fuel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3066 of 5621

EM-3

C

D

E

F

G

H

I

J

K

L

M

EMA

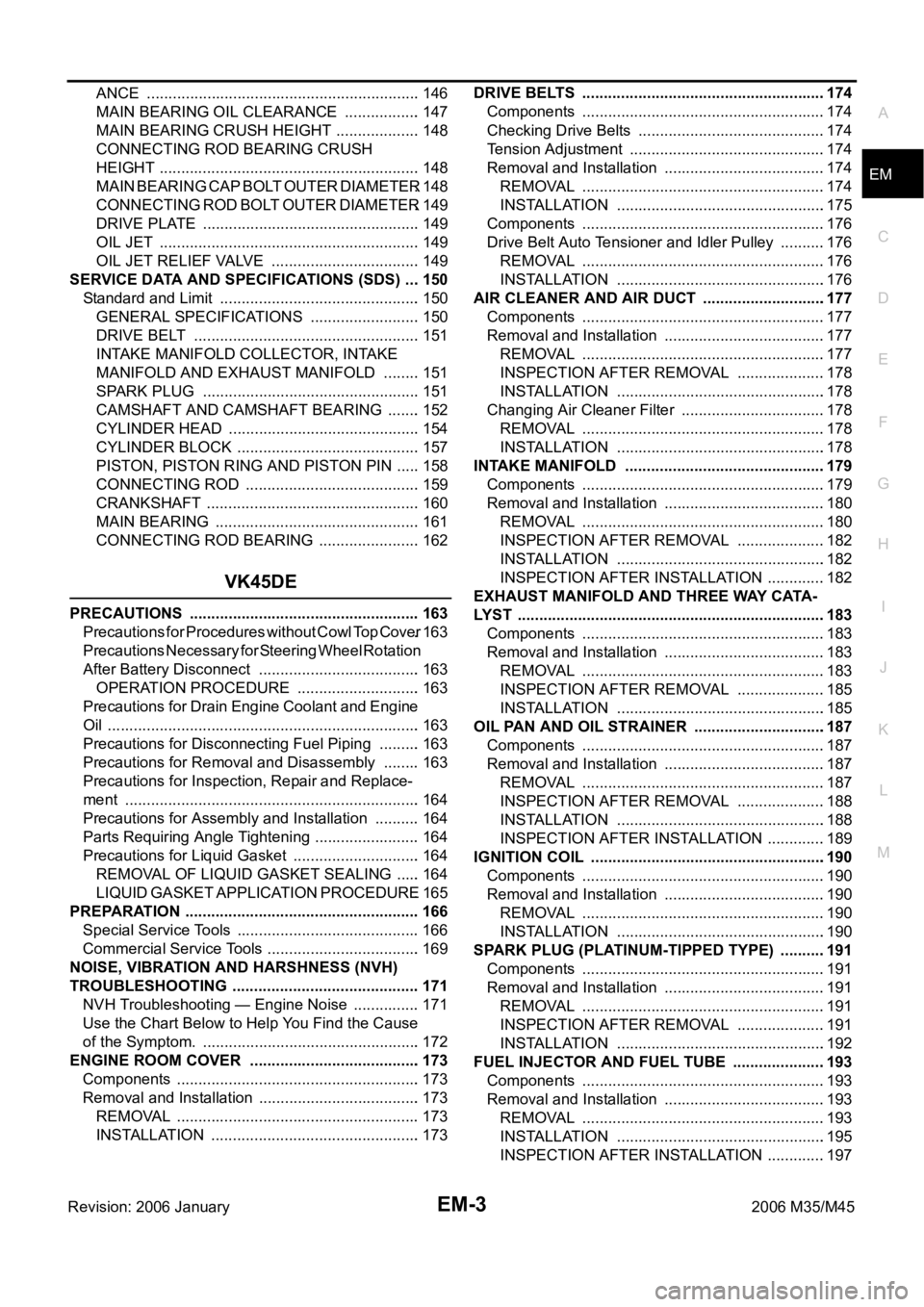

Revision: 2006 January2006 M35/M45 ANCE ................................................................146

MAIN BEARING OIL CLEARANCE ..................147

MAIN BEARING CRUSH HEIGHT ....................148

CONNECTING ROD BEARING CRUSH

HEIGHT .............................................................148

MAIN BEARING CAP BOLT OUTER DIAMETER .148

CONNECTING ROD BOLT OUTER DIAMETER .149

DRIVE PLATE ...................................................149

OIL JET .............................................................149

OIL JET RELIEF VALVE ...................................149

SERVICE DATA AND SPECIFICATIONS (SDS) ....150

Standard and Limit ...............................................150

GENERAL SPECIFICATIONS ..........................150

DRIVE BELT .....................................................151

INTAKE MANIFOLD COLLECTOR, INTAKE

MANIFOLD AND EXHAUST MANIFOLD .........151

SPARK PLUG ...................................................151

CAMSHAFT AND CAMSHAFT BEARING ........152

CYLINDER HEAD .............................................154

CYLINDER BLOCK ...........................................157

PISTON, PISTON RING AND PISTON PIN ......158

CONNECTING ROD .........................................159

CRANKSHAFT ..................................................160

MAIN BEARING ................................................161

CONNECTING ROD BEARING ........................162

VK45DE

PRECAUTIONS ......................................................163

Precautions for Procedures without Cowl Top Cover .163

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect ......................................163

OPERATION PROCEDURE .............................163

Precautions for Drain Engine Coolant and Engine

Oil .........................................................................163

Precautions for Disconnecting Fuel Piping ..........163

Precautions for Removal and Disassembly .........163

Precautions for Inspection, Repair and Replace-

ment .....................................................................164

Precautions for Assembly and Installation ...........164

Parts Requiring Angle Tightening .........................164

Precautions for Liquid Gasket ..............................164

REMOVAL OF LIQUID GASKET SEALING ......164

LIQUID GASKET APPLICATION PROCEDURE .165

PREPARATION .......................................................166

Special Service Tools ...........................................166

Commercial Service Tools ....................................169

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................171

NVH Troubleshooting — Engine Noise ................171

Use the Chart Below to Help You Find the Cause

of the Symptom. ...................................................172

ENGINE ROOM COVER ........................................173

Components .........................................................173

Removal and Installation ......................................173

REMOVAL ........................................................

.173

INSTALLATION .................................................173DRIVE BELTS .........................................................174

Components .........................................................174

Checking Drive Belts ............................................174

Tension Adjustment .............................................

.174

Removal and Installation ......................................174

REMOVAL ........................................................

.174

INSTALLATION .................................................175

Components .........................................................176

Drive Belt Auto Tensioner and Idler Pulley ...........176

REMOVAL ........................................................

.176

INSTALLATION .................................................176

AIR CLEANER AND AIR DUCT .............................177

Components .........................................................177

Removal and Installation ......................................177

REMOVAL ........................................................

.177

INSPECTION AFTER REMOVAL .....................178

INSTALLATION .................................................178

Changing Air Cleaner Filter ..................................178

REMOVAL ........................................................

.178

INSTALLATION .................................................178

INTAKE MANIFOLD ..............................................

.179

Components .........................................................179

Removal and Installation ......................................180

REMOVAL ........................................................

.180

INSPECTION AFTER REMOVAL .....................182

INSTALLATION .................................................182

INSPECTION AFTER INSTALLATION ..............182

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST ........................................................................183

Components .........................................................183

Removal and Installation ......................................183

REMOVAL ........................................................

.183

INSPECTION AFTER REMOVAL .....................185

INSTALLATION .................................................185

OIL PAN AND OIL STRAINER ...............................187

Components .........................................................187

Removal and Installation ......................................187

REMOVAL ........................................................

.187

INSPECTION AFTER REMOVAL .....................188

INSTALLATION .................................................188

INSPECTION AFTER INSTALLATION ..............189

IGNITION COIL .......................................................190

Components .........................................................190

Removal and Installation ......................................190

REMOVAL ........................................................

.190

INSTALLATION .................................................190

SPARK PLUG (PLATINUM-TIPPED TYPE) ...........191

Components .........................................................191

Removal and Installation ......................................191

REMOVAL ........................................................

.191

INSPECTION AFTER REMOVAL .....................191

INSTALLATION .................................................192

FUEL INJECTOR AND FUEL TUBE ......................193

Components .........................................................193

Removal and Installation ......................................193

REMOVAL ........................................................

.193

INSTALLATION .................................................195

INSPECTION AFTER INSTALLATION ..............197

Page 3068 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced](/img/42/57023/w960_57023-3067.png)

PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RR

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004MH

Drain engine coolant and engine oil when the engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004MI

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004MJ

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

PIIB3706J

Page 3069 of 5621

![INFINITI M35 2006 Factory Service Manual EM-6

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

make sure that dowel pins are insta INFINITI M35 2006 Factory Service Manual EM-6

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

make sure that dowel pins are insta](/img/42/57023/w960_57023-3068.png)

EM-6

[VQ35DE]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

make sure that dowel pins are installed in the original position.

Cover openings of engine system with a tape or equivalent, if necessary, to seal out foreign materials.

Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be

used in the step.

Precautions for Inspection, Repair and ReplacementNBS004MK

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationNBS004ML

Use torque wrench to tighten bolts or nuts to specification.

When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

Replace with new gasket, packing, oil seal or O-ring.

Dowel pins are used for several parts alignment.When replacing and reassembling parts with dowel

pins,make sure that dowel pins are installed in the original position.

Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start the engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Precautions for Angle TighteningNBS004MM

Use the angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

–Cylinder head bolts

–Main bearing cap bolts

–Connecting rod cap bolts

–Crankshaft pulley bolt

Do not use a torque value for final tightening.

The torque value for these parts are for a preliminary step.

Ensure thread and seat surfaces are clean and coated with engine oil.

Precautions for Liquid GasketNBS004MN

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating

surface using the seal cutter (SST) and remove old liquid gasket

sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it (1), and then slide it (2) by tapping

on the side as shown in the figure.

In areas where the seal cutter (SST) is difficult to use, use a

plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver

is used, be careful not to damage the mating surfaces.

PBIC0002E

Page 3072 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

EM-9

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45WS39930000

(—)

Tube presserPressing the tube of liquid gasket

KV10112100

(BT8653-A)

Angle wrenchTightening bolts INFINITI M35 2006 Factory Service Manual PREPARATION

EM-9

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45WS39930000

(—)

Tube presserPressing the tube of liquid gasket

KV10112100

(BT8653-A)

Angle wrenchTightening bolts](/img/42/57023/w960_57023-3071.png)

PREPARATION

EM-9

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45WS39930000

(—)

Tube presserPressing the tube of liquid gasket

KV10112100

(BT8653-A)

Angle wrenchTightening bolts for connecting rod bearing

cap, cylinder head, etc. in angle

KV10114400

(J38365)

Heated oxygen sensor wrenchLoosening or tightening air fuel ratio sensor 1

a: 22 mm (0.87 in)

KV10117700

(J44716)

Ring gear stopperRemoving and installing crankshaft pulley

—

(J-45488)

Quick connector releaseRemoving fuel tube quick connectors in

engine room Tool number

(Kent-Moore No.)

To o l n a m eDescription

NT052

NT014

NT636

NT822

PBIC0198E

Page 3074 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing pis INFINITI M35 2006 Factory Service Manual PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing pis](/img/42/57023/w960_57023-3073.png)

PREPARATION

EM-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

(—)

Valve seat cutter setFinishing valve seat dimensions

(—)

Piston ring expanderRemoving and installing piston ring

(—)

Valve guide driftRemoving and installing valve guide

Intake and Exhaust:

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

(—)

Valve guide reamer(1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

Intake and Exhaust:

d

1 : 6.0 mm (0.236 in) dia.

d

2 : 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleanerReconditioning the exhaust system threads

before installing a new air fuel ratio sensor

and heated oxygen sensor (Use with anti-

seize lubricant shown below.)

a: J-43897-18 [18 mm (0.71 in) dia.] for

z ir c on i a h e a t e d o x y g e n s e ns o r a n d a i r f u e l

ratio sensor

b: J-43897-12 [12 mm (0.47 in) dia.] for

titania heated oxygen sensor and air fuel

ratio sensor

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL

specification MIL-A-907)Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads (Kent-Moore No.)

To o l n a m eDescription

NT048

NT030

NT015

NT016

AEM488

AEM489

Page 3083 of 5621

![INFINITI M35 2006 Factory Service Manual EM-20

[VQ35DE]

INTAKE MANIFOLD COLLECTOR

Revision: 2006 January2006 M35/M45

1. Remove engine cover (1) with power tool.

2. Disconnect water hoses from intake manifold collector (upper), attach blind p INFINITI M35 2006 Factory Service Manual EM-20

[VQ35DE]

INTAKE MANIFOLD COLLECTOR

Revision: 2006 January2006 M35/M45

1. Remove engine cover (1) with power tool.

2. Disconnect water hoses from intake manifold collector (upper), attach blind p](/img/42/57023/w960_57023-3082.png)

EM-20

[VQ35DE]

INTAKE MANIFOLD COLLECTOR

Revision: 2006 January2006 M35/M45

1. Remove engine cover (1) with power tool.

2. Disconnect water hoses from intake manifold collector (upper), attach blind plug to prevent engine coolant

leakage.

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

3. Remove air cleaner case and air duct. Refer to EM-17, "

AIR CLEANER AND AIR DUCT" .

4. Remove electric throttle control actuator as follows:

a. Disconnect harness connector.

b. Loosen mounting bolts in reverse order as shown in the figure.

CAUTION:

Handle carefully to avoid any shock to electric throttle

control actuator.

Do not disassemble.

5. Remove fuel sub-tube mounting bolt to disconnect from rear of intake manifold collector (lower). Refer to

EM-45, "

FUEL INJECTOR AND FUEL TUBE" .

6. Disconnect vacuum hose from intake manifold collector (upper).

7. Remove EVAP canister purge volume control solenoid valve and bracket mounting bolt from intake mani-

fold collector (upper).

PBIC3507E

KBIA0957E

Page 3087 of 5621

![INFINITI M35 2006 Factory Service Manual EM-24

[VQ35DE]

INTAKE MANIFOLD

Revision: 2006 January2006 M35/M45

INTAKE MANIFOLDPFP:14003

ComponentsNBS004N2

Removal and InstallationNBS004N3

REMOVAL

1. Release fuel pressure. Refer to EC-98, "FU INFINITI M35 2006 Factory Service Manual EM-24

[VQ35DE]

INTAKE MANIFOLD

Revision: 2006 January2006 M35/M45

INTAKE MANIFOLDPFP:14003

ComponentsNBS004N2

Removal and InstallationNBS004N3

REMOVAL

1. Release fuel pressure. Refer to EC-98, "FU](/img/42/57023/w960_57023-3086.png)

EM-24

[VQ35DE]

INTAKE MANIFOLD

Revision: 2006 January2006 M35/M45

INTAKE MANIFOLDPFP:14003

ComponentsNBS004N2

Removal and InstallationNBS004N3

REMOVAL

1. Release fuel pressure. Refer to EC-98, "FUEL PRESSURE RELEASE" .

2. Remove intake manifold collectors (upper and lower). Refer to EM-19, "

INTAKE MANIFOLD COLLEC-

TOR" .

3. Remove fuel tube and fuel injector assembly. Refer to EM-45, "

FUEL INJECTOR AND FUEL TUBE" .

4. Loosen mounting bolts and nuts in reverse order as shown in

the figure to remove intake manifold with power tool.

5. Remove gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

1. Harness bracket 2. Intake manifold 3. Gasket

SBIA0487E

PBIC0778E

Page 3089 of 5621

![INFINITI M35 2006 Factory Service Manual EM-26

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

EXHAUST MANIFOLDPFP:14004

ComponentsNBS004N4

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and Instal INFINITI M35 2006 Factory Service Manual EM-26

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

EXHAUST MANIFOLDPFP:14004

ComponentsNBS004N4

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and Instal](/img/42/57023/w960_57023-3088.png)

EM-26

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

EXHAUST MANIFOLDPFP:14004

ComponentsNBS004N4

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and InstallationNBS004N5

REMOVAL

WAR NING :

Perform the work when the exhaust and cooling system have completely cooled down.

1. Remove engine room cover (RH and LH). Refer to EM-14, "

ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-19, "

INTAKE MANIFOLD COLLECTOR" .

3. Remove air cleaner case and air duct. Refer to EM-17, "

AIR CLEANER AND AIR DUCT" .

4. Remove front and rear engine undercover with power tool.

5. Remove exhaust front tube and three way catalysts (right and left bank). Refer to EX-3, "

EXHAUST SYS-

TEM" .

6. Disconnect air fuel ratio sensor 1 (bank 1 and bank 2) harness connectors and remove harness clip.

1. Air fuel ratio sensor 1 (bank 1) 2. Exhaust manifold cover (right bank) 3. Exhaust manifold (right bank)

4. Gasket 5. Stud bolt 6. Exhaust manifold (left bank)

7. Exhaust manifold cover (left bank) 8. Air fuel ratio sensor 1 (bank 2)

PBIC3200E

Page 3090 of 5621

![INFINITI M35 2006 Factory Service Manual EXHAUST MANIFOLD

EM-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Using the heated oxygen sensor wrench (SST), remove air fuel

ratio sensor 1 (bank 1 and bank 2).

CAUTION INFINITI M35 2006 Factory Service Manual EXHAUST MANIFOLD

EM-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Using the heated oxygen sensor wrench (SST), remove air fuel

ratio sensor 1 (bank 1 and bank 2).

CAUTION](/img/42/57023/w960_57023-3089.png)

EXHAUST MANIFOLD

EM-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Using the heated oxygen sensor wrench (SST), remove air fuel

ratio sensor 1 (bank 1 and bank 2).

CAUTION:

Be careful not to damage air fuel ratio sensor 1.

Discard any air fuel ratio sensor 1 which has been

dropped onto a hard surface such as a concrete floor;

replace with a new sensor.

8. Remove exhaust manifold cover (right and left bank).

9. Loosen mounting nuts in the reverse order as shown in the fig-

ure to remove exhaust manifold with power tool.

NOTE:

Disregard the numerical order No. 7 and 8 in removal.

10. Remove gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSPECTION AFTER REMOVAL

Surface Distortion

Check the surface distortion of the exhaust manifold mating sur-

face with a straightedge and a feeler gauge.

If it exceeds the limit, replace exhaust manifold.

INSTALLATION

Note the following, and install in the reverse order of removal.

SBIA0575E

PBIC2042E

Limit : 0.3 mm (0.012 in)

PBIC1096E

Page 3091 of 5621

![INFINITI M35 2006 Factory Service Manual EM-28

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

Exhaust Manifold Gasket

Install in direction shown below. (Follow same procedure for

both banks.)

Locate thick side of port c INFINITI M35 2006 Factory Service Manual EM-28

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

Exhaust Manifold Gasket

Install in direction shown below. (Follow same procedure for

both banks.)

Locate thick side of port c](/img/42/57023/w960_57023-3090.png)

EM-28

[VQ35DE]

EXHAUST MANIFOLD

Revision: 2006 January2006 M35/M45

Exhaust Manifold Gasket

Install in direction shown below. (Follow same procedure for

both banks.)

Locate thick side of port connecting part on right side from tech-

nician’s view.

Locate round press in thick side of port connecting part above

center level line of port.

Exhaust Manifold

If stud bolts were removed, install them and tighten to the specified torque below.

Install exhaust manifold and tighten mounting bolts in numerical

order as shown in the figure.

NOTE:

Tighten nuts No. 1 and 2 in two steps. The numerical order No. 7

and 8 shows second step.

Air Fuel Ratio Sensor

CAUTION:

Before installing a new air fuel ratio sensor, clean exhaust system threads using heated oxygen

sensor thread cleaner tool (Commercial Service Tool: J-43897-18 or J-43897-12) and apply anti-

seize lubricant.

Do not over torque air fuel ratio sensor. Doing so may cause damage to air fuel ratio sensor,

resulting in the “MIL” coming on.

KBIA1051E

: 14.7 Nꞏm (1.5 kg-m, 11 ft-lb)

PBIC2042E