Brake fluid INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 16 of 5621

![INFINITI M35 2006 Factory Service Manual DESCRIPTION

ACS-7

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Components DescriptionNKS004CH

CAN CommunicationNKS004CI

CAN (Controller Area Network) is a serial communication l INFINITI M35 2006 Factory Service Manual DESCRIPTION

ACS-7

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Components DescriptionNKS004CH

CAN CommunicationNKS004CI

CAN (Controller Area Network) is a serial communication l](/img/42/57023/w960_57023-15.png)

DESCRIPTION

ACS-7

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Components DescriptionNKS004CH

CAN CommunicationNKS004CI

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tric control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

Refer to LAN-34, "CAN Communication Unit" .

ComponentVehicle-to-

vehicle

distance

control modeConventional

(fixed speed)

cruise

control modeBrake assist

(with pre-

view func-

tion)Description

ICC sensor integrated unit

Controls vehicle distance by operating electric throttle

control actuator based on that sensor signals and

CAN communication data.

Controls vehicle distance by transmitting deceleration

degree commandment value signal to ABS actuator

and electric unit (control unit) when deceleration with

brake is needed.

Irradiates laser beam, and receives reflected laser

beam to measure distance from preceding vehicle.

ECM

Transmits accelerator pedal position signal, ICC brake

switch signal, stop lamp switch signal and ICC steering

switch signal to ICC sensor integrated unit through CAN

communication.

ABS actuator and electric

unit (control unit)

Transmits vehicle speed signal (wheel speed) and

stop lamp switch signal to ICC sensor integrated unit

through CAN communication.

Receives Deceleration degree commandment value

signal from ICC sensor integrated unit, and controls

brake fluid pressure with the ABS motor.

BCM

Transmits front wiper request signal to ICC sensor inte-

grated unit through CAN communication.

TCM

Transmits gear position signal and output shaft revolu-

tion signal to ICC sensor integrated unit through CAN

communication.

Unified meter and A/C amp.

Receives meter display signal, ICC warning lamp signal

and buzzer output signal from ICC sensor integrated

unit through CAN communication.

ICC brake switch

Transmits operating signal to ECM when depressing

brake pedal. ICC sensor integrated unit cancels cruise

system at driver's brake operation.

Stop lamp switch

Transmits operating signal to ECM and ABS actuator

and electric unit (control unit) when depressing brake

pedal. ICC sensor integrated unit cancels cruise system

at driver's brake operation.

Page 80 of 5621

AT-1

AUTOMATIC TRANSMISSION

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

Revision: 2006 January2006 M35/M45

AUTOMATIC TRANSMISSION

INDEX FOR DTC ........................................................ 5

Alphabetical Index .................................................... 5

DTC No. Index ......................................................... 6

PRECAUTIONS .......................................................... 7

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 7

Precautions for On Board Diagnostic (OBD) System

of A/T and Engine .................................................... 7

Precautions .............................................................. 8

Service Notice or Precautions .................................. 9

PREPARATION ......................................................... 10

Special Service Tools ............................................. 10

Commercial Service Tools ....................................... 11

A/T FLUID ................................................................. 12

Changing A/T Fluid .............................................

... 12

Checking A/T Fluid ................................................. 13

A/T Fluid Cooler Cleaning ...................................... 14

A/T CONTROL SYSTEM .......................................... 17

Cross-Sectional View (VQ35DE Models for 2WD) ... 17

Cross-Sectional View (VK45DE Models for 2WD) ... 18

Cross-Sectional View (AWD Models) ..................... 19

Shift Mechanism ..................................................... 20

TCM Function ......................................................... 31

CAN Communication .............................................. 32

Input/Output Signal of TCM .................................... 32

Line Pressure Control ............................................ 33

Shift Control ........................................................... 34

Lock-up Control ...................................................... 37

Engine Brake Control ............................................. 38

Control Valve .......................................................... 38

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 40

Introduction ............................................................ 40

OBD-II Function for A/T System ............................. 40

One or Two Trip Detection Logic of OBD-II ............ 40

OBD-II Diagnostic Trouble Code (DTC) ................. 40

Malfunction Indicator Lamp (MIL) ........................... 43

TROUBLE DIAGNOSIS ............................................ 44

DTC Inspection Priority Chart ................................ 44

Fail-safe ................................................................. 44How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 46

A/T Electrical Parts Location .................................. 51

Circuit Diagram ....................................................... 52

Inspections before Trouble Diagnosis .................... 53

Check before Engine Is Started .............................. 57

Check at Idle ........................................................... 57

Cruise Test - Part 1 ................................................. 59

Cruise Test - Part 2 ................................................. 61

Cruise Test - Part 3 ................................................. 62

Vehicle Speed at Which Gear Shifting Occurs ....... 63

Vehicle Speed at Which Lock-Up Occurs/Releases ... 63

Symptom Chart ....................................................... 64

TCM Input/Output Signal Reference Values ........... 89

CONSULT-II Function (A/T) .................................... 90

Diagnostic Procedure without CONSULT-II ..........103

DTC U1000 CAN COMMUNICATION LINE ............105

Description ............................................................105

On Board Diagnosis Logic ....................................105

Possible Cause .....................................................105

DTC Confirmation Procedure ...............................105

Wiring Diagram — AT — CAN ..............................106

Diagnostic Procedure ...........................................107

DTC P0615 START SIGNAL CIRCUIT ...................108

Description ............................................................108

CONSULT-II Reference Value ..............................108

On Board Diagnosis Logic ....................................108

Possible Cause .....................................................108

DTC Confirmation Procedure ...............................108

Wiring Diagram — AT — STSIG ..........................109

Diagnostic Procedure ...........................................110

DTC P0700 TCM .....................................................112

Description ............................................................112

On Board Diagnosis Logic ....................................112

Possible Cause .....................................................112

DTC Confirmation Procedure ...............................112

Diagnostic Procedure ...........................................112

DTC P0705 PARK/NEUTRAL POSITION SWITCH .113

Description ............................................................113

CONSULT-II Reference Value ..............................113

Page 81 of 5621

AT-2Revision: 2006 January2006 M35/M45 On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ...............................113

Wiring Diagram — AT — PNP/SW .......................114

Diagnostic Procedure ...........................................115

DTC P0717 TURBINE REVOLUTION SENSOR ....117

Description ............................................................117

CONSULT-II Reference Value ..............................117

On Board Diagnosis Logic ....................................117

Possible Cause .....................................................117

DTC Confirmation Procedure ...............................117

Diagnostic Procedure ...........................................118

DTC P0720 VEHICLE SPEED SENSOR A/T (REV-

OLUTION SENSOR) ...............................................119

Description ............................................................119

CONSULT-II Reference Value ..............................119

On Board Diagnosis Logic ....................................119

Possible Cause .....................................................119

DTC Confirmation Procedure ...............................119

Wiring Diagram — AT — VSSA/T .........................121

Diagnostic Procedure ...........................................122

DTC P0725 ENGINE SPEED SIGNAL ...................124

Description ............................................................124

CONSULT-II Reference Value ..............................124

On Board Diagnosis Logic ....................................124

Possible Cause .....................................................124

DTC Confirmation Procedure ...............................124

Diagnostic Procedure ...........................................125

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................126

Description ............................................................126

CONSULT-II Reference Value ..............................126

On Board Diagnosis Logic ....................................126

Possible Cause .....................................................126

DTC Confirmation Procedure ...............................126

Diagnostic Procedure ...........................................127

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) . 128

Description ............................................................128

CONSULT-II Reference Value ..............................128

On Board Diagnosis Logic ....................................128

Possible Cause .....................................................128

DTC Confirmation Procedure ...............................128

Diagnostic Procedure ...........................................129

DTC P0745 LINE PRESSURE SOLENOID VALVE .130

Description ............................................................130

CONSULT-II Reference Value ..............................130

On Board Diagnosis Logic ....................................130

Possible Cause .....................................................130

DTC Confirmation Procedure ...............................130

Diagnostic Procedure ...........................................131

DTC P1705 THROTTLE POSITION SENSOR .......132

Description ............................................................132

CONSULT-II Reference Value ..............................132

On Board Diagnosis Logic ....................................132

Possible Cause .....................................................132

DTC Confirmation Procedure ...............................132

Diagnostic Procedure ...........................................133

DTC P1710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................135Description ............................................................135

CONSULT-II Reference Value ...............................135

On Board Diagnosis Logic ....................................135

Possible Cause .....................................................135

DTC Confirmation Procedure ................................135

Wiring Diagram — AT — FTS ...............................136

Diagnostic Procedure ............................................137

Component Inspection ..........................................139

DTC P1721 VEHICLE SPEED SENSOR MTR .......140

Description ............................................................140

CONSULT-II Reference Value ...............................140

On Board Diagnosis Logic ....................................140

Possible Cause .....................................................140

DTC Confirmation Procedure ................................140

Diagnostic Procedure ............................................141

DTC P1730 A/T INTERLOCK .................................142

Description ............................................................142

On Board Diagnosis Logic ....................................142

Possible Cause .....................................................142

DTC Confirmation Procedure ................................142

Judgement of A/T Interlock ...................................143

Diagnostic Procedure ............................................143

DTC P1731 A/T 1ST ENGINE BRAKING ...............145

Description ............................................................145

CONSULT-II Reference Value ...............................145

On Board Diagnosis Logic ....................................145

Possible Cause .....................................................145

DTC Confirmation Procedure ................................145

Diagnostic Procedure ............................................146

DTC P1752 INPUT CLUTCH SOLENOID VALVE ..147

Description ...................................................

.........147

CONSULT-II Reference Value ...............................147

On Board Diagnosis Logic ....................................147

Possible Cause .....................................................147

DTC Confirmation Procedure ................................147

Diagnostic Procedure ............................................148

DTC P1754 INPUT CLUTCH SOLENOID VALVE

FUNCTION ..............................................................149

Description ............................................................149

CONSULT-II Reference Value ...............................149

On Board Diagnosis Logic ....................................149

Possible Cause .....................................................149

DTC Confirmation Procedure ................................149

Diagnostic Procedure ............................................150

DTC P1757 FRONT BRAKE SOLENOID VALVE ...151

Description ............................................................151

CONSULT-II Reference Value ...............................151

On Board Diagnosis Logic ....................................151

Possible Cause .....................................................151

DTC Confirmation Procedure ................................151

Diagnostic Procedure ............................................152

DTC P1759 FRONT BRAKE SOLENOID VALVE

FUNCTION ..............................................................153

Description ............................................................153

CONSULT-II Reference Value ...............................153

On Board Diagnosis Logic ....................................153

Possible Cause .....................................................153

DTC Confirmation Procedure ................................153

Diagnostic Procedure ............................................154

Page 83 of 5621

AT-4Revision: 2006 January2006 M35/M45 A/T Does Not Shift: 4th Gear

3rd Gear ............215

A/T Does Not Shift: 3rd Gear

2nd Gear ...........217

A/T Does Not Shift: 2nd Gear

1st Gear ............218

Vehicle Does Not Decelerate by Engine Brake ....220

SHIFT CONTROL SYSTEM ....................................222

Control Device Removal and Installation ..............222

Control Rod Removal and Installation ..................226

Adjustment of A/T Position ...................................227

Checking of A/T Position ......................................228

A/T SHIFT LOCK SYSTEM .....................................229

Description ............................................................229

Shift Lock System Electrical Parts Location .........229

Wiring Diagram — AT — SHIFT ...........................230

Diagnostic Procedure ...........................................232

ON-VEHICLE SERVICE ..........................................236

C o n t r o l V a l v e W i t h T C M a n d A / T F l u i d Te m p e r a t u r e

Sensor 2 ...............................................................236

Parking Components (2WD Models Only) ............248

Rear Oil Seal (VQ35DE Models Only) ..................260

Revolution Sensor Components (2WD Models

Only) .....................................................................261

AIR BREATHER HOSE ...........................................269

Removal and Installation ......................................269

TRANSMISSION ASSEMBLY ................................271

Removal and Installation (2WD Models) ..............271

Removal and Installation (AWD Models) ..............275

OVERHAUL .............................................................278

Components .........................................................278Oil Channel ...........................................................292

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................295

DISASSEMBLY .......................................................298

Disassembly ..........................................................298

REPAIR FOR COMPONENT PARTS ......................318

Oil Pump ...............................................................318

Front Sun Gear, 3rd One-Way Clutch ...................321

Front Carrier, Input Clutch, Rear Internal Gear .....323

Mid Sun Gear, Rear Sun Gear, High and Low

Reverse Clutch Hub ..............................................329

High and Low Reverse Clutch ..............................335

Direct Clutch .........................................................337

ASSEMBLY .............................................................340

Assembly (1) .........................................................340

Adjustment ............................................................356

Assembly (2) .........................................................358

SERVICE DATA AND SPECIFICATIONS (SDS) ....365

General Specifications ......................................... .365

Vehicle Speed at Which Gear Shifting Occurs ......365

Vehicle Speed at Which Lock-Up Occurs/Releases .366

Stall Speed ............................................................366

Line Pressure ........................................................366

A/T Fluid Temperature Sensor ..............................366

Turbine Revolution Sensor ....................................367

Vehicle Speed Sensor A/T (Revolution Sensor) ...367

Reverse Brake ......................................................367

Total End Play .......................................................367

Page 92 of 5621

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

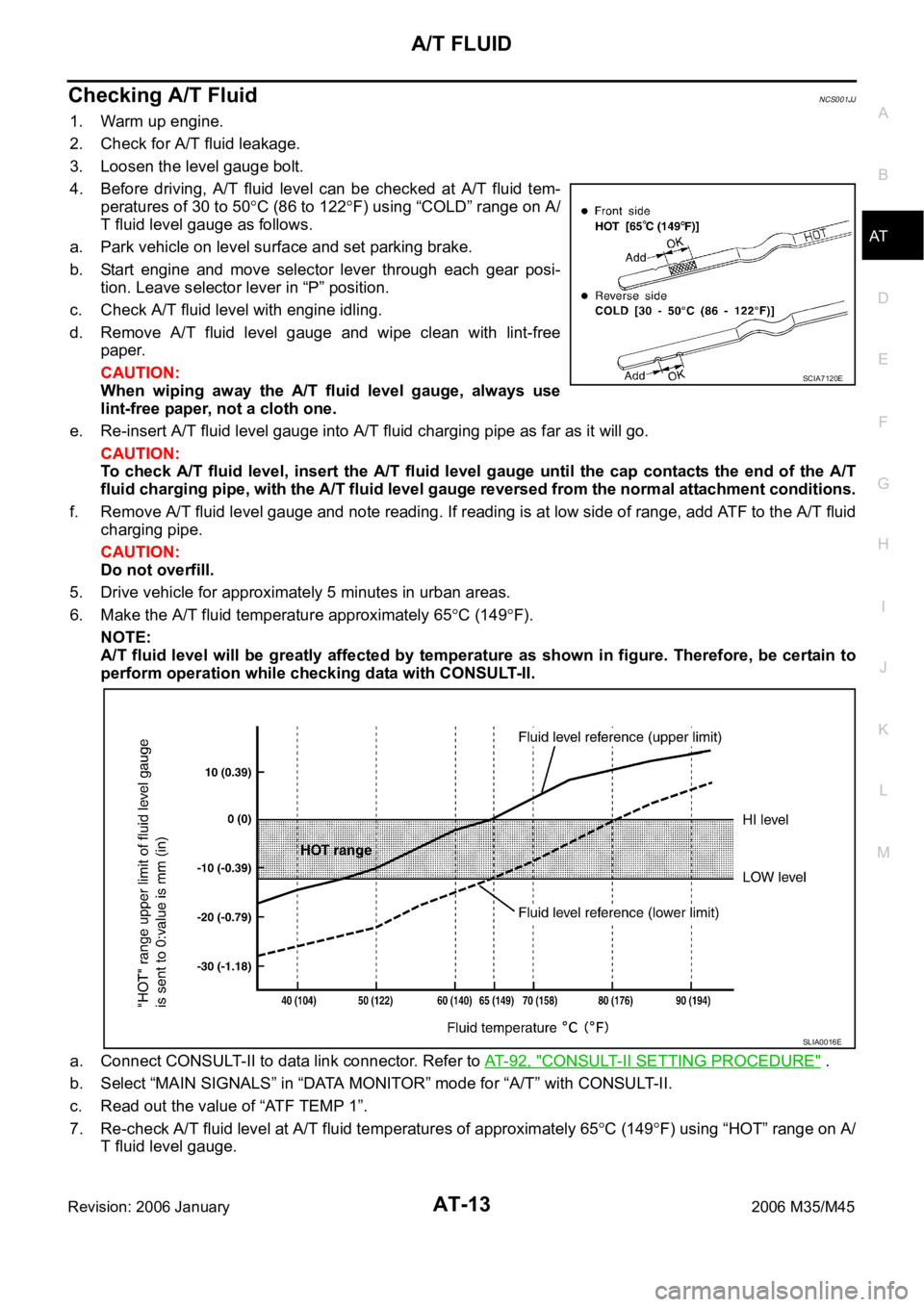

Checking A/T FluidNCS001JJ

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Loosen the level gauge bolt.

4. Before driving, A/T fluid level can be checked at A/T fluid tem-

peratures of 30 to 50

C (86 to 122F) using “COLD” range on A/

T fluid level gauge as follows.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free

paper.

CAUTION:

When wiping away the A/T fluid level gauge, always use

lint-free paper, not a cloth one.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

To check A/T fluid level, insert the A/T fluid level gauge until the cap contacts the end of the A/T

fluid charging pipe, with the A/T fluid level gauge reversed from the normal attachment conditions.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add ATF to the A/T fluid

charging pipe.

CAUTION:

Do not overfill.

5. Drive vehicle for approximately 5 minutes in urban areas.

6. Make the A/T fluid temperature approximately 65

C (149F).

NOTE:

A/T fluid level will be greatly affected by temperature as shown in figure. Therefore, be certain to

perform operation while checking data with CONSULT-II.

a. Connect CONSULT-II to data link connector. Refer to AT- 9 2 , "

CONSULT-II SETTING PROCEDURE" .

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

c. Read out the value of “ATF TEMP 1”.

7. Re-check A/T fluid level at A/T fluid temperatures of approximately 65

C (149F) using “HOT” range on A/

T fluid level gauge.

SCIA7120E

SLIA0016E

Page 110 of 5621

A/T CONTROL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

TCM FunctionNCS001JP

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The A/T senses vehicle operating conditions through various sensors or signals. It always controls the opti-

mum shift position and reduces shifting and lock-up shocks.

CONTROL SYSTEM DIAGRAM

SENSORS (or SIGNAL)TCMACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switchShift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN systemInput clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch

solenoid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Back-up lamp relay

Sta r te r re l a y

SCIA5325E

Page 111 of 5621

AT-32

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

CAN CommunicationNCS001JQ

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. Refer to LAN-34, "

CAN

Communication Unit" .

Input/Output Signal of TCMNCS001JR

*1: Spare for vehicle speed sensorꞏA/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnostics are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

function

(*3)Self-diag-

nostics

function

InputAccelerator pedal position signal

(*5)XXXXXXX

Vehicle speed sensor A/T

(revolution sensor)XXXXXXX

Vehicle speed sensor MTR

(*1) (*5)X

Closed throttle position signal

(*5)X(*2) X X X X(*4)

Wide open throttle position signal

(*5)XX(*4)

Turbine revolution sensor 1 X X X X X

Turbine revolution sensor 2

(for 4th speed only)X XXXX

Engine speed signals

(*5)XXXXXXX

Stop lamp switch signal

(*5)XXX X(*4)

A/T fluid temperature sensors 1, 2XXXX XX

ASCD or ICC

sensor inte-

grated unitOperation signal

(*5)XXX

Overdrive cancel

signal

(*5)X

Out-

putDirect clutch solenoid

(ATF pressure switch 5)XX XX

Input clutch solenoid

(ATF pressure switch 3)XX XX

High and low reverse clutch solenoid

(ATF pressure switch 6)XX XX

Front brake solenoid

(ATF pressure switch 1)XX XX

Low coast brake solenoid

(ATF pressure switch 2)XX XXX

Line pressure solenoidXXXXXXX

TCC solenoid X X X

Self-diagnostics table

(*6)X

Starter relayXX

Page 113 of 5621

AT-34

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

During Shift Change

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlNCS001JT

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change charac-

teristic is attained.

PCIA0010E

PCIA0011E

PCIA0012E

Page 127 of 5621

AT-48

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

WHAT..... Vehicle and A/T model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Diagnostic Worksheet Chart

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency

Continuous Intermittent ( times a day)

Symptoms

Vehicle does not move. ( Any position Particular position)

No up-shift ( 1st 2nd 2nd 3rd 3rd 4th 4th 5th)

No down-shift ( 5th 4th 4th 3rd 3rd 2nd 2nd 1st)

Lock-up malfunction

Shift point too high or too low.

Shift shock or slip ( N D N R Lock-up Any drive position)

Noise or vibration

No kick down

No pattern select

Others

()

A/T CHECK indicator lamp

Continuously lit Not lit

Malfunction indicator lamp (MIL)

Continuously lit Not lit

1 Read the item on cautions concerning fail-safe and understand the customer's complaint.AT- 4 4

2

A/T fluid inspectionAT- 5 3

Leak (Repair leak location.)

State

Amount

3

Stall test and line pressure testAT- 5 3, AT-

55 Stall test

Torque converter one-way clutch

Front brake

High and low reverse clutch

Low coast brake

Forward brake

Reverse brake

Forward one-way clutch

1st one-way clutch

3rd one-way clutch

Engine

Line pressure low

Except for input clutch and direct

clutch, clutches and brakes OK

Line pressure inspection - Suspected part:

Page 128 of 5621

TROUBLE DIAGNOSIS

AT-49

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

4

Perform all road tests and enter checks in required inspection items.AT- 5 7

4-1.Check before engine is started AT- 5 7

AT- 1 9 0 , "A/T CHECK Indicator Lamp Does Not Come On"

Perform self-diagnostics. Enter checks for detected items. AT- 9 2 ,AT-103

AT-105, "DTC U1000 CAN COMMUNICATION LINE"

AT-108, "DTC P0615 START SIGNAL CIRCUIT"

AT-112, "DTC P0700 TCM"

AT-113, "DTC P0705 PARK/NEUTRAL POSITION SWITCH"

AT-117, "DTC P0717 TURBINE REVOLUTION SENSOR"

AT-119, "DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)"

AT-124, "DTC P0725 ENGINE SPEED SIGNAL"

AT-126, "DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE"

AT-128, "DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)"

AT-130, "DTC P0745 LINE PRESSURE SOLENOID VALVE"

AT-132, "DTC P1705 THROTTLE POSITION SENSOR"

AT-135, "DTC P1710 A/T FLUID TEMPERATURE SENSOR CIRCUIT"

AT-140, "DTC P1721 VEHICLE SPEED SENSOR MTR"

AT-142, "DTC P1730 A/T INTERLOCK"

AT-145, "DTC P1731 A/T 1ST ENGINE BRAKING"

AT-147, "DTC P1752 INPUT CLUTCH SOLENOID VALVE"

AT-149, "DTC P1754 INPUT CLUTCH SOLENOID VALVE FUNCTION"

AT-151, "DTC P1757 FRONT BRAKE SOLENOID VALVE"

AT-153, "DTC P1759 FRONT BRAKE SOLENOID VALVE FUNCTION"

AT-155, "DTC P1762 DIRECT CLUTCH SOLENOID VALVE"

AT-157, "DTC P1764 DIRECT CLUTCH SOLENOID VALVE FUNCTION"

AT-159, "DTC P1767 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE"

AT-161, "DTC P1769 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE

FUNCTION"

AT-163, "DTC P1772 LOW COAST BRAKE SOLENOID VALVE"

AT-165, "DTC P1774 LOW COAST BRAKE SOLENOID VALVE FUNCTION"

AT-167, "DTC P1815 MANUAL MODE SWITCH"

AT-172, "DTC P1841 ATF PRESSURE SWITCH 1"

AT-174, "DTC P1843 ATF PRESSURE SWITCH 3"

AT-176, "DTC P1845 ATF PRESSURE SWITCH 5"

AT-178, "DTC P1846 ATF PRESSURE SWITCH 6"

4-2.Check at IdleAT- 5 7

AT- 1 9 0 , "Engine Cannot Be Started in “P” or “N” Position"

AT- 1 9 1 , "In “P” Position, Vehicle Moves When Pushed"

AT- 1 9 2 , "In “N” Position, Vehicle Moves"

AT- 1 9 3 , "Large Shock (“N” to “D” Position)"

AT- 1 9 5 , "Vehicle Does Not Creep Backward in “R” Position"

AT- 1 9 7 , "Vehicle Does Not Creep Forward in “D” Position"

4-3.Cruise TestAT- 5 9

Part 1

AT- 1 9 9 , "Vehicle Cannot Be Started from D1"

AT- 2 0 1 , "A/T Does Not Shift: D1 D2"

AT- 2 0 3 , "A/T Does Not Shift: D2 D3"

AT- 2 0 5 , "A/T Does Not Shift: D3 D4"

AT- 2 0 7 , "A/T Does Not Shift: D4 D5"

AT- 2 0 9 , "A/T Does Not Lock-Up"

AT- 2 1 0 , "A/T Does Not Hold Lock-Up Condition"

AT- 2 1 2 , "Lock-Up Is Not Released"

AT- 2 1 2 , "Engine Speed Does Not Return to Idle"