than above 0

16 W/LMirror motor LH DOWN sig-

nalWhen mirror motor LH DOWN opera-

tionBattery voltage

Other than above 0

Mirror motor LH RIGHT sig-

nalWhen mirror motor LH RIGHT opera-

tionBattery voltage

Other than above 0

17 LG Tilt switch DOWN signalWhen tilt switch is DOWN position 0

Other than above 5

SKIA0175E

Page 5215 of 5621

SE-34

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

21 SBMirror sensor (RH horizon-

tal) signalWhen mirror motor RH is LEFT or

RIGHT operationChanges between 3.5 (close to left

edge) 0.5 (close to right edge)

22 O/LMirror sensor (LH horizontal)

signalWhen mirror motor LH is LEFT or

RIGHT operationChanges between 0.5 (close to left

edge) 3.5 (close to right edge)

23 GR Telescopic sensor inputTelescopic position : Top 4.6

Telescopic position : Bottom 0.4

24 BR/W Set switch signalSet switch ON 0

Other than above 5

25 LG/B Memory switch 2 signalMemory switch 2 ON 0

Other than above 5

26 P UART LINE (RX) Tilt switch is operated

27 WTelescopic switch backward

signalTelescopic switch turned to backward 0

Other than above 5

30 GRMirror motor RH DOWN sig-

nalWhen mirror motor RH DOWN opera-

tionBattery voltage

Other than above 0

Mirror motor RH RIGTH sig-

nalWhen mirror motor RH RIGHT opera-

tionBattery voltage

Other than above 0

31 BR Mirror motor LH UP signalWhen mirror motor LH UP operation Battery voltage

Other than above 0

32 V Mirror motor LH LEFT signalWhen mirror motor LH LEFT operation Battery voltage

Other than above 0

33 W Sensor power supply — 5

34 R Power source (Fuse) — Battery voltage

35 LG Tilt motor UP signalTilt switch is UP operation Battery voltage

Other than above 0

36 PTelescopic motor forward sig-

nalTelescopic switch is forward operation Battery voltage

Other than above 0

39 L Power source (C/B) — Battery voltage

40 B Ground — 0

41 Y Sensor ground — 0

42 G Tilt motor DOWN signalTilt switch is DOWN operation Battery voltage

Other than above 0

44 GTelescopic motor backward

signalTelescopic switch is backward opera-

tionBattery voltage

Other than above 0

48 B Ground — 0 Termi-

nal Wire

colorItem ConditionVoltage (V)

(Approx)

SKIA0175E

Page 5217 of 5621

SE-36

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

6. Select diagnosis mode.

“DATA MONITOR”, “ACTIVE TEST”, “SELF-DIAG RESULTS“,

“ECU PART NUMBER”, “CAN DIAG SUPPORT MNTR” and

“WORK SUPPORT” are available.

SELF-DIAGNOSIS RESULTS

HOW TO READ SELF-DIAG RESULTS

NOTE:

CAN communication malfunction and detention switch malfunction are displayed on “TIME”. (1)

–If error is detected in the present, “CRNT” is displayed.

–If error is detected in the past (present error is not detected), “PAST” is displayed.

–If error has never been detected, nothing is displayed on “TIME”.

Any items other than CAN communication malfunction and detention switch malfunction are counted. (2)

–If error is detected, error detection frequency is displayed from “1” to “127” on “TIME”.

–If error has never been detected, nothing is displayed on “TIME”.

–Can clear the detected memory.

Normal: Clear memory in normal condition, history is erased and nothing is displayed on “TIME”.

Error: Clear memory in error condition, error is detected again and “1” is displayed on “TIME”.

DISPLAY ITEM LIST

BCIA0031E

CONSULT-II display Item Malfunction is detected when...Reference

page

CAN COMM CIRC

[U1000]CAN communication Malfunction is detected in CAN communication.SE-41

SEAT SLIDE

[B2112]Seat slide motorWhen any manual and automatic operations are not performed, if

any motor operations of seat slide is detected for 0.1 second or

more, status is judged “Output error”.SE-44

SE-52

SEAT RECLINING

[B2113]Seat reclining motorWhen any manual and automatic operations are not performed, if

any motor operations of seat reclining is detected for 0.1 second or

more, status is judged “Output error”.SE-45

SE-54

PIIB6449E