turn signals INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 927 of 5621

BCS-6

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

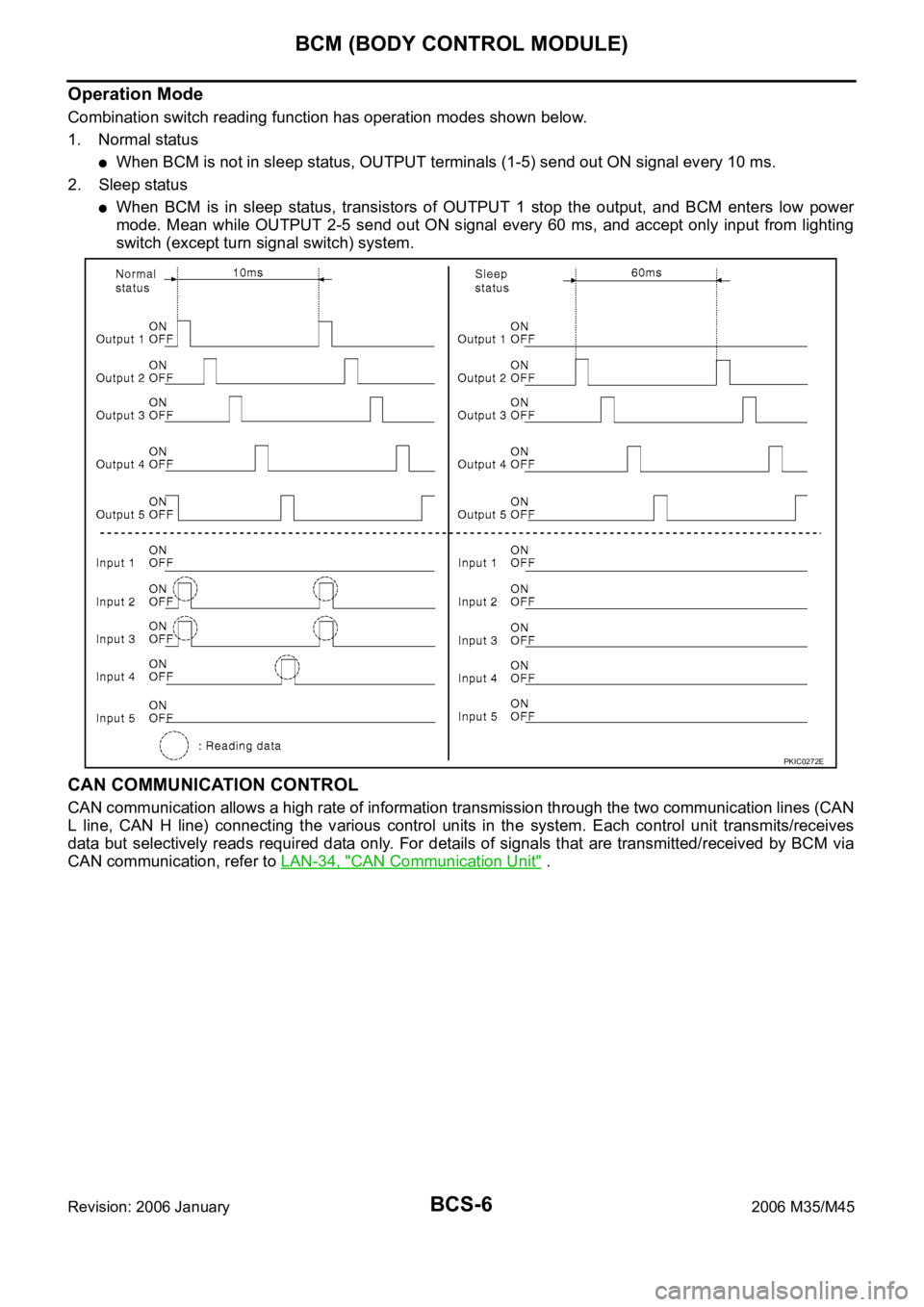

Operation Mode

Combination switch reading function has operation modes shown below.

1. Normal status

When BCM is not in sleep status, OUTPUT terminals (1-5) send out ON signal every 10 ms.

2. Sleep status

When BCM is in sleep status, transistors of OUTPUT 1 stop the output, and BCM enters low power

mode. Mean while OUTPUT 2-5 send out ON signal every 60 ms, and accept only input from lighting

switch (except turn signal switch) system.

CAN COMMUNICATION CONTROL

CAN communication allows a high rate of information transmission through the two communication lines (CAN

L line, CAN H line) connecting the various control units in the system. Each control unit transmits/receives

data but selectively reads required data only. For details of signals that are transmitted/received by BCM via

CAN communication, refer to LAN-34, "

CAN Communication Unit" .

PKIC0272E

Page 971 of 5621

BL-32

POWER DOOR LOCK SYSTEM

Revision: 2006 January2006 M35/M45

CONSULT-II Function (BCM)NIS001WX

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunction might be detected

in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch “OFF”.

2. Connect “CONSULT-II” and “CONSULT-II CONVERTER” to the

data link connector (1).

3. Turn ignition switch “ON”.

4. Touch “START”. (NISSAN BASED VHCL)

5. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, go to GI-40, "

CONSULT-II Data Link

Connector (DLC) Circuit" .

BCM diagnosis

partInspection item, self-diagnosis

modeContent

Door lockDATA MONITOR Displays the input data of BCM in real time basis.

ACTIVE TEST Give a drive signals to load to check the operation check.

PBIB2712E

BCIA0029E

BCIA0030E

Page 975 of 5621

BL-36

POWER DOOR LOCK SYSTEM

Revision: 2006 January2006 M35/M45

Check Door Lock and Unlock Switch NIS001X0

1. CHECK POWER WINDOW SWITCH OUTPUT SIGNAL

With CONSULT-II

Check (“CDL LOCK SW ”, “CDL UNLOCK SW”) in DATA MONITOR mode with CONSULT-II.

Without CONSULT-II

1. Remove key from ignition switch, and the door of driver side and passenger side is closed.

2. Check signal between BCM connector and ground with oscilloscope when door lock and unlock switch

(driver side and passenger side) is turned “LOCK” or “UNLOCK”.

3. Make sure signals which are shown in the figure below can be detected during 10 second just after door

lock and unlock switch (driver side and passenger side) is turned “LOCK” or “UNLOCK”.

OK or NG

OK >> Door lock and unlock switch is OK.

NG >> GO TO 2.

Monitor item Condition

CDL LOCK SW LOCK : ON

UNLOCK : OFF

CDL UNLOCK SW LOCK : OFF

UNLOCK : ON

PIIA7068E

Terminal

Signal

(Reference value) (+)

(–)

BCM connector Terminal

M1 22 Ground

PIIB5957EPIIA1297E

Page 990 of 5621

INTELLIGENT KEY SYSTEM

BL-51

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Hazard and buzzer reminder can be changed using “HAZARD ANSWER BACK”, “ANSWER BACK WITH I-

KEY LOCK” and “ANSWER BACK WITH I-KEY UNLOCK” mode in “WORK SUPPORT”.Refer to BL-83,

"WORK SUPPORT" .

Auto Door Lock Function

When all doors are locked, ignition switch is in OFF position and key switch is OFF (Intelligent Key is not

inserted in key slot), doors are unlocked with door request switch

When Intelligent Key unit does not receive the following signals within 60 seconds, all doors are locked.

Door switch is ON (door is opened)

Door is locked

Ignition switch is ON (ignition switch is pressed)

Key switch is ON (Intelligent Key is inserted in key slot)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-

83, "WORK SUPPORT" .

Room Lamp Operation

When the following conditions are met:

Condition of interior lamp switch is in DOOR position

Door switch OFF (all the doors are closed)

Intelligent Key system turns on interior lamp (for 30 seconds) by receiving UNLOCK signal from door request

switch. For detailed description, refer to LT-270, "

ROOM LAMP TIMER OPERATION" .

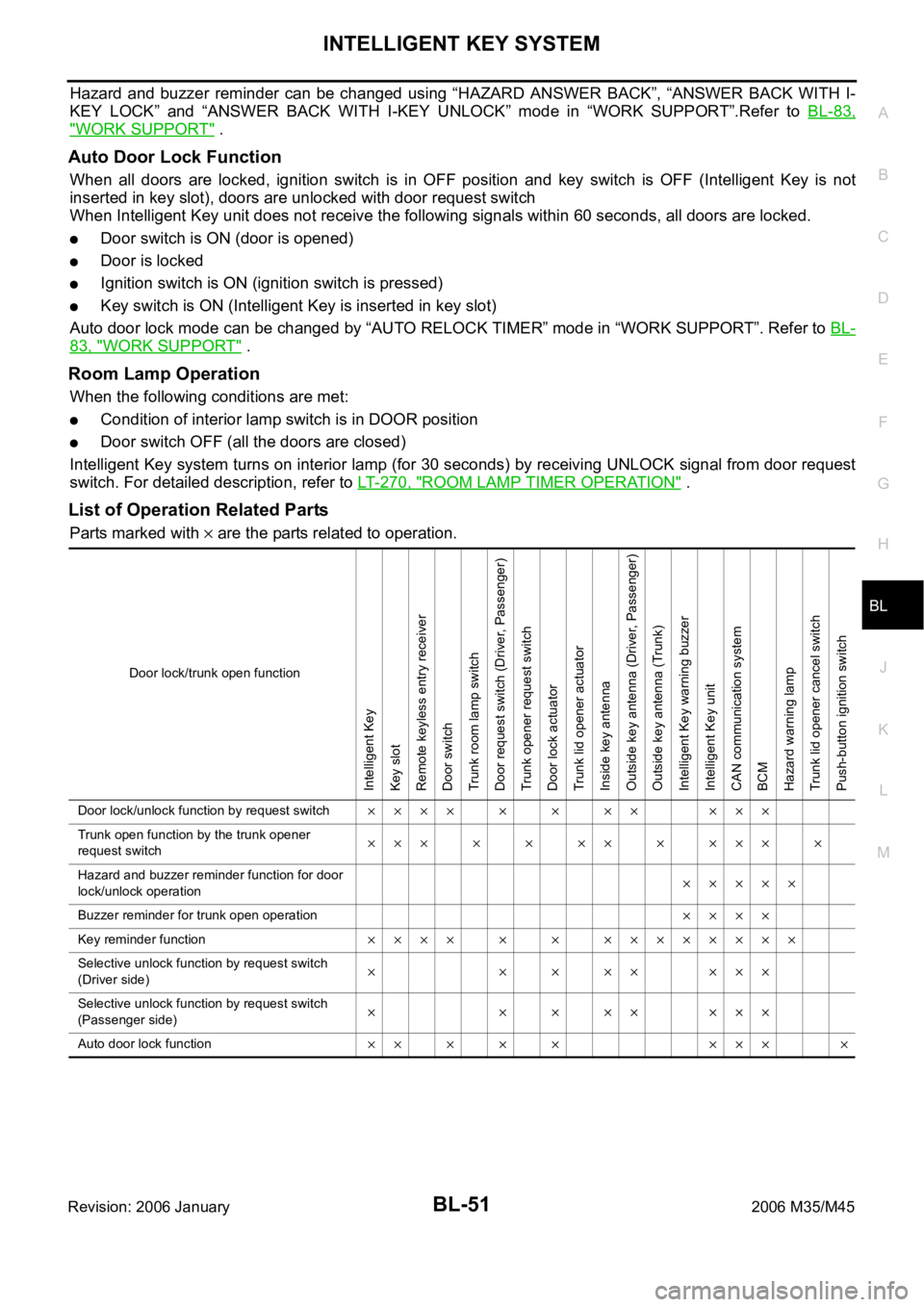

List of Operation Related Parts

Parts marked with are the parts related to operation.

Door lock/trunk open function

Intelligent Key

Key slot

Remote keyless entry receiver

Door switch

Trunk room lamp switch

Door request switch (Driver, Passenger)

Trunk opener request switch

Door lock actuator

Trunk lid opener actuator

Inside key antenna

Outside key antenna (Driver, Passenger)

Outside key antenna (Trunk)

Intelligent Key warning buzzer

Intelligent Key unit

CAN communication system

BCM

Hazard warning lamp

Trunk lid opener cancel switch

Push-button ignition switch

Door lock/unlock function by request switch

Trunk open function by the trunk opener

request switch

Hazard and buzzer reminder function for door

lock/unlock operation

Buzzer reminder for trunk open operation

Key reminder function

Selective unlock function by request switch

(Driver side)

Selective unlock function by request switch

(Passenger side)

Auto door lock function

Page 992 of 5621

INTELLIGENT KEY SYSTEM

BL-53

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

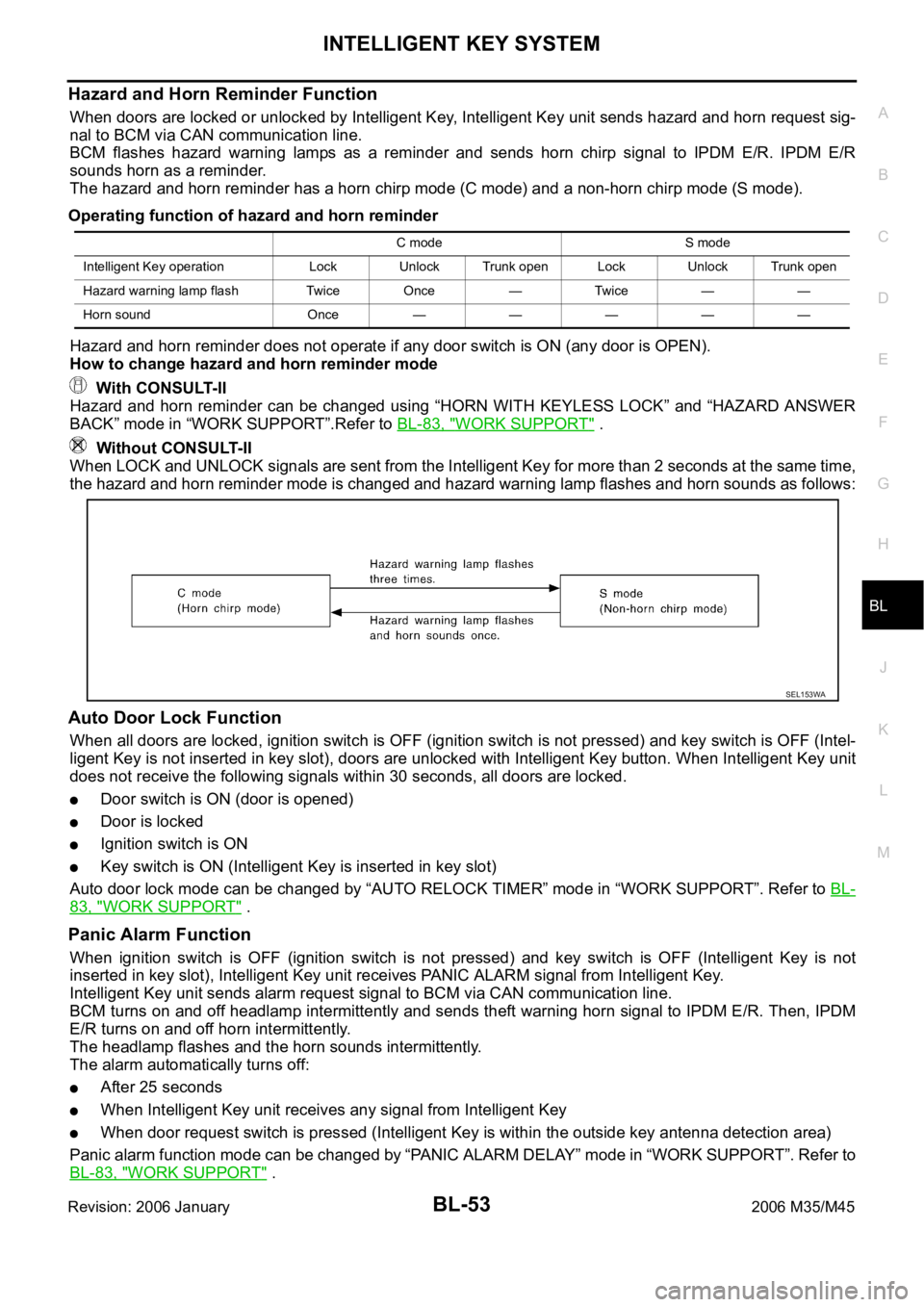

Hazard and Horn Reminder Function

When doors are locked or unlocked by Intelligent Key, Intelligent Key unit sends hazard and horn request sig-

nal to BCM via CAN communication line.

BCM flashes hazard warning lamps as a reminder and sends horn chirp signal to IPDM E/R. IPDM E/R

sounds horn as a reminder.

The hazard and horn reminder has a horn chirp mode (C mode) and a non-horn chirp mode (S mode).

Operating function of hazard and horn reminder

Hazard and horn reminder does not operate if any door switch is ON (any door is OPEN).

How to change hazard and horn reminder mode

With CONSULT-II

Hazard and horn reminder can be changed using “HORN WITH KEYLESS LOCK” and “HAZARD ANSWER

BACK” mode in “WORK SUPPORT”.Refer to BL-83, "

WORK SUPPORT" .

Without CONSULT-II

When LOCK and UNLOCK signals are sent from the Intelligent Key for more than 2 seconds at the same time,

the hazard and horn reminder mode is changed and hazard warning lamp flashes and horn sounds as follows:

Auto Door Lock Function

When all doors are locked, ignition switch is OFF (ignition switch is not pressed) and key switch is OFF (Intel-

ligent Key is not inserted in key slot), doors are unlocked with Intelligent Key button. When Intelligent Key unit

does not receive the following signals within 30 seconds, all doors are locked.

Door switch is ON (door is opened)

Door is locked

Ignition switch is ON

Key switch is ON (Intelligent Key is inserted in key slot)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-

83, "WORK SUPPORT" .

Panic Alarm Function

When ignition switch is OFF (ignition switch is not pressed) and key switch is OFF (Intelligent Key is not

inserted in key slot), Intelligent Key unit receives PANIC ALARM signal from Intelligent Key.

Intelligent Key unit sends alarm request signal to BCM via CAN communication line.

BCM turns on and off headlamp intermittently and sends theft warning horn signal to IPDM E/R. Then, IPDM

E/R turns on and off horn intermittently.

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off:

After 25 seconds

When Intelligent Key unit receives any signal from Intelligent Key

When door request switch is pressed (Intelligent Key is within the outside key antenna detection area)

Panic alarm function mode can be changed by “PANIC ALARM DELAY” mode in “WORK SUPPORT”. Refer to

BL-83, "

WORK SUPPORT" .

C mode S mode

Intelligent Key operation Lock Unlock Trunk open Lock Unlock Trunk open

Hazard warning lamp flash Twice Once — Twice — —

Horn sound Once—————

SEL153WA

Page 1068 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-129

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

In the Intelligent Key system of model Y50, the transponder (the chip for immobilizer ID verifica-

tion) is integrated into the Intelligent Key. (For the conventional models, it is integrated into the

mechanical key.) Therefore, the mechanical key cannot perform the ID verification, and thus it can-

not start the engine. Instead of it, the immobilizer ID verification can be performed by inserting the

Intelligent Key into the key slot, and then it can start the engine.

When registering the Intelligent Key, 2 registration procedures (immobilizer ID registration and

Intelligent Key ID registration) should be performed. The immobilizer ID registration is the proce-

dure that registers the ID stored into the transponder (integrated into Intelligent Key) to the BCM.

The Intelligent Key ID registration is the procedure that registers the ID to the Intelligent Key unit.

Each registration is a different procedure.

When performing the Intelligent Key ID registration only, the engine cannot be started by inserting

the key into the key slot. When performing the engine immobilizer ID registration only, the engine

cannot be started by the operation when carrying the key. The registrations of both systems

should be performed.

Operation DescriptionNIS001Y9

SYSTEM DIAGRAM

OPERATION WHEN INTELLIGENT KEY IS CARRIED

Description

1. When the push-button switch is pressed, the Intelligent Key unit signals the inside key antenna and sends

the request signal to the Intelligent Key.

2. The Intelligent Key receives the request signal and sends the Intelligent Key ID signal to the Intelligent

Key unit via the remote keyless entry receiver.

3. The Intelligent Key receives the Intelligent Key ID signal and verifies it with the registered ID.

4. If the ID is successfully verified, the Intelligent Key unit sends the steering unlock signal to the steering

lock unit. Then, it sends each power supply request signal to PDU (Power Distribution Unit) after unlock-

ing the steering lock.

5. If the Intelligent Key unit judges that the engine start condition is satisfied, it sends the starter request sig-

nal via CAN communication to IPDM E/R and turns the starter motor relay ON.

6. The steering lock unit unlocks the steering lock when receiving the signal. PDU starts the power supply

distribution according to the push-button ignition switch operation when receiving the signal. If it enters the

engine start permission mode, the power supply is supplied from PDU to the starter motor relay and the

cranking is started.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning lamp in the combina-

tion meter illuminates for 15 seconds. At that time, the engine cannot be started.

7. When Intelligent Key unit received feedback signal from ECM acknowledging the engine has been initi-

ated, the Intelligent Key unit sends a stop signal to IPDM E/R and stops the cranking by turning OFF the

PIIB6272E

Page 1103 of 5621

BL-164

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Revision: 2006 January2006 M35/M45

SELF-DIAGNOSTIC LOGIC

DIAGNOSTIC PROCEDURE

1. CHECK POWER SUPPLY CIRCUIT

With CONSULT-II

Check (“IGN ON SW”) in DATA MONITOR mode with CONSULT-II.

Without CONSULT-II

Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> Check the condition of harness and connector. If it is

OK, check the self-diagnosis results using CONSULT-II

again.

NG >> Check Intelligent Key unit power supply circuit for open or short.

DTC B2554 ACC POWER CIRCUITNIS001YR

DIAGNOSIS DESCRIPTION

B2554 ACC power supply circuit monitors the following 2 signals.

Though the power supply switching control to ACC position by push-button ignition switch operation is

performed normally, if there is no ACC power supply input to the Intelligent Key unit, it judges that it is the

malfunction and displays the DTC (Diagnostic Trouble Code)

When performing the power supply switching control to ACC position by push-button ignition switch oper-

ation, if the power supply position switching cannot be performed because the wake-up signal is not

entered into PDU (Power Distribution Unit), it judges that it is the malfunction and displays the DTC (Diag-

nostic Trouble Code)

DTCSelf-diagnosis

nameDTC detecting condition Possible causes

B2553IGN POWER CIR-

CUITThough the changing control to ON position by push-

button ignition switch operation is performed normally,

ON position power supply to the Intelligent Key unit is

not supplied

10A fuse

Harness and connector

(Open or shorted in the circuit)

When ignition switch is turned to ON

IGN ON SW : ON

PIIB6233E

Terminals

Ignition switch

conditionVoltage (V)

(Approx.) (+)

(–)

Intelligent Key

unit connectorTerminal

M32 31 GroundON Battery voltage

OFF 0

PIIB6234E

Page 1153 of 5621

BL-214

TRUNK LID OPENER

Revision: 2006 January2006 M35/M45

CONSULT-II Function (BCM)NIS001ZR

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch “OFF”.

2. Connect “CONSULT-II” and CONSULT-II CONVERTER to data

link connector (1).

3. Turn ignition switch “ON”.

4. Touch “START(NISSAN BASED VHCL)”.

5. Touch “BCM”.

If “BCM” is not indicated, go to GI-40, "

CONSULT-II Data Link

Connector (DLC) Circuit" .

BCM diagnosis

partInspection item, self-diagnosis

modeContent

TRUNKDATA MONITOR Displays the input data of BCM in real time basis.

ACTIVE TEST Give a drive signals to load to check the operation check.

PBIB2712E

BCIA0029E

BCIA0030E

Page 1163 of 5621

BL-224

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Revision: 2006 January2006 M35/M45

VEHICLE SECURITY SYSTEM ALARM OPERATION

The vehicle security system is triggered by

opening a door

opening the trunk

opening the hood

detection of battery disconnect and connect.

The vehicle security system will be triggered once the system is in armed phase,

when BCM receives a ground signal at terminals 12 (passenger side door), 13 (rear RH door), 57 (trunk), 62

(driver side door), 63 (rear LH door), or receives a signal from the IPDM E/R (hood switch).

When the vehicle security system is triggered,

ground is supplied intermittently to both headlamp relay and horn relay.

When headlamp relay and horn relay are energized, then power is supplied to headlamps (LH and RH) and

horns (HIGH and LOW).

The headlamps flash and the horn sounds intermittently.

The alarm automatically turns off after 50 seconds, but will reactivate if the vehicle is tampered with again.

VEHICLE SECURITY SYSTEM DEACTIVATION

To deactivate the vehicle security system, a door or the trunk must be unlocked with the key, Intelligent Key.

When the key is used to unlock a door, BCM terminal 22 receives signal

from the power window main switch (door lock and unlock switch) terminal 14.

When the BCM receives either one of these signals or unlock signal from key cylinder switch or Intelligent Key,

the vehicle security system is deactivated. (Disarmed phase)

PANIC ALARM OPERATION

Intelligent Key system may or may not operate vehicle security system (horn and headlamps) as required.

When the Intelligent Key system is triggered, ground is supplied intermittently to both headlamp relay and horn

relay.

When headlamp relay and horn relay are energized, then power is supplied to headlamps (LH and RH) and

horns (HIGH and LOW).

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off after 25 seconds or when BCM receives any signal from Intelligent Key.

CAN Communication System DescriptionNIS001ZV

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNIS001ZW

Refer to LAN-34, "CAN COMMUNICATION" .

Page 1317 of 5621

![INFINITI M35 2006 Factory Repair Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to INFINITI M35 2006 Factory Repair Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to](/img/42/57023/w960_57023-1316.png)

BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to the list below, make sure to adjust neutral position of steering angle sen-

sor before running vehicle.

: Required

–: Not required

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-II.

(Adjustment cannot be done without CONSULT-II.)

1. Stop vehicle with front wheels in straight-ahead position.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector on vehicle.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

3. Turn ignition switch ON and touch the CONSULT-II screen in the order of “ABS”, “WORK SUPPORT” and

“ST ANG SEN ADJUSTMENT”.

4. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle

sensor.

5. After approximately 10 seconds, touch “END”. (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select “DATA MONITOR”, “ECU INPUT SIGNALS”, and “STR ANGLE SIG” on CONSULT-II screen. Then

make sure “STR ANGLE SIG” is within 0

2.5. If value is more than specification, repeat steps 1 to 7.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM. ABS actuator and electric unit

(control unit): Refer to BRC-23, "

ERASE MEMORY" . ECM: Refer to EC-100, "TROUBLE DIAGNOSIS"

(VQ35DE), EC-811, "TROUBLE DIAGNOSIS" (VK45DE).

10. Turn ignition switch OFF.

Situation Adjustment of Steering Angle Sensor Neutral Position

Removing/Installing ABS actuator and electric unit (control unit)

Replacing ABS actuator and electric unit (control unit)

Removing/Installing steering angle sensor

Removing/Installing steering components

Removing/Installing suspension components

Change tires to new ones–

Tire rotation–

Adjusting wheel alignment

SFIA0793E