center console INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1051 of 5621

BL-112

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

Check Inside Key AntennaNIS001XW

1. CHECK INSIDE KEY ANTENNA FUNCTION

With CONSULT-II

1. Check the operation with (“ANTENNA”) in the ACTIVE TEST.

2. Touch “ROOM ANT1” “ROOM ANT2” “ROOM ANT3” “LUG ANT” on screen.

3. Carry the Intelligent Key into the antenna detection area.

Do the hazard lamps flash?

Yes >> Inside key antenna is OK.

No >> GO TO 2.

2. CHECK INSIDE KEY ANTENNA INPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Check the condition of harness and connector.

NG >> GO TO 3.

Test item Corresponding antenna

ROOM ANT1 Inside key antenna instrument center

ROOM ANT2 Inside key antenna console

ROOM ANT3 Inside key antenna rear seat

LUG ANT1 Inside key antenna trunk room

PIIB6345E

Terminals

ConditionSignal

(Reference value.) (+)

(–)

Intelligent Key

unit connectorTe r -

minal

M33Instru-

ment

center47

GroundAny door

is open

close Console 49

Rear seat 51

Trunk

room53

PIIB6350E

SIIA1910J

Page 1052 of 5621

INTELLIGENT KEY SYSTEM

BL-113

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

3. CHECK INSIDE KEY ANTENNA CIRCUIT

1. Disconnect Intelligent Key unit and inside key antenna connector.

2. Check continuity between Intelligent Key unit connector and inside key antenna connector.

3. Check continuity between Intelligent Key unit connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between Intelligent Key unit and inside key antenna.

AB

Continuity

Intelligent Key

unit connectorTerminalInside key antenna

connectorTerminal

M3347

M83Instrument

center1

Ye s 48 2

49

M142 Console1

50 2

51

B45 Rear seat1

52 2

53

B132 Trunk room1

54 2

A

GroundContinuity

Intelligent Key unit

connectorTerminal

M33Instrument center47

No 48

Console49

50

Rear seat51

52

Trunk room53

54

PIIB6351E

Page 1053 of 5621

BL-114

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

4. CHECK INDE KEY ANTENNA INPUT SIGNAL 2

1. Replace inside key antenna. (New antenna or other antenna)

2. Connect Intelligent Key unit and inside key antenna connector.

3. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Replace malfunction inside key antenna.

NG >> Replace Intelligent Key unit.

Terminals

ConditionSignal

(Reference value.) (+)

(–)

Intelligent Key

unit connectorTe r -

minal

M33Instru-

ment

center47

GroundAny door

is open

close Console 49

Rear seat 51

Trunk

room53

PIIB6350E

SIIA1910J

Page 1084 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-145

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

34 R PDU feed back signalLOCKSleep condition (30 seconds or more

after all doors are closed under the

condition that the ignition switch posi-

tion is in the LOCK position)1

—Wake-up condition (any condition

other than above)0

35 LG Vehicle speed signal ONAt speedometer operation (vehicle

speed approx. 40 km/h)

37 P CAN-L — — —

38 L CAN-H — — —

39 BR/WPush-button ignition

switch—Push-button ignition switch is pressed 0

Push-button ignition switch is released Battery voltage

40 B Ground — — 0

41 Y Power source (fuse) — — Battery voltage

42 P PDU wake up signalLOCKSleep condition (30 seconds or more

after all doors are closed under the

condition that the ignition switch posi-

tion is in the LOCK position)Battery voltage

— Wake-up condition (Open driver door) 0

43 G Starter signalON At starter motor cranking 0

— Any condition other than above Battery voltage

46 VSteering lock control

signal-1—Push-button ignition switch is pressed

under the condition that Intelligent Key

is in the vehicle or Intelligent Key is

insertedBattery voltage

LOCKIgnition switch position is in LOCK

position (Steering lock activated)Battery voltage

0 Battery voltage

(Battery voltage is detected when acti-

vating the steering lock)

47 LGInside key antenna (+)

signal

(Instrument center)

LOCK Any door open

closed

(Door switch: ON

OFF)

48 VInside key antenna (–)

signal

(Instrument center)

49 BInside key antenna (+)

signal

(console)

LOCKAny door open

closed

(Door switch: ON

OFF)

50 WInside key antenna (–)

signal

(console) Te r m i -

nal

No.Wire

colorItemCondition

Voltage (V)

(Approx.) Push-

button

ignition

switch

positionOperation or conditions

PKIA1935E

SIIA1910J

SIIA1910J

Page 1094 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-155

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

ACTIVE TEST

TRUNK OPEN DELAYTrunk button's pressing time on Intelligent Key button can be selected from the following with this

mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen is

touched.0.5 sec

1.5 sec

OFF: Non-operation

P/W DOWN DELAYUnlock button's pressing time on Intelligent Key button can be selected from the following with

this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen

is touched.

3 sec

5 sec

OFF: Non-operation

ENGINE START BY I-KEYEngine start function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen is touched.

LOCK/UNLOCK BY I-KEYDoor lock/unlock function by door request switch (driver side, passenger side and trunk) mode

can be changed to operate (ON) or not operate (OFF) with this mode. The operation mode will be

changed when “CHANGE SETT” on CONSULT-II screen is touched. Monitor item Description

Test item Description

DOOR LOCK/UNLOCKThis test is able to check door lock/unlock operation.

The all door lock actuators are locked when “LOCK” on CONSULT-II screen is touched.

The all door lock actuators are unlocked when “ALL UNLK” on CONSULT-II screen is touched.

The door lock actuator (driver side) is unlocked when “DR UNLK” on CONSULT-II screen is

touched.

The door lock actuator (passenger side) is unlocked when “AS UNLK” on CONSULT- II screen

is touched.

The trunk lid opener actuator is open when “TRUNK OPEN” on CONSULT- II screen is

touched.

ANTENNAThis test is able to check Intelligent Key antenna operation.

When the following conditions are met, hazard warning lamps flash.

Inside key antenna (Instrument center) detects Intelligent Key, when “ROOM ANT1” on CON-

SULT-II screen is touched.

Inside key antenna (Center console) detects Intelligent Key, when “ROOM ANT2” on CON-

SULT-II screen is touched.

Inside key antenna (rear seat) detects Intelligent Key, when “ROOM ANT3” on CONSULT-II

screen is touched.

Inside key antenna (Trunk room) detects Intelligent Key, when “LAG ANT1” on CONSULT-II

screen is touched.

Outside key antenna (Driver side) detects Intelligent Key, when “DRIVER ANT” on CONSULT-II

screen is touched.

Outside key antenna (Passenger side) detects Intelligent Key, when “ASSIST ANT” on CON-

SULT-II screen is touched.

Outside key antenna (Trunk room) detects Intelligent Key, when “BD/TR ANT” on CONSULT-II

screen is touched.

OUTSIDE BUZZERThis test is able to check Intelligent Key warning buzzer operation.

Intelligent Key warning buzzer sounds when “ON” on CONSULT-II screen is touched.

INSIDE BUZZERThis test is able to check warning chime into combination meter operation.

Take away warning chime sounds when “TAKE OUT” on CONSULT-II screen is touched.

Key warning chime sounds when “KEY WARN” on CONSULT-II screen is touched.

P position warning chime sounds when “P RNG WARN” on CONSULT-II screen is touched.

ACC warning chime sounds when “ACC WARN” on CONSULT-II screen is touched.

Page 1122 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-183

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Check Inside Key AntennaNIS001Z5

1. CHECK INSIDE KEY ANTENNA FUNCTION

With CONSULT-II

1. Check the operation with (“ANTENNA”) in the ACTIVE TEST.

2. Touch “ROOM ANT1” “ROOM ANT2” “ROOM ANT3” “LUG ANT” on screen.

3. Carry the Intelligent Key into the antenna detection area.

Do the hazard lamps flash?

Yes >> Inside key antenna is OK.

No >> GO TO 2.

2. CHECK INSIDE KEY ANTENNA INPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Check the condition of harness and connector.

NG >> GO TO 3.

Test item Corresponding antenna

ROOM ANT1 Inside key antenna instrument center

ROOM ANT2 Inside key antenna console

ROOM ANT3 Inside key antenna rear seat

LUG ANT1 Inside key antenna trunk room

PIIB6345E

Terminals

ConditionSignal

(Reference value.) (+)

(–)

Intelligent Key

unit connectorTe r -

minal

M33Instru-

ment

center47

GroundAny door

is open

close Console 49

Rear seat 51

Trunk

room53

PIIB6350E

SIIA1910J

Page 1123 of 5621

BL-184

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Revision: 2006 January2006 M35/M45

3. CHECK INSIDE KEY ANTENNA CIRCUIT

1. Disconnect Intelligent Key unit and inside key antenna connector.

2. Check continuity between Intelligent Key unit connector and inside key antenna connector.

3. Check continuity between Intelligent Key unit connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between Intelligent Key unit and inside key antenna.

AB

Continuity

Intelligent Key

unit connectorTerminalInside key antenna

connectorTerminal

M3347

M83Instrument

center1

Ye s 48 2

49

M142 Console1

50 2

51

B45 Rear seat1

52 2

53

B132 Trunk room1

54 2

A

GroundContinuity

Intelligent Key unit

connectorTe r m i n a l

M33Instrument center47

No 48

Console49

50

Rear seat51

52

Trunk room53

54

PIIB6351E

Page 1124 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-185

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

4. CHECK INDE KEY ANTENNA INPUT SIGNAL 2

1. Replace inside key antenna. (New antenna or other antenna)

2. Connect Intelligent Key unit and inside key antenna connector.

3. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Replace malfunction inside key antenna.

NG >> Replace Intelligent Key unit.

Check Remote Keyless Entry ReceiverNIS001Z6

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect remote keyless entry receiver connector.

3. Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace Intelligent Key unit.

Terminals

ConditionSignal

(Reference value.) (+)

(–)

Intelligent Key

unit connectorTe r -

minal

M33Instru-

ment

center47

GroundAny door

is open

close Console 49

Rear seat 51

Trunk

room53

PIIB6350E

SIIA1910J

Terminals

ConditionVoltage (V)

(Approx.) (+)

(–) Intelli-

gent Key

unit con-

nectorTe r -

minal

M32 4 GroundCarry the Intelli-

gent Key within

the inside key

antenna detec-

tion area, and

then push the

push-button

ignition switch.0

Other than the

above.

PIIB6264E

PIIB5657J

Page 1373 of 5621

![INFINITI M35 2006 Factory User Guide BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little enduran INFINITI M35 2006 Factory User Guide BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little enduran](/img/42/57023/w960_57023-1372.png)

BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little endurance to impact.

Do not use power tool etc., because yaw rate/side G sensor is sensitive for the impact.

REMOVAL

1. Remove center console. Refer to IP-10, "Component Parts

Drawing" .

2. Disconnect yaw rate/side G sensor harness connector.

3. Remove mounting bolts. Remove yaw rate/side G sensor.

(Shown in the figure 1).

INSTALLATION

Installation is the reverse order of removal.

SFIA2725J

Yaw rate/side G sensor mounting bolt

: 6.5 Nꞏm (0.66 kgꞏm, 58 in-lb)

Page 3006 of 5621

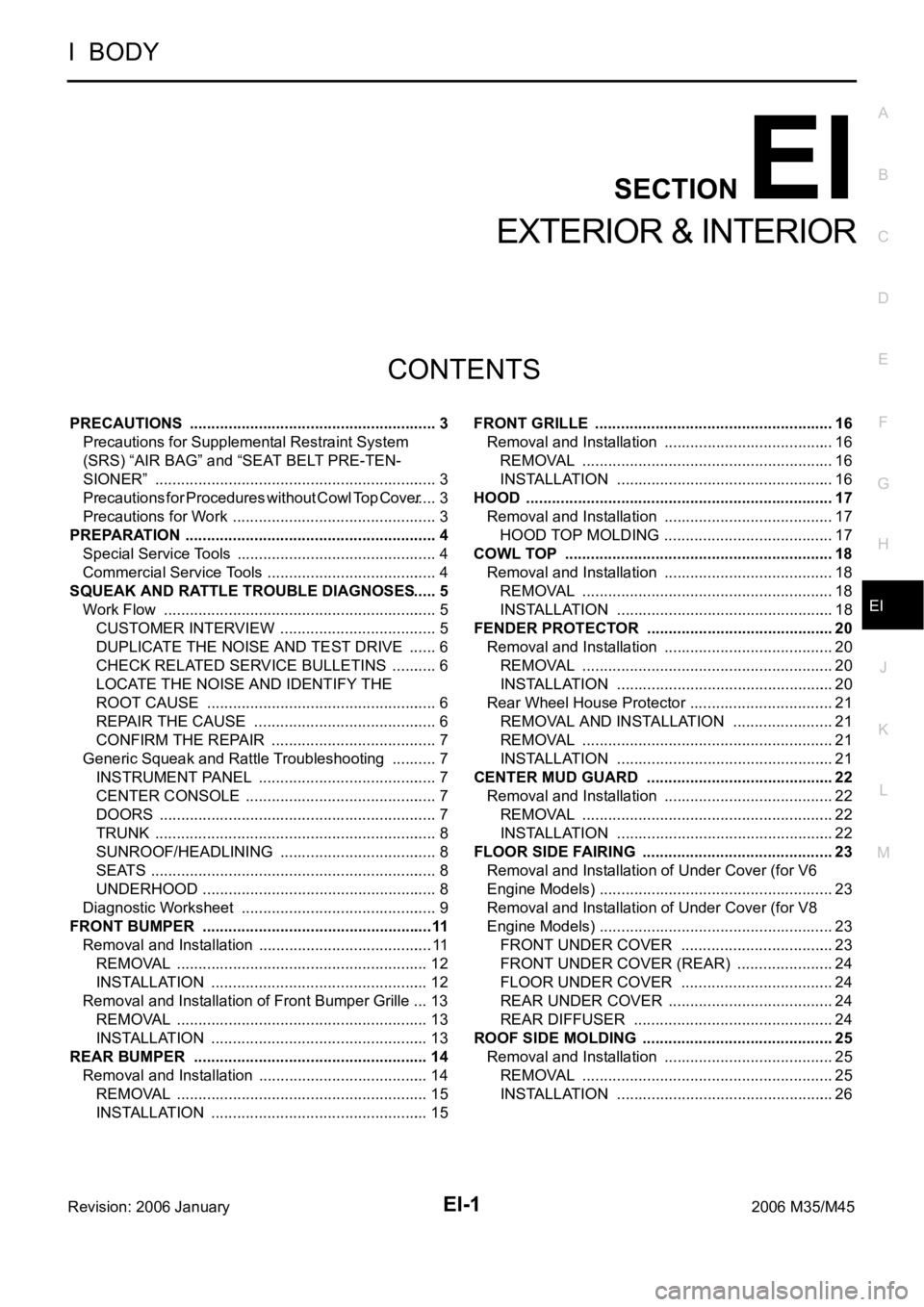

EI-1

EXTERIOR & INTERIOR

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION EI

A

B

EI

Revision: 2006 January2006 M35/M45

EXTERIOR & INTERIOR

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Work ...........................................

..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

FRONT BUMPER ......................................................11

Removal and Installation ......................................... 11

REMOVAL ........................................................

... 12

INSTALLATION ................................................... 12

Removal and Installation of Front Bumper Grille ... 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 13

REAR BUMPER ....................................................

... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 15

INSTALLATION ................................................... 15FRONT GRILLE ........................................................ 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSTALLATION ................................................... 16

HOOD ........................................................................ 17

Removal and Installation ........................................ 17

HOOD TOP MOLDING ........................................ 17

COWL TOP ............................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................

... 18

FENDER PROTECTOR ............................................ 20

Removal and Installation ........................................ 20

REMOVAL ........................................................

... 20

INSTALLATION ................................................... 20

Rear Wheel House Protector .................................. 21

REMOVAL AND INSTALLATION ........................ 21

REMOVAL ........................................................

... 21

INSTALLATION ................................................... 21

CENTER MUD GUARD ............................................ 22

Removal and Installation ........................................ 22

REMOVAL ........................................................

... 22

INSTALLATION ................................................... 22

FLOOR SIDE FAIRING ............................................. 23

Removal and Installation of Under Cover (for V6

Engine Models) ....................................................... 23

Removal and Installation of Under Cover (for V8

Engine Models) ....................................................... 23

FRONT UNDER COVER .................................... 23

FRONT UNDER COVER (REAR) ....................... 24

FLOOR UNDER COVER .................................... 24

REAR UNDER COVER ....................................... 24

REAR DIFFUSER ............................................... 24

ROOF SIDE MOLDING ............................................. 25

Removal and Installation ........................................ 25

REMOVAL ........................................................

... 25

INSTALLATION ................................................... 26