length INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 362 of 2395

Return SpringsNBAT0165Unit: mm (in)

PartsItem

Part No.* Free length Outer diameter

Control valveUpper body1 Torque converter relief valve spring 31742-41X23 38.0 (1.496) 9.0 (0.354)

2 Pressure regulator valve spring 31742-41X24 44.02 (1.7331) 14.0 (0.551)

3 Pressure modifier valve spring 31742-41X19 31.95 (1.2579) 6.8 (0.268)

Ð Accumulator control valve spring Ð Ð Ð

4 Shuttle shift valve D spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

5 4-2 sequence valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

6 Shift valve B spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

7 4-2 relay valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

8 Shift valve A spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

9 Overrun clutch control valve spring 31762-41X03 23.6 (0.929) 7.0 (0.276)

10 Overrun clutch reducing valve spring 31742-41X14 38.9 (1.531) 7.0 (0.276)

11 Shuttle shift valve S spring 31762-41X04 51.0 (2.008) 5.65 (0.2224)

12 Pilot valve spring 31742-41X13 25.7 (1.012) 9.0 (0.354)

13 Torque converter clutch control valve spring 31742-41X22 18.5 (0.728) 13.0 (0.512)

Lower body1 Modifier accumulator piston spring 31742-27X70 31.4 (1.236) 9.8 (0.386)

2 1st reducing valve spring 31756-60X00 20.5 (0.807) 7.0 (0.276)

3 3-2 timing valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

4 Servo charger valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

Reverse clutch Ð 31505-41X07 Ð Ð

High clutch10 pcs31521-41X03

(Assembly)24.2 (0.9528) 11.6 (0.457)

Forward clutch (Overrun clutch) 20 pcs31521-41X04

(Assembly)35.77 (1.4083) 9.7 (0.382)

Low & reverse brake 18 pcs31655-41X00

(Assembly)22.3 (0.878) 11.2 (0.441)

Band servoSpring A 31605-4AX03 45.6 (1.795) 34.3 (1.350)

Spring B 31605-41X01 29.7 (1.169) 27.6 (1.087)

AccumulatorAccumulator A 31605-41X02 43.0 (1.693) 18.0 (0.709)

Accumulator B 31605-41X14 47.6 (1.874) 26.5 (1.043)

Accumulator C 31605-41X09 45.0 (1.772) 29.3 (1.154)

Accumulator D 31605-41X06 58.4 (2.299) 17.3 (0.681)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Return Springs

AT-357

Page 380 of 2395

Joint Assembly (Final drive side)NBAX0019S03IReplace any parts of double offset joint which show signs of

scorching, rust, wear or excessive play.

ICheck serration for deformation. Replace if necessary.

ICheck slide joint housing for any damage. Replace if neces-

sary.

Joint Assembly (Wheel side)NBAX0019S04Replace joint assembly if it is deformed or damaged.

ASSEMBLYNBAX0020IAfter drive shaft has been assembled, ensure that it

moves smoothly over its entire range without binding.

IUse NISSAN GENUINE GREASE or equivalent after every

overhaul.

SFA800

Final Drive Side (TS82F)NBAX0020S011. Install new small boot band, boot and side joint housing to

drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

SFA397

2. Install spider assembly securely, ensuring marks are properly

aligned.

IPress-fit with spider assembly serration chamfer facing

shaft.

3. Install new snap ring.

SFA460BA

4. Pack with grease.

Specified amount of grease:

95 - 105 g (3.35 - 3.70 oz)

5. Make sure that boot is properly installed on the drive shaft

groove. Set boot so that it does not swell and deform when its

length is ªL

1º.

Length ªL

1º: 95 - 97 mm (3.74 - 3.82 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-13

Page 381 of 2395

SFA443B

6. Lock new larger boot band securely with a suitable tool, then

lock new smaller boot band.

7. Install new plug seal to slide joint housing by lightly tapping it.

Apply sealant to mating surface of plug seal.

SFA800

Wheel Side (ZF100)NBAX0020S021. Install new small boot band and boot on drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

SFA884

2. Set joint assembly onto drive shaft by lightly tapping it.

Install joint assembly securely, ensuring marks which were

made during disassembly are properly aligned.

SFA473BA

3. Pack drive shaft with specified amount of grease.

Specified amount of grease:

135 - 145 g (4.76 - 5.11 oz)

4. Make sure that boot is properly installed on the drive shaft

groove. Set boot so that it does not swell and deform when its

length is ªL

2º.

Length ªL

2º: 96 - 98 mm (3.78 - 3.86 in)

5. Lock new larger boot band securely with a suitable tool.

6. Lock new smaller boot band.

SFA887

INSTALLATIONNBAX00211. Apply multi-purpose grease.

FRONT AXLE

Drive Shaft (Cont'd)

AX-14

Page 383 of 2395

DRIVE SHAFT=NBAX0033

Drive shaft joint typeFinal drive sideTS82F

Wheel sideZF100

Fixed joint axial end play limit 1 mm (0.04 in)

Diameter Wheel side (D

1)29.0 mm (1.142 in)

GreaseQualityNissan genuine grease or equivalent

Specified amount of greaseFinal drive side 95 - 105 g (3.35 - 3.70 oz)

Wheel side 135 - 145 g (4.76 - 5.11 oz)

Drive shaft axial end play0.45 mm (0.0177 in) or less

Boot lengthFinal drive side (L

1) 95 - 97 mm (3.74 - 3.82 in)

Wheel side (L

2) 96 - 98 mm (3.78 - 3.86 in)

SAX001

Drive Shaft End Snap RingNBAX0033S01

Thickness mm (in) Part No. Thickness mm (in) Part No.

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)39253-88G10

39253-88G11

39253-88G12

39253-88G131.9 (0.075)

2.1 (0.083)

2.3 (0.091)39253-88G14

39253-88G15

39253-88G16

FRONT AXLE

Service Data and Specifications (SDS) (Cont'd)

AX-16

Page 390 of 2395

BRAKE SYSTEM

SECTION

BR

CONTENTS

PRECAUTIONS...............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

Precautions for Brake System .....................................3

Wiring Diagrams and Trouble Diagnoses....................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart.........................................6

ON-VEHICLE SERVICE..................................................7

Checking Brake Fluid Level.........................................7

Checking Brake Line ...................................................7

Changing Brake Fluid ..................................................7

Bleeding Brake System ...............................................8

BRAKE HYDRAULIC LINE.............................................9

Hydraulic Circuit...........................................................9

Removal .....................................................................10

Inspection...................................................................10

Installation ..................................................................10

PROPORTIONING VALVE (2WD)................................ 11

Inspection................................................................... 11

Removal and Installation (Built-in type)..................... 11

LOAD SENSING VALVE (4WD)...................................12

Inspection...................................................................12

Removal and Installation ...........................................12

BRAKE PEDAL AND BRACKET..................................14

Removal and Installation ...........................................14

Inspection...................................................................14

Adjustment .................................................................14

MASTER CYLINDER.....................................................16

Removal .....................................................................16

Disassembly...............................................................16

Inspection...................................................................17

Assembly ...................................................................17

Installation ..................................................................18

BRAKE BOOSTER........................................................19

On-vehicle Service.....................................................19OPERATING CHECK...............................................19

AIRTIGHT CHECK...................................................19

Removal .....................................................................19

Inspection...................................................................19

OUTPUT ROD LENGTH CHECK..............................19

Installation ..................................................................20

VACUUM PIPING...........................................................21

Vacuum Hose ............................................................21

Removal and Installation ...........................................21

Inspection...................................................................21

HOSES AND CONNECTORS...................................21

CHECK VALVE........................................................21

FRONT DISC BRAKE...................................................22

Components...............................................................22

Pad Replacement ......................................................22

Removal .....................................................................23

Disassembly...............................................................24

Inspection...................................................................24

CALIPER.................................................................24

ROTOR...................................................................24

Assembly ...................................................................25

Installation ..................................................................25

Brake Burnishing Procedure......................................25

REAR DRUM BRAKE...................................................26

Components...............................................................26

Removal .....................................................................26

Inspection...................................................................27

WHEEL CYLINDER..................................................27

Wheel Cylinder Overhaul...........................................28

Inspection...................................................................28

DRUM.....................................................................28

LINING....................................................................28

Installation ..................................................................28

PARKING BRAKE CONTROL......................................30

Components...............................................................30

Removal and Installation ...........................................30

Inspection...................................................................30

Adjustment .................................................................31

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

Page 401 of 2395

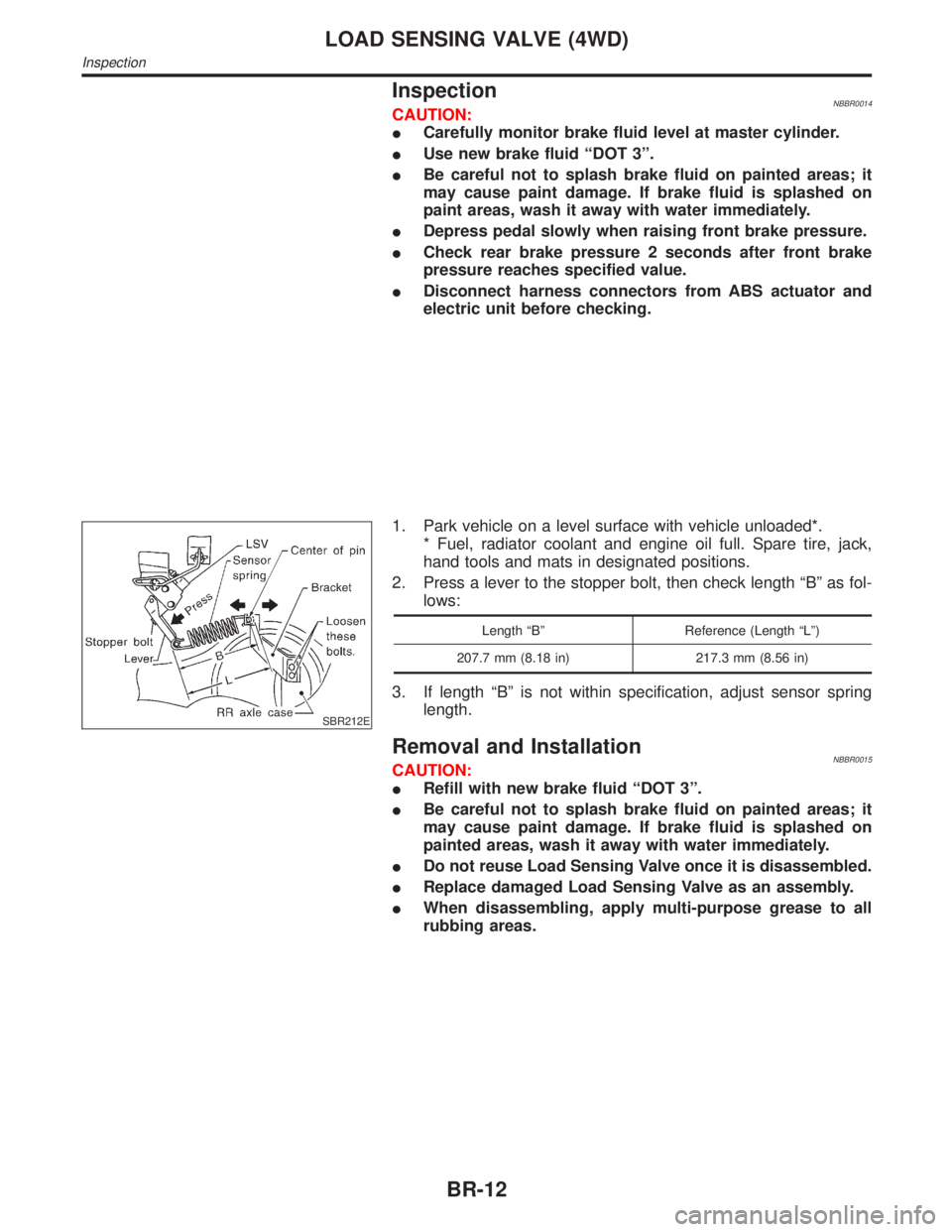

InspectionNBBR0014CAUTION:

ICarefully monitor brake fluid level at master cylinder.

IUse new brake fluid ªDOT 3º.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

paint areas, wash it away with water immediately.

IDepress pedal slowly when raising front brake pressure.

ICheck rear brake pressure 2 seconds after front brake

pressure reaches specified value.

IDisconnect harness connectors from ABS actuator and

electric unit before checking.

SBR212E

1. Park vehicle on a level surface with vehicle unloaded*.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

2. Press a lever to the stopper bolt, then check length ªBº as fol-

lows:

Length ªBº Reference (Length ªLº)

207.7 mm (8.18 in) 217.3 mm (8.56 in)

3. If length ªBº is not within specification, adjust sensor spring

length.

Removal and InstallationNBBR0015CAUTION:

IRefill with new brake fluid ªDOT 3º.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

IDo not reuse Load Sensing Valve once it is disassembled.

IReplace damaged Load Sensing Valve as an assembly.

IWhen disassembling, apply multi-purpose grease to all

rubbing areas.

LOAD SENSING VALVE (4WD)

Inspection

BR-12

Page 408 of 2395

SBR002A

SBR365AA

On-vehicle ServiceNBBR0024OPERATING CHECKNBBR0024S011. Depress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECKNBBR0024S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR368DA

RemovalNBBR0025CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

IBe careful not to deform or bend brake pipes, during

removal of booster.

SBR208E

InspectionNBBR0026OUTPUT ROD LENGTH CHECKNBBR0026S011. Apply vacuum of þ66.7 kPa (þ500 mmHg, þ19.69 inHg) to

brake booster with a hand vacuum pump.

2. Add preload of 19.6 N (2.0 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

BRAKE BOOSTER

On-vehicle Service

BR-19

Page 472 of 2395

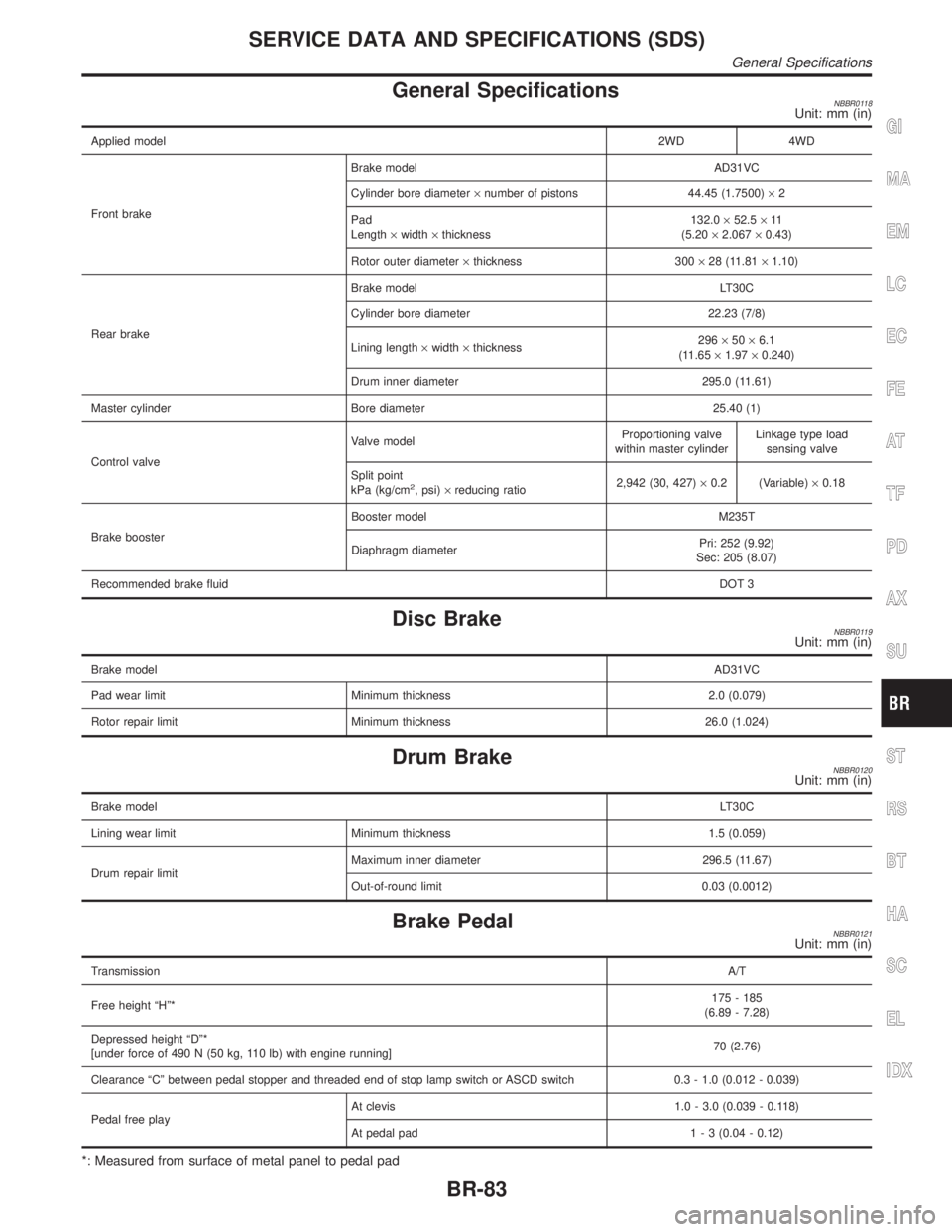

General SpecificationsNBBR0118Unit: mm (in)

Applied model2WD 4WD

Front brakeBrake model AD31VC

Cylinder bore diameter´number of pistons 44.45 (1.7500)´2

Pad

Length´width´thickness132.0´52.5´11

(5.20´2.067´0.43)

Rotor outer diameter´thickness 300´28 (11.81´1.10)

Rear brakeBrake model LT30C

Cylinder bore diameter 22.23 (7/8)

Lining length´width´thickness296´50´6.1

(11.65´1.97´0.240)

Drum inner diameter 295.0 (11.61)

Master cylinder Bore diameter 25.40 (1)

Control valveValve modelProportioning valve

within master cylinderLinkage type load

sensing valve

Split point

kPa (kg/cm

2, psi)´reducing ratio2,942 (30, 427)´0.2 (Variable)´0.18

Brake boosterBooster model M235T

Diaphragm diameterPri: 252 (9.92)

Sec: 205 (8.07)

Recommended brake fluidDOT 3

Disc BrakeNBBR0119Unit: mm (in)

Brake modelAD31VC

Pad wear limit Minimum thickness 2.0 (0.079)

Rotor repair limit Minimum thickness 26.0 (1.024)

Drum BrakeNBBR0120Unit: mm (in)

Brake modelLT30C

Lining wear limit Minimum thickness 1.5 (0.059)

Drum repair limitMaximum inner diameter 296.5 (11.67)

Out-of-round limit 0.03 (0.0012)

Brake PedalNBBR0121Unit: mm (in)

TransmissionA/T

Free height ªHº*175 - 185

(6.89 - 7.28)

Depressed height ªDº*

[under force of 490 N (50 kg, 110 lb) with engine running]70 (2.76)

Clearance ªCº between pedal stopper and threaded end of stop lamp switch or ASCD switch 0.3 - 1.0 (0.012 - 0.039)

Pedal free playAt clevis 1.0 - 3.0 (0.039 - 0.118)

At pedal pad1 - 3 (0.04 - 0.12)

*: Measured from surface of metal panel to pedal pad

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

BR-83

Page 518 of 2395

AdjustmentNBBT0016Install motor & limit SW assembly and sunroof rail assembly in the following sequence:

1. Arrange equal lengths of link and wire assemblies on both sides of sunroof opening.

2. Connect sunroof connector to sunroof switch and positive (+) power supply.

3. Set lid assembly to fully closed position

by operating OPEN switch and TILT switch.

4. Fit outer side of lid assembly to the surface of roof on body outer panel.

5. Remove motor, and keep OPEN switch pressed until motor pinion gear reaches the end of its rotating

range.

6. Install motor.

7. Check that motor drive gear fits properly in wires.

8. Press TILT-UP switch to check lid assembly for normal tilting.

9. Check sunroof lid assembly for normal operations (tilt-up, tilt-down, open, and close).

SBF920F

Removal and InstallationNBBT0017IAfter any adjustment, check sunroof operation and lid align-

ment.

IHandle finisher plate and glass lid with care so not to cause

damage.

IIt is desirable for easy installation to mark each point before

removal.

CAUTION:

IAlways work with a helper.

IBefore removal, fully close the glass lid assembly, then

after removal, do not move motor assembly.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

SUNROOF

Adjustment

BT-45

Page 530 of 2395

AlignmentNBBT0021IAll dimensions indicated in figures are actual ones.

IWhen using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

IWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

IMeasurements should be taken at the center of the mounting holes.

IAn asterisk (H) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

IThe coordinates of the measurement points are the distances measured from the standard line of ªXº, ªYº

and ªZº.

SBF874GD

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY (ALIGNMENT)

Alignment

BT-57