automatic transmission INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1820 of 2395

RHA441GA

Transmission Data and Transmission OrderNBHA0014S0802Amplifier data is transmitted consecutively to each of the door motors following the form shown in figure below.

Start: Initial compulsory signal sent to each of the door motors.

Address: Data sent from the auto amplifier is selected according to data-based decisions made by the air mix

door motor and mode door motor.

If the addresses are identical, the opening angle data and error check signals are received by the door motor

LCUs. The LCUs then make the appropriate error decision. If the opening angle data is normal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle: Data that shows the indicated door opening angle of each door motor.

Error check: Procedure by which sent and received data is checked for errors. Error data is then compiled.

The error check prevents corrupted data from being used by the air mix door motor and mode door motor.

Error data can be related to the following problems.

IAbnormal electrical frequency

IPoor electrical connections

ISignal leakage from transmission lines

ISignal level fluctuation

Stop signal: At the end of each transmission, a stop operation, in-operation, or internal problem message is

delivered to the auto amplifier. This completes one data transmission and control cycle.

RHA442G

Air Mix Door Control (Automatic Temperature Control)NBHA0014S0803The air mix door is automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by: The temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Features (Cont'd)

HA-21

Page 1961 of 2395

A

AAC/V - Wiring diagram ...............................EC-425

ABS - Wiring diagram ....................................BR-37

ABS sensor rotor ........................................AX-6, 19

Absolute pressure sensor ............................EC-158

A/C air flow .....................................................HA-25

A/C component layout ....................................HA-19

A/C compressor clutch removal and

installation .................................................HA-150

A/C compressor precaution..............................HA-6

A/C compressor special service tool..............HA-10

A/C control operation (auto A/C) ....................HA-23

A/C diagnostic work flow (auto A/C) ..............HA-65

A/C HFC134a (R134a) system

precaution .....................................................HA-2

A/C HFC134a (R134a) system service

procedure ..................................................HA-144

A/C HFC134a (R134a) system service

tools.............................................................HA-11

A/C HFC134a system service equip-

ment precaution ............................................HA-7

A/C lubricant (R134a)...................................HA-146

A/C operational check ....................................HA-66

A/C performance chart .................................HA-116

A/C performance test diagnoses ..................HA-114

A/C relay .......................................................HA-110

A/C self-diagnoses (auto A/C)........................HA-44

A/C service data specification ......................HA-160

A/C system description (auto A/C) .................HA-23

A/C trouble diagnoses (auto A/C) ..................HA-27

A/C, A - Wiring diagram ...........................HA-31, 36

Accelerator control system ...............................FE-3

Accelerator wire adjustment .............................FE-3

Actuator lever (Transfer) ...............................TF-120

Air bag ............................................................RS-10

Air bag disposal..............................................RS-22

Air bag precautions ...........................................GI-3

Air bleeding for brake system ..........................BR-8

Air cleaner filter replacement .........................MA-17

Air conditioner cut control ..............................EC-31

Air flow meter - See Mass air flow

sensor .......................................................EC-150

Air mix door control linkage adjustment.........HA-85

Air mix. door motor ................................HA-82, 141

Air spoiler, rear................................................BT-35

All - mode 4WD system ..................................TF-10

Alternator ........................................................SC-28

Ambient sensor ............................................HA-129

Angular tightening application..........................EM-3

Antenna - See Power antenna .....................EL-169

Anti-lock brake system - Wiring

diagram .......................................................BR-37

AP/SEN - Wiring diagram ............................EC-160

ASCD (automatic speed control device) ......EL-221

ASCD - Wiring diagram ................................EL-225

A/T - Wiring diagram - AT - FTS ...................AT-107

A/T - Wiring diagram - AT - MAIN ...................AT-96

A/T - Wiring diagram - AT - PNP/SW............AT-101A/T - Wiring diagram - AT - VSS A/T ............AT-113

A/T control ....................................................EC-440

A/T diagnosis communication line................EC-603

A/T fluid temperature sensor .........................AT-110

A/T self-diagnoses...........................................AT-46

A/T shift lock system .....................................AT-265

A/T shift lock system - Wiring diagram .........AT-266

A/T trouble diagnoses .....................................AT-53

A/T Wiring diagram - AT - ENG SS...............AT-117

A/T Wiring diagram AT - 1ST ........................AT-123

A/T Wiring diagram AT - 2ND .......................AT-129

A/T Wiring diagram AT - 3RD .......................AT-135

A/T Wiring diagram AT - 4TH ........................AT-142

A/T Wiring diagram AT - BA/FTS ..................AT-192

A/T Wiring diagram AT - LPSV .....................AT-164

A/T Wiring diagram AT - NONDTC ...............AT-215

A/T Wiring diagram AT - OVRCSV ...............AT-187

A/T Wiring diagram AT - SSV/A ....................AT-169

A/T Wiring diagram AT - SSV/B ....................AT-173

A/T Wiring diagram AT - TCCSIG .................AT-156

A/T Wiring diagram AT - TCV .......................AT-150

A/T Wiring diagram AT - TPS........................AT-179

A/T Wiring diagram AT - VSSMTR................AT-199

AT/C - Wiring diagram ..................................EC-442

ATP switch.....................................................TF-112

ATP warning lamp .........................................TF-102

Audio .............................................................EL-160

AUDIO - Wiring diagram ...............................EL-162

Audio and A/C control removal and

installation - See Instrument panel .............BT-21

AUT/DP - Wiring diagram .............................EL-191

Auto air conditioner - Wiring diagram ......HA-31, 36

Automatic amplifier...................................HA-40, 72

Automatic drive positioner ............................EL-186

Automatic speed control system - See

ASCD ........................................................EL-221

Automatic transmission fluid

replacement ................................................MA-21

Automatic transmission number ......................GI-43

Auxiliary air control (AAC) valve ..................EC-422

Axle housing (rear) .........................................AX-19

B

Back door ........................................................BT-15

Back door opener - See Back door ................BT-15

Back door trim.................................................BT-34

Back-up lamp ..................................................EL-69

BACK/L - Wiring diagram................................EL-69

Ball joint (front) ...............................................SU-12

Base idle air volume initialiging......................EC-57

Basic inspection ...........................................EC-101

Battery ..............................................................SC-4

Battery/Starting/Charging System

Tester ................................................SC-7, 12, 21

Blower motor ..................................................HA-95

Body alignment ...............................................BT-57

Brake booster .................................................BR-19

Brake control valve (Proportioning

valve)...........................................................BR-11

ALPHABETICAL INDEX

IDX-2

Page 2003 of 2395

CHASSIS AND BODY MAINTENANCENBMA0004S0102

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page or

- Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.5

(12)

611.25

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

2433.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Brake lines & cables I I I I MA-25

Brake pads, rotors, drums & linings I IIIIIIIMA-25, 26

Automatic transmission & all-mode

4WD transfer fluid & differential

gear oil (exc. LSD)NOTE (1) I I I I MA-21, 22, 23

LSD gear oil NOTE (1) I R I R MA-24

Steering gear, linkage & transfer

gear, axle & suspension partsIIIIIIIIMA-26

NOTE (6)

Tire rotation NOTE (2)MA-4

Drive shaft boots (

) IIIIIIIIAX-10, ªDrive

Shaftº

Propeller shaft NOTE (3) L LLLLLLLMA-23

Front wheel bearing grease (4x2) I I

Front wheel bearing

grease (

)NOTE (4) I R I RAX-4, ªFront

Wheel Bearingº

Exhaust system I IIIIIIIMA-21

Supplemental air bag systems NOTE (5)RS-14, ªMainte-

nance Itemsº

Ventilation air filter I RIRIRIRHA-159, ªVentila-

tion Air Filterº

ASCD vacuum hoses I I I IEL-237, ªASCD

ACTUATOR/

PUMP CHECKº

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fluid (A/T, all mode 4WD transfer)/differential gear oil (exc.

LSD) at every 30,000 miles (48,000 km) or 24 months, and change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) Refer to ªTire rotationº under the ªGENERAL MAINTENANCEº heading earlier in this section.

(3) The propeller shaft should be re-greased after being immersed in water.

(4) If operating frequently in water, replace grease every 3,750 miles (6,000 km) or 3 months.

(5) Inspect the air bag system 10 years after the date of manufacture noted on the FMVSS certification label.

(6) Refer to SU-5, ªFront Suspension Partsº and SU-16, ªRear Suspension Partsº, AX-3, ªFront Axle Partsº and AX-18, ªRear Axle Partsº.

PERIODIC MAINTENANCE

Schedule 1 (Cont'd)

MA-8

Page 2005 of 2395

CHASSIS AND BODY MAINTENANCENBMA0004S0202

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Section

- Page

or

- Content Title Perform at number of miles, kilometers

or months, whichever comes first.Miles x 1,000

(km x 1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

Brake lines & cablesIIIIMA-25

Brake pads, rotors, drums & liningsIIIIMA-25, 26

Automatic transmission & all-mode 4WD

transfer fluid & differential gear oil (exc.

LSD)IIIIMA-21, 22, 23

LSD gear oilIRIRMA-24

Steering gear, linkage & transfer gear,

axle & suspension partsIIMA-26

NOTE (4)

Tire rotation NOTE (1)MA-4

Drive shaft boots (

) IIIIAX-10, ªDrive shaftº

Propeller shaft NOTE (2)LLLLMA-23

Front wheel bearing grease (4x2) I I

Front wheel bearing grease (

) IRIRAX-4, ªFront Wheel

Bearingº

Exhaust systemI I MA-21

Supplemental air bag systems NOTE (3)RS-14, ªMaintenance

Itemº

Ventilation air filterRRRRHA-159, ªVentilation Air

Filterº

ASCD vacuum hosesIIIIEL-237, ªASCD

ACTUATOR/PUMP

CHECKº

NOTE:

(1) Refer to ªTire rotationº under the ªGENERAL MAINTENANCEº heading earlier in this section.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Inspect the air bag system 10 years after the date of manufacture noted on the FMVSS certification label.

(4) Refer to SU-5, ªFront Suspension Partsº and SU-16, ªRear Suspension Partsº, AX-3, ªFront Axle Partsº and AX-18, ªRear Axle Partsº.

PERIODIC MAINTENANCE

Schedule 2 (Cont'd)

MA-10

Page 2006 of 2395

NBMA0005

Fluids and LubricantsNBMA0005S01

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oilDrain and

refillWith oil filter 5-1/4 qt 4-3/8 qt 5.0

IAPI Certification Mark*1

IAPI grade SG/SH, Energy Conserv-

ingI&IIorAPIgrade SJ, Energy

Conserving*1

IILSAC grade GF-I & GF-II*1 Without oil

filter5-1/8 qt 4-1/4 qt 4.8

Dry engine

(Engine overhaul)7-1/4 qt 6 qt 6.8

Cooling system (With reservoir) 9-3/4 qt 8-1/8 qt 9.2Genuine Nissan anti-freeze coolant or

equivalent

All-mode 4WD transfer fluid 3-1/8 qt 2-5/8 qt 3.0Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*2

Differential

carrier gear

oilFront (4WD) 3-7/8 pt 3-1/4 pt 1.85Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear:

Use only LSD gear oil API GL-5 and

SAE 80W-90*5 approved for Nissan

LSD*6. Rear 5-7/8 pt 4-7/8 pt 2.8

Automatic transmission fluid2WD

9 qt 7-1/2 qt 8.5Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*3 4WD

Power steering fluid Ð Ð Ð Genuine NISSAN PSF II or equivalent*7

Brake fluid Ð Ð ÐGenuine Nissan Brake Fluid*4 or

equivalent DOT 3 (U.S. FMVSS No.

116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Outside the continental United States and Alaska contact an authorized INFINITI dealership for more information regarding suitable

fluids, including recommended brand(s) of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: DEXRONTMIII/MERCONTMor equivalent may also be used. Outside the continental United States and Alaska contact an autho-

rized INFINITI dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTMIII/MERCONTM

Automatic Transmission Fluid.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF).

*6: Contact an INFINITI dealer for a list of approved oils.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, DEXRON

TMIII/MERCONTMor equivalent ATF may also be

used.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-11

Page 2016 of 2395

SMA211A

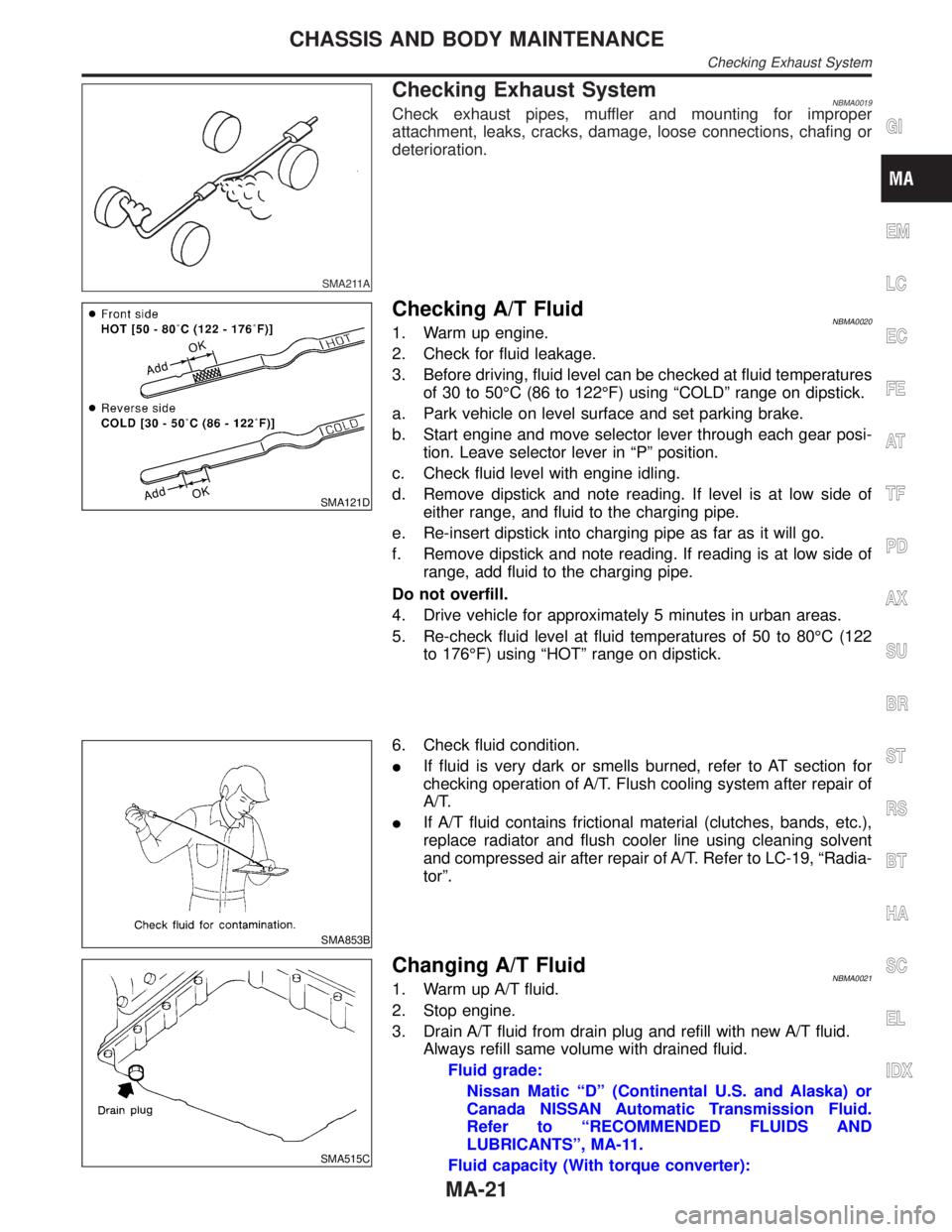

Checking Exhaust SystemNBMA0019Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, loose connections, chafing or

deterioration.

SMA121D

Checking A/T FluidNBMA00201. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of

range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

SMA853B

6. Check fluid condition.

IIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

IIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC-19, ªRadia-

torº.

SMA515C

Changing A/T FluidNBMA00211. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic ªDº (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid.

Refer to ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-11.

Fluid capacity (With torque converter):

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CHASSIS AND BODY MAINTENANCE

Checking Exhaust System

MA-21

Page 2017 of 2395

2WD, 4WD model

8.5(9 US qt, 7-1/2 Imp qt)

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to MA-21, ªChecking A/T

Fluidº. If fluid is still dirty, repeat steps 2 through 5.

SMA439B

Checking All-mode 4WD Transfer FluidNBMA0022Check for oil leakage and fluid level.

A/T fluid is used for the all-mode 4WD transfer in the factory.

Never start engine while checking fluid level.

Filler plug:

: 10 - 20 N´m (1.0 - 2.0 kg-m, 87 - 174 in-lb)

SMA444B

Changing All-mode 4WD Transfer FluidNBMA0023When changing all-mode 4WD transfer fluid completely, A/T fluid

may be used.

Fluid grade:

Nissan Matic ªDº (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid.

Refer to ªFluids and Lubricantsº, ªRECOMMENDED

FLUIDS AND LUBRICANTSº, MA-11.

Fluid capacity:

3.0(3-1/8 US qt, 2-5/8 Imp qt)

Drain plug:

: 10 - 20 N´m (1.0 - 2.0 kg-m, 87 - 174 in-lb)

CHASSIS AND BODY MAINTENANCE

Changing A/T Fluid (Cont'd)

MA-22