maintenance INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4799 of 5621

MA-22

ENGINE MAINTENANCE (VK45DE ENGINE)

Revision: 2006 January2006 M35/M45

ENGINE MAINTENANCE (VK45DE ENGINE)PFP:10001

Checking Drive BeltsNLS0007Q

WAR NING :

Be sure to perform when the engine is stopped.

Remove air duct (inlet) when inspecting drive belt for alternator, water pump and A/C compressor.

Remove front engine undercover with power tool when inspecting power steering oil pump belt.

Make sure that indicator (single line notch) of each auto tensioner is within the allowable working range

(between three line notches).

NOTE:

Check auto tensioner indication when engine is cold.

When new drive belt is installed, the range should be “A”.

The indicator notch is located on the moving side of the tensioner for alternator, water pump and A/C

compressor belt, while it is found on the fixed side for power steering oil pump belt.

Visually check entire belt for wear, damage or cracks.

If the indicator is out of allowable working range or belt is damaged, replace belt.

Te n s i o n A d j u s t m e n tNLS0007R

Belt tensioning is not necessary, as it is automatically adjusted by auto tensioner.

Changing Engine CoolantNLS0007S

WAR NING :

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Remove engine room cover (RH and LH) Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-179, "

INTAKE MANIFOLD" .

3. Open radiator drain plug at the bottom of radiator, and then remove radiator cap.

PBIC3822E

Page 4800 of 5621

ENGINE MAINTENANCE (VK45DE ENGINE)

MA-23

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to EM-250, "

DISASSEMBLY" .

4. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to MA-24, "

FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-254,

"ASSEMBLY" .

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug (1) on heater hose.

4. Fill thermostat housing and reservoir tank to specified level.

Refill engine coolant up to filler neck of thermostat housing.

Pour engine coolant through engine coolant filler neck slowly of less than 2 (2-1/8 US qt, 1-3/4

Imp qt) a minute to allow air in system to escape.

Use Genuine NISSAN Long Life Antifreeze/Coolant or equivalent mixed with water (distilled or

demineralized). Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

1 : Radiator drain plug hole

2 : Front engine undercover

: Engine front

PBIC3395E

Radiator drain plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

: Engine front

PBIC3394E

Engine coolant capacity

(With reservoir tank at “MAX” level):

Approx. 10.4 (11 US qt, 9-1/8 Imp qt)

Page 4801 of 5621

MA-24

ENGINE MAINTENANCE (VK45DE ENGINE)

Revision: 2006 January2006 M35/M45

When engine coolant overflows air relief hole on heater hose,

install air relief plug.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop engine and cool down to less than approximately 50

C (122F).

Cool down using a fan to reduce the time.

If necessary, refill engine coolant up to filler neck of thermostat housing.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer

drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-254,

"ASSEMBLY" .

2. Remove air relief plug (1) on heater hose.

3. Fill thermostat housing with water until water spills from the air relief hole, then close air relief plug. Fill

thermostat housing and reservoir tank with water and reinstall radiator cap. Reservoir tank engine coolant capacity

(At “MAX” level):

0.6 (5/8 US qt, 1/2 lmp qt)

Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

SMA412B

Radiator drain plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

: Engine front

PBIC3394E

Page 4802 of 5621

ENGINE MAINTENANCE (VK45DE ENGINE)

MA-25

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to CO-40, "

DRAINING ENGINE COOLANT" .

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LinesNLS0007T

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterNLS0007U

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-7,

"PERIODIC MAINTENANCE" .

Changing Engine OilNLS0007V

WAR NING :

Be careful not to burn yourself, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct

skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-26, "

ENGINE OIL LEAKAGE" .

2. Stop engine and wait for 15 minutes.

3. Loosen oil filler cap.

4. Remove mounting bolts, and then pull down the rear of front engine undercover and secure it using clip.

5. Remove drain plug and then drain engine oil.

6. Install drain plug with new washer. Refer to EM-187, "

OIL PAN AND OIL STRAINER" .

CAUTION:

Be sure to clean drain plug and install with new washer.Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

SMA803A

PBIC0993E

Oil pan drain plug:

: 34.3 Nꞏm (3.5 kg-m, 25 ft-lb)

Page 4803 of 5621

MA-26

ENGINE MAINTENANCE (VK45DE ENGINE)

Revision: 2006 January2006 M35/M45

7. Refill with new engine oil.

Engine oil specification and viscosity:

Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in the engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 15 minutes.

10. Check the engine oil level.

Changing Oil FilterNLS0007W

REMOVAL

WAR NING :

Be careful not to get burned when the engine and engine oil may be hot.

1. Remove front engine undercover with power tool.

2. Using the oil filter wrench (SST), remove the oil filter.

CAUTION:

Oil filter is provided with relief valve. Use Genuine Nissan

Oil Filter or equivalent.

When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

Do not allow engine oil to adhere to drive belts.

Completely wipe off any engine oil that adhere to engine

and vehicle.

INSTALLATION

1. Remove foreign materials adhering to oil filter installation surface.

2. Apply new engine oil to the oil seal circumference of the new oil

filter.

Drain and refillWith oil filter change 5.5 (5-3/4, 4-7/8)

without oil filter change 4.9 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.7 (7-1/8, 5-7/8)

PBIC0801E

PBIC1525E

SMA010

Page 4804 of 5621

ENGINE MAINTENANCE (VK45DE ENGINE)

MA-27

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Start engine, and check there is no leaks of engine oil.

2. Stop engine and wait for 15 minutes.

3. Check the engine oil level and add engine oil. Refer to MA-25, "

Changing Engine Oil" .

Changing Spark Plugs (Platinum-Tipped Type)NLS0007X

REMOVAL

1. Remove engine cover with power tool. Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove ignition coil. Refer to EM-190, "

IGNITION COIL" .

3. Remove spark plug with spark plug wrench (commercial service

tool).

CAUTION:

Do not drop or shock it.

INSPECTION AFTER REMOVAL

Use standard type spark plug for normal condition.

Hot type spark plug is suitable when fouling occurs with standard type spark plug under conditions such as:

Frequent engine starts

Low ambient temperatures

Cold type spark plug is suitable when spark plug knock occurs with standard type spark plug under conditions

such as:

Extended highway driving

Frequent high engine revolution

CAUTION:

Do not drop or shock spark plug.Oil filter:

:17.7 Nꞏm (1.8 kg-m, 13 ft-lb)

SMA229B

SEM294A

MakeNGK

Standard typePLFR5A-11

Hot typePLFR4A-11

Cold typePLFR6A-11

Gap (Nominal) : 1.1 mm (0.043 in)

Page 4805 of 5621

MA-28

ENGINE MAINTENANCE (VK45DE ENGINE)

Revision: 2006 January2006 M35/M45

Do not use wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may

be used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Checking EVAP Vapor LinesNLS0007Y

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc.

Refer to EC-749, "

EVAPORATIVE EMISSION SYSTEM" . Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2 , 85 psi)

Cleaning time:

Less than 20 seconds

SMA773C

SMA806CA

Spark plug:

: 24.6 Nꞏm (2.5 kg-m, 18 ft-lb)

Page 4806 of 5621

CHASSIS AND BODY MAINTENANCE

MA-29

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

CHASSIS AND BODY MAINTENANCEPFP:00100

Checking Exhaust SystemNLS0007Z

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage, chafing or deterioration.

If anything is found, repair or replace damaged parts.

Checking A/T FluidNLS00080

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Loosen the level gauge bolt.

4. Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50

C (86 to 122F) using “COLD” range on A/

T fluid level gauge as follows.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free

paper.

CAUTION:

When wiping away the A/T fluid level gauge, always use

lint-free paper, not a cloth one.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

To check A/T fluid level, insert the A/T fluid level gauge until the cap contacts the end of the A/T

fluid charging pipe, with the A/T fluid level gauge reversed from the normal attachment conditions.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add ATF to the A/T fluid

charging pipe.

CAUTION:

Do not overfill.

5. Drive vehicle for approximately 5 minutes in urban areas.

6. Make the A/T fluid temperature approximately 65

C (149F).

SMA211A

SCIA4835E

Page 4807 of 5621

MA-30

CHASSIS AND BODY MAINTENANCE

Revision: 2006 January2006 M35/M45

NOTE:

A/T fluid level will be greatly affected by temperature as shown in figure. Therefore, be certain to

perform operation while checking data with CONSULT-II.

a. Connect CONSULT-II to data link connector. Refer to AT-92, "

CONSULT-II SETTING PROCEDURE" .

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

c. Read out the value of “ATF TEMP 1”.

7. Re-check A/T fluid level at A/T fluid temperatures of approximately 65

C (149F) using “HOT” range on A/

T fluid level gauge.

CAUTION:

When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

To check A/T fluid level, insert the A/T fluid level gauge

until the cap contacts the end of the A/T fluid charging

pipe, with the A/T fluid level gauge reversed from the nor-

mal attachment conditions as shown.

8. Check A/T fluid condition.

If ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to CO-14,

"RADIATOR" (for VQ35DE engine), CO-43, "RADIATOR"

(for VK45DE engine) and AT- 1 4 , "A/T Fluid Cooler Cleaning" .

9. Install the removed A/T fluid level gauge in the A/T fluid charging

pipe.

10. Tighten level gauge bolt.

Level gauge bolt

: 5.1 Nꞏm (0.52 kg-m, 45 in-lb)

SLIA0016E

SCIA2899E

SCIA4896E

Page 4808 of 5621

CHASSIS AND BODY MAINTENANCE

MA-31

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

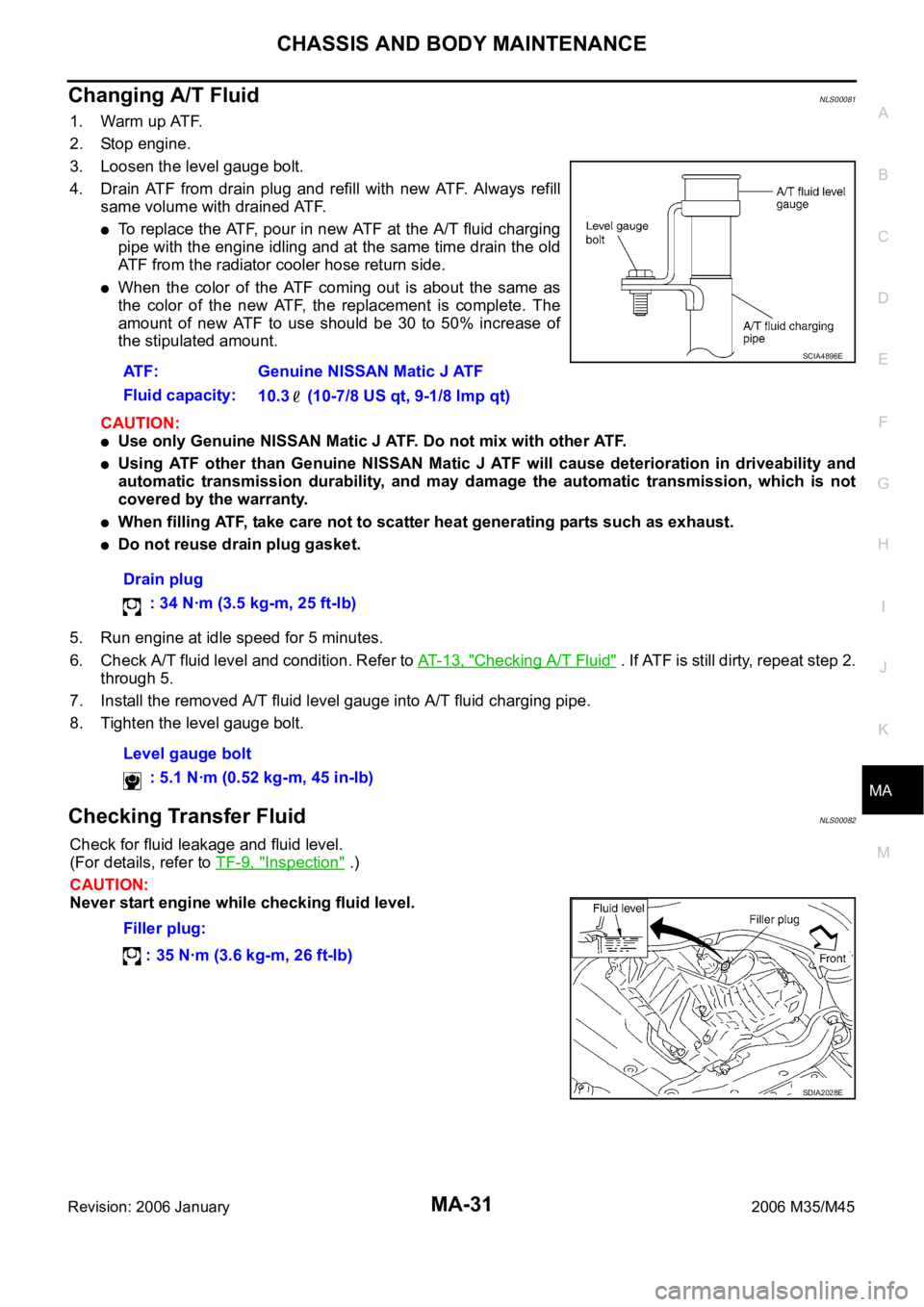

Changing A/T FluidNLS00081

1. Warm up ATF.

2. Stop engine.

3. Loosen the level gauge bolt.

4. Drain ATF from drain plug and refill with new ATF. Always refill

same volume with drained ATF.

To replace the ATF, pour in new ATF at the A/T fluid charging

pipe with the engine idling and at the same time drain the old

ATF from the radiator cooler hose return side.

When the color of the ATF coming out is about the same as

the color of the new ATF, the replacement is complete. The

amount of new ATF to use should be 30 to 50% increase of

the stipulated amount.

CAUTION:

Use only Genuine NISSAN Matic J ATF. Do not mix with other ATF.

Using ATF other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not

covered by the warranty.

When filling ATF, take care not to scatter heat generating parts such as exhaust.

Do not reuse drain plug gasket.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to AT- 1 3 , "

Checking A/T Fluid" . If ATF is still dirty, repeat step 2.

through 5.

7. Install the removed A/T fluid level gauge into A/T fluid charging pipe.

8. Tighten the level gauge bolt.

Checking Transfer FluidNLS00082

Check for fluid leakage and fluid level.

(For details, refer to TF-9, "

Inspection" .)

CAUTION:

Never start engine while checking fluid level.ATF: Genuine NISSAN Matic J ATF

Fluid capacity:

10.3 (10-7/8 US qt, 9-1/8 lmp qt)

Drain plug

: 34 Nꞏm (3.5 kg-m, 25 ft-lb)

Level gauge bolt

: 5.1 Nꞏm (0.52 kg-m, 45 in-lb)

SCIA4896E

Filler plug:

: 35 Nꞏm (3.6 kg-m, 26 ft-lb)

SDIA2028E