check engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 886 of 2395

6 CHECK IGNITION SPARK

1. Turn ignition switch ªOFFº.

2. Disconnect ignition coil assembly from rocker cover.

3. Connect a known good spark plug to the ignition coil assembly.

4. Place end of spark plug against a suitable ground and crank engine.

5. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil with power transistor and their circuit. Refer to EC-499.

7 CHECK INJECTOR

1. Turn ignition switch ªOFFº.

2. Remove injector assembly.

Refer to EC-41.

Keep fuel hose and all injectors connected to injector gallery.

3. Disconnect all ignition coil harness connectors.

4. Turn ignition switch ªONº.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip.)©GO TO 8.

NG (Drips.)©Replace the injector(s) from which fuel is dripping.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

Trouble is fixed.©INSPECTION END

Trouble is not fixed.©Replace warm-up three way catalyst.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0420 (RIGHT BANK, -B1), P0430 (LEFT BANK, -B2) THREE WAY

CATALYST FUNCTION

Diagnostic Procedure (Cont'd)

EC-351

Page 887 of 2395

On Board Diagnosis LogicNBEC0218NOTE:

If DTC P0440 is displayed with P1448, perform trouble diagno-

sis for DTC P1448 first. (See EC-573.)

This diagnosis detects leaks in the EVAP purge line using engine

intake manifold vacuum.

If pressure does not increase, the ECM will check for leaks in the

line between the fuel tank and EVAP canister purge volume con-

trol solenoid valve, under the following ªVacuum testº conditions.

The vacuum cut valve bypass valve is opened to clear the line

between the fuel tank and the EVAP canister purge volume control

solenoid valve. The EVAP canister vent control valve will then be

closed to shut the EVAP purge line off. The EVAP canister purge

volume control solenoid valve is opened to depressurize the EVAP

purge line using intake manifold vacuum. After this occurs, the

EVAP canister purge volume control solenoid valve will be closed.

SEF373Z

Malfunction is detected when EVAP control system has a leak,

EVAP control system does not operate properly.

CAUTION:

IUse only a genuine NISSAN fuel filler cap as a replace-

ment. If an incorrect fuel filler cap is used, the MIL may

come on.

IIf the fuel filler cap is not tightened properly, the MIL may

come on.

IUse only a genuine NISSAN rubber tube as a replacement.

Possible CauseNBEC0510IIncorrect fuel tank vacuum relief valve

IIncorrect fuel filler cap used

IFuel filler cap remains open or fails to close.

IForeign matter caught in fuel filler cap.

ILeak is in line between intake manifold and EVAP canister

purge volume control solenoid valve.

IForeign matter caught in EVAP canister vent control valve.

IEVAP canister or fuel tank leaks

IEVAP purge line (pipe and rubber tube) leaks

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

On Board Diagnosis Logic

EC-352

Page 896 of 2395

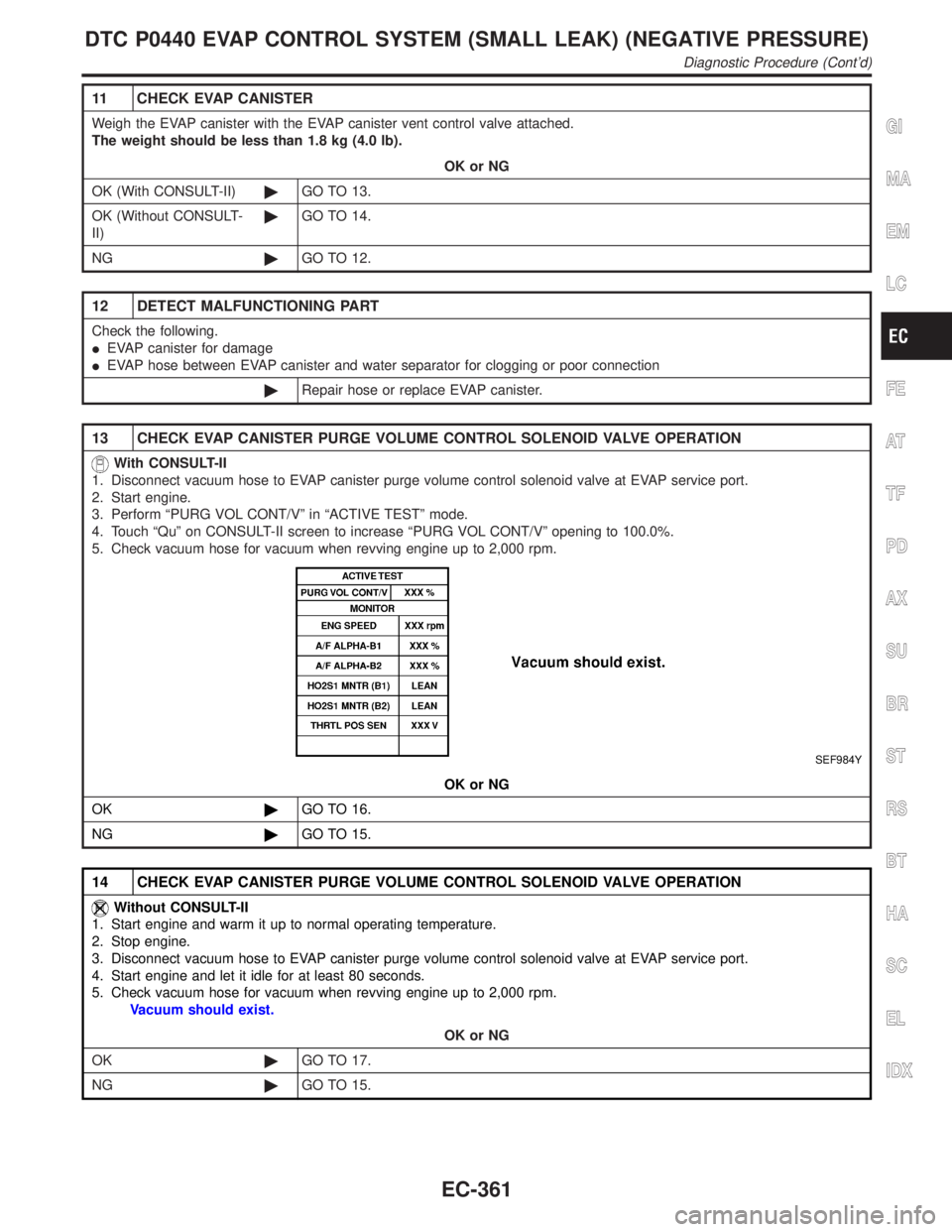

11 CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve attached.

The weight should be less than 1.8 kg (4.0 lb).

OK or NG

OK (With CONSULT-II)©GO TO 13.

OK (Without CONSULT-

II)©GO TO 14.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IEVAP canister for damage

IEVAP hose between EVAP canister and water separator for clogging or poor connection

©Repair hose or replace EVAP canister.

13 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode.

4. Touch ªQuº on CONSULT-II screen to increase ªPURG VOL CONT/Vº opening to 100.0%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

SEF984Y

OK or NG

OK©GO TO 16.

NG©GO TO 15.

14 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

OK or NG

OK©GO TO 17.

NG©GO TO 15.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-361

Page 897 of 2395

15 CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to ªVacuum Hose Drawingº, EC-26.

OK or NG

OK (With CONSULT-II)©GO TO 16.

OK (Without CONSULT-

II)©GO TO 17.

NG©Repair or reconnect the hose.

16 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

1. Start engine.

2. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II. Check that engine speed varies according

to the valve opening.

SEF985Y

OK or NG

OK©GO TO 18.

NG©GO TO 17.

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-362

Page 899 of 2395

18 CHECK ABSOLUTE PRESSURE SENSOR

1. Remove absolute pressure sensor with its harness connector connected.

SEF961Y

2. Remove hose from absolute pressure sensor.

3. Install a vacuum pump to absolute pressure sensor.

4. Turn ignition switch ªONº and check output voltage between ECM terminal 80 and engine ground under the following

conditions.

SEF300XA

CAUTION:

IAlways calibrate the vacuum pump gauge when using it.

IDo not apply below þ93.3 kPa (±700 mmHg, ±27.56 inHg) or over 101.3 kPa (760 mmHg, 29.92 inHg) of pressure.

OK or NG

OK©GO TO 19.

NG©Replace absolute pressure sensor.

19 CHECK FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check resistance between fuel level sensor unit and fuel pump terminals 1 and 2 by heating with hot water or heat gun

as shown in the figure.

SEF974Y

OK or NG

OK©GO TO 20.

NG©Replace fuel level sensor unit.

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-364

Page 907 of 2395

3 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 1 and EVAP canister purge volume control solenoid valve terminal 2.

Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK (With CONSULT-II)©GO TO 4.

OK (Without CONSULT-

II)©GO TO 5.

NG©Repair open circuit or short to ground and short to power in harness or connetors.

4 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Start engine.

2. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II. Check that engine speed varies according

to the valve opening.

SEF985Y

OK or NG

OK©GO TO 6.

NG©GO TO 5.

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-372

Page 918 of 2395

SEF194Y

SEF340X

WITH CONSULT-IINBEC0239S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº.

4) Select ªDATA MONITORº mode with CONSULT-II.

5) Make sure that ªFUEL T/TEMP SEº is more than 0ÉC (32ÉF).

6) Start engine and wait at least 20 seconds.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-385.

WITH GSTNBEC0239S021) Start engine and warm it up to normal operating temperature.

2) Check that voltage between ECM terminal 92 (Fuel tank tem-

perature sensor signal) and ground is less than 4.2V.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine and wait at least 20 seconds.

5) Select ªMODE 7º with GST.

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-385.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

DTC Confirmation Procedure (Cont'd)

EC-383

Page 920 of 2395

Diagnostic ProcedureNBEC0241

1 CHECK RUBBER TUBE

1. Turn ignition switch ªOFFº.

2. Check rubber tube connected to the EVAP control system pressure sensor for clogging, vent, kink, disconnection or

improper connection.

SEF495R

OK or NG

OK©GO TO 2.

NG©Reconnect, repair or replace.

2 RETIGHTEN GROUND SCREWS

Loosen and retighten engine ground screws.

SEF959Y

©GO TO 3.

3 CHECK CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check sensor harness connector for water.

Water should not exist.

OK or NG

OK©GO TO 4.

NG©Repair or replace harness connector.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

Diagnostic Procedure

EC-385

Page 921 of 2395

4 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªONº.

2. Check voltage between EVAP control system pressure sensor terminal 3 and ground with CONSULT-II or tester.

SEF992Y

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors B101, B43

IHarness connectors B1, M2 and M94, F27

IHarness for open or short between EVAP control system pressure sensor and ECM

©Repair harness or connectors.

6 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between EVAP control system pressure sensor terminal 1 and engine ground.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors B101, B43

IHarness connectors B1, M2 and M94, F27

IHarness for open between EVAP control system pressure sensor and ECM

IHarness for open between EVAP control system pressure sensor and TCM (Transmission Control Module)

©Repair open circuit or short to power in harness or connectors.

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

Diagnostic Procedure (Cont'd)

EC-386

Page 922 of 2395

8 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 84 and EVAP control system pressure sensor terminal 2.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK (With CONSULT-II)©GO TO 10.

OK (Without CONSULT-

II)©GO TO 11.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors B101, B43

IHarness connectors B1, M2 and M94, F27

IHarness for open or short between ECM and EVAP control system pressure sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

10 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

1. Start engine.

2. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II. Check that engine speed varies according

to the valve opening.

SEF985Y

OK or NG

OK©GO TO 12.

NG©GO TO 11.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

Diagnostic Procedure (Cont'd)

EC-387