charging INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5138 of 5621

SC-1

STARTING & CHARGING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION SC

A

B

SC

Revision: 2006 January2006 M35/M45

STARTING & CHARGING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions for Power Generation Voltage Variable

Control System ......................................................... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

BATTERY .................................................................... 4

How to Handle Battery ............................................. 4

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................................................... 4

CHECKING ELECTROLYTE LEVEL .................... 5

SPECIFIC GRAVITY CHECK ............................... 5

CHARGING THE BATTERY ................................. 6

Trouble Diagnosis with Battery/Starting/Charging

System Tester (Battery) ............................................ 7

DIAGNOSTIC RESULT ITEM CHART .................. 8

Removal and Installation .......................................... 9

REMOVAL ........................................................

..... 9

INSTALLATION ..................................................... 9

STARTING SYSTEM ................................................ 10

System Description ................................................ 10

Wiring Diagram — START — .................................. 11

VQ35DE ENGINE MODELS ................................ 11

VK45DE ENGINE MODELS ............................... 12

Trouble Diagnosis with Battery/Starting/Charging

System Tester (Starting) ......................................... 13

DIAGNOSTIC RESULT ITEM CHART ................ 13

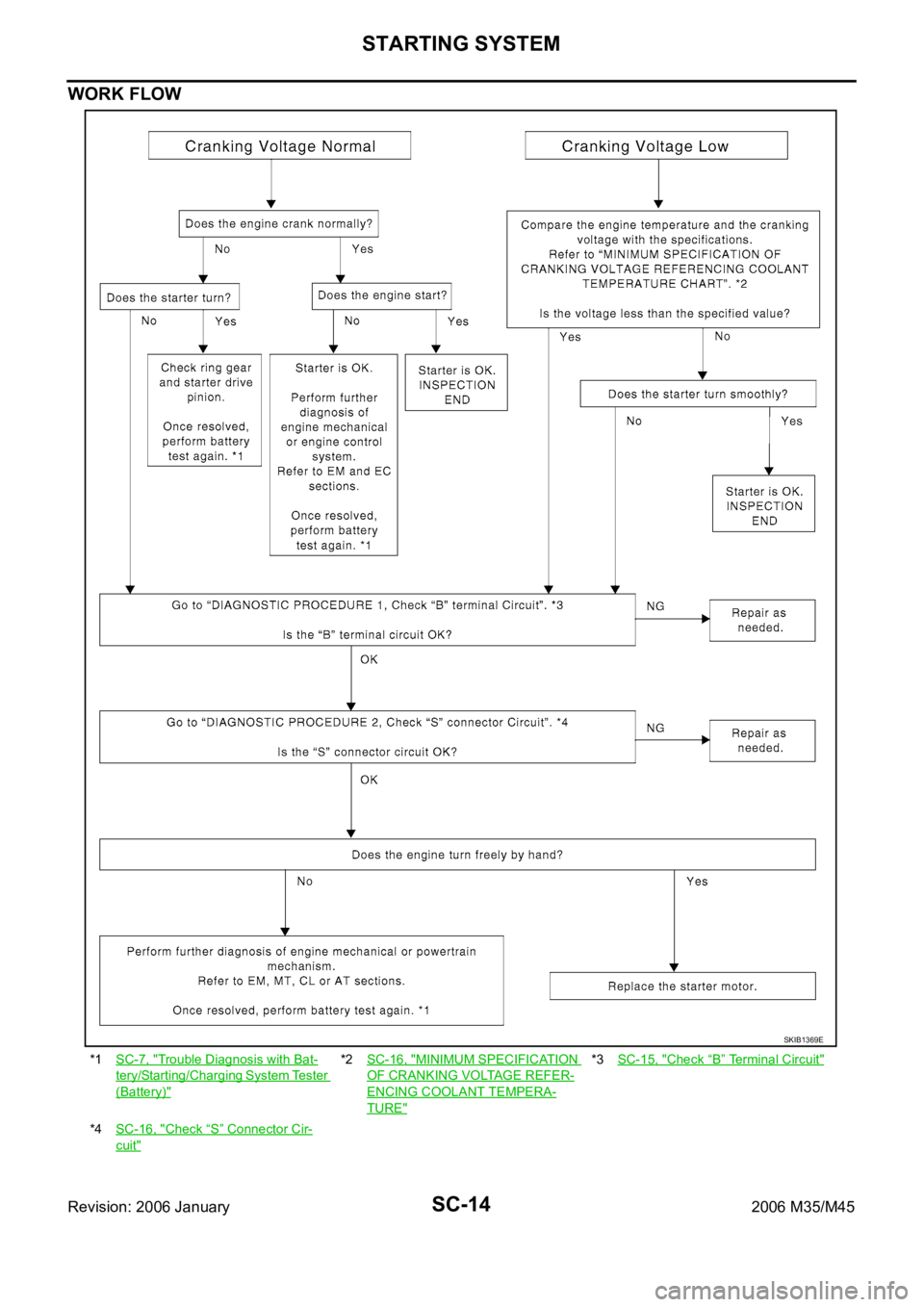

WORK FLOW ...................................................... 14

DIAGNOSTIC PROCEDURE 1 ........................... 15

DIAGNOSTIC PROCEDURE 2 ........................... 16

MINIMUM SPECIFICATION OF CRANKING

VOLTAGE REFERENCING COOLANT TEM-

PERATURE ......................................................... 16

Removal and Installation ........................................ 17

VQ35DE ENGINE MODELS (2WD) .................... 17VQ35DE ENGINE MODELS (AWD) .................... 18

VK45DE ENGINE MODELS ................................ 19

Disassembly and Assembly .................................... 20

VQ35DE ENGINE MODELS (2WD) .................... 20

VQ35DE ENGINE MODELS (AWD) .................... 21

VK45DE ENGINE MODELS ................................ 22

INSPECTION AFTER DISASSEMBLY ................ 22

CHARGING SYSTEM ............................................... 23

System Description ................................................. 23

DESCRIPTION .................................................... 23

MALFUNCTION INDICATOR .............................. 23

POWER GENERATION VOLTAGE VARIABLE

CONTROL SYSTEM ........................................... 24

Wiring Diagram — CHARGE — ............................. 25

VQ35DE ENGINE MODELS (2WD) .................... 25

VQ35DE ENGINE MODELS (AWD) .................... 26

VK45DE ENGINE MODELS .............................

... 27

Trouble Diagnoses with Battery/Starting/Charging

System Tester (Charging) ....................................... 28

DIAGNOSTIC RESULT ITEM CHART ................ 30

WORK FLOW ...................................................... 31

PRELIMINARY INSPECTION ............................. 32

DIAGNOSTIC PROCEDURE 1 ........................... 32

DIAGNOSTIC PROCEDURE 2 ........................... 33

DIAGNOSTIC PROCEDURE 3 ........................... 33

DIAGNOSTIC PROCEDURE 4 ........................... 34

Power Generation Voltage Variable Control System

Operation Inspection .............................................. 35

Removal and Installation ........................................ 37

VQ35DE ENGINE MODELS ............................... 37

VK45DE ENGINE MODELS ................................ 39

Disassembly and Assembly .................................... 41

VQ35DE ENGINE MODELS ............................... 41

VK45DE ENGINE MODELS ................................ 42

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 43

Battery .................................................................... 43

Starter ..................................................................... 43

Alternator ................................................................ 43

Page 5139 of 5621

SC-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONS PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NKS003NB

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Power Generation Voltage Variable Control SystemNKS003NC

CAUTION:

For this model, the battery current sensor that is installed to the battery cable at the negative terminal

measures the charging/discharging current of the battery, and performs various controls. If the electri-

cal component or the ground wire is connected directly to the battery terminal, the current other than

that being measured with the battery current sensor is charging to or discharging from the battery.

This condition causes the malfunction of the control, and then the battery discharge may occur. Do

not connect the electrical component or the ground wire directly to the battery terminal.

Page 5140 of 5621

PREPARATION

SC-3

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNKS003ND

Commercial Service ToolsNKS003NE

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-44373 Model 620)

Battery/Starting/Charging system

tester

SEL403X

Tool nameDescription

Power toolLoosening bolts, nuts and screws

PIIB1407E

Page 5141 of 5621

SC-4

BATTERY

Revision: 2006 January2006 M35/M45

BATTERY PFP:00011

How to Handle Battery NKS003NF

CAUTION:

If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

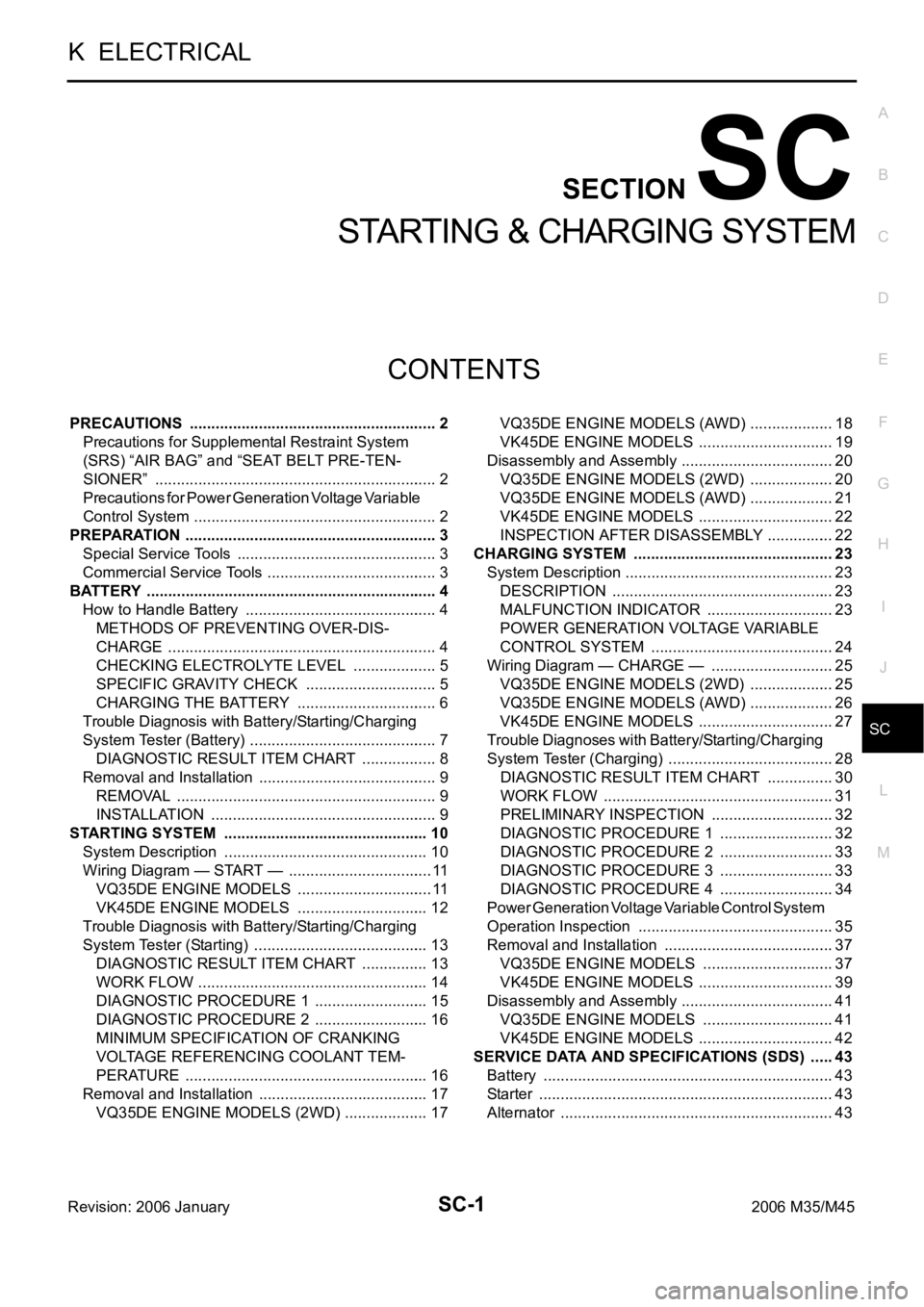

The battery surface (particularly its top) should always be kept

clean and dry.

The terminal connections should be clean and tight.

At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

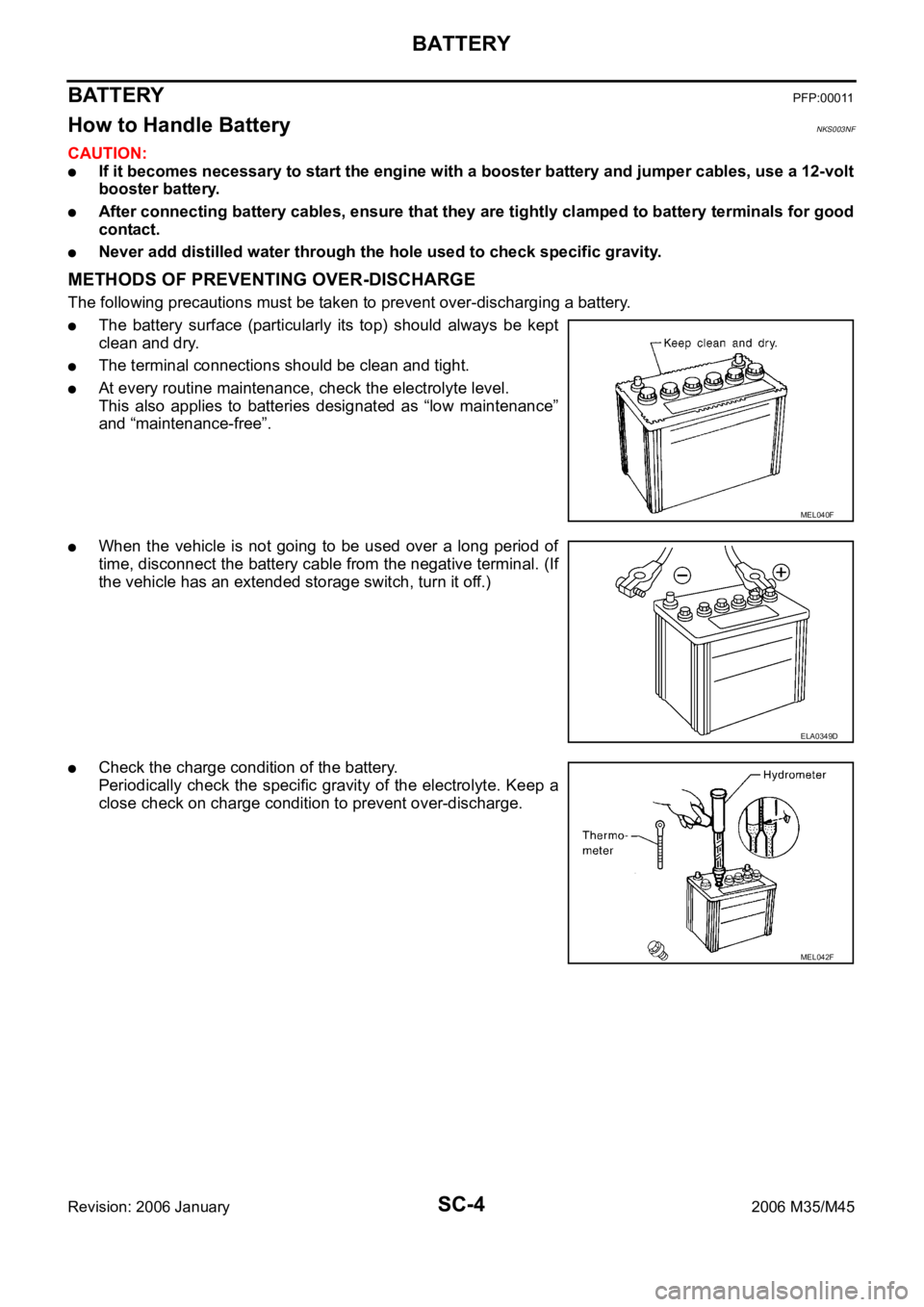

When the vehicle is not going to be used over a long period of

time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

MEL040F

ELA0349D

MEL042F

Page 5142 of 5621

BATTERY

SC-5

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

CHECKING ELECTROLYTE LEVEL

WAR NING :

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Remove the cell plug using a suitable tool.

Add distilled water up to the MAX level.

Sulphation

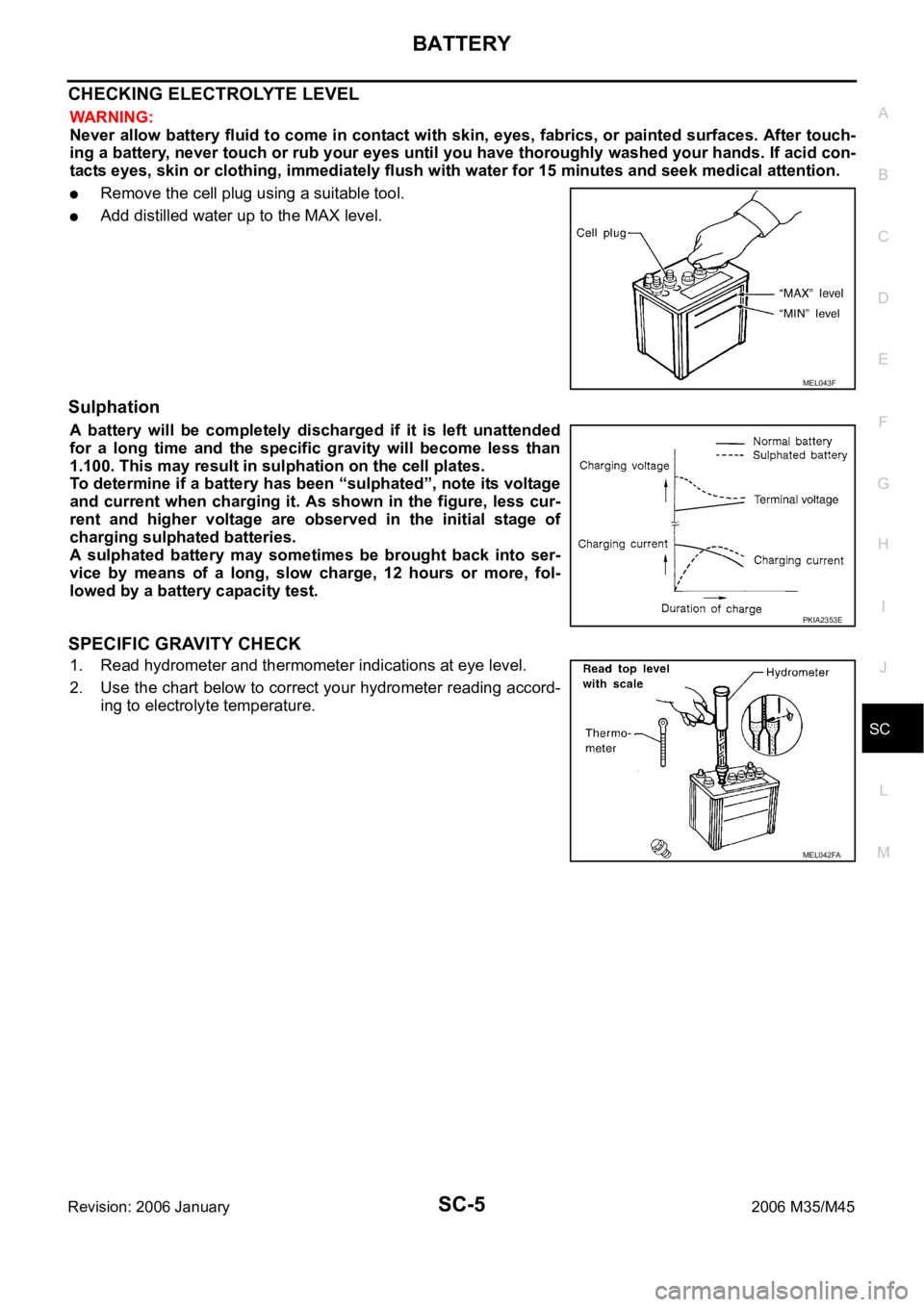

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been “sulphated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Use the chart below to correct your hydrometer reading accord-

ing to electrolyte temperature.

MEL043F

PKIA2353E

MEL042FA

Page 5143 of 5621

SC-6

BATTERY

Revision: 2006 January2006 M35/M45

Hydrometer Temperature Correction

CHARGING THE BATTERY

CAUTION:

Never “quick charge” a fully discharged battery.

Keep the battery away from open flame while it is being charged.

When connecting the charger, connect the leads first, then turn on the charger. Never turn on the

charger first, as this may cause a spark.

If battery electrolyte temperature rises above 55 C (131 F), stop charging. Always charge battery

at a temperature below 55

C (131 F).

Charging Rates

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indi-

cates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

Battery electrolyte temperature [C (F)] Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70)

0.004

16 (60)

0.008

10 (50)

0.012

4 (40)

0.016

1 (30)0.020

7 (20)0.024

12 (10)0.028

18 (0)0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Page 5144 of 5621

BATTERY

SC-7

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

If, after charging, the specific gravity of any two cells varies more than 0.050, the battery should be

replaced.

Trouble Diagnosis with Battery/Starting/Charging System Tester (Battery)NKS003NG

CAUTION:

When working with batteries, always wear appropriate eye protection.

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be

done as a set from start to finish.

If battery surface charge is detected while testing, the tester will prompt you to turn on the headlamps to

remove the surface charge.

If necessary, the tester will prompt you to determine if the battery temperature is above or below 0 C (32

F). Choose the appropriate selection by pressing the up or down arrow button, then press “ENTER” to

make the selection.

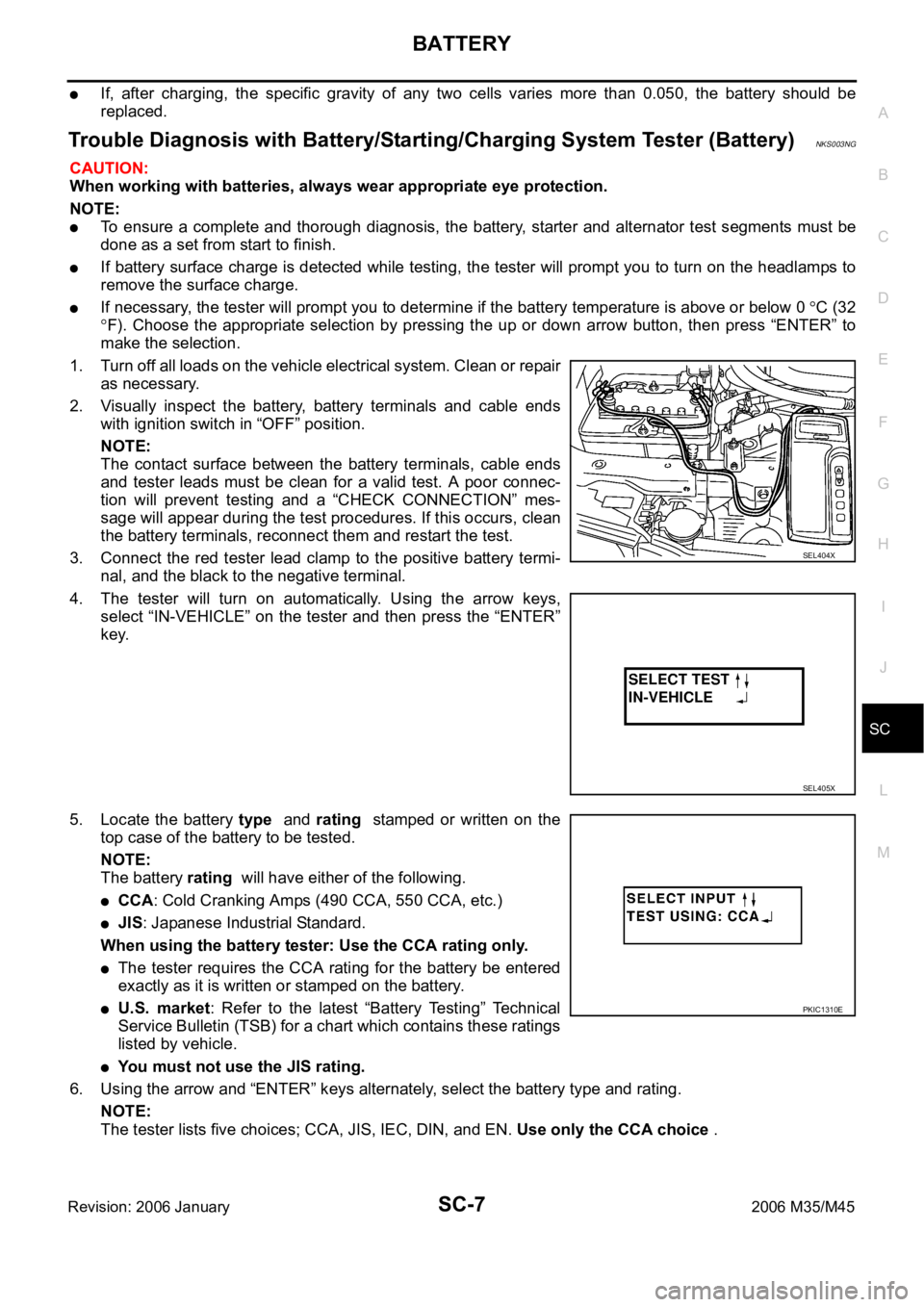

1. Turn off all loads on the vehicle electrical system. Clean or repair

as necessary.

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in “OFF” position.

NOTE:

The contact surface between the battery terminals, cable ends

and tester leads must be clean for a valid test. A poor connec-

tion will prevent testing and a “CHECK CONNECTION” mes-

sage will appear during the test procedures. If this occurs, clean

the battery terminals, reconnect them and restart the test.

3. Connect the red tester lead clamp to the positive battery termi-

nal, and the black to the negative terminal.

4. The tester will turn on automatically. Using the arrow keys,

select “IN-VEHICLE” on the tester and then press the “ENTER”

key.

5. Locate the battery type and rating stamped or written on the

top case of the battery to be tested.

NOTE:

The battery rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard.

When using the battery tester: Use the CCA rating only.

The tester requires the CCA rating for the battery be entered

exactly as it is written or stamped on the battery.

U.S. market: Refer to the latest “Battery Testing” Technical

Service Bulletin (TSB) for a chart which contains these ratings

listed by vehicle.

You must not use the JIS rating.

6. Using the arrow and “ENTER” keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Use only the CCA choice .

SEL404X

SEL405X

PKIC1310E

Page 5145 of 5621

SC-8

BATTERY

Revision: 2006 January2006 M35/M45

7. Press “ENTER” to begin the test. Diagnosis results are dis-

played on the tester. Refer to SC-8, "

DIAGNOSTIC RESULT

ITEM CHART" .

8. Press “ENTER”, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

NOTE:

If necessary, the tester will ask the user to determine if the bat-

tery has just been charged. Choose the appropriate selection by

pressing the up or down arrow button and then press the

“ENTER” button to make the selection.

When testing a battery installed in a vehicle that has recently

been driven, select “BEFORE CHANGE”.

If the battery has just been slow charged due to a “CHARGE &

RETEST” decision by the tester, and the tester asks the user “BEFORE CHARGE/AFTER CHARGE”,

select “AFTER CHARGE”.

DIAGNOSTIC RESULT ITEM CHART

SEL407X

SEL576X

Diagnostic item Service procedure

GOOD BATTERYBattery is OK, go to “Trouble Diagnosis”, “STARTING SYSTEM”. Refer to SC-13, "

Trouble Diagnosis with

Battery/Starting/Charging System Tester (Starting)" .

REPLACE BATTERYReplace battery.

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery test again with

Battery/Starting/Charging system tester. If second test result is “Replace Battery”, then do so. Perform bat-

tery test again to confirm repair.

BAD CELL-REPLACEReplace the battery. Perform battery test again with Battery/Starting/Charging system tester to confirm

repair.

GOOD-RECHARGEPerform the slow battery charging procedure. (Initial rate of charge is 10 A for 12 hours.) Perform battery

test again with Battery/Starting/Charging system tester.

CHARGE & RETESTPerform the slow battery charging. (Initial rate of charge is 10 A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester to confirm repair.

NOTE:

If the tester asks the user “BEFORE CHARGE/AFTER CHARGE”, select “AFTER CHARGE”.

Page 5150 of 5621

STARTING SYSTEM

SC-13

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

Trouble Diagnosis with Battery/Starting/Charging System Tester (Starting)NKS003NK

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

1. Turn off all loads on the vehicle electrical system.

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-7, "

Trouble Diagnosis with Battery/Starting/

Charging System Tester (Battery)" .

3. Press “ENTER” to begin the starting system test.

4. Start the engine.

5. Diagnostic result is displayed on the tester. Refer to SC-13,

"DIAGNOSTIC RESULT ITEM CHART" .

NOTE:

If the starter performs normally but the engine does not start,

perform engine diagnosis.

For intermittent “NO CRANK” or “NO STARTER OPERA-

TION” incidents, go to DIAGNOSTIC PROCEDURE 2.

DIAGNOSTIC RESULT ITEM CHART

SEL408X

SEL409X

SEL410X

Diagnostic item Service procedure

CRANKING VOLTAGE NORMAL

Go to SC-14, "

WORK FLOW" .

CRANKING VOLTAGE LOW

CHARGE BATTERYPerform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Perform

battery test again with Battery/Starting/Charging system tester. Refer to SC-7, "

Trouble Diagnosis

with Battery/Starting/Charging System Tester (Battery)" .

REPLACE BATTERYBefore replacing battery, clean the battery cable clamps and battery posts. Perform battery test

again with Battery/Starting/Charging system tester. Refer to SC-7, "

Trouble Diagnosis with Bat-

tery/Starting/Charging System Tester (Battery)" . If second test result is “REPLACE BATTERY”,

then do so. Perform battery test again to confirm repair.

Page 5151 of 5621

SC-14

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

WORK FLOW

*1SC-7, "Trouble Diagnosis with Bat-

tery/Starting/Charging System Tester

(Battery)"

*2SC-16, "MINIMUM SPECIFICATION

OF CRANKING VOLTAGE REFER-

ENCING COOLANT TEMPERA-

TURE"

*3SC-15, "Check “B” Terminal Circuit"

*4SC-16, "Check “S” Connector Cir-

cuit"

SKIB1369E