air condition INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5368 of 5621

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-7

C

D

E

F

G

I

J

K

L

MA

B

SRS

Revision: 2006 January2006 M35/M45

Occupant Classification System (OCS) NHS0008W

The occupant classification system identifies different size occupants, out of position occupants, and detects if

child seat is present in the front passenger seat. The occupant classification system receives inputs from the

occupant classification sensor (located inside the passenger seat cushion assembly) and belt tension sensor

(part of the passenger front seat belt assembly and located at the belt anchor location). Depending on classifi-

cation of passenger, the occupant classification system sends a signal to the diagnosis sensor unit. The diag-

nosis sensor unit uses this signal to determine full, partial, or non deployment of passenger front air bag in the

event of a collision. Depending on the signal received, the diagnosis sensor unit can disable the passenger

front air bag completely.

NOTE:

In case of customer concern, CONSULT-ll can be used to confirm the passenger air bag status (readiness).

Passenger Air Bag Status Condition NHS0008X

NOTE:

Passenger does not meet Ocuupant classification System specifications for passenger air bag activation.

Component Parts of Occupant Classification System NHS0008Y

Front Passenger Seat

(Condition)PASS AIR BAG OFF Indicator

(Status)Passenger Air Bag Status

(Readiness)CONSULT-ll Display

Seat occupied OFF Active (enabled) ON

seat occupiedNOTE ON Deactivated (disabled) OFF

Seat empty OFF Deactivated (disabled) OFF

PHIA1177E

1.Occupant classification system con-

trol unit2. Belt tension sensor 3. Seat pressure sensor

4. Bladder 5.Front passenger air bag OFF indica-

tor (Cutoff telltaile)

Page 5369 of 5621

SRS-8

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionNHS00090

CAUTION:

Do not use electrical test equipment on any circuit related to the SRS unless instructed in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Do not repair, splice or modify the SRS wiring harness. If the harness is damaged, replace it with a

new one.

Keep ground portion clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using “AIR BAG” warning lamp and/or CONSULT-II.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” warning lamp and CONSULT-II are as follows:

HOW TO PERFORM TROUBLE DIAGNOSIS FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information from Customer

WHAT..... Vehicle model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Preliminary Check

Make sure the following parts are in good order.

Battery (Refer to SC-4, "How to Handle Battery" .)

Fuse (Refer to SRS-12, "Wiring Diagram — SRS —" .)

System component-to-harness connections

User mode Diagnosis mode Display type

“AIR BAG” warning lamp X X ON-OFF operation

CONSULT-II — X Monitoring

Page 5381 of 5621

SRS-20

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

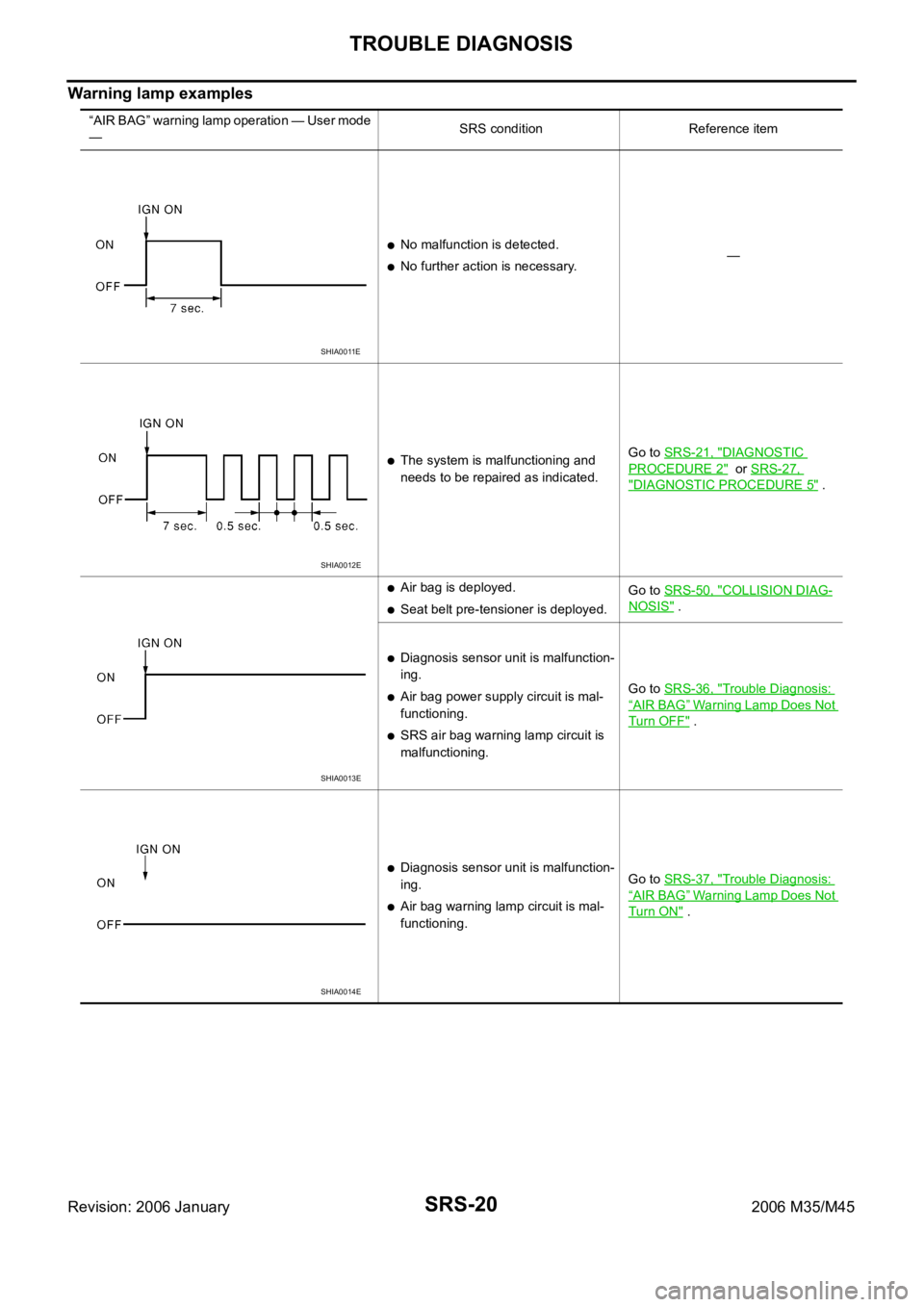

Warning lamp examples

“AIR BAG” warning lamp operation — User mode

—SRS condition Reference item

No malfunction is detected.

No further action is necessary.—

The system is malfunctioning and

needs to be repaired as indicated.Go to SRS-21, "DIAGNOSTIC

PROCEDURE 2" or SRS-27,

"DIAGNOSTIC PROCEDURE 5" .

Air bag is deployed.

Seat belt pre-tensioner is deployed.Go to SRS-50, "

COLLISION DIAG-

NOSIS" .

Diagnosis sensor unit is malfunction-

ing.

Air bag power supply circuit is mal-

functioning.

SRS air bag warning lamp circuit is

malfunctioning.Go to SRS-36, "

Trouble Diagnosis:

“AIR BAG” Warning Lamp Does Not

Turn OFF" .

Diagnosis sensor unit is malfunction-

ing.

Air bag warning lamp circuit is mal-

functioning.Go to SRS-37, "

Trouble Diagnosis:

“AIR BAG” Warning Lamp Does Not

Turn ON" .

SHIA0011E

SHIA0012E

SHIA0013E

SHIA0014E

Page 5403 of 5621

SRS-42

FRONT PASSENGER AIR BAG MODULE

Revision: 2006 January2006 M35/M45

FRONT PASSENGER AIR BAG MODULEPFP:K8515

Removal and InstallationNHS0009E

REMOVAL

CAUTION:

Before servicing, turn ignition switch OFF, disconnect both battery terminal and wait at

least 3 minutes.

Do not use air tools or electric tools for servicing.

Always work from the side of air bag module. Do not work from the front of it.

Always place air bag module with pad side facing upward.

Do not use old fixing bolts after removal; replace with new bolts.

Do not make an impact to the air bag module by dropping etc. Replace the air bag module if it has

been dropped or sustained an impact.

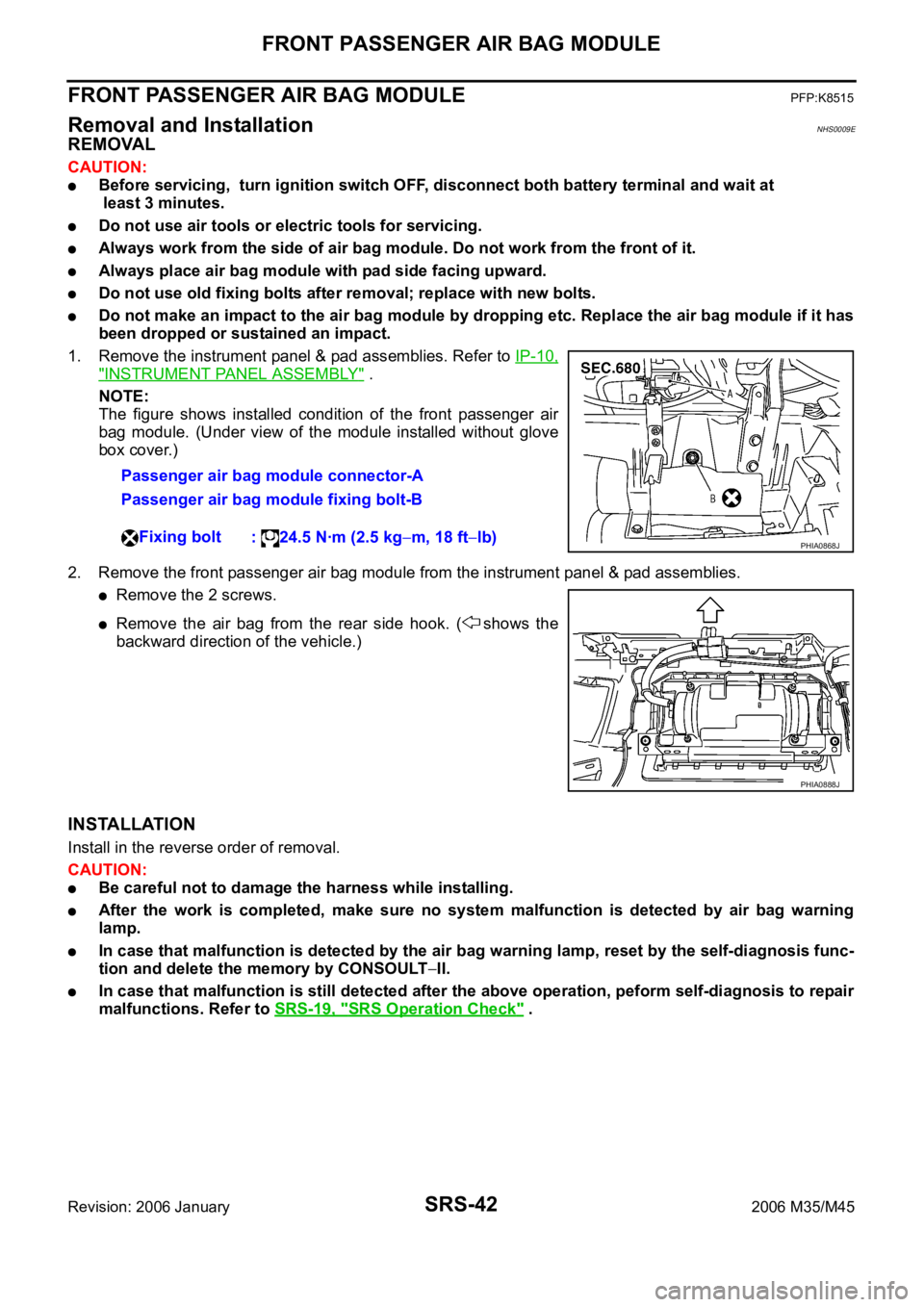

1. Remove the instrument panel & pad assemblies. Refer to IP-10,

"INSTRUMENT PANEL ASSEMBLY" .

NOTE:

The figure shows installed condition of the front passenger air

bag module. (Under view of the module installed without glove

box cover.)

2. Remove the front passenger air bag module from the instrument panel & pad assemblies.

Remove the 2 screws.

Remove the air bag from the rear side hook. ( shows the

backward direction of the vehicle.)

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the harness while installing.

After the work is completed, make sure no system malfunction is detected by air bag warning

lamp.

In case that malfunction is detected by the air bag warning lamp, reset by the self-diagnosis func-

tion and delete the memory by CONSOULT

II.

In case that malfunction is still detected after the above operation, peform self-diagnosis to repair

malfunctions. Refer to SRS-19, "

SRS Operation Check" . Passenger air bag module connector-A

Passenger air bag module fixing bolt-B

Fixing bolt

: 24.5 Nꞏm (2.5 kg

m, 18 ftlb)PHIA0868J

PHIA0888J

Page 5424 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr](/img/42/57023/w960_57023-5423.png)

TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pressure and size of tires proper?

Is the specified part used for the steering wheel?

Is control unit a genuine part?

Are there any fluid leakage from steering gear assembly, power steering oil pump, and hydraulic pipes,

etc? Refer to PS-8, "

POWER STEERING FLUID" .

Is the fluid level proper? Refer to PS-8, "POWER STEERING FLUID" .

Is the wheel alignment adjusted properly? Refer to FSU-19, "SERVICE DATA AND SPECIFICATIONS

(SDS)" (2WD), FSU-36, "SERVICE DATA AND SPECIFICATIONS (SDS)" (AWD).

Are there any damage or modification to suspension or body resulting in increased weight or altered

ground clearance?

Check each link installation condition of suspension and axle.

Check each connector connection condition.

Check the following items while driving the vehicle

Check conditions when the malfunction occurred (5W 1H).

Is the engine condition normal?

Basic InspectionNGS000E2

POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery terminals for looseness on both positive and negative ones and ground connection. Also make

sure that battery voltage does not drop.

Inspection: Power Steering Control Unit Power Supply Circuit and GroundNGS000E3

1. CHECK POWER STEERING CONTROL UNIT CONNECTOR

Turn ignition switch OFF, disconnect power steering control unit harness connector, and check terminal for

deformation, disconnection, looseness, etc.

OK or NG

OK >> GO TO 2.

NG >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

2. CHECK POWER STEERING CONTROL UNIT GROUND CIRCUIT

Disconnect power steering control unit harness connector M8, and

then check continuity between power steering control unit harness

connector M8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Ground circuit open or shorted. Repair or replace any

inoperative parts. Terminal 2 – Ground : Continuity exist.

SGIA1231E

Page 5444 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-29

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

How to Erase Self-Diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repai INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-29

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

How to Erase Self-Diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repai](/img/42/57023/w960_57023-5443.png)

TROUBLE DIAGNOSIS

STC-29

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

How to Erase Self-Diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine, and touch “START (NISSAN BASED VHCL)” “RAS/HICAS” “SELF-DIAG RESULTS” and

“ERASE” in this order to erase the diagnostic memory.

CAUTION:

If memory cannot be erased, repeat step 1, 2.

3. Perform self-diagnosis again, and make sure that DTC memory is erased.

C1912 MOTOR_VOLTAGE [BAD_OBSTRCT] (ꞏ b)The motor power supply voltage is

inputting for some time with motor

power supply OFF by RAS control

unit.STC-35

C1913 MOTOR_OUTPUT [ABNORMAL_SIG] (ꞏ a)When the motor current value is

10A or more, actual output is

excessively low and the condition

continues for some time.STC-37

C1902 MOTOR_OUTPUT [REV_CURRENT] (ꞏ c)The current flows in the opposite

direction when the motor current is

output. STC-37

C1903 MOTOR_OUTPUT [NO_CURRENT] (ꞏ d)The current flows when the motor

current is not output. STC-37

C1904 MOTOR_OUTPUT [OVERCURRENT] (ꞏ e)The excessive high current flows

when the motor current is output.STC-37

C1910 MOTOR_OUTPUT [MOTOR_LOCK] (ꞏ b)When 17 A or more current flows to

the motor, the rear wheel steering

angle sensor signal does not

change for some time.STC-37

C1919 VEHICLE_SPEED_SEN [NO_SIGNAL]No vehicle speed signal is input for

some time.STC-38

C1900

CONTROL_UNIT [ABNORMAL1 - 9] Control unit malfunctionSTC-35

C1901

C1905

C1906

C1907

C1908

C1909

C1922

C1928

C1920 STEERING_ANGLE_SEN [NO_SIGNAL]No steering angle signal is input for

some time.STC-38

C1926 STEERING_ANGLE_SEN

An unexpected signal is input.

Steering angle sensor outputs the

malfunction signal.STC-38

C1929 VDCABS actuator and electric unit (con-

trol unit) outputs the malfunction

signal.STC-42

U1000 CAN COMM CIRCUITWhen a control unit (except for

RAS) is not transmitting or receiving

CAN communication signal 2 sec-

onds or less.STC-43

U1010 CONTROL_UNIT [CAN]When detected error during the ini-

tial diagnosis of CAN controller of

each control unit.STC-43

DTC code Diagnostic item Diagnostic item is detected when... Check items

Page 5447 of 5621

![INFINITI M35 2006 Factory Service Manual STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires p INFINITI M35 2006 Factory Service Manual STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires p](/img/42/57023/w960_57023-5446.png)

STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires proper?

Is the specified part used for the steering wheel?

Is control unit a genuine part?

Are there any fluid leakage from steering gear assembly, power steering oil pump, and hydraulic pipes,

etc? Refer to PS-8, "

POWER STEERING FLUID" .

Is the fluid level proper? Refer to PS-8, "POWER STEERING FLUID" .

Is the wheel alignment is adjusted properly? Refer to FSU-19, "SERVICE DATA AND SPECIFICATIONS

(SDS)" (2WD), FSU-36, "SERVICE DATA AND SPECIFICATIONS (SDS)" (AWD).

Are there any damage or modification to suspension or body resulting in increased weight or altered

ground clearance?

Check each link installation condition of suspension and axle.

Is the battery voltage proper?

Check each connector connection condition.

Check the following items while driving the vehicle

Conditions when the error occurred (5W 1H).

Is the engine is normal?

Basic InspectionNGS000EO

BASIC INSPECTION 1: POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery terminals for looseness on both positive and negative ones and ground connection. Also make

sure that battery voltage does not drop.

BASIC INSPECTION 2: RAS WARNING LAMP INSPECTION

1. Make sure RAS warning lamp turns on when ignition switch is turned ON.

If it does not turn on, refer to STC-33, "Trouble Diagnosis Chart" .

2. Make sure that RAS warning lamp turns off when the engine is started after ignition switch is turned ON. If

it does not turn off, perform self-diagnosis. Refer to STC-28, "

SELF-DIAG RESULT MODE" .

3. Always erase DTC memory after completing self-diagnosis. Refer to STC-29, "

How to Erase Self-Diag-

nostic Results" .

BASIC INSPECTION 3: RAS CONTROL UNIT POWER SUPPLY CIRCUIT AND GROUND CIR-

CUIT INSPECTION

1. CHECK RAS CONTROL UNIT CONNECTOR

Turn ignition switch OFF, disconnect RAS control unit harness connector, and check terminal for deformation,

disconnection, looseness, etc.

OK or NG

OK >> GO TO 2.

NG >> Poor connection of connector terminal. Repair or replace the terminal.

2. CHECK RAS CONTROL UNIT GROUND CIRCUIT

1. Disconnect RAS control unit harness connector B127, and then

check continuity between RAS control unit harness connector

B127 and ground.

OK or NG

OK >> GO TO 3.

NG >> Ground circuit open or shorted. Repair or replace any

inoperative parts. Terminal 34 – Ground : Continuity

SGIA1244E

Page 5454 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-39

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, and disconnect INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-39

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, and disconnect](/img/42/57023/w960_57023-5453.png)

TROUBLE DIAGNOSIS

STC-39

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, and disconnect steering angle sensor harness connector M47.

2. Check continuity steering angle sensor harness connector M47

and ground.

3. Turn ignition switch ON, and then check voltage steering angle

sensor harness connector M47 and ground.

OK or NG

OK >> GO TO 4.

NG >> Steering angle sensor power supply and ground circuit

open or shorted. Repair or replace the applicable mal-

functioning circuit.

4. DATA MONITOR

1. Connect steering angle sensor harness connector.

2. Select ”DATA MONITOR“ on “STEERING ANG” mode, and then check the steering angle.

OK or NG

OK >> RAS control unit malfunction. Replace RAS control unit.

NG >> Replace steering angle sensor and adjust neutral position of steering angle sensor. Refer to BRC-

6, "Adjustment of Steering Angle Sensor Neutral Position" .

Steering angle sensor Ground Continuity

Te r m i n a l 2 — Ye s

SGIA1270E

Steering angle sensor Ground Continuity

Terminal 3 — Battery voltage (approx. 12V)

SGIA1271E

Steering condition DATA MONITOR

Straight-ahead position – 3.5 - +3.5

Turn wheel to the right by 90Approx. R 90

Turn wheel to the left by 90Approx. R 90

Page 5456 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-41

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK (2): REAR WHEEL STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-41

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK (2): REAR WHEEL STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF,](/img/42/57023/w960_57023-5455.png)

TROUBLE DIAGNOSIS

STC-41

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

3. CHECK (2): REAR WHEEL STEERING ANGLE SENSOR POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, disconnect rear wheel steering angle sensor harness connector B104 and RAS

control unit harness connector B127.

2. Check continuity each harness connector of rear wheel steering

angle sensor harness connector B 104 and RAS control unit

harness connector B127.

OK or NG

OK >> RAS control unit malfunction. Replace RAS control unit.

NG >> Harness between rear wheel steering angle sensor and RAS control unit open or shorted. Repair

or replace harness.

4. CHECK REAR WHEEL STEERING ANGLE SENSOR OUTPUT SIGNAL

1. Connect rear wheel steering angle sensor harness connector B104.

2. Check voltage RAS control unit harness connector B127 when

starting the engine and turning the steering wheel from neutral

position clockwise/counterclockwise by 180

.

CAUTION:

There is approximately 1 V or more difference between main output and sub output at straight-ahead position, inspection

results are “NG”.

OK or NG

OK >> RAS control unit malfunction. Replace RAS control unit.

NG >> GO TO 5.

SGIA1274E

Rear wheel steering angle sensor RAS control unit Continuity

Terminal 1 Terminal 5 Yes

Te r m i n a l 3 Te r m i n a l 1 5 Ye s

SGIA1275E

Steering conditionRear wheel steering angle sensor

Rear main output

Terminal 4 (+) - 15 (-)Rear sub output

Terminal 7 (+) - 15 (-)

Straight-ahead (neutral position) Approx. 2.4 V Approx. 2.4 V

Turn wheel to the right by 180

Approx. 4.4 V Approx. 4.4 V

Turn wheel to the left by 180

Approx. 0.4 V Approx. 0.4 V

Page 5459 of 5621

![INFINITI M35 2006 Factory Service Manual STC-44

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 10: Stop Lamp Switch HarnessNGS000EZ

1. CHECK STOP LAMP SWITCH SIGNAL

With CONSULT-II

Select “STOP LAMP SW” on DATA MON INFINITI M35 2006 Factory Service Manual STC-44

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 10: Stop Lamp Switch HarnessNGS000EZ

1. CHECK STOP LAMP SWITCH SIGNAL

With CONSULT-II

Select “STOP LAMP SW” on DATA MON](/img/42/57023/w960_57023-5458.png)

STC-44

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 10: Stop Lamp Switch HarnessNGS000EZ

1. CHECK STOP LAMP SWITCH SIGNAL

With CONSULT-II

Select “STOP LAMP SW” on DATA MONITOR, and then check the stop lamp switch.

Without CONSULT-II

1. Turn ignition switch OFF, disconnect RAS control unit harness connector B127.

2. Operate brake pedal, and then check voltage between RAS con-

trol unit harness connector B127 and ground.

OK or NG

OK >> Stop lamp switch harness is normal.

NG >> Stop lamp switch harness malfunction. Repair circuit.

Inspection 11: RAS Warning Lamp HarnessNGS000F0

1. CHECK RAS WARNING LAMP SIGNAL

Turn ignition switch ON, and then check voltage between RAS con-

trol unit harness connector B127 and ground.

OK or NG

OK >> Perform self-diagnosis. Refer to STC-28, "SELF-DIAG

RESULT MODE" .

NG >> GO TO 2.

Measuring condition Data monitor

Brake pedal depressed ON

Brake pedal released OFF

SGIA1277E

RAS C/U Ground Measuring condition Voltage

Terminal 22 —Brake pedal depressed Battery voltage (approx. 12 V)

Brake pedal released Approx. 0 V

RAS C/U Ground Voltage

Terminal26 —Warning lamp OFF : Approx. 2.8 V or more

Warning lamp ON : Approx. 1.4 V or less

SGIA1278E