IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 626 of 2395

![INFINITI QX4 2001 Factory Service Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running INFINITI QX4 2001 Factory Service Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running](/img/42/57027/w960_57027-625.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control. A/F ALPHA-B2 [%]q

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ªB1º indicates bank 1 and ªB2º indicates bank 2.

ACTIVE TEST MODENBEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IIACV-AAC valve

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IA/C switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

VIAS SOL VALVEIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

SWIRL CONT

S O L VA LV EIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

PURG VOL

CONT/VIEngine: After warming up, run

engine at 1,500 rpm.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

ISolenoid valve

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-91

Page 628 of 2395

DTC Work Support ModeNBEC0034S0802

Test mode Test item Condition Reference page

EVAPORATIVE SYSTEMEVAP SML LEAK P0440

Refer to corresponding

trouble diagnosis for

DTC.EC-352

EVAP VERY SML LEAK P1441 EC-526

PURG VOL CN/V P1444 EC-541

PURGE FLOW P1447 EC-561

VC CUT/V BP/V P1491 EC-591

HEATED OXYGEN SEN-

SOR 1 (FRONT)HO2S1 (B1) P0130 EC-192

HO2S1 (B1) P0131 EC-202

HO2S1 (B1) P0132 EC-210

HO2S1 (B1) P0133 EC-218

HO2S1 (B2) P0150 EC-192

HO2S1 (B2) P0151 EC-202

HO2S1 (B2) P0152 EC-210

HO2S1 (B2) P0153 EC-218

HEATED OXYGEN SEN-

SOR 2 (REAR)HO2S2 (B1) P0137 EC-247

HO2S2 (B1) P0138 EC-257

HO2S2 (B1) P0139 EC-267

HO2S2 (B2) P0157 EC-247

HO2S2 (B2) P0158 EC-257

HO2S2 (B2) P0159 EC-267

SEF705Y

SEF707X

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

(RECORDING VEHICLE DATA)

NBEC0034S10CONSULT-II has two kinds of triggers and they can be selected by

touching ªSETTINGº in ªDATA MONITORº mode.

1) ªAUTO TRIGº (Automatic trigger):

IThe malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, ªMONITORº

in ªDATA MONITORº screen is changed to ªRecording Data ...

xx%º as shown at left, and the data after the malfunction detec-

tion is recorded. Then when the percentage reached 100%,

ªREAL-TIME DIAGº screen is displayed. If ªSTOPº is touched

on the screen during ª Recording Data ... xx%º, ªREAL-TIME

DIAGº screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by ªTRIGGER POINTº and

ªRecording Speedº. Refer to CONSULT-II OPERATION

MANUAL.

2) ªMANU TRIGº (Manual trigger):

IDTC/1st trip DTC and malfunction item will not be displayed

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-93

Page 630 of 2395

SEF139P

Generic Scan Tool (GST)=NBEC0035DESCRIPTIONNBEC0035S01Generic Scan Tool (OBDII scan tool) complying with SAE J1978

has 8 different functions explained on the next page.

ISO9141 is used as the protocol.

The name ªGSTº or ªGeneric Scan Toolº is used in this service

manual.

SEF941Y

GST INSPECTION PROCEDURENBEC0035S021. Turn ignition switch OFF.

2. Connect GST to data link connector, which is located under LH

dash panel near the fuse box cover.

SEF398S

3. Turn ignition switch ON.

4. Enter the program according to instruction on the screen or in

the operation manual.

(*: Regarding GST screens in this section, sample screens are

shown.)

SEF416S

5. Perform each diagnostic mode according to each service pro-

cedure.

For further information, see the GST Operation Manual of the

tool maker.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Generic Scan Tool (GST)

EC-95

Page 632 of 2395

MEF036D

IntroductionNBEC0036

SEF233G

SEF234G

The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-99.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

SEF907L

DIAGNOSTIC WORKSHEETNBEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and

DTC to be detected. Examples:

IVehicle ran out of fuel, which caused the engine to misfire.

IFuel filler cap was left off or incorrectly screwed on, allowing

fuel to evaporate into the atmosphere.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction

EC-97

Page 634 of 2395

![INFINITI QX4 2001 Factory Service Manual Work FlowNBEC0037

SEF510ZF

*1 EC-117

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-140.

*3 If the incident can INFINITI QX4 2001 Factory Service Manual Work FlowNBEC0037

SEF510ZF

*1 EC-117

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-140.

*3 If the incident can](/img/42/57027/w960_57027-633.png)

Work FlowNBEC0037

SEF510ZF

*1 EC-117

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-140.

*3 If the incident cannot be verified,

perform ªTROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENTº,

EC-140.*4 If the on board diagnostic system

cannot be performed, check main

power supply and ground circuit.

Refer to ªTROUBLE DIAGNOSIS

FOR POWER SUPPLYº, EC-142.

*5 If malfunctioning part cannot bedetected, perform ªTROUBLE

DIAGNOSIS FOR INTERMIT-

TENT INCIDENTº, EC-140.

*6 EC-66

*7 EC-136

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Work Flow

EC-99

Page 636 of 2395

Basic InspectionNBEC0038Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

IAir conditioner switch is OFF,

IRear window defogger switch is OFF,

ISteering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

IHarness connectors for improper connections

IVacuum hoses for splits, kinks and improper connections

IWiring for improper connections, pinches and cuts

IAir cleaner clogging

IHoses and ducts for leaks

SEF983U

©GO TO 2.

2 CHECK THROTTLE OPENER OPERATION-I

Confirm that there is a clearance between throttle drum and stopper.

SEF950Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection

EC-101

Page 638 of 2395

6 CHECK VACUUM HOSE

1. Stop engine.

2. Remove the vacuum hose.

3. Check the vacuum hose for splits, kinks and clogging.

SEF109L

OK or NG

OK©1. Clean vacuum port by blowing air.

2. GO TO 4.

NG©1. Replace vacuum hose.

2. GO TO 4.

7 CHECK THROTTLE DRUM OPERATION

Confirm that throttle drum moves to contact the stopper.

SEF950Y

OK or NG

OK©GO TO 10.

NG©GO TO 8.

8 CHECK ACCELERATOR WIRE INSTALLATION

1. Stop engine.

2. Check accelerator wire for slack.

OK or NG

OK©GO TO 9.

NG©1. Adjust accelerator wire. Refer to FE-3, ªAdjusting Accelerator Wireº.

2. GO TO 7.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-103

Page 640 of 2395

11 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªTP SW/TP SEN IDLE POSI ADJº in ªWORK SUPPORTº mode with CONSULT-II.

3. Read ªCLSD THL/P SWº signal under the following conditions.

IInsert a 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between stopper and throttle drum as

shown in the figure and check the signal.

SEF953Y

SEF987Y

ªCLSD THL/P SWº signal should remain ªONº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªCLSD THL/P SWº signal should remain ªOFFº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 14.

NG©GO TO 12.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-105

Page 642 of 2395

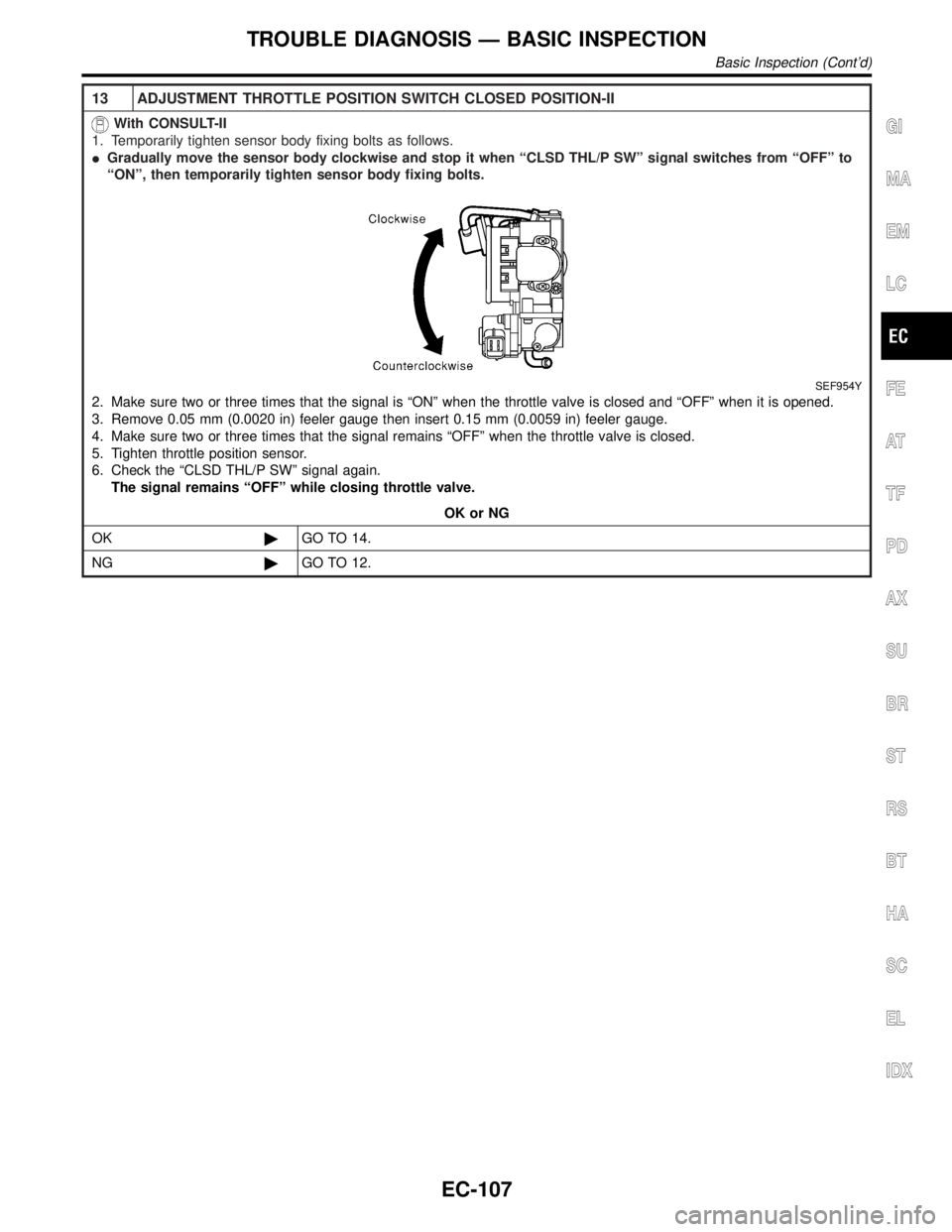

13 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

IGradually move the sensor body clockwise and stop it when ªCLSD THL/P SWº signal switches from ªOFFº to

ªONº, then temporarily tighten sensor body fixing bolts.

SEF954Y

2. Make sure two or three times that the signal is ªONº when the throttle valve is closed and ªOFFº when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the signal remains ªOFFº when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the ªCLSD THL/P SWº signal again.

The signal remains ªOFFº while closing throttle valve.

OK or NG

OK©GO TO 14.

NG©GO TO 12.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-107

Page 644 of 2395

15 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

1. Disconnect closed throttle position switch harness connector.

2. Check continuity between closed throttle position switch terminals6and5under the following conditions.

SEF330Z

IInsert the 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between the stopper and throttle drum

as shown in the figure.

SEF953Y

ªContinuity should existº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªContinuity should not existº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 18.

NG©GO TO 16.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-109