INSTALLATION INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2232 of 2395

SBR686C

Removal and InstallationNBSU00261. Support axle and suspension components with a suitable jack

and block.

2. Disconnect brake hydraulic line and parking brake cables at

back plates.

CAUTION:

IUse flare nut wrench when removing and installing brake

tubes.

IBefore removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Then move

it away from the rear suspension assembly. Failure to do

so may result in damage to the sensor wires and the sen-

sor becoming inoperative.

3. Remove stabilizer bar from body.

4. Remove upper links and lower links from body.

5. Remove panhard rod from body.

6. Disconnect rear end of propeller shaft. Refer to PD-6,

ªRemoval and Installationº.

7. Remove upper end nuts of shock absorber.

SRA935

Final tightening for rubber parts requires to be carried out

under unladen condition with tires on ground.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Removal and Installation

SU-17

Page 2234 of 2395

SRA645A

REMOVAL AND INSTALLATIONNBSU0028Refer to ªRemoval and Installationº, ªREAR SUSPENSIONº,

SU-17.

When installing coil spring, pay attention to its direction.

Be sure spring rubber seat is not twisted and has not slipped

off when installing coil spring.

INSPECTIONNBSU0029ICheck coil spring for yield, deformation and cracks.

ICheck shock absorber for oil leakage, cracks and deformation.

ICheck all rubber parts for wear, cracks and deformation.

Replace if necessary.

Upper Link, Lower Link and Panhard Rod

INSPECTIONNBSU0030Check for cracks, distortion and other damage. Replace if

necessary.

SRA898

BUSHING REPLACEMENTNBSU0031Check for cracks and other damage. Replace with suitable tool if

necessary.

IRemove bushing with suitable tool.

SRA900

When installing bushing, apply a coat of 1% soapy water to

outer wall of bushing.

Always install new bushing.

Do not tap end face of bushing directly with a hammer.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Coil Spring and Shock Absorber (Cont'd)

SU-19

Page 2235 of 2395

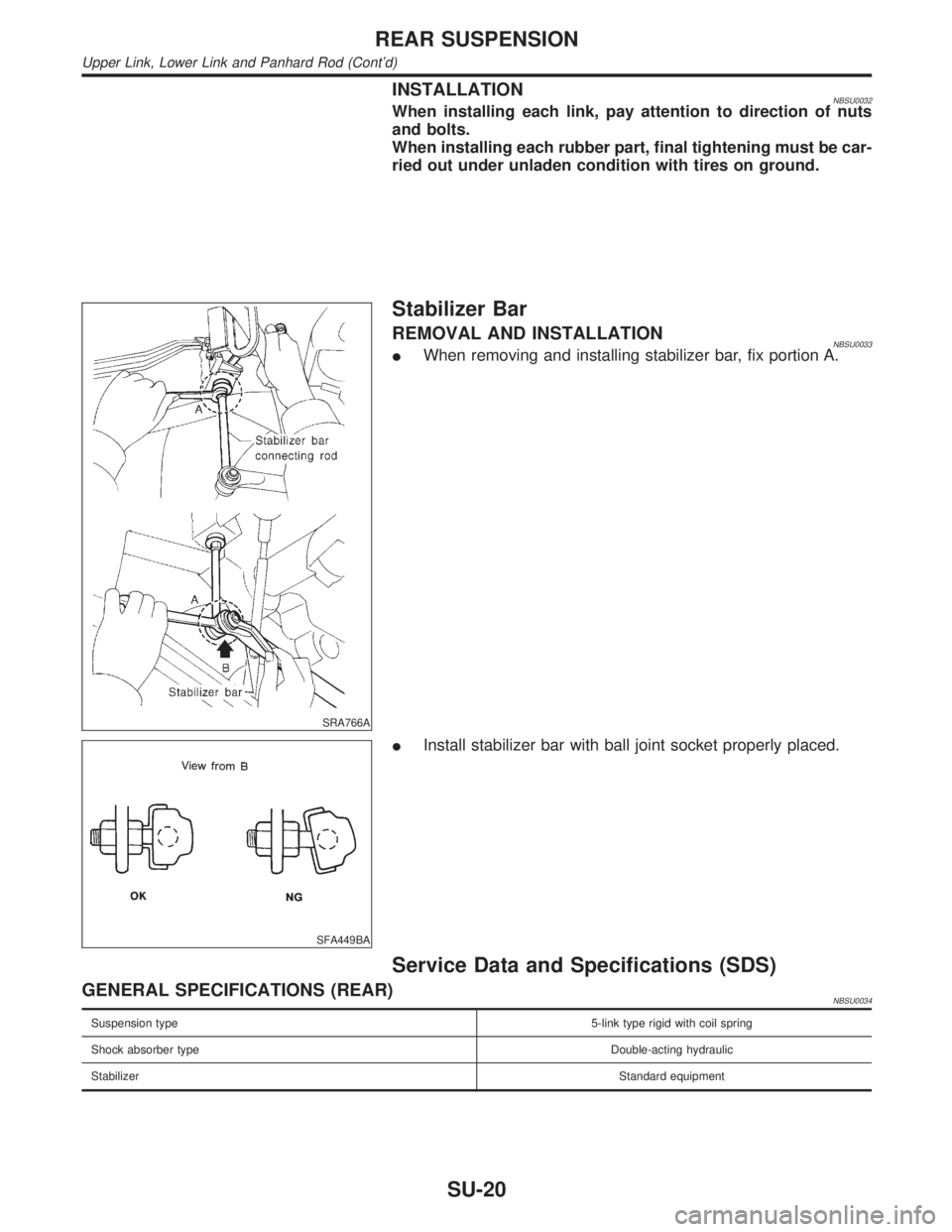

INSTALLATIONNBSU0032When installing each link, pay attention to direction of nuts

and bolts.

When installing each rubber part, final tightening must be car-

ried out under unladen condition with tires on ground.

SRA766A

Stabilizer Bar

REMOVAL AND INSTALLATIONNBSU0033IWhen removing and installing stabilizer bar, fix portion A.

SFA449BA

IInstall stabilizer bar with ball joint socket properly placed.

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (REAR)NBSU0034

Suspension type5-link type rigid with coil spring

Shock absorber typeDouble-acting hydraulic

StabilizerStandard equipment

REAR SUSPENSION

Upper Link, Lower Link and Panhard Rod (Cont'd)

SU-20

Page 2236 of 2395

TRANSFER

SECTION

TF

CONTENTS

PRECAUTIONS...............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

Precautions ..................................................................3

Service Notice..............................................................4

Wiring Diagrams and Trouble Diagnosis .....................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................9

ALL-MODE 4WD SYSTEM...........................................10

Cross-sectional View .................................................10

Control System .......................................................... 11

ALL-MODE 4WD TRANSFER BASIC CONTROL........12

HYDRAULIC CONTROL CIRCUITS...........................12

OUTLINE................................................................12

CONTROL SYSTEM DIAGRAM................................13

INDICATIONS OF 4WD WARNING LAMP..................13

Location of Electrical Parts ........................................14

Description of Electrical Parts ...................................15

TRANSFER MOTOR................................................15

WAIT DETECTION SWITCH.....................................15

2-4WD SHIFT SOLENOID VALVE.............................16

LINE PRESSURE SWITCH.......................................16

Circuit Diagram for Quick Pinpoint Check.................17

Wiring Diagram - TF -................................................18

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................27

Trouble Diagnosis without CONSULT-II ....................27

DESCRIPTION........................................................27

SELF-DIAGNOSTIC PROCEDURE............................28

INDICATIONS OF 4WD WARNING LAMP..................29

Trouble Diagnosis with CONSULT-II .........................30

SELF-DIAGNOSIS...................................................30

SELF-DIAGNOSTIC ITEMS......................................31

DATA MONITOR......................................................33

DATA MONITOR ITEMS...........................................34

REFERENCE VALUE IN DATA MONITOR MODE......36

WORK SUPPORT....................................................38

CLUTCH FORCE RELEASE LIMIT ADJUSTMENT.....39

TROUBLE DIAGNOSIS - INTRODUCTION..................41Introduction ................................................................41

DESCRIPTION........................................................41

DIAGNOSTIC WORKSHEET.....................................41

Work Flow ..................................................................43

HOW TO PERFORM TROUBLE DIAGNOSES FOR

QUICK AND ACCURATE REPAIR

.............................43

TROUBLE DIAGNOSIS - BASIC INSPECTION...........44

Listen to Customer Complaints .................................44

Transfer Fluid Check .................................................44

Road Test...................................................................44

PREPARATION FOR ROAD TEST............................44

1. CHECK BEFORE ENGINE IS STARTED...............45

2. CHECK AT IDLE..................................................47

3. CRUISE TEST.....................................................51

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................54

Transfer Control Unit Terminals and Reference

Value ..........................................................................54

REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

......................................................54

INSPECTION OF TRANSFER CONTROL UNIT..........54

TRANSFER CONTROL UNIT INSPECTION TABLE....55

VEHICLE SPEED SENSOR (FRONT

REVOLUTION SENSOR)..............................................61

Diagnostic Procedure ................................................61

4WD SOLENOID VALVE...............................................64

Diagnostic Procedure ................................................64

2-4WD SHIFT SOLENOID VALVE AND 4WD

SHIFT SWITCH..............................................................66

Diagnostic Procedure ................................................66

TRANSFER MOTOR AND TRANSFER MOTOR

RELAY...........................................................................70

Diagnostic Procedure ................................................70

TRANSFER FLUID TEMPERATURE SENSOR............73

Diagnostic Procedure ................................................73

ATP SWITCH, WAIT DETECTION SWITCH AND

NEUTRAL-4LO SWITCH...............................................76

Diagnostic Procedure ................................................76

CLUTCH PRESSURE SWITCH....................................80

Diagnostic Procedure ................................................80

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2237 of 2395

LINE PRESSURE SWITCH...........................................83

Diagnostic Procedure ................................................83

ABS OPERATION SIGNAL...........................................86

Diagnostic Procedure ................................................86

DATA ERASE/DISPLAY...............................................88

Diagnostic Procedure ................................................88

SHIFT ACTUATOR........................................................89

Diagnostic Procedure ................................................89

SHIFT ACTUATOR POSITION SWITCH......................92

Diagnostic Procedure ................................................92

SHIFT ACTUATOR CIRCUIT........................................94

Diagnostic Procedure ................................................94

TROUBLE DIAGNOSES FOR SYMPTOMS.................98

Symptom 1. 4WD Shift Indicator Lamp Does Not

Turn ON .....................................................................98

Symptom 2. 4WD Warning Lamp Does Not Turn

ON............................................................................100

Symptom 3. 4WD Shift Indicator Lamp Does Not

Turn OFF .................................................................102

Symptom 4. ATP Warning Lamp Does Not Turn

ON............................................................................102

Symptom 5. 4LO Indicator Lamp Does Not Turn

ON............................................................................104

Symptom 6. 4WD Shift Indicator Lamp Does Not

Indicate²4H²............................................................106

Symptom 7. 4WD Shift Indicator Lamp Repeats

Flickering..................................................................107

Symptom 8. Tight Corner Braking Symptom...........108

Symptom 9. 4WD System Does Not Operate.........109

COMPONENT INSPECTION....................................... 111

4WD Shift Switch ..................................................... 111

2-4WD Shift Solenoid Valve and Transfer Fluid

Temperature Sensor ................................................ 111

4WD Solenoid Valve, Clutch Pressure Switch

and Line Pressure Switch........................................ 111

Front Revolution Sensor .......................................... 112

Transfer Dropping Resistor...................................... 112

ATP Switch, Neutral-4LO Switch and Wait

Detection Switch ...................................................... 112

Transfer Motor ......................................................... 113

Transfer Motor Relay ............................................... 113

Transfer Sub-harness .............................................. 113

FRONT REVOLUTION SENSOR SUB-HARNESS

CONNECTOR

........................................................ 113

TRANSFER SWITCH ASSEMBLY SUB-HARNESS

CONNECTOR

........................................................ 114

TRANSFER TERMINAL CORD ASSEMBLY SUB-

HARNESS CONNECTOR

....................................... 114

Transfer Shift Relay (High & low) ............................ 114

Actuator & Actuator Position Switch ........................ 115

ACTUATOR........................................................... 115

ACTUATOR POSITION SWITCH............................ 115

ON-VEHICLE SERVICE.............................................. 116

Replacing Oil Seal ................................................... 116

FRONT CASE OIL SEAL........................................ 116

SHIFT SHAFT OIL SEAL........................................ 117

REAR OIL SEAL.................................................... 117

Transfer Motor ......................................................... 117

REMOVAL............................................................. 117

INSTALLATION...................................................... 117

Transfer Oil Filter ..................................................... 118

REMOVAL............................................................. 118

INSTALLATION...................................................... 118

REMOVAL AND INSTALLATION............................... 119

Removal ................................................................... 119

Installation ................................................................ 119

OVERHAUL.................................................................120

Transfer Gear Control ..............................................120

Transfer Components ..............................................121

DISASSEMBLY............................................................123

Rear Case................................................................123

DISASSEMBLY......................................................123

Center Case.............................................................123

DISASSEMBLY......................................................123

Front Case ...............................................................133

DISASSEMBLY......................................................133

REPAIR FOR COMPONENT PARTS.........................137

Front Case ...............................................................137

INSPECTION.........................................................137

Center Case.............................................................138

INSPECTION.........................................................138

ASSEMBLY..................................................................141

Front Case ...............................................................141

ASSEMBLY...........................................................141

Center Case.............................................................145

ASSEMBLY...........................................................145

Final Assembly.........................................................153

SERVICE DATA AND SPECIFICATIONS (SDS).......157

General Specifications .............................................157

Inner Gear and Outer Gear .....................................157

SUB-OIL PUMP.....................................................157

MAIN OIL PUMP....................................................157

Control Valve ...........................................................157

VALVE..................................................................157

SPRING................................................................157

Clutch .......................................................................158

DRIVE PLATE.......................................................158

DRIVEN PLATE.....................................................158

RETURN SPRING..................................................158

RETAINING PLATE................................................158

Seal Ring (Mainshaft side) ......................................159

Bearing Race (Thrust needle bearing side) ............159

Snap Ring (Sun gear side) ......................................159

CONTENTS(Cont'd)

TF-2

Page 2238 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBTF0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRSsection of this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

SEF289H

PrecautionsNBTF0092IBefore connecting or disconnecting the Transfer control

unit harness connector, turn ignition switch OFF and dis-

connect negative battery terminal. Failure to do so may

damage the Transfer control unit. Because battery voltage

is applied to Transfer control unit even if ignition switch

is turned off.

SEF291H

IWhen connecting or disconnecting pin connectors into or

from Transfer control unit, take care not to damage pin

terminals (bend or break).

Make sure that there are not any bends or breaks on

Transfer control unit pin terminal, when connecting pin

connectors.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

TF-3

Page 2289 of 2395

SMT862D

Transfer Control Unit Terminals and Reference

Value

NBTF0018REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

NBTF0018S03RemovalNBTF0018S03011. Turn ignition switch OFF and disconnect negative battery ter-

minal.

2. Remove console box.

3. Remove cluster lid C.

4. Remove audio assembly and A/C control unit.

5. Remove instrument lower panel on driver side.

6. Remove glove box.

7. Remove instrument lower panel on passenger side.

8. Remove instrument lower center panel.

9. Remove transfer control unit.

IFor steps 2 through 8 above, refer to BT-21, ªInstrument Panel

Assemblyº.

InstallationNBTF0018S0302IInstallation is in the reverse order of removal.

When installing transfer control unit, tighten transfer control unit

lock nut.

Tightening torque:

: 4.3 - 5.8 N´m (0.44 - 0.59 kg-m, 38 - 51 in-lb)

SMT771D

INSPECTION OF TRANSFER CONTROL UNITNBTF0018S01IMeasure voltage between each terminal and terminal 6 or 45

by following ªTRANSFER CONTROL UNIT INSPECTION

TABLEº, TF-55.

IPin connector terminal layout

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value

TF-54

Page 2351 of 2395

SMT844DB

Replacing Oil SealNBTF0068FRONT CASE OIL SEALNBTF0068S011. Drain transfer fluid.

2. Remove exhaust front tube and heat insulator. Refer to

ªRemovalº, TF-119.

3. Remove front propeller shaft. Refer to PD-6, ªRemoval and

Installationº.

4. Remove companion flange lock nut.

IDo not reuse lock nut.

SMT112D

5. Put a matchmark on top of drive pinion thread. The mark

should be in line with the mark on the companion flange.

IAlways mark top of drive pinion screw using paint.

SMT802C

6. Remove companion flange.

SMT803C

7. Remove front case oil seal.

8. Install front case oil seal.

IBefore installing, apply multi-purpose grease to seal lip.

9. Install companion flange.

SMT845DB

10. Tighten nut to the specified torque.

Refer to TF-121.

11. Install front propeller shaft.

ON-VEHICLE SERVICE

Replacing Oil Seal

TF-116

Page 2352 of 2395

SMT808D

SHIFT SHAFT OIL SEALNBTF0068S021. Remove front propeller shaft. Refer to PD-6, ªRemoval and

Installationº.

2. Remove companion flange. Refer to ªFRONT CASE OIL

SEALº, TF-116.

3. Remove actuator lever from transfer outer shift lever. Then

remove outer shift lever.

SMT491A

4. Remove shift shaft oil seal.

IBe careful not to damage cross shaft.

SMT805C

5. Install shift shaft oil seal.

IBefore installing, apply multi-purpose grease to seal lip.

6. Install transfer control linkage.

7. Install companion flange. Refer to ªFRONT CASE OIL SEALº,

TF-116.

8. Install front propeller shaft.

SMT892C

REAR OIL SEALNBTF0068S031. Remove rear propeller shaft. Refer to PD-6, ªRemoval and

Installationº.

2. Remove rear oil seal.

3. Install rear oil seal.

IBefore installing, apply multi-purpose grease to seal lip.

4. Install rear propeller shaft.

SMT874C

Transfer Motor

REMOVALNBTF00691. Disconnect transfer motor harness connector.

2. Remove breather pipe from transfer motor.

3. Remove bolts to detach transfer motor.

IAfter removing transfer motor, be sure to replace O-ring

with new one.

INSTALLATIONNBTF00701. Apply petroleum jelly or ATF to O-ring.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Replacing Oil Seal (Cont'd)

TF-117

Page 2353 of 2395

2. Align width across flat-notch with oil pump groove, and install

transfer motor.

3. Tighten bolts.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

4. Install breather pipe to transfer motor.

5. Connect transfer motor harness connector.

SMT875C

Transfer Oil Filter

REMOVALNBTF0071IRemove bolts to detach oil filter.

IWhen removing oil filter from transfer, avoid damaging it.

Be sure to loosen bolts evenly.

IWhen removing oil filter, be sure to replace O-ring with

new one.

INSTALLATIONNBTF00721. Apply petroleum jelly or ATF to O-ring.

2. Tighten bolts evenly to install oil filter.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

IBe sure not to damage oil filter.

ON-VEHICLE SERVICE

Transfer Motor (Cont'd)

TF-118