INFINITI M35 2006 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 441 of 5621

AT-362

ASSEMBLY

Revision: 2006 January2006 M35/M45

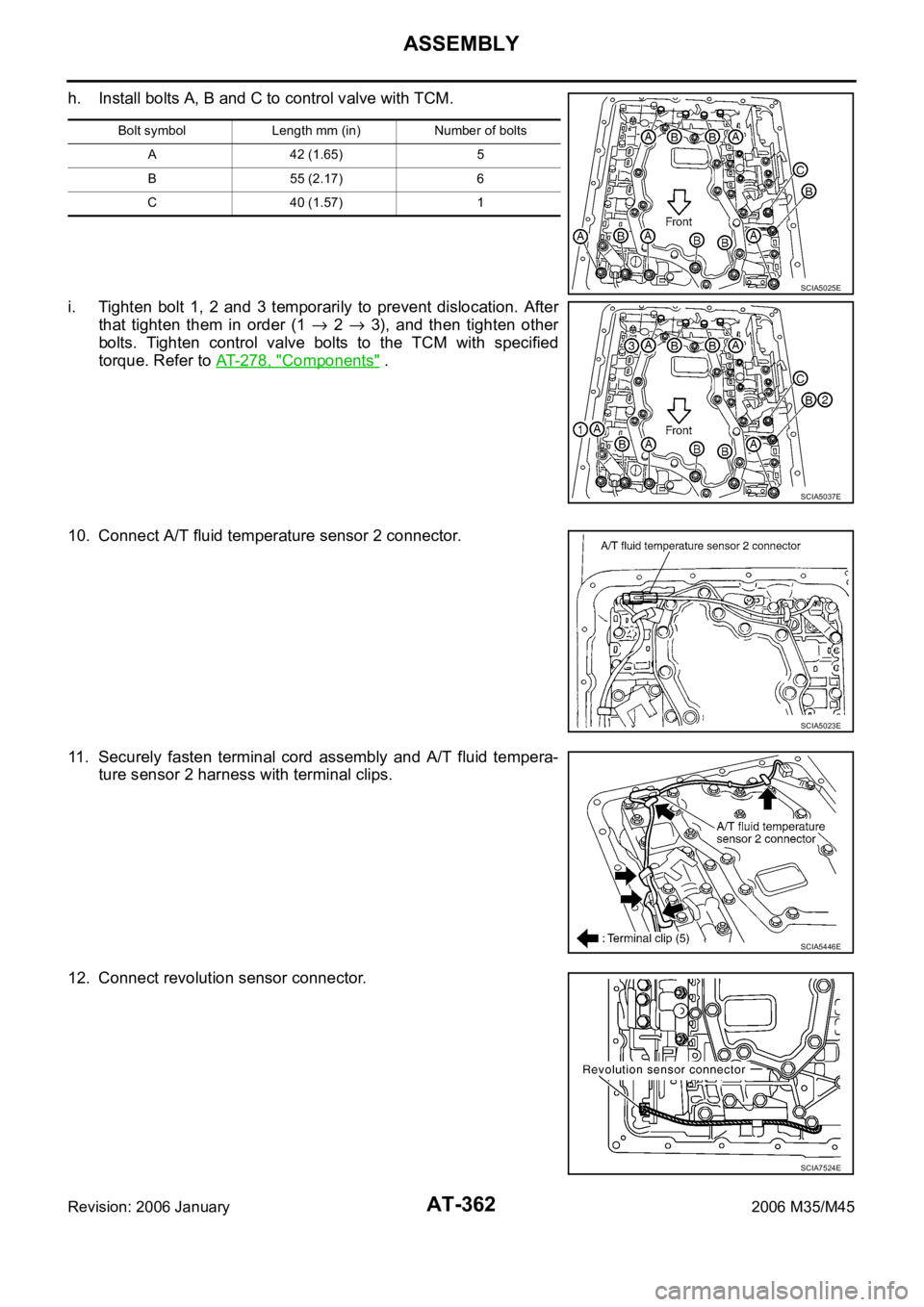

h. Install bolts A, B and C to control valve with TCM.

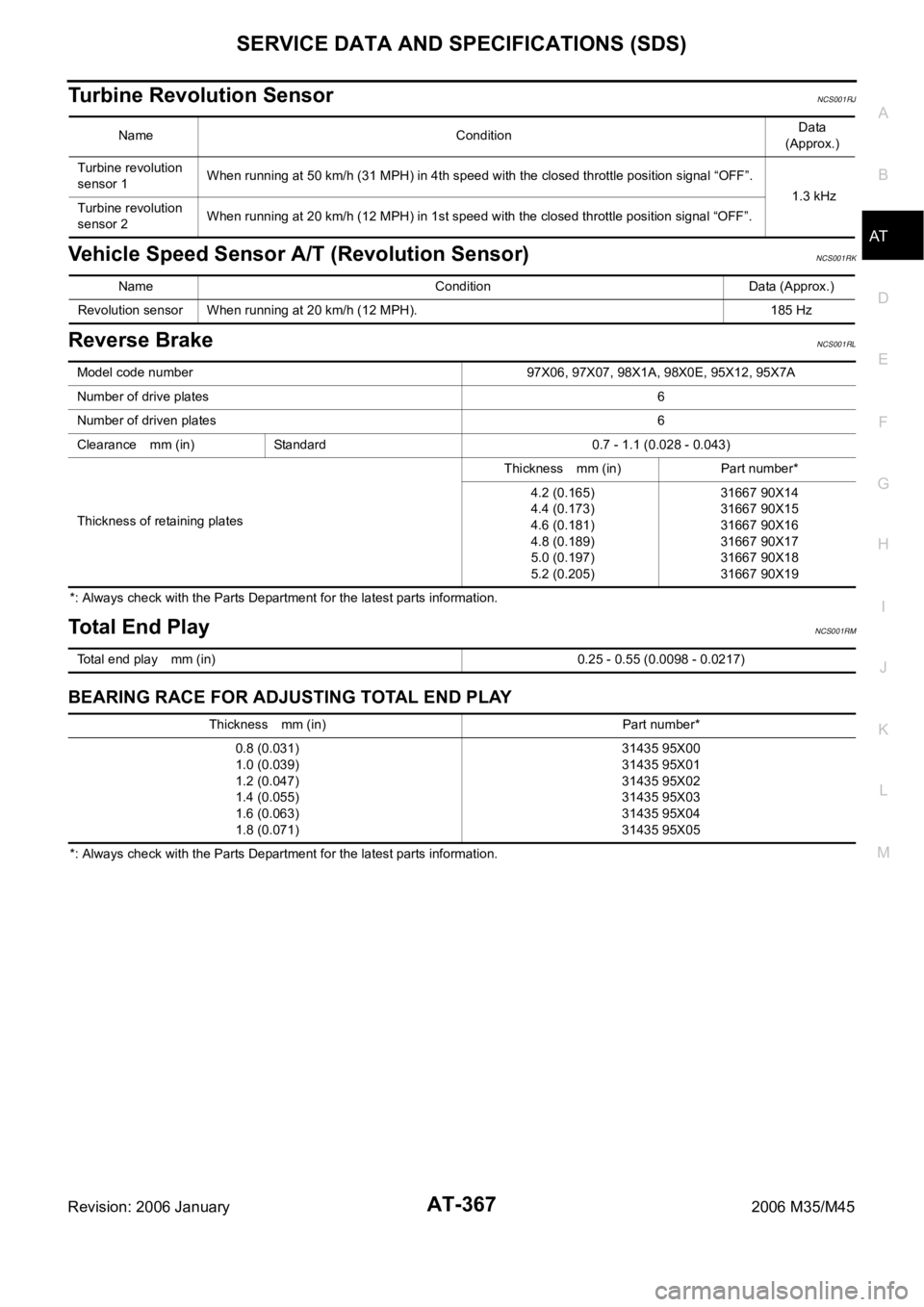

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1

2 3), and then tighten other

bolts. Tighten control valve bolts to the TCM with specified

torque. Refer to AT-278, "

Components" .

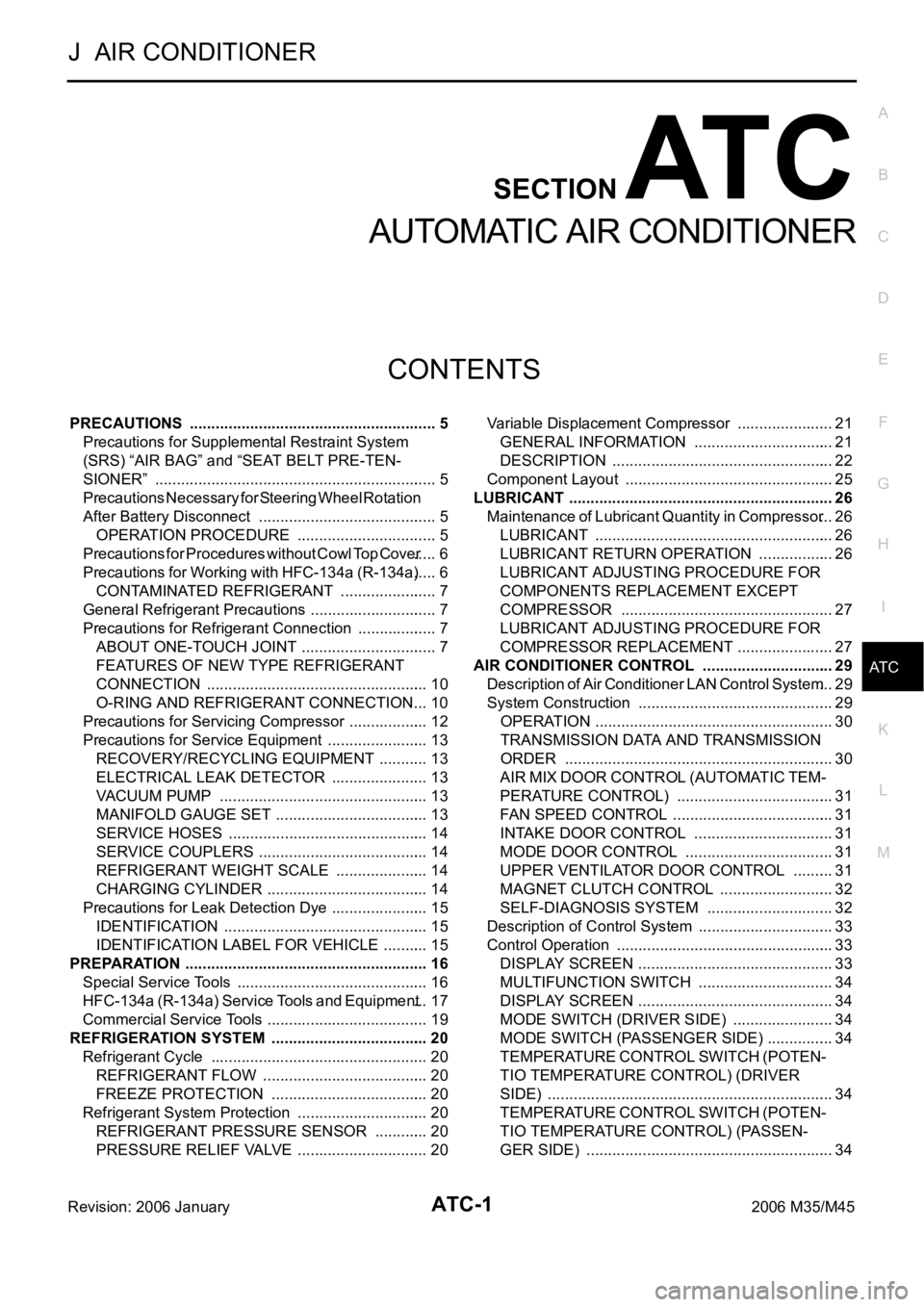

10. Connect A/T fluid temperature sensor 2 connector.

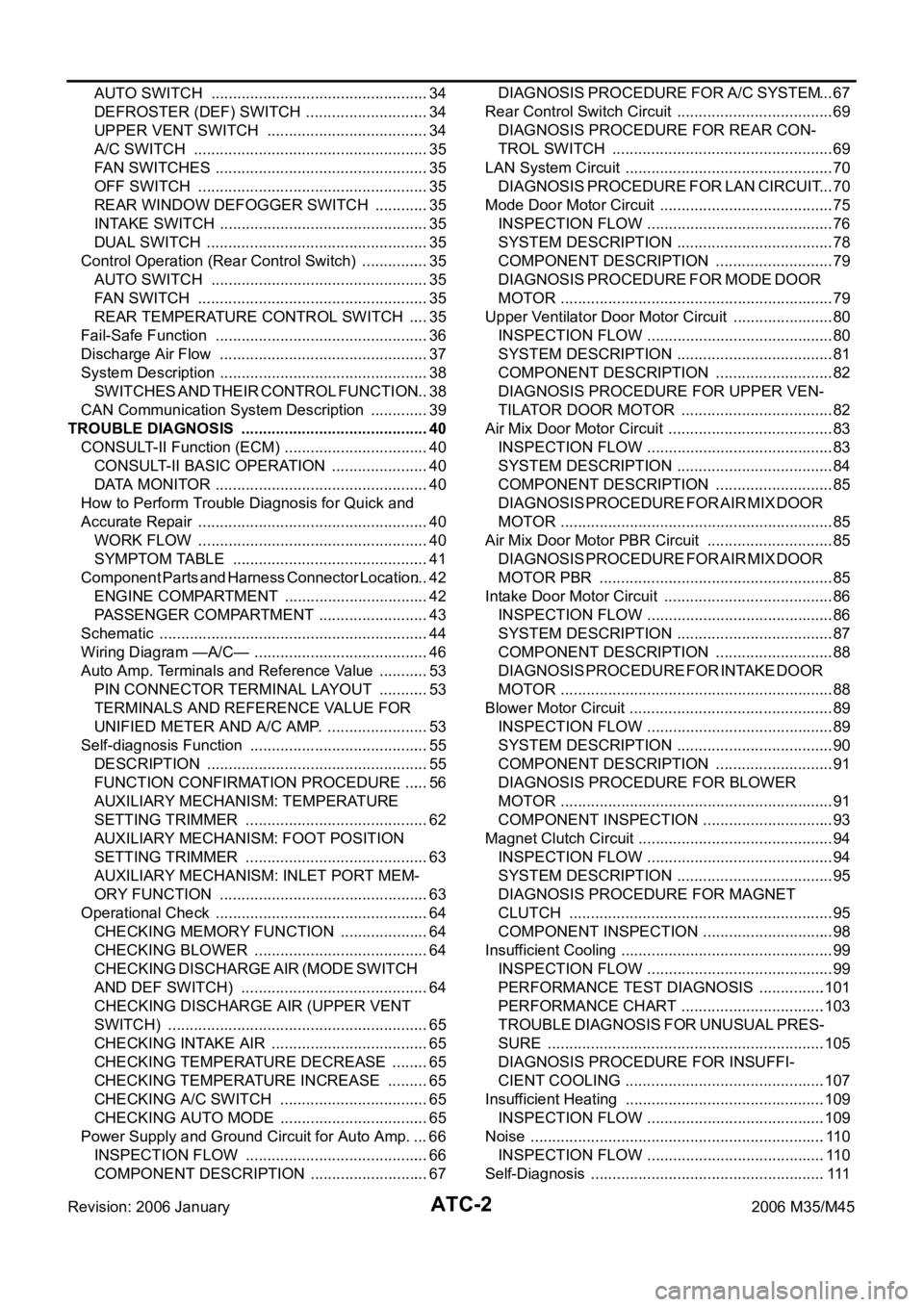

11. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

12. Connect revolution sensor connector.

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

SCIA5446E

SCIA7524E

Page 442 of 5621

ASSEMBLY

AT-363

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

13. Securely fasten revolution sensor harness with terminal clip.

14. Pull down A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

15. Install snap ring to A/T assembly harness connector.

16. Install magnets in oil pan.

17. Install oil pan to transmission case.

a. Install oil pan gasket to transmission case.

CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Complete remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

SCIA7526E

SCIA5299E

SCIA5300E

SCIA5200E

Page 443 of 5621

AT-364

ASSEMBLY

Revision: 2006 January2006 M35/M45

b. Install oil pan to transmission case.

CAUTION:

Install it so that drain plug comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening them.

Tighten oil pan mounting bolts to the specified torque. Refer to

AT-278, "

Components" .

CAUTION:

Do not reuse oil pan mounting bolts.

18. Install drain plug to oil pan. Tighten drain plug to the specified

torque. Refer to AT-278, "

Components" .

CAUTION:

Do not reuse drain plug gasket.

19. Install torque converter.

a. Pour ATF into torque converter.

Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of ATF is

required for a new torque converter.

When reusing old torque converter, add the same amount

of ATF as was drained.

b. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

CAUTION:

Install torque converter while rotating it.

c. Measure distance “A” to make sure that torque converter is in

proper position.

SCIA2308E

SCIA4113E

SAT428DA

SCIA5010E

Distance “A”

VQ35DE models: 25.0 mm (0.98 in) or more

VK45DE models: 22.0 mm (0.87 in) or more

SCIA5694E

Page 444 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-365

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsNCS001RD

*1: Refer to MA-12, "Fluids and Lubricants" .

Vehicle Speed at Which Gear Shifting OccursNCS001RE

2WD MODELS

At half throttle, the accelerator opening is 4/8 of the full opening.

At half throttle, the accelerator opening is 4/8 of the full opening.

AWD MODELS

At half throttle, the accelerator opening is 4/8 of the full opening. Applied modelVQ35DE engine VK45DE engine

2WD AWD 2WD

Automatic transmission model RE5R05A

Transmission model code number 97X06, 98X1A 97X07, 98X0E 95X12, 95X7A

Stall torque ratio 1.72: 1 1.85: 1

Transmission gear ratio1st 3.842 3.827

2nd 2.353 2.368

3rd 1.529 1.520

4th 1.000 1.000

5th 0.839 0.834

Reverse 2.765 2.613

Recommended fluid Genuine NISSAN Matic J ATF*1

Fluid capacity 10.3 liter (10-7/8 US qt, 9-1/8 Imp qt)

CAUTION:

Use only Genuine NISSAN Matic J ATF. Do not mix with other fluid.

Using ATF other than Genuine NISSAN Matic J ATF will deteriorate in driveability and A/T durability, and may damage the

A/T, which is not covered by the warranty.

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 50 - 58

(31 - 36)85 - 93

(53 - 58)127 - 135

(79 - 84)196 - 204

(122 - 127)192 - 200

(119 - 124)114- 122

(71 - 76)70 - 78

(43 - 48)26 - 34

(16 - 21)

Half throttle 40 - 48

(25 - 30)69 - 77

(43 - 48)107 - 115

(66 - 71)139 - 147

(86 - 91)111 - 11 9

(69 - 74)67 - 75

(42 - 47)34 - 42

(21 - 26)19 - 27

(12 - 17)

Engine model VK45DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 54 - 62

(34 - 39)89 - 97

(55 - 60)139 - 147

(86 - 91)207 - 215

(129 - 134)203 - 211

(126 - 131)122 - 130

(76 - 81)73 - 81

(45 - 50)28 - 36

(17 - 22)

Half throttle 46 - 54

(29 - 34)81 - 89

(50 - 55)126 - 134

(78 - 83)155 - 163

(96 - 101)128 - 136

(80 - 85)70 - 78

(43 - 48)28 - 36

(17 - 22)7 - 15

(4 - 9)

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 48 - 56

(30 - 35)81 - 89

(50 - 55)121 - 129

(75 - 80)188 - 196

(117 - 122)184 - 192

(114 - 119)109 - 117

(68 - 73)66 - 74

(41 - 46)25 - 33

(16 - 21)

Half throttle 38 - 46

(24 - 29)66 - 74

(41 - 46)102 - 110

(63 - 68)133 - 141

(83 - 88)106 - 114

(66 - 71)64 - 72

(40 - 45)32 - 40

(20 - 25)18 - 26

(11 - 16)

Page 445 of 5621

AT-366

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Vehicle Speed at Which Lock-Up Occurs/ReleasesNCS001RF

2WD MODELS

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

AW D M OD E LS

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

Stall SpeedNCS001RG

Line PressureNCS001RH

A/T Fluid Temperature SensorNCS001RI

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 53 - 61 (33 - 38) 50 - 58 (31 - 36)

Half throttle 196 - 204 (122 - 127) 138 - 146 (86 - 91)

Engine model VK45DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 67 - 75 (42 - 47) 50 - 58 (31 - 36)

Half throttle 181 - 189 (112 - 117) 160 - 168 (99 - 104)

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 51 - 59 (32 - 37) 48 - 56 (30 - 35)

Half throttle 188 - 196 (117 - 122) 132 - 140 (82 - 87)

Engine model Stall speed

VQ35DE 2,650 - 2,950 rpm

VK45DE 2,260 - 2,560 rpm

Engine speedLine pressure [kPa (kg/cm

2 , psi)]

“R” position “D”, “M” positions

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Name Condition CONSULT-II “DATA MONITOR” (Approx.) Resistance (Approx.)

ATF TEMP SE 10

C (32F) 3.3 V 15 k

20C (68F) 2.7 V 6.5 k

80C (176F) 0.9 V 0.9 k

ATF TEMP SE 20

C (32F) 3.3 V 10 k

20C (68F) 2.5 V 4 k

80C (176F) 0.7 V 0.5 k

Page 446 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-367

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Turbine Revolution SensorNCS001RJ

Vehicle Speed Sensor A/T (Revolution Sensor)NCS001RK

Reverse BrakeNCS001RL

*: Always check with the Parts Department for the latest parts information.

Total End PlayNCS001RM

BEARING RACE FOR ADJUSTING TOTAL END PLAY

*: Always check with the Parts Department for the latest parts information. Name ConditionData

(Approx.)

Turbine revolution

sensor 1When running at 50 km/h (31 MPH) in 4th speed with the closed throttle position signal “OFF”.

1.3 kHz

Turbine revolution

sensor 2When running at 20 km/h (12 MPH) in 1st speed with the closed throttle position signal “OFF”.

Name Condition Data (Approx.)

Revolution sensor When running at 20 km/h (12 MPH). 185 Hz

Model code number 97X06, 97X07, 98X1A, 98X0E, 95X12, 95X7A

Number of drive plates6

Number of driven plates6

Clearance mm (in) Standard 0.7 - 1.1 (0.028 - 0.043)

Thickness of retaining platesThickness mm (in) Part number*

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205) 31667 90X14

31667 90X15

31667 90X16

31667 90X17

31667 90X18

31667 90X19

Total end play mm (in) 0.25 - 0.55 (0.0098 - 0.0217)

Thickness mm (in) Part number*

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)31435 95X00

31435 95X01

31435 95X02

31435 95X03

31435 95X04

31435 95X05

Page 447 of 5621

AT-368

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Page 448 of 5621

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION AT C

A

B

AT C

Revision: 2006 January2006 M35/M45

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 5

OPERATION PROCEDURE ................................. 5

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions for Working with HFC-134a (R-134a) ..... 6

CONTAMINATED REFRIGERANT ....................... 7

General Refrigerant Precautions .............................. 7

Precautions for Refrigerant Connection ................... 7

ABOUT ONE-TOUCH JOINT ................................ 7

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION .................................................... 10

O-RING AND REFRIGERANT CONNECTION ... 10

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 13

RECOVERY/RECYCLING EQUIPMENT ............ 13

ELECTRICAL LEAK DETECTOR ....................... 13

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 14

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 15

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment ... 17

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 20Variable Displacement Compressor ....................... 21

GENERAL INFORMATION ................................. 21

DESCRIPTION .................................................... 22

Component Layout ................................................. 25

LUBRICANT .............................................................. 26

Maintenance of Lubricant Quantity in Compressor ... 26

LUBRICANT ........................................................ 26

LUBRICANT RETURN OPERATION .................. 26

LUBRICANT ADJUSTING PROCEDURE FOR

COMPONENTS REPLACEMENT EXCEPT

COMPRESSOR .................................................. 27

LUBRICANT ADJUSTING PROCEDURE FOR

COMPRESSOR REPLACEMENT ....................... 27

AIR CONDITIONER CONTROL ............................... 29

Description of Air Conditioner LAN Control System ... 29

System Construction .............................................. 29

OPERATION ........................................................ 30

TRANSMISSION DATA AND TRANSMISSION

ORDER ............................................................... 30

AIR MIX DOOR CONTROL (AUTOMATIC TEM-

PERATURE CONTROL) ..................................... 31

FAN SPEED CONTROL ...................................... 31

INTAKE DOOR CONTROL ................................. 31

MODE DOOR CONTROL ................................... 31

UPPER VENTILATOR DOOR CONTROL .......... 31

MAGNET CLUTCH CONTROL ........................... 32

SELF-DIAGNOSIS SYSTEM .............................. 32

Description of Control System ................................ 33

Control Operation ................................................... 33

DISPLAY SCREEN .............................................. 33

MULTIFUNCTION SWITCH ................................ 34

DISPLAY SCREEN .............................................. 34

MODE SWITCH (DRIVER SIDE) ........................ 34

MODE SWITCH (PASSENGER SIDE) ................ 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (DRIVER

SIDE) ................................................................... 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (PASSEN-

GER SIDE) .......................................................... 34

Page 449 of 5621

ATC-2Revision: 2006 January2006 M35/M45 AUTO SWITCH ................................................... 34

DEFROSTER (DEF) SWITCH ............................. 34

UPPER VENT SWITCH ...................................... 34

A/C SWITCH ....................................................... 35

FAN SWITCHES .................................................. 35

OFF SWITCH ...................................................... 35

REAR WINDOW DEFOGGER SWITCH ............. 35

INTAKE SWITCH ................................................. 35

DUAL SWITCH .................................................... 35

Control Operation (Rear Control Switch) ................ 35

AUTO SWITCH ................................................... 35

FAN SWITCH ...................................................... 35

REAR TEMPERATURE CONTROL SWITCH ..... 35

Fail-Safe Function .................................................. 36

Discharge Air Flow ................................................. 37

System Description ................................................. 38

SWITCHES AND THEIR CONTROL FUNCTION ... 38

CAN Communication System Description .............. 39

TROUBLE DIAGNOSIS ............................................ 40

CONSULT-II Function (ECM) .................................. 40

CONSULT-II BASIC OPERATION ....................... 40

DATA MONITOR .................................................. 40

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 40

WORK FLOW ...................................................... 40

SYMPTOM TABLE .............................................. 41

Component Parts and Harness Connector Location ... 42

ENGINE COMPARTMENT .................................. 42

PASSENGER COMPARTMENT .......................... 43

Schematic ............................................................... 44

Wiring Diagram —A/C— ......................................... 46

Auto Amp. Terminals and Reference Value ............ 53

PIN CONNECTOR TERMINAL LAYOUT ............ 53

TERMINALS AND REFERENCE VALUE FOR

UNIFIED METER AND A/C AMP. ........................ 53

Self-diagnosis Function .......................................... 55

DESCRIPTION .................................................... 55

FUNCTION CONFIRMATION PROCEDURE ...... 56

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 62

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 63

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION ................................................. 63

Operational Check .................................................. 64

CHECKING MEMORY FUNCTION ..................... 64

CHECKING BLOWER ......................................... 64

CHECKING DISCHARGE AIR (MODE SWITCH

AND DEF SWITCH) ............................................ 64

CHECKING DISCHARGE AIR (UPPER VENT

SWITCH) ............................................................. 65

CHECKING INTAKE AIR ..................................... 65

CHECKING TEMPERATURE DECREASE ......... 65

CHECKING TEMPERATURE INCREASE .......... 65

CHECKING A/C SWITCH ................................... 65

CHECKING AUTO MODE ................................... 65

Power Supply and Ground Circuit for Auto Amp. ... 66

INSPECTION FLOW ........................................... 66

COMPONENT DESCRIPTION ............................ 67DIAGNOSIS PROCEDURE FOR A/C SYSTEM ... 67

Rear Control Switch Circuit ..................................... 69

DIAGNOSIS PROCEDURE FOR REAR CON-

TROL SWITCH .................................................... 69

LAN System Circuit ................................................. 70

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT ... 70

Mode Door Motor Circuit ......................................... 75

INSPECTION FLOW ............................................ 76

SYSTEM DESCRIPTION ..................................... 78

COMPONENT DESCRIPTION ............................ 79

DIAGNOSIS PROCEDURE FOR MODE DOOR

MOTOR ................................................................ 79

Upper Ventilator Door Motor Circuit ........................ 80

INSPECTION FLOW ............................................ 80

SYSTEM DESCRIPTION ..................................... 81

COMPONENT DESCRIPTION ............................ 82

DIAGNOSIS PROCEDURE FOR UPPER VEN-

TILATOR DOOR MOTOR .................................... 82

Air Mix Door Motor Circuit ....................................... 83

INSPECTION FLOW ............................................ 83

SYSTEM DESCRIPTION ..................................... 84

COMPONENT DESCRIPTION ............................ 85

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR

MOTOR ................................................................ 85

Air Mix Door Motor PBR Circuit .............................. 85

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR

MOTOR PBR ....................................................... 85

Intake Door Motor Circuit ........................................ 86

INSPECTION FLOW ............................................ 86

SYSTEM DESCRIPTION ..................................... 87

COMPONENT DESCRIPTION ............................ 88

DIAGNOSIS PROCEDURE FOR INTAKE DOOR

MOTOR ................................................................ 88

Blower Motor Circuit ................................................ 89

INSPECTION FLOW ............................................ 89

SYSTEM DESCRIPTION ..................................... 90

COMPONENT DESCRIPTION ............................ 91

DIAGNOSIS PROCEDURE FOR BLOWER

MOTOR ................................................................ 91

COMPONENT INSPECTION ............................... 93

Magnet Clutch Circuit .............................................. 94

INSPECTION FLOW ............................................ 94

SYSTEM DESCRIPTION ..................................... 95

DIAGNOSIS PROCEDURE FOR MAGNET

CLUTCH .............................................................. 95

COMPONENT INSPECTION ............................... 98

Insufficient Cooling .................................................. 99

INSPECTION FLOW ............................................ 99

PERFORMANCE TEST DIAGNOSIS ................101

PERFORMANCE CHART ..................................103

TROUBLE DIAGNOSIS FOR UNUSUAL PRES-

SURE .................................................................105

DIAGNOSIS PROCEDURE FOR INSUFFI-

CIENT COOLING ...............................................107

Insufficient Heating ...............................................109

INSPECTION FLOW ..........................................109

Noise .....................................................................110

INSPECTION FLOW ..........................................110

Self-Diagnosis ....................................................... 111

Page 450 of 5621

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45 INSPECTION FLOW ......................................... . 111

Memory Function .................................................. 112

INSPECTION FLOW .......................................... 112

Ambient Sensor Circuit ......................................... 113

COMPONENT DESCRIPTION .......................... 113

AMBIENT TEMPERATURE INPUT PROCESS .. 113

DIAGNOSIS PROCEDURE FOR AMBIENT

SENSOR ............................................................ 113

COMPONENT INSPECTION ............................. 115

In-Vehicle Sensor Circuit ....................................... 116

COMPONENT DESCRIPTION .......................... 116

DIAGNOSIS PROCEDURE FOR IN-VEHICLE

SENSOR ............................................................ 117

COMPONENT INSPECTION ............................. 118

Sunload Sensor Circuit ......................................... 119

COMPONENT DESCRIPTION .......................... 119

SUNLOAD INPUT PROCESS ........................... 119

DIAGNOSIS PROCEDURE FOR SUNLOAD

SENSOR ............................................................ 119

COMPONENT INSPECTION ............................121

Intake Sensor Circuit ............................................122

COMPONENT DESCRIPTION .........................122

DIAGNOSIS PROCEDURE FOR INTAKE SEN-

SOR ..................................................................122

COMPONENT INSPECTION ............................123

CONTROLLER .......................................................124

Removal and Installation of Multifunction Switch . 124

REMOVAL ........................................................

.124

INSTALLATION .................................................124

AUTO AMP .............................................................125

Removal and Installation of Unified Meter and A/C

Auto Amp. ............................................................125

REMOVAL ........................................................

.125

INSTALLATION .................................................125

AMBIENT SENSOR ................................................126

Removal and Installation ......................................126

REMOVAL ........................................................

.126

INSTALLATION .................................................126

IN-VEHICLE SENSOR ............................................127

Removal and Installation ......................................127

REMOVAL ........................................................

.127

INSTALLATION .................................................127

SUNLOAD SENSOR ..............................................128

Removal and Installation ......................................128

REMOVAL ........................................................

.128

INSTALLATION .................................................128

INTAKE SENSOR .................................................. .129

Removal and Installation ......................................129

REMOVAL ........................................................

.129

INSTALLATION .................................................129

BLOWER UNIT .......................................................130

Removal and Installation ......................................130

REMOVAL ........................................................

.130

INSTALLATION .................................................130

Disassembly and Assembly .................................131

BLOWER MOTOR ..................................................132

Removal and Installation ......................................132

REMOVAL ........................................................

.132

INSTALLATION .................................................132INTAKE DOOR MOTOR .........................................133

Removal and Installation ......................................133

REMOVAL ........................................................

.133

INSTALLATION .................................................133

IN-CABIN MICROFILTER .......................................134

Removal and Installation ......................................134

FUNCTION .......................................................

.134

REPLACEMENT TIMING ..................................134

REPLACEMENT PROCEDURES .....................134

HEATER & COOLING UNIT ASSEMBLY ...............135

Removal and Installation ......................................135

REMOVAL ........................................................

.135

INSTALLATION .................................................136

Disassembly and Assembly ..................................138

MODE DOOR MOTOR ............................................140

Removal and Installation ......................................140

REMOVAL ........................................................

.140

INSTALLATION .................................................140

AIR MIX DOOR MOTOR .........................................141

Removal and Installation ......................................141

REMOVAL ........................................................

.141

INSTALLATION .................................................141

UPPER VENTILATOR DOOR MOTOR ..................142

Removal and Installation ......................................142

REMOVAL ........................................................

.142

INSTALLATION .................................................142

HEATER CORE .......................................................143

Removal and Installation ......................................143

REMOVAL ........................................................

.143

INSTALLATION .................................................143

DUCTS AND GRILLES ...........................................144

Removal and Installation ......................................144

COMPONENT LAYOUT ....................................144

REMOVAL ........................................................

.146

INSTALLATION .................................................150

REFRIGERANT LINES ...........................................151

HFC-134a (R-134a) Service Procedure ...............151

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................151

Components ....................................................

.....153

VQ35DE ............................................................153

VK45DE .............................................................154

Removal and Installation of Compressor ..............155

REMOVAL ........................................................

.155

INSTALLATION .................................................157

Check Disc to Pulley Clearance ...........................157

Removal and Installation of Low-Pressure Flexible

Hose and Pipe ......................................................158

REMOVAL ........................................................

.158

INSTALLATION .................................................158

Removal and Installation of High-Pressure Flexible

Hose .....................................................................159

REMOVAL ........................................................

.159

INSTALLATION .................................................160

Removal and Installation of High-Pressure Pipe 1

(Engine Compartment) .........................................160

REMOVAL ........................................................

.160

INSTALLATION .................................................161

Removal and Installation of Low-Pressure Pipe 1