length INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2222 of 2395

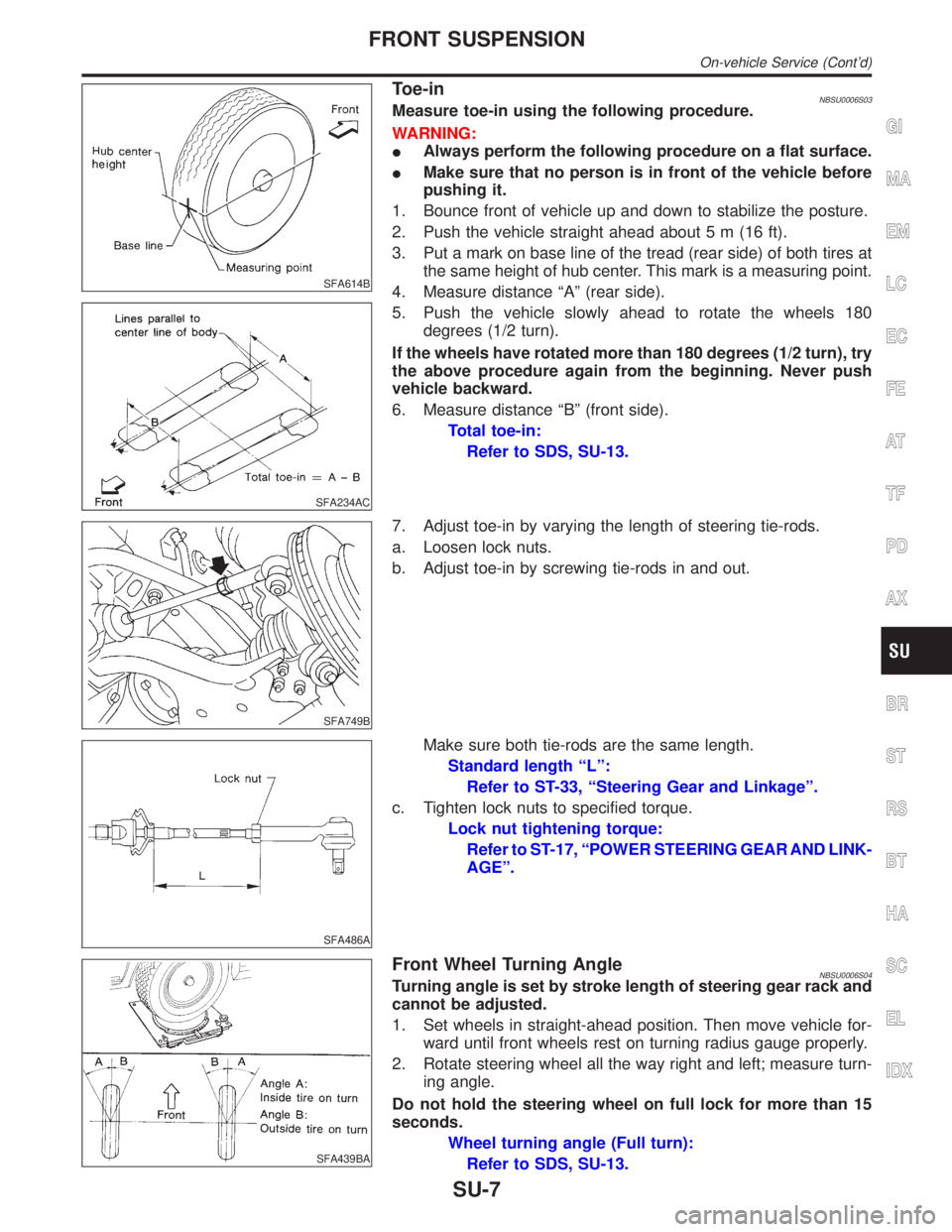

SFA614B

SFA234AC

Toe-inNBSU0006S03Measure toe-in using the following procedure.

WARNING:

IAlways perform the following procedure on a flat surface.

IMake sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance ªAº (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance ªBº (front side).

Total toe-in:

Refer to SDS, SU-13.

SFA749B

7. Adjust toe-in by varying the length of steering tie-rods.

a. Loosen lock nuts.

b. Adjust toe-in by screwing tie-rods in and out.

SFA486A

Make sure both tie-rods are the same length.

Standard length ªLº:

Refer to ST-33, ªSteering Gear and Linkageº.

c. Tighten lock nuts to specified torque.

Lock nut tightening torque:

Refer to ST-17, ªPOWER STEERING GEAR AND LINK-

AGEº.

SFA439BA

Front Wheel Turning AngleNBSU0006S04Turning angle is set by stroke length of steering gear rack and

cannot be adjusted.

1. Set wheels in straight-ahead position. Then move vehicle for-

ward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Do not hold the steering wheel on full lock for more than 15

seconds.

Wheel turning angle (Full turn):

Refer to SDS, SU-13.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

On-vehicle Service (Cont'd)

SU-7

Page 2354 of 2395

SMT897C

RemovalNBTF00731. Remove exhaust front and rear tubes. Refer to FE-8,

ªEXHAUST SYSTEMº.

2. Remove front and rear propeller shaft. Refer to PD-6,

ªRemoval and Installationº.

3. Insert plug into rear oil seal after removing propeller shaft.

IBe careful not to damage spline, sleeve yoke and rear oil

seal, when removing propeller shaft.

4. Disconnect neutral-4LO switch, front revolution sensor, ATP

switch, transfer motor and 4WD shift switch harness connec-

tors.

SMT808D

5. Remove center console and A/T control device.

6. Remove floor panel for transfer.

7. Remove upper side fixing bolt for A/T and TF.

8. Remove actuator lever from transfer outer shift lever and

remove sub-oil pump from transfer.

9. Remove remaining fixing bolt for AT and TF.

SMT899C

SMT871C

10. Remove transfer from transmission.

WARNING:

Support transfer while removing it.

SMT872C

InstallationNBTF0074ITighten bolts securing transfer.

Bolt length:

45 mm (1.77 in)

Tightening torque:

: 31 - 42 N´m (3.2 - 4.3 kg-m, 23 - 31 ft-lb)

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REMOVAL AND INSTALLATION

Removal

TF-119

Page 2374 of 2395

SMT945C

Control ValveNBTF0081S04ICheck oil filter screen for damage. If any is found, replace with

new one.

SMT946CA

ICheck resistance between terminals of 4WD solenoid valve,

2-4WD shift solenoid valve and transfer fluid temperature sen-

sor.

Resistance:

Refer to ªCOMPONENT INSPECTIONº, TF-111.

SMT947C

ICheck sliding faces of control valves and plugs for abnormal-

ity. If any is found, replace the control valve assembly with new

one.

CAUTION:

Replace control valve body together with clutch return spring

as a set.

Control valve:

Refer to SDS, TF-157.

SMT948C

ICheck each control valve spring for damage or distortion, and

also check its free length, outer diameter and wire diameter. If

any damage or fatigue is found, replace control valve body with

new one.

IReplace control valve body together with clutch return

spring as a set.

Inspection standard:

Refer to SDS, TF-157.

SMT949C

ClutchNBTF0081S05ICheck drive plate and driven plate facings for damage, cracks

or other abnormality. If any, replace with new one.

ICheck the thickness of drive plate and driven plate facings.

Inspection standard:

Refer to SDS, TF-158.

CAUTION:

IMeasure facing thickness at 3 points to take an average.

ICheck all the drive and driven plates.

ICheck return spring for damage or deformation.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Center Case (Cont'd)

TF-139

Page 2375 of 2395

SMT950C

ICheck stamped mark shown in the figure. Then, check that

free length, outer diameter and wire diameter are within speci-

fications. If any abnormality is found, replace with new return

spring assembly of the same stamped number.

Inspection standard:

Refer to SDS, TF-158.

REPAIR FOR COMPONENT PARTS

Center Case (Cont'd)

TF-140

Page 2383 of 2395

SMT911D

9. Install bolts as shown in the figure, and tighten them to speci-

fied torque.

Bolt symbol a b *c d e f

Length under head

mm (in)38

(1.50)43.5

(1.713)62

(2.44)19

(0.75)52

(2.05)47

(1.85)

Q'ty 1732111

Tightening torque

N´m (kg-m, in-lb)6.9 - 8.8 (0.70 - 0.90, 61.1 - 77.9)

*: Tighten with oil strainer.

SMT920C

10. Install control valve assembly to center case, and tighten bolts.

: 6.9 - 8.8 N´m (0.70 - 0.90 kg-m, 61.1 - 77.9 in-lb)

SMT921C

11. Secure terminal body with snap ring.

SMT919C

12. Apply ATF or petroleum jelly to O-rings, and install them to oil

strainer.

CAUTION:

Do not reuse snap ring.

13. Install oil strainer to control valve assembly.

14. Install mainshaft and clutch drum to center case. Refer to

ªMainshaft and Clutch Drumº, TF-149.

15. Install front case assembly and rear case assembly. Refer to

ªFinal Assemblyº, TF-153.

SMT917C

Clutch PistonNBTF0083S051. Apply ATF to D-ring and lip seal, and install them to clutch pis-

ton.

ASSEMBLY

Center Case (Cont'd)

TF-148

Page 2392 of 2395

General SpecificationsNBTF0085

Transfer modelATX14A

Gear ratioHigh1.000

Low2.596

Number of teethPlanetary gearSun gear 57

Internal gear 91

Front drive sprocket 35

Front drive shaft 35

Fluid capacity(US qt, Imp qt)*3.0 (3-1/8, 2-5/8)

*: Refer to MA-11, ªFluids and Lubricantsº.

Inner Gear and Outer GearNBTF0086SUB-OIL PUMPNBTF0086S01

Allowable clearance 0.015 - 0.035 mm (0.0006 - 0.0014 in)

Gear thickness mm (in)Part No.*

Inner gear Outer gear

9.27 - 9.28 (0.3650 - 0.3654) 31346 0W462 31347 0W462

9.28 - 9.29 (0.3654 - 0.3657) 31346 0W461 31347 0W461

9.29 - 9.30 (0.3657 - 0.3661) 31346 0W460 31347 0W460

*: Always check with the Parts Department for the latest parts information.

MAIN OIL PUMPNBTF0086S02

Allowable clearance 0.015 - 0.035 mm (0.0006 - 0.0014 in)

Gear thickness mm (in)Part No.*

Inner gear Outer gear

14.67 - 14.68 (0.5776 - 0.5780) 31346 0W412 31347 0W412

14.68 - 14.69 (0.5780 - 0.5783) 31346 0W411 31347 0W411

14.69 - 14.70 (0.5783 - 0.5787) 31346 0W410 31347 0W410

*: Always check with the Parts Department for the latest parts information.

Control ValveNBTF0087VALVENBTF0087S01

Mounting position Part name Part No.* Outer dia. mm (in) Overall length mm (in)

L1 2-4 shift valve 31772 21X00 8.0 (0.315) 38.5 (1.516)

L2 Clutch valve 31772 80X11 10.0 (0.394) 40.0 (1.575)

L4 Pilot valve 31772 80X11 10.0 (0.394) 40.0 (1.575)

L5 Regulator valve 31741 0W410 12.0 (0.472) 68.0 (2.677)

*: Always check with the Parts Department for the latest parts information.

SPRINGNBTF0087S02

Mounting position Part name Part No.*Free length

mm (in)Outer dia.

mm (in)Wire dia. mm (in) Winding direction

L12-4 shift valve

spring31742 0W400 31.85 (1.2539) 7.0 (0.276) 0.6 (0.024) Clockwise

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

TF-157

Page 2393 of 2395

Mounting position Part name Part No.*Free length

mm (in)Outer dia.

mm (in)Wire dia. mm (in) Winding direction

L2 Clutch valve spring 31742 0W405 40.6 (1.598) 9.0 (0.354) 0.8 (0.031) Clockwise

L4 Pilot valve spring 31742 0W410 28.1 (1.106) 9.0 (0.354) 1.2 (0.047) Clockwise

L5Regulator valve

spring31742 0W415 39.7 (1.563) 11.0 (0.433) 1.3 (0.051) Clockwise

*: Always check with the Parts Department for the latest parts information.

ClutchNBTF0088DRIVE PLATENBTF0088S01

Part No.* Quantity Initial thickness mm (in) Limit value mm (in)

31532 0W410 8 2.0 (0.079) 1.8 (0.071)

*: Always check with the Parts Department for the latest parts information.

DRIVEN PLATENBTF0088S04

Part No.* Quantity Initial thickness mm (in) Limit value mm (in)

31536 0W410 14 2.0 (0.079) 0 (0) (steel plate)

*: Always check with the Parts Department for the latest parts information.

RETURN SPRINGNBTF0088S02

Stamped mark Part No.* Free length mm (in) Outer dia. mm (in) Wire dia. mm (in) Winding direction

1 31521 0W401 37.3 (1.496)

12.0 (0.472) 1.8 (0.071) Clockwise 2 31521 0W402 37.8 (1.488)

3 31521 0W403 38.4 (1.512)

4 31521 0W404 38.9 (1.531)

5 31521 0W405 39.4 (1.551)

6 31521 0W406 40.0 (1.575)

7 31521 0W407 36.8 (1.449)

8 31521 0W408 40.5 (1.594)

*: Always check with the Parts Department for the latest parts information.

RETAINING PLATENBTF0088S03

Standard end play 0.2 - 0.5 mm (0.008 - 0.020 in)

Measured value mm (in) Part No.* Thickness mm (in)

2.30 - 2.50 (0.0906 - 0.0984) 31537 0W410 2.1 (0.083)

2.50 - 2.70 (0.0984 - 0.1063) 31537 0W411 2.3 (0.091)

2.70 - 2.90 (0.1063 - 0.1142) 31537 0W412 2.5 (0.098)

2.90 - 3.10 (0.1142 - 0.1220) 31537 0W413 2.7 (0.106)

3.10 - 3.30 (0.1220 - 0.1299) 31537 0W414 2.9 (0.114)

3.30 - 3.50 (0.1299 - 0.1378) 31537 0W415 3.1 (0.122)

3.50 - 3.70 (0.1378 - 0.1457) 31537 0W416 3.3 (0.130)

3.70 - 3.90 (0.1457 - 0.1535) 31537 0W417 3.5 (0.138)

3.90 - 4.10 (0.1535 - 0.1614) 31537 0W418 3.7 (0.146)

4.10 - 4.30 (0.1614 - 0.1693) 31537 0W419 3.9 (0.154)

SERVICE DATA AND SPECIFICATIONS (SDS)

Control Valve (Cont'd)

TF-158