ECU INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4430 of 5621

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45 OUTLINE ...........................................................136

AFS OPERATION .............................................137

HEADLAMP AUTO AIMING OPERATION ........139

CAN COMMUNICATION SYSTEM DESCRIP-

TION ..................................................................139

CAN COMMUNICATION UNIT .........................139

Component Parts Description ..............................140

AFS CONTROL UNIT .......................................140

SWIVEL ACTUATOR ........................................140

AIMING MOTOR ...............................................140

AFS SWITCH ....................................................141

HEIGHT SENSOR ............................................141

STEERING ANGLE SENSOR ..........................141

IPDM E/R ..........................................................141

ECM ..................................................................141

TCM ..................................................................141

UNIFIED METER AND A/C AMP. .....................141

COMBINATION METER ...................................141

Schematic ............................................................142

Wiring Diagram — AFS — ...................................143

Terminals and Reference Values for AFS Control

Unit .......................................................................149

How to Proceed with Trouble Diagnosis ..............151

Preliminary Check ................................................151

CONSULT-II Function (ADAPTIVE LIGHT) ..........152

CONSULT-II BASIC OPERATION .....................152

WORK SUPPORT (STEERING ANGLE SEN-

SOR ADJUSTMENT) ........................................153

WORK SUPPORT (LEVELIZER ADJUSTMENT)

.153

SELF-DIAG RESULTS ......................................154

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................160

Symptom Chart ....................................................161

DTC B2503 SWIVEL ACTUATOR RH .................162

DTC B2504 SWIVEL ACTUATOR LH ..................168

DTC B2514 HI SEN UNUSUAL RR .....................174

DTC B2521 ECU CIRC ........................................178

AFS Operation Check (Function Test) .................181

Auto Aiming Operation Check (Function Test) .....183

AFS Switch Does Not Operate .............................185

Auto Aiming Does Not Operate (Check Aiming

Motor System Circuit) ..........................................

.187

AFS OFF Indicator Does Not Operate .................190

Removal and Installation of Steering Angle Sensor .190

Removal and Installation of Front Combination

Lamp ....................................................................190

Removal and Installation of AFS Control Unit ......191

REMOVAL ........................................................

.191

INSTALLATION .................................................191

Removal and Installation of AFS Switch ..............191

REMOVAL ........................................................

.191

INSTALLATION .................................................191

Removal and Installation of Height Sensor ..........192

REMOVAL ........................................................

.192

INSTALLATION .................................................192

FRONT FOG LAMP ................................................193

Component Parts and Harness Connector Location .193

System Description ..............................................193OUTLINE ...........................................................194

COMBINATION SWITCH READING FUNCTION .195

EXTERIOR LAMP BATTERY SAVER CONTROL .195

CAN Communication System Description ............195

CAN Communication Unit .....................................195

Schematic .............................................................196

Wiring Diagram — F/FOG — ................................197

Terminals and Reference Values for BCM ............201

Terminals and Reference Values for IPDM E/R ....202

How to Perform Trouble Diagnoses .....................202

Preliminary Check ................................................202

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................202

CONSULT-II Functions (BCM) ..............................203

CONSULT-II Functions (IPDM E/R) ......................203

Front Fog Lamps Do Not Illuminate (Both Sides) . 204

Front Fog Lamp Does Not Illuminate (One Side) . 207

Front Fog Lamps Do Not Turn OFF ......................208

Aiming Adjustment ................................................209

Bulb Replacement ................................................210

Removal and Installation ......................................210

REMOVAL ........................................................

.210

INSTALLATION .................................................210

TURN SIGNAL AND HAZARD WARNING LAMPS .211

Component Parts and Harness Connector Location .211

System Description ...............................................211

TURN SIGNAL OPERATION ............................211

HAZARD LAMP OPERATION ...........................212

COMBINATION SWITCH READING FUNCTION .213

CAN Communication System Description ............213

CAN Communication Unit .....................................213

Schematic .............................................................214

Wiring Diagram — TURN — .................................215

Terminals and Reference Values for BCM ............219

How to Perform Trouble Diagnoses .....................220

Preliminary Check ................................................221

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................221

CONSULT-II Functions (BCM) ..............................223

CONSULT-II BASIC OPERATION .....................223

DATA MONITOR ...............................................224

ACTIVE TEST ...................................................224

Turn Signal Lamp Does Not Operate ...................225

H a z a r d W a r n i n g L a m p D o e s N o t O p e r a t e B u t T u r n

Signal Lamp Operate ............................................227

Turn Signal Indicator Lamp Does Not Operate ....228

Bulb Replacement/Removal and Installation of Side

Turn Signal Lamp .................................................229

REMOVAL ........................................................

.229

INSTALLATION .................................................229

Bulb Replacement (Front Turn Signal Lamp) .......229

Bulb Replacement (Rear Turn Signal Lamp) ........229

Removal and Installation of Front Turn Signal Lamp .229

Removal and Installation of Rear Turn Signal Lamp .229

LIGHTING AND TURN SIGNAL SWITCH ..............230

Removal and Installation ......................................230

REMOVAL ........................................................

.230

INSTALLATION .................................................230

Switch Circuit Inspection ......................................230

Page 4467 of 5621

LT-40

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

HEADLAMP (OUTER) LOW BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove fender protector (front). Refer to EI-20, "

Removal and Installation" .

4. Turn plastic cap counterclockwise and unlock it.

5. Unlock retaining spring and remove bulb from headlamp.

6. Remove the socket connected the bulb.

PARKING LAMP (CLEARANCE) LAMP

1. Turn bulb socket counterclockwise and unlock it.

2. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Remove washer tank inlet when replaced bulb RH. Refer to WW-47, "Removal and Installation of Washer

Ta n k" .

Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from its socket.

FRONT SIDE MARKER LAMP

1. Remove fender protector (front) to obtain work space between the fender protector and fender.

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from its socket.

CAUTION:

After installing bulb, be sure to install plastic cap and socket securely to insure watertightness. Headlamp (outer) low beam : 12V - 55W (H1)

Parking lamp (Clearance lamps) : 12V - 5W

Front turn signal lamp : 12V - 21W

Front side marker lamp : 12V - 5W

Page 4469 of 5621

LT-42

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

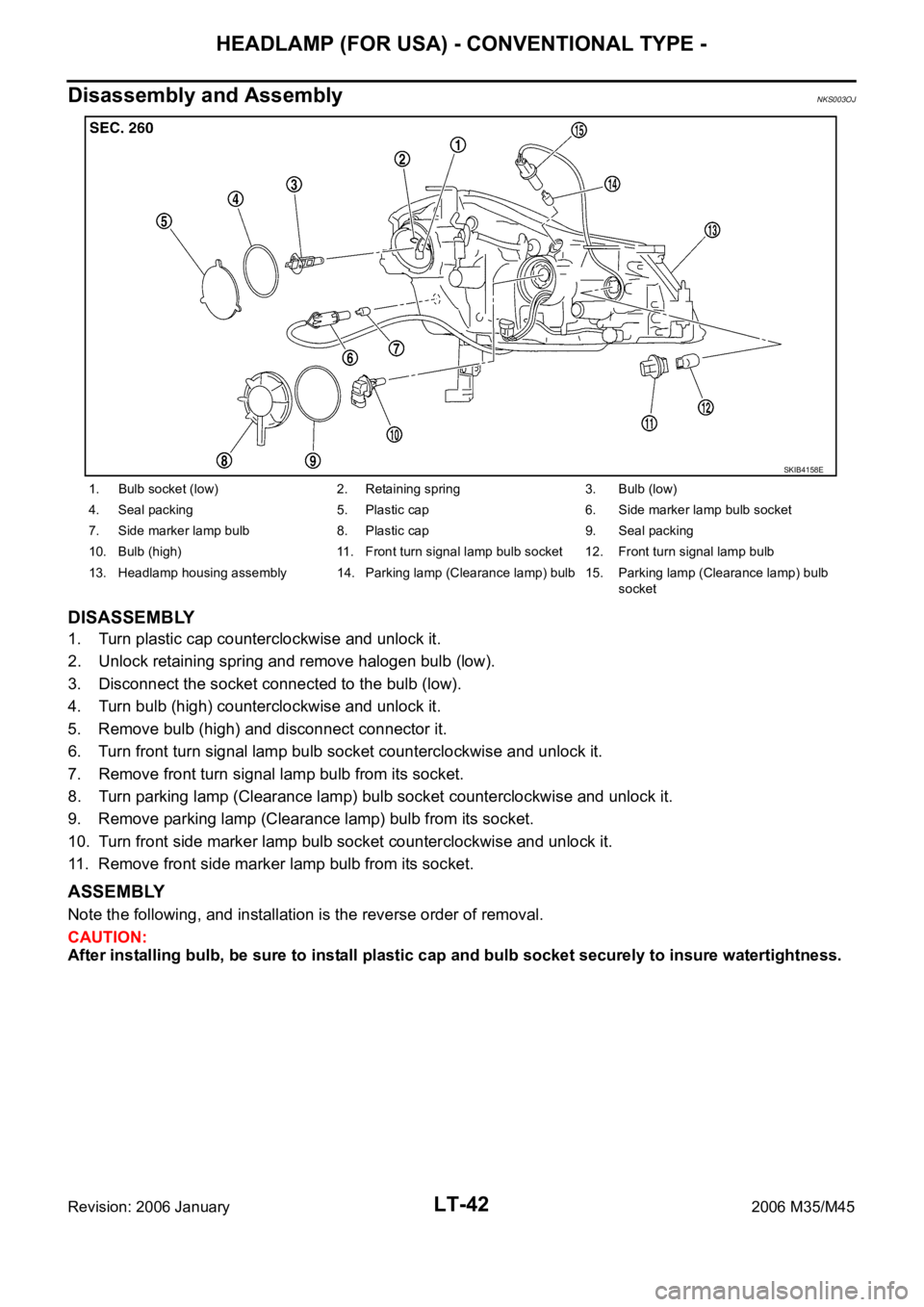

Disassembly and AssemblyNKS003OJ

DISASSEMBLY

1. Turn plastic cap counterclockwise and unlock it.

2. Unlock retaining spring and remove halogen bulb (low).

3. Disconnect the socket connected to the bulb (low).

4. Turn bulb (high) counterclockwise and unlock it.

5. Remove bulb (high) and disconnect connector it.

6. Turn front turn signal lamp bulb socket counterclockwise and unlock it.

7. Remove front turn signal lamp bulb from its socket.

8. Turn parking lamp (Clearance lamp) bulb socket counterclockwise and unlock it.

9. Remove parking lamp (Clearance lamp) bulb from its socket.

10. Turn front side marker lamp bulb socket counterclockwise and unlock it.

11. Remove front side marker lamp bulb from its socket.

ASSEMBLY

Note the following, and installation is the reverse order of removal.

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to insure watertightness.

1. Bulb socket (low) 2. Retaining spring 3. Bulb (low)

4. Seal packing 5. Plastic cap 6. Side marker lamp bulb socket

7. Side marker lamp bulb 8. Plastic cap 9. Seal packing

10. Bulb (high) 11. Front turn signal lamp bulb socket 12. Front turn signal lamp bulb

13. Headlamp housing assembly 14. Parking lamp (Clearance lamp) bulb 15. Parking lamp (Clearance lamp) bulb

socket

SKIB4158E

Page 4503 of 5621

LT-76

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

HEADLAMP (OUTER) LOW BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove fender protector (front). Refer toEI-20, "

Removal and Installation" .

4. Turn plastic cap counterclockwise and unlock it.

5. Turn bulb socket (1) counterclockwise and unlock it.

6. Unlock retaining spring and remove bulb from headlamp.

PARKING LAMP (CLEARANCE LAMP)

1. Turn bulb socket counterclockwise and unlock it.

2. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Remove washer tank inlet when replacing bulb RH. Refer to WW-47, "Removal and Installation of Washer

Ta n k" .

2. Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from its socket.

FRONT SIDE MARKER LAMP

1. Turn off the fender protector (front) to obtain work space between the fender protector and fender.

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from its socket.

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to insure watertight-

ness.

Removal and InstallationNKS003P7

Refer to LT-41, "Removal and Installation" .

NOTE:

After installation, perform aiming adjustment. Refer to LT- 7 4 , "

Aiming Adjustment" . Headlamp (outer) low beam : 12V - 35W (D2S)

SKIB4154E

Parking lamp (Clearance lamp) : 12V - 5W

Front turn signal lamp : 12V - 21W

Front side marker lamp : 12V - 5W

Page 4505 of 5621

LT-78

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

ASSEMBLY

Note the following, and installation is the reverse order of removal.

CAUTION:

When HID control unit is removed, reinstall it securely and avoid any looseness.

After installing bulb, be sure to install plastic cap and bulb socket securely to insure watertight-

ness HID control unit mounting screw : 3.2 Nꞏm (0.32 kg-m, 28 in-lb)

Page 4551 of 5621

LT-124

AUTO LIGHT SYSTEM

Revision: 2006 January2006 M35/M45

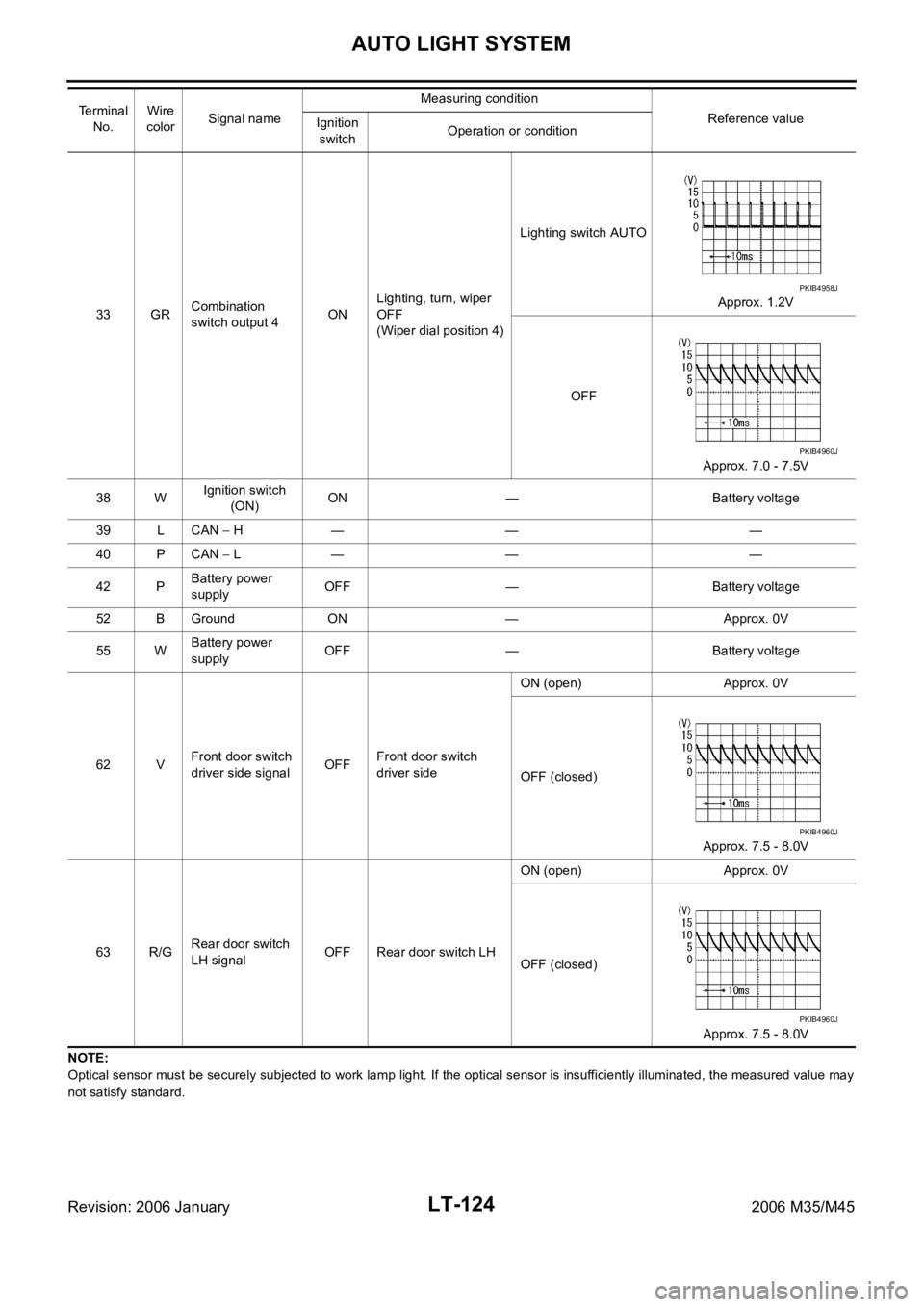

NOTE:

Optical sensor must be securely subjected to work lamp light. If the optical sensor is insufficiently illuminated, the measured value may

not satisfy standard.33 GRCombination

switch output 4ONLighting, turn, wiper

OFF

(Wiper dial position 4)Lighting switch AUTO

Approx. 1.2V

OFF

Approx. 7.0 - 7.5V

38 WIgnition switch

(ON) ON — Battery voltage

39 L CAN

H — — —

40 P CAN

L — — —

42 PBattery power

supplyOFF — Battery voltage

52 B Ground ON — Approx. 0V

55 WBattery power

supplyOFF — Battery voltage

62 VFront door switch

driver side signalOFFFront door switch

driver sideON (open) Approx. 0V

OFF (closed)

Approx. 7.5 - 8.0V

63 R/GRear door switch

LH signalOFF Rear door switch LHON (open) Approx. 0V

OFF (closed)

Approx. 7.5 - 8.0V Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

PKIB4958J

PKIB4960J

PKIB4960J

PKIB4960J

Page 4558 of 5621

AUTO LIGHT SYSTEM

LT-131

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Lighting Switch InspectionNKS003QB

1. CHECK LIGHTING SWITCH INPUT SIGNAL

With CONSULT-II

1. Select “BCM” on CONSULT-II, and select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen,

and make sure “AUTO LIGHT SW” turns ON–OFF linked with

operation of lighting switch.

Without CONSULT-II

Refer to LT-240, "

Combination Switch Inspection" .

OK or NG

OK >> INSPECTION END

NG >> Replace combination switch (lighting switch). Refer to LT- 2 4 0 , "

Combination Switch Inspection" .

Optical Sensor System InspectionNKS003QC

1. CHECK OPTICAL SENSOR INPUT SIGNAL

With CONSULT-II

1. Select “BCM” on CONSULT-II, and select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

On “OPTICAL SENSOR”, check difference in the voltage when

optical sensor is illuminated and not illuminated.

CAUTION:

Optical sensor must be securely subjected to work lamp light. If the optical sensor is insufficiently

illuminated, the measured value may not satisfy the standard.

Without CONSULT-II

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector M1 terminal 14

and ground.

CAUTION:

Optical sensor must be securely subjected to work lamp

light. If the optical sensor is insufficiently illuminated, the

measured value may not satisfy the standard.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.When lighting switch is AUTO

position: AUTO LIGHT SW ON

PKIA7595E

Illuminated

OPTICAL SENSOR : 3.1V or more

Not illuminated

OPTICAL SENSOR : 0.6V or less

Illuminated

OPTICAL SENSOR : 3.1V or more

Not illuminated

OPTICAL SENSOR : 0.6V or less

PKIA7596E

PKIB6163E

Page 4579 of 5621

LT-152

ACTIVE AFS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (ADAPTIVE LIGHT)NKS003QM

CONSULT-II can display each diagnostic item using diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect “CONSULT-II” and “CON-

SULT-II CONVERTER” to the data link connector, and then turn

ignition switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “ADAPTIVE LIGHT” on “SELECT SYSTEM” screen. If

“ADAPTIVE LIGHT” is not indicated, check power supply and

ground of AFS control unit. If it is normal, refer to GI-40, "

CON-

SULT-II Data Link Connector (DLC) Circuit" in “GI section”.

System part Check item, diagnosis mode Description

ADAPTIVE LIGHTWORK SUPPORTAdjusts steering angle sensor (Never use this function but on VDC side) and

adjusts levelizer.

SELF-DIAG RESULTS Displays self-diagnosis

DATA MONITOR Displays AFS control unit inputs and outputs in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TESTAFS control unit sends a drive signal to electronic components to check their

operation.

ECU PART NUMBER AFS control unit part number can be read.

SKIB3794E

BCIA0029E

BCIA0030E

Page 4584 of 5621

![INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time, INFINITI M35 2006 Factory Service Manual ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time,](/img/42/57023/w960_57023-4583.png)

ACTIVE AFS

LT-157

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

CAUTION:

If DTC relating to CAN communication [U1000] and other components are displayed at the same

time, diagnose CAN communication first.

Make sure of the normal operation after the parts (except AFS control unit) replacement according

to the self-diagnosis results. Delete the malfunction history.

Display Results

0: There is malfunction now.

1 – 39: Displays when it is normal at present and finds malfunction in the past. It increases in order

of 0

12...3839 after returning to the normal condition whenever IGN OFFON. If it is over 39,

it is fixed to 39 until the self-diagnostic results are erased. It returns to 0 when malfunction is

detected again in the process.

ECU CIRC

[B2521]Any of several statuses below

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of swivel position sensor (RH) power

supply (AFS control unit terminal 4).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of swivel position sensor (RH) signal (AFS con-

trol unit terminal 9).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of swivel position sensor (LH) power

supply (AFS control unit terminal 24).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of swivel position sensor (LH) signal (AFS con-

trol unit terminal 29).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) or ground of height sensor power supply (AFS

control unit terminal 6).

Short circuit exists for 2 seconds or longer on power supply

(approx. 12 V) of height sensor signal (AFS control unit termi-

nal 28).

AFS control unit (RAM/ROM) malfunctions.1. Stop the swivel motor RH and

LH when the malfunction

occurred.

2. Stop aiming motors when the

malfunction occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.LT-178, "

DTC

B2521 ECU

CIRC"

ECM SIG

[B2522]Cannot receive engine speed signal.1. Back to the initial position.

2. Stop when the malfunction

occurred.

3. Flash at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.EC-137,

"SELF-DIAG

RESULTS

MODE" in EC

section.

If above sys-

tem is normal,

replace AFS

control unit.

AFS SIG

[B2523]Cannot transmit AFS off indicator signal.1. Back to the initial position.

2. Normal operation

3. Flashes at intervals of approx. 1

second when keeping error state

for 2 seconds or longer.

4. Turn ignition switch OFF.Replace

AFS control

unit LT-191

Details of

error

indication

detected by

CONSULT-

IIConditions of error detectionFail-safe

1. Swivel operation

2. Auto aiming operation

3. AFS OFF indicator operation

4. CancellationReference

Page 4591 of 5621

LT-164

ACTIVE AFS

Revision: 2006 January2006 M35/M45

7. CHECK SWIVEL POSITION SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect AFS control unit connector and front combination lamp RH connector.

3. Check continuity between AFS control unit harness connector

(A) F110 terminal 2 and front combination lamp RH harness

connector (B) E48 terminal 19.

OK or NG

OK >> Replace front combination lamp RH (swivel position

sensor malfunction). Refer to LT- 1 9 0 , "

Removal and

Installation of Front Combination Lamp" .

NG >> Repair harness or connector.

8. CHECK DIAGNOSIS RESULT

Select “ADAPTIVE LIGHT” on CONSULT-II. Select “SELF-DIAG

RESULTS” on “SELECT DIAG MODE” screen.

Is DTC B2521 ECU CIRC detected?

YES >> Refer to LT- 1 7 8 , "DTC B2521 ECU CIRC" .

NO >> GO TO 9.

9. CHECK SWIVEL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH connector.

3. Turn ignition switch ON.

4. Check voltage between AFS control unit harness connector

F110 terminal 4 and Ground.

OK or NG

OK >> GO TO 10.

NG >> GO TO 11.2 – 19 : Continuity should exist.

PKIC0650E

SKIB4975E

4 – Ground : Approx. 4 – 6 V

PKIC0651E