heater INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1388 of 5621

![INFINITI M35 2006 Factory Owners Manual ENGINE COOLANT

CO-13

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

7. Stop the engine and cool down to less than approximately 50C (122F).

Cool down using fan to reduce the tim INFINITI M35 2006 Factory Owners Manual ENGINE COOLANT

CO-13

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

7. Stop the engine and cool down to less than approximately 50C (122F).

Cool down using fan to reduce the tim](/img/42/57023/w960_57023-1387.png)

ENGINE COOLANT

CO-13

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

7. Stop the engine and cool down to less than approximately 50C (122F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer

drops.

10. Check cooling system for leaks with engine running.

11. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to

3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating step 4 through 7 until engine coolant level no

longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-128,

"ASSEMBLY" .

2. Remove air relief plug on heater hose.

3. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap.

4. Run the engine and warm it up to normal operating temperature.

5. Rev the engine two or three times under no-load.

6. Stop the engine and wait until it cools down.

7. Drain water from the system. Refer to CO-11, "

DRAINING ENGINE COOLANT" .

8. Repeat steps 1 through 7 until clear water begins to drain from radiator. Radiator drain plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

SBIA0445E

Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 ft-lb)

Page 1406 of 5621

![INFINITI M35 2006 Factory Owners Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM INFINITI M35 2006 Factory Owners Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM](/img/42/57023/w960_57023-1405.png)

WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-19, "

INTAKE MANIFOLD COLLECTOR" .

3. Remove air duct (inlet) and air cleaner case assembly. Refer to EM-17, "

AIR CLEANER AND AIR DUCT"

.

4. Remove front engine undercover with power tool.

5. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-11, "

Changing Engine Coolant" and CO-24, "WATER PUMP" .

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

6. Remove radiator hose (upper) and heater hose.

7. Remove the following parts, when remove water outlet.

A/T fluid charging pipe: Refer to AT-271, "TRANSMISSION ASSEMBLY" .

Intake manifold collectors (upper and lower): Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Rocker cover (right bank): Refer to EM-51, "ROCKER COVER" .

8. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

1. Harness bracket 2. Water hose 3. Water bypass hose

4. Engine coolant temperature sensor 5. Gasket 6. Water outlet

7. Heater hose 8. Water pipe 9. Radiator hose (upper)

10. Heater pipe 11. Washer 12. O-ring

SBIA0484E

Page 1407 of 5621

![INFINITI M35 2006 Factory Owners Manual CO-32

[VQ35DE]

WATER OUTLET AND WATER PIPING

Revision: 2006 January2006 M35/M45

9. Remove heater pipe, water bypass hoses and water pipe.

INSTALLATION

Note the following, and install in the reverse or INFINITI M35 2006 Factory Owners Manual CO-32

[VQ35DE]

WATER OUTLET AND WATER PIPING

Revision: 2006 January2006 M35/M45

9. Remove heater pipe, water bypass hoses and water pipe.

INSTALLATION

Note the following, and install in the reverse or](/img/42/57023/w960_57023-1406.png)

CO-32

[VQ35DE]

WATER OUTLET AND WATER PIPING

Revision: 2006 January2006 M35/M45

9. Remove heater pipe, water bypass hoses and water pipe.

INSTALLATION

Note the following, and install in the reverse order of removal.

Securely insert each hose, and install clamp at a position where it does not interfere with the pipe bulge.

When inserting water pipe into water outlet, apply neutral detergent to O-ring.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301 (J33984-A)]

and the radiator cap tester (commercial service tool). Refer to CO-11, "

LEAK CHECK" .

Start and warm up the engine. Visually make sure that there is no leaks of engine coolant.

Page 1416 of 5621

![INFINITI M35 2006 Factory Owners Manual ENGINE COOLANT

CO-41

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, f INFINITI M35 2006 Factory Owners Manual ENGINE COOLANT

CO-41

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, f](/img/42/57023/w960_57023-1415.png)

ENGINE COOLANT

CO-41

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

5. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-42, "

FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-254,

"ASSEMBLY" .

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug (1) on heater hose.

4. Fill thermostat housing and reservoir tank to specified level.

Refill engine coolant up to filler neck of thermostat housing.

Pour engine coolant through engine coolant filler neck slowly of less than 2 (2-1/8 US qt, 1-3/4

Imp qt) a minute to allow air in system to escape.

Use Genuine Nissan Long Life Antifreeze/Coolant or equivalent mixed with water (distilled or

demineralized). Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

When engine coolant overflows air relief hole on heater hose,

install air relief plug.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop engine and cool down to less than approximately 50

C (122F).

Cool down using a fan to reduce the time.Radiator drain plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

: Engine front

PBIC3394E

Engine coolant capacity

(With reservoir tank at “MAX” level):

Approx. 10.4 (11 US qt, 9-1/8 Imp qt)

Reservoir tank engine coolant capacity

(At “MAX” level):

0.6 (5/8 US qt, 1/2 lmp qt)

Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

SMA412B

Page 1417 of 5621

![INFINITI M35 2006 Factory Owners Manual CO-42

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

If necessary, refill engine coolant up to filler neck of thermostat housing.

8. Refill reservoir tank to “MAX” level line with engi INFINITI M35 2006 Factory Owners Manual CO-42

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

If necessary, refill engine coolant up to filler neck of thermostat housing.

8. Refill reservoir tank to “MAX” level line with engi](/img/42/57023/w960_57023-1416.png)

CO-42

[VK45DE]

ENGINE COOLANT

Revision: 2006 January2006 M35/M45

If necessary, refill engine coolant up to filler neck of thermostat housing.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer

drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-254,

"ASSEMBLY" .

2. Remove air relief plug (1) on heater hose.

3. Fill thermostat housing with water until water spills from the air relief hole, then close air relief plug. Fill

thermostat housing and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to CO-40, "

DRAINING ENGINE COOLANT" .

8. Repeat steps 1 through 7 until clear water begins to drain from radiator. Radiator drain plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

: Engine front

PBIC3394E

Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

Page 1430 of 5621

![INFINITI M35 2006 Factory Owners Manual THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Compo INFINITI M35 2006 Factory Owners Manual THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Compo](/img/42/57023/w960_57023-1429.png)

THERMOSTAT AND WATER CONTROL VALVE

CO-55

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

THERMOSTAT AND WATER CONTROL VALVEPFP:21200

ComponentsNBS004RR

Refer to GI-11, "Components" for symbol marks in the figure.

Removal and InstallationNBS004RS

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-179, "

INTAKE MANIFOLD" .

3. Remove air duct (inlet). Refer to EM-177, "

AIR CLEANER AND AIR DUCT" .

4. Drain engine coolant from drain plugs on radiator and both side of cylinder block. Refer to CO-40, "

Chang-

ing Engine Coolant" and EM-250, "DISASSEMBLY" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

1. Water connector 2. O-ring 3. Rubber ring

4. Heater hose 5. Water control valve 6. Water outlet

7. Gasket 8. O-ring 9. Water outlet pipe

10. Thermostat housing 11. Radiator cap 12. Radiator hose (upper)

13. Thermostat 14. Rubber ring 15. Water inlet

16. Water suction hose 17. Water suction pipe 18. Radiator hose (lower)

19. Gasket 20. O-ring 21. Heater pipe

22. Heater hose

A. To radiator B. To intake manifold adapter C. To cylinder block

D. To cylinder head (right bank) E. To cylinder head (left bank) F.To heater core

PBIC3306E

Page 1431 of 5621

![INFINITI M35 2006 Factory Owners Manual CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassembl INFINITI M35 2006 Factory Owners Manual CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassembl](/img/42/57023/w960_57023-1430.png)

CO-56

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

Revision: 2006 January2006 M35/M45

5. Disconnect water suction hose from water inlet.

6. Remove water inlet and thermostat.

CAUTION:

Do not disassemble thermostat.

7. Remove intake manifolds (upper and lower). Refer to EM-179, "

INTAKE MANIFOLD" .

8. Disconnect radiator hose (upper) from thermostat housing.

9. Disconnect heater hoses from water outlet and heater pipe.

10. Remove thermostat housing, water outlet pipe, water connector, water control valve, water outlet and

heater pipe.

CAUTION:

Do not disassemble water control valve.

INSPECTION AFTER REMOVAL

Make sure that valves both in thermostat and water control valve are completely closing at normal tempar-

ature.

Place a thread so that it is caught in the valves of the thermostat

and water control valve. Immerse fully in a container filled with

water. Heat while stirring. (The example in the figure shows ther-

mostat.)

The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

Continue heating. Check the maximum valve lift.

NOTE:

The maximum valve lift standard temperature for water control

valve is the reference value.

After checking the maximum valve lift, lower the water tempera-

ture and check the valve closing temperature.

Standard values:

If the malfunctioning condition, when closing valve at normal temperature, or measured values are out of

the standard, replace thermostat and/or water control valve.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over engine room. Use rag to absorb engine coolant.

Thermostat and Water Control Valve

Install thermostat and water control valve with the whole circum-

ference of each flange part fit securely inside rubber ring. (The

example in the figure shows thermostat.)

SLC252B

Thermostat Water control valve

Valve opening temperature 80 - 84

C (176 - 183F) 93.5 - 96.5C (200 - 206F)

Maximum valve liftMore than 10 mm/ 95

C

(0.39 in/ 203

F)More than 8 mm/ 108

C

(0.315 in/ 226

F)

Valve closing temperature 77

C (171F) 90C (194F)

PBIC0157E

Page 1432 of 5621

![INFINITI M35 2006 Factory Owners Manual THERMOSTAT AND WATER CONTROL VALVE

CO-57

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

Install thermostat with jiggle valve facing upwards. (The position

deviation may be withi INFINITI M35 2006 Factory Owners Manual THERMOSTAT AND WATER CONTROL VALVE

CO-57

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

Install thermostat with jiggle valve facing upwards. (The position

deviation may be withi](/img/42/57023/w960_57023-1431.png)

THERMOSTAT AND WATER CONTROL VALVE

CO-57

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

Install thermostat with jiggle valve facing upwards. (The position

deviation may be within the range of

10 degrees)

Install water control valve with the up-mark facing up and the

frame center part facing upwards. (The position deviation may

be within the range of

10 degrees)

Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to O-rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using radiator cap tester adapter [SST: EG17650301 (J33984-A)] and

radiator cap tester (commercial service tool). Refer to CO-40, "

LEAK CHECK" .

Start and warm up engine. Visually check if there is no leaks of engine coolant.

PBIC0158E

Page 1545 of 5621

EC-2Revision: 2006 January2006 M35/M45 Inspection Procedure ...........................................

.155

Diagnostic Procedure ...........................................156

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................165

Description ............................................................165

Diagnostic Procedure ...........................................165

POWER SUPPLY AND GROUND CIRCUIT ...........166

Wiring Diagram .....................................................166

Diagnostic Procedure ...........................................167

Ground Inspection ................................................172

DTC U1000, U1001 CAN COMMUNICATION LINE .173

Description ............................................................173

On Board Diagnosis Logic ....................................173

DTC Confirmation Procedure ...............................173

Wiring Diagram .....................................................174

Diagnostic Procedure ...........................................175

DTC U1010 CAN COMMUNICATION .....................176

Description ............................................................176

On Board Diagnosis Logic ....................................176

DTC Confirmation Procedure ...............................176

Diagnostic Procedure ...........................................177

DTC P0011, P0021 IVT CONTROL ........................178

Description ............................................................178

CONSULT-II Reference Value in Data Monitor Mode

.178

On Board Diagnosis Logic ....................................179

DTC Confirmation Procedure ...............................179

Diagnostic Procedure ...........................................180

Component Inspection ..........................................181

Removal and Installation ......................................181

DTC P0031, P0032, P0051, P0052 A/F SENSOR 1

HEATER ..................................................................182

Description ............................................................182

CONSULT-II Reference Value in Data Monitor Mode

.182

On Board Diagnosis Logic ....................................182

DTC Confirmation Procedure ...............................182

Wiring Diagram .....................................................183

Diagnostic Procedure ...........................................186

Component Inspection ..........................................188

Removal and Installation ......................................188

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER .189

Description ............................................................189

CONSULT-II Reference Value in Data Monitor Mode

.189

On Board Diagnosis Logic ....................................189

DTC Confirmation Procedure ...............................190

Wiring Diagram ....................................................

.191

Diagnostic Procedure ...........................................194

Component Inspection ..........................................196

Removal and Installation ......................................196

DTC P0075, P0081 IVT CONTROL SOLENOID

VALVE .....................................................................197

Component Description ........................................197

CONSULT-II Reference Value in Data Monitor Mode

.197

On Board Diagnosis Logic ....................................197

DTC Confirmation Procedure ...............................197

Wiring Diagram .....................................................198Diagnostic Procedure ............................................202

Component Inspection ..........................................204

Removal and Installation .......................................204

DTC P0101 MAF SENSOR .....................................205

Component Description ........................................205

CONSULT-II Reference Value in Data Monitor Mode

.205

On Board Diagnosis Logic ....................................205

DTC Confirmation Procedure ................................206

Overall Function Check .........................................207

Wiring Diagram .....................................................208

Diagnostic Procedure ............................................209

Component Inspection ..........................................212

Removal and Installation .......................................213

DTC P0102, P0103 MAF SENSOR .........................214

Component Description ........................................214

CONSULT-II Reference Value in Data Monitor Mode

.214

On Board Diagnosis Logic ....................................214

DTC Confirmation Procedure ................................215

Wiring Diagram .....................................................216

Diagnostic Procedure ............................................217

Component Inspection ..........................................219

Removal and Installation .......................................220

DTC P0112, P0113 IAT SENSOR ............................221

Component Description ........................................221

On Board Diagnosis Logic ....................................221

DTC Confirmation Procedure ................................221

Wiring Diagram .....................................................223

Diagnostic Procedure ............................................224

Component Inspection ..........................................225

Removal and Installation .......................................225

DTC P0117, P0118 ECT SENSOR ..........................226

Component Description ........................................226

On Board Diagnosis Logic ....................................226

DTC Confirmation Procedure ................................227

Wiring Diagram .....................................................228

Diagnostic Procedure ...........................................

.229

Component Inspection ..........................................230

Removal and Installation .......................................230

DTC P0122, P0123 TP SENSOR ............................231

Component Description ........................................231

CONSULT-II Reference Value in Data Monitor Mode

.231

On Board Diagnosis Logic ....................................231

DTC Confirmation Procedure ................................232

Wiring Diagram .....................................................233

Diagnostic Procedure ............................................234

Component Inspection ..........................................237

Removal and Installation .......................................237

DTC P0125 ECT SENSOR ......................................238

Component Description ........................................238

On Board Diagnosis Logic ....................................238

DTC Confirmation Procedure ................................239

Diagnostic Procedure ............................................239

Component Inspection ..........................................240

Removal and Installation .......................................240

DTC P0127 IAT SENSOR ........................................241

Component Description ........................................241

Page 1551 of 5621

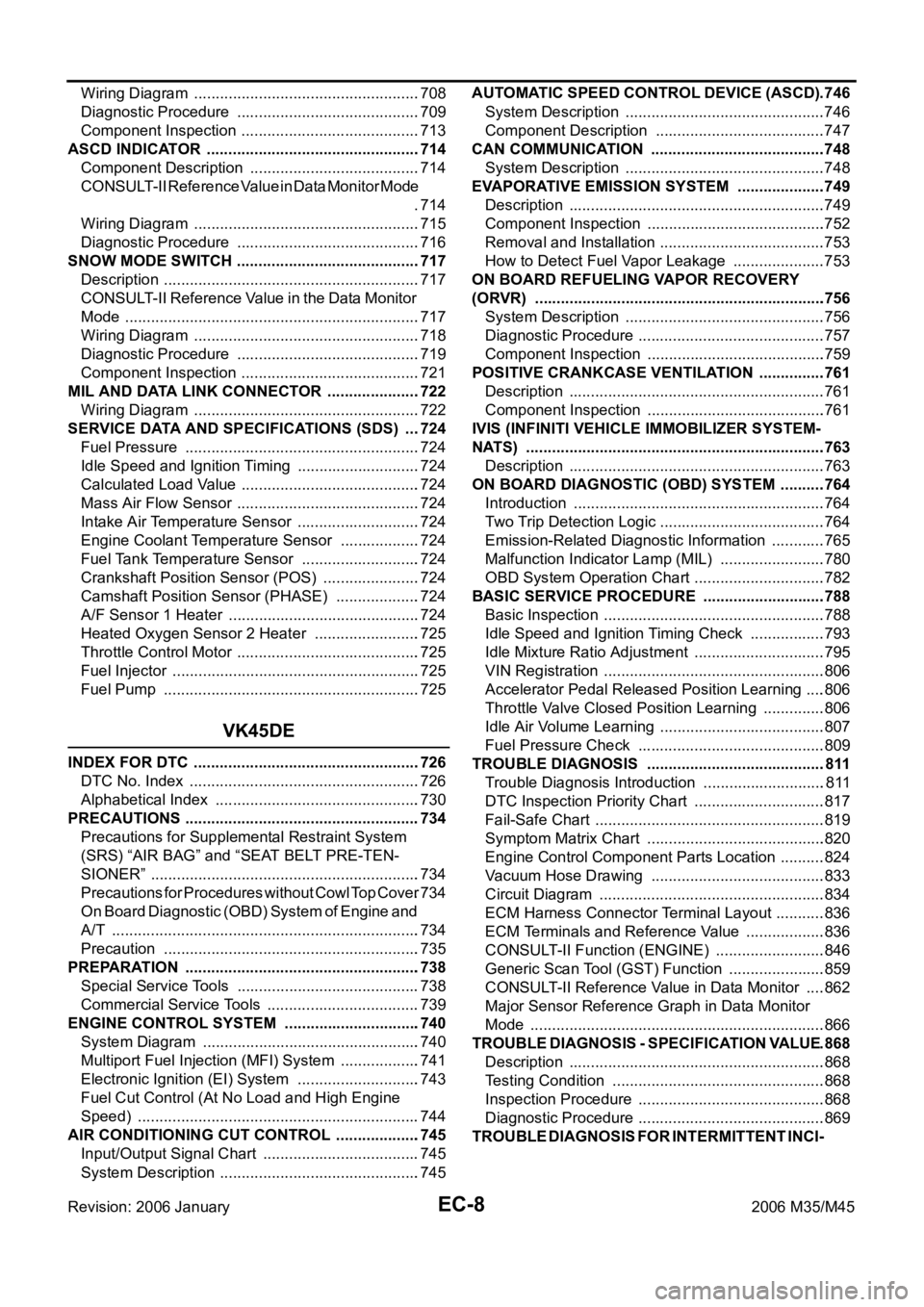

EC-8Revision: 2006 January2006 M35/M45 Wiring Diagram .....................................................708

Diagnostic Procedure ...........................................709

Component Inspection ..........................................713

ASCD INDICATOR .................................................

.714

Component Description ........................................714

CONSULT-II Reference Value in Data Monitor Mode

.714

Wiring Diagram .....................................................715

Diagnostic Procedure ...........................................716

SNOW MODE SWITCH ...........................................717

Description ............................................................717

CONSULT-II Reference Value in the Data Monitor

Mode .....................................................................717

Wiring Diagram .....................................................718

Diagnostic Procedure ...........................................719

Component Inspection ..........................................721

MIL AND DATA LINK CONNECTOR ......................722

Wiring Diagram .....................................................722

SERVICE DATA AND SPECIFICATIONS (SDS) ....724

Fuel Pressure .......................................................724

Idle Speed and Ignition Timing .............................724

Calculated Load Value ..........................................724

Mass Air Flow Sensor ...........................................724

Intake Air Temperature Sensor .............................724

Engine Coolant Temperature Sensor ...................724

Fuel Tank Temperature Sensor ............................724

Crankshaft Position Sensor (POS) .......................724

Camshaft Position Sensor (PHASE) ....................724

A/F Sensor 1 Heater ............................................ .724

Heated Oxygen Sensor 2 Heater .........................725

Throttle Control Motor ...........................................725

Fuel Injector ..........................................................725

Fuel Pump ............................................................725

VK45DE

INDEX FOR DTC .....................................................726

DTC No. Index ......................................................726

Alphabetical Index ................................................730

PRECAUTIONS .......................................................734

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................734

Precautions for Procedures without Cowl Top Cover .734

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................734

Precaution ............................................................735

PREPARATION .......................................................738

Special Service Tools ...........................................738

Commercial Service Tools ....................................739

ENGINE CONTROL SYSTEM ................................740

System Diagram ...................................................740

Multiport Fuel Injection (MFI) System ...................741

Electronic Ignition (EI) System .............................743

Fuel Cut Control (At No Load and High Engine

Speed) ..................................................................744

AIR CONDITIONING CUT CONTROL ....................745

Input/Output Signal Chart .....................................745

System Description ...............................................745AUTOMATIC SPEED CONTROL DEVICE (ASCD) .746

System Description ...............................................746

Component Description ........................................747

CAN COMMUNICATION .........................................748

System Description ...............................................748

EVAPORATIVE EMISSION SYSTEM .....................749

Description ............................................................749

Component Inspection ..........................................752

Removal and Installation .......................................753

How to Detect Fuel Vapor Leakage ......................753

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ....................................................................756

System Description ...............................................756

Diagnostic Procedure ............................................757

Component Inspection ..........................................759

POSITIVE CRANKCASE VENTILATION ................761

Description ............................................................761

Component Inspection ..........................................761

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ......................................................................763

Description ............................................................763

ON BOARD DIAGNOSTIC (OBD) SYSTEM ...........764

Introduction ..........................................................

.764

Two Trip Detection Logic .......................................764

Emission-Related Diagnostic Information .............765

Malfunction Indicator Lamp (MIL) .........................780

OBD System Operation Chart ...............................782

BASIC SERVICE PROCEDURE .............................788

Basic Inspection ....................................................788

Idle Speed and Ignition Timing Check ..................793

Idle Mixture Ratio Adjustment ...............................795

VIN Registration ....................................................806

Accelerator Pedal Released Position Learning .....806

Throttle Valve Closed Position Learning ...............806

Idle Air Volume Learning .......................................807

Fuel Pressure Check ............................................809

TROUBLE DIAGNOSIS ..........................................811

Trouble Diagnosis Introduction .............................811

DTC Inspection Priority Chart ...............................817

Fail-Safe Chart ......................................................819

Symptom Matrix Chart ..........................................820

Engine Control Component Parts Location ...........824

Vacuum Hose Drawing .........................................833

Circuit Diagram .....................................................834

ECM Harness Connector Terminal Layout ............836

ECM Terminals and Reference Value ...................836

CONSULT-II Function (ENGINE) ..........................846

Generic Scan Tool (GST) Function .......................859

CONSULT-II Reference Value in Data Monitor .....862

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................866

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .868

Description ............................................................868

Testing Condition ..................................................868

Inspection Procedure ...........................................

.868

Diagnostic Procedure ............................................869

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-