check engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 971 of 2395

4 CHECK IGNITION TIMING AND ENGINE IDLE SPEED

Check the following items. Refer to ªBasic Inspectionº, EC-101.

MTBL0656

Models with CONSULT-II©GO TO 6.

Models without CON-

SULT-II©GO TO 6.

5 CHECK THROTTLE POSITION SWITCH

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Remove vacuum hose connected to throttle opener.

4. Connect suitable vacuum hose to vacuum pump and the throttle opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ªONº.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check indication of ªCLSD THL/P SWº under the following conditions.

Measurement must be made with throttle position switch installed in vehicle.

MTBL0355

OK or NG

OK (With CONSULT-II)©GO TO 8.

OK (Without CONSULT-

II)©GO TO 9.

NG©GO TO 7.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-436

Page 972 of 2395

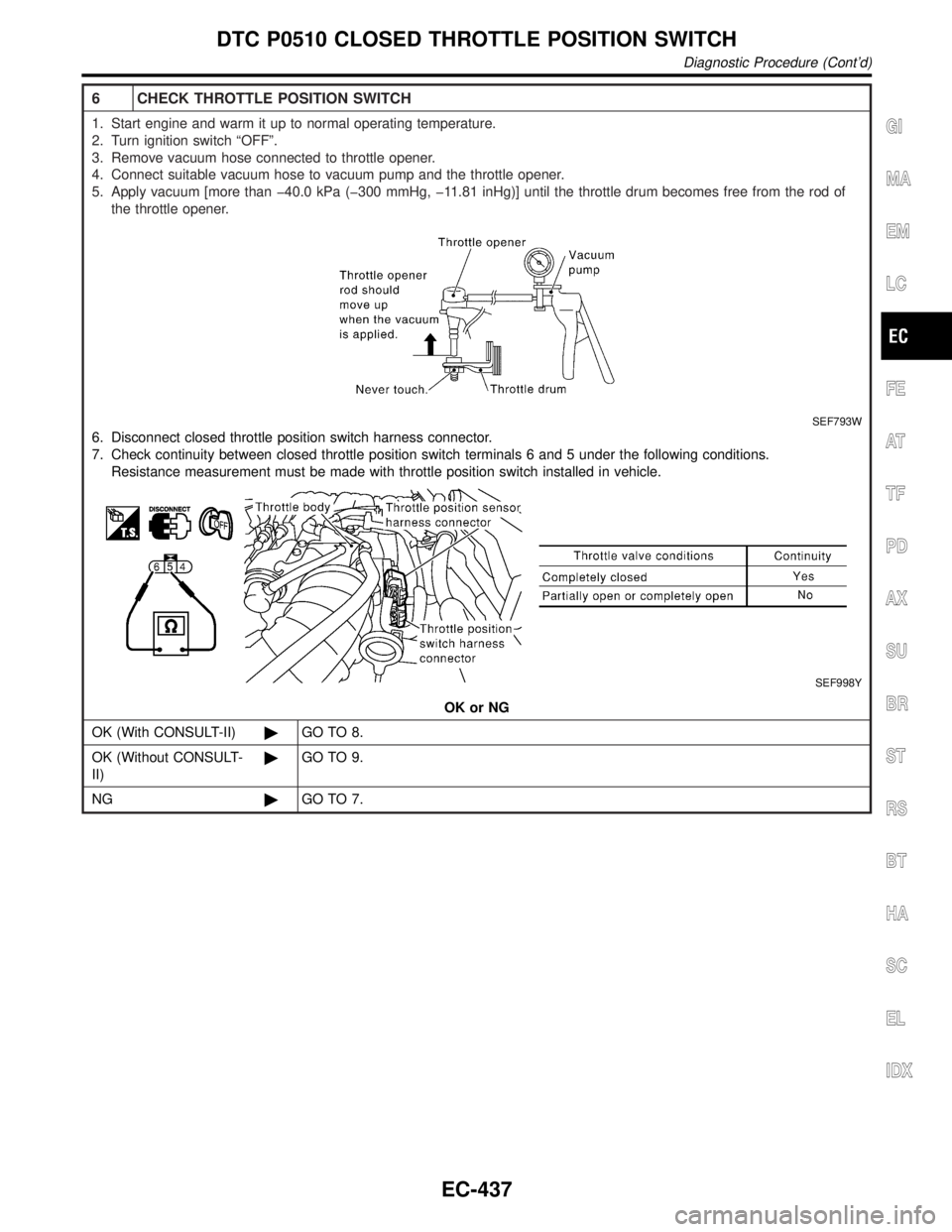

6 CHECK THROTTLE POSITION SWITCH

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Remove vacuum hose connected to throttle opener.

4. Connect suitable vacuum hose to vacuum pump and the throttle opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Disconnect closed throttle position switch harness connector.

7. Check continuity between closed throttle position switch terminals 6 and 5 under the following conditions.

Resistance measurement must be made with throttle position switch installed in vehicle.

SEF998Y

OK or NG

OK (With CONSULT-II)©GO TO 8.

OK (Without CONSULT-

II)©GO TO 9.

NG©GO TO 7.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-437

Page 973 of 2395

7 ADJUST THROTTLE POSITION SWITCH

Check the following items. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

Is it possible to adjust closed throttle position switch?

YesorNo

Yes (With CONSULT-II)©GO TO 9.

Yes (Without CONSULT-

II)©GO TO 9.

No©Replace throttle position switch.

8 CHECK THROTTLE POSITION SENSOR

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check voltage of ªTHRTL POS SENº under the following conditins.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0230

OK or NG

OK©GO TO 10.

NG©Replace throttle position sensor.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-438

Page 974 of 2395

9 CHECK THROTTLE POSITION SENSOR

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Check voltage between ECM terminal 91 (Throttle position sensor signal) and ground.

Voltage measurement must be made with throttle position sensor installed in vehicle.

SEF348X

OK or NG

OK©GO TO 10.

NG©Replace throttle position sensor.

10 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-439

Page 990 of 2395

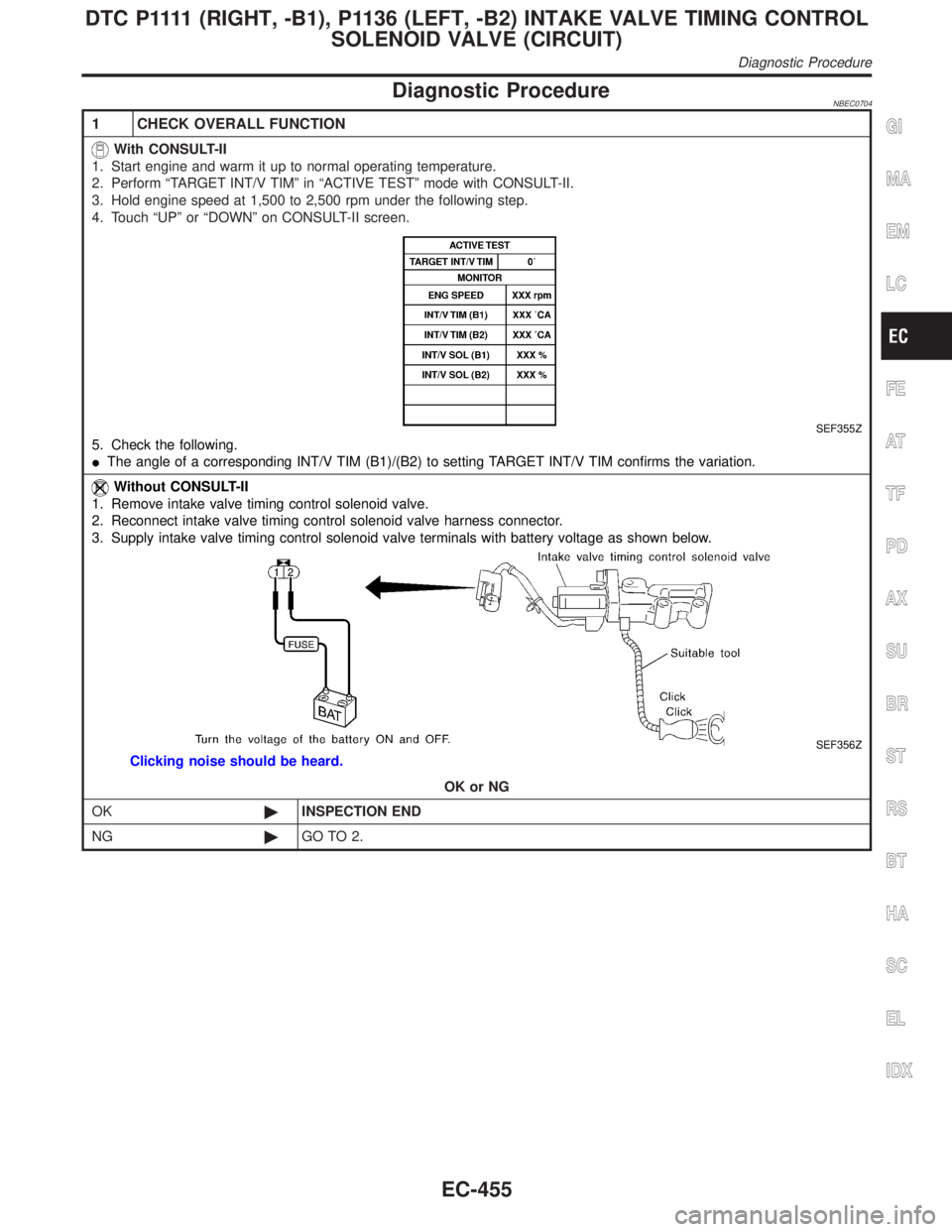

Diagnostic ProcedureNBEC0704

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Perform ªTARGET INT/V TIMº in ªACTIVE TESTº mode with CONSULT-II.

3. Hold engine speed at 1,500 to 2,500 rpm under the following step.

4. Touch ªUPº or ªDOWNº on CONSULT-II screen.

SEF355Z

5. Check the following.

IThe angle of a corresponding INT/V TIM (B1)/(B2) to setting TARGET INT/V TIM confirms the variation.

Without CONSULT-II

1. Remove intake valve timing control solenoid valve.

2. Reconnect intake valve timing control solenoid valve harness connector.

3. Supply intake valve timing control solenoid valve terminals with battery voltage as shown below.

SEF356Z

Clicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

D T C P 1111(RIGHT, -B1), P1136 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

SOLENOID VALVE (CIRCUIT)

Diagnostic Procedure

EC-455

Page 991 of 2395

2 INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Stop engine.

2. Disconnect intake valve timing control solenoid valve harness connector.

SEF357Z

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF603X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTION PART

Check the following.

IHarness connectors M32, F23

I10A fuse

IHarness continuity between fuse and intake valve timing control solenoid valve

©Repair harness or connectors.

4 CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE OUTPUT CIRCUIT FOR OPEN AND

SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness connectors continuity between ECM terminal 13 (Right) or 15 (Left) and terminal 2. Refer to Wiring Dia-

gram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

D T C P 1111(RIGHT, -B1), P1136 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

SOLENOID VALVE (CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-456

Page 996 of 2395

SEF174Y

PROCEDURE FOR MALFUNCTION BNBEC0528S02TESTING CONDITION:

IFor best results, perform the test at a temperature above

5ÉC (41ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle, then stop engine

immediately.

With CONSULT-IINBEC0528S02011) Turn ignition switch ªOFFº and wait at least 10 seconds.

2) Turn ignition switch ªONº.

3) Check ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with

CONSULT-II.

4) Confirm COOLAN TEMP/S value is 40ÉC (104ÉF) or less.

If the value is more than 40ÉC (104ÉF), park the vehicle in a

cool place and retry from step 1.

5) Start engine and wait until COOLAN TEMP/S value increases

to more than 55ÉC (131ÉF).

If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-463.

With GSTNBEC0528S0202Follow the procedure ªWith CONSULT-IIº above.

SEF174Y

PROCEDURE FOR MALFUNCTION CNBEC0528S03TESTING CONDITION:

IFor best results, perform the test at a temperature above

5ÉC (41ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle.

With CONSULT-IINBEC0528S03011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº again and select ªDATA MONITORº

mode with CONSULT-II.

4) Start engine and let it idle for at least 20 seconds. If 1st trip

DTC is detected, go to ªDiagnostic Procedureº, EC-463.

With GSTNBEC0528S0302Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

DTC Confirmation Procedure (Cont'd)

EC-461

Page 1000 of 2395

6 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

With CONSULT-II

1. Reconnect the disconnected harness connectors.

2. Start engine and let it idle.

3. Remove vacuum hose connected to swirl control valve actuator.

4. Select ªSWIRL CONT SOL VALVEº in ªACTIVE TESTº mode with CONSULT-II.

5. Touch ªONº and ªOFFº on CONSULT-II screen.

6. Check vacuum existence and operation delay time under the following conditions.

SEF004Z

Without CONSULT-II

1. Reconnect ECM harness connector.

2. Remove vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Apply 12V of direct current between swirl control valve control solenoid valve terminals 1 and 2.

5. Check vacuum existence and operation delay time under the following conditions.

SEF005Z

OK or NG

OK©GO TO 7.

NG©Replace intake manifold collector assembly.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-465

Page 1001 of 2395

PROCEDURE BNBEC0530S02

1 CHECK INTAKE SYSTEM

1. Start engine and let it idle.

2. Check intake air system for air leaks.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Repair intake system.

2 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE CIRCUIT

With CONSULT-II

1. Select ªSWIRL CONT SOL VALVEº in ªACTIVE TESTº mode with CONSULT-II.

2. Touch ªONº and ªOFFº on CONSULT-II screen.

SEF003Z

3. Make sure that clicking sound is heard from the swirl control valve control solenoid valve.

OK or NG

OK©GO TO 6.

NG©GO TO 3.

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-466

Page 1004 of 2395

7 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

With CONSULT-II

1. Reconnect the disconnected harness connectors.

2. Start engine and let it idle.

3. Remove vacuum hose connected to swirl control valve actuator.

4. Select ªSWIRL CONT SOL/Vº in ªACTIVE TESTº mode with CONSULT-II.

5. Touch ªONº and ªOFFº on CONSULT-II screen.

6. Check vacuum existence and operation delay time under the following conditions.

SEF004Z

Without CONSULT-II

1. Reconnect ECM harness connector.

2. Remove vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Apply 12V of direct current between swirl control valve control solenoid valve terminals 1 and 2.

5. Check vacuum existence and operation delay time under the following conditions.

SEF005Z

OK or NG

OK©GO TO 8.

NG©Replace intake manifold collector assembly.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-469