lock INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2189 of 2395

SST601C

Checking Gear Housing MovementNBST00081. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

IApply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

SST602C

Adjusting Rack RetainerNBST0009IPerform this driving test on a flat road.

a) Check whether vehicle moves in a straight line when steering

wheel is released.

b) Check whether steering wheel returns to neutral position when

steering wheel is released from a slightly turned (approx. 20É)

position.

IIf any abnormality is found, correct it by resetting adjusting

screw.

Checking and Adjusting Drive BeltsNBST0010Refer to MA-13, ªChecking Drive Beltsº.

SST280BA

Checking Fluid LevelNBST0011Check fluid level.

Use the correct range of the dipstick depending on the fluid tem-

perature. Use the ªHOTº range at 50 to 80ÉC (122 to 176ÉF), or the

ªCOLDº range at 0 to 30ÉC (32 to 86ÉF).

CAUTION:

IDo not overfill.

IRecommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, ªFluids and Lubricantsº.

SST458C

Checking Fluid LeakageNBST0012Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds

and carefully check for fluid leakage.

ON-VEHICLE SERVICE

Checking Gear Housing Movement

ST-8

Page 2190 of 2395

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. Check rack boots for accumulation of power steering fluid.

Bleeding Hydraulic SystemNBST00131. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then, quickly turn

steering wheel fully to right and left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

IIncomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning steering wheel

slowly. This does not affect performance or durability of the system.

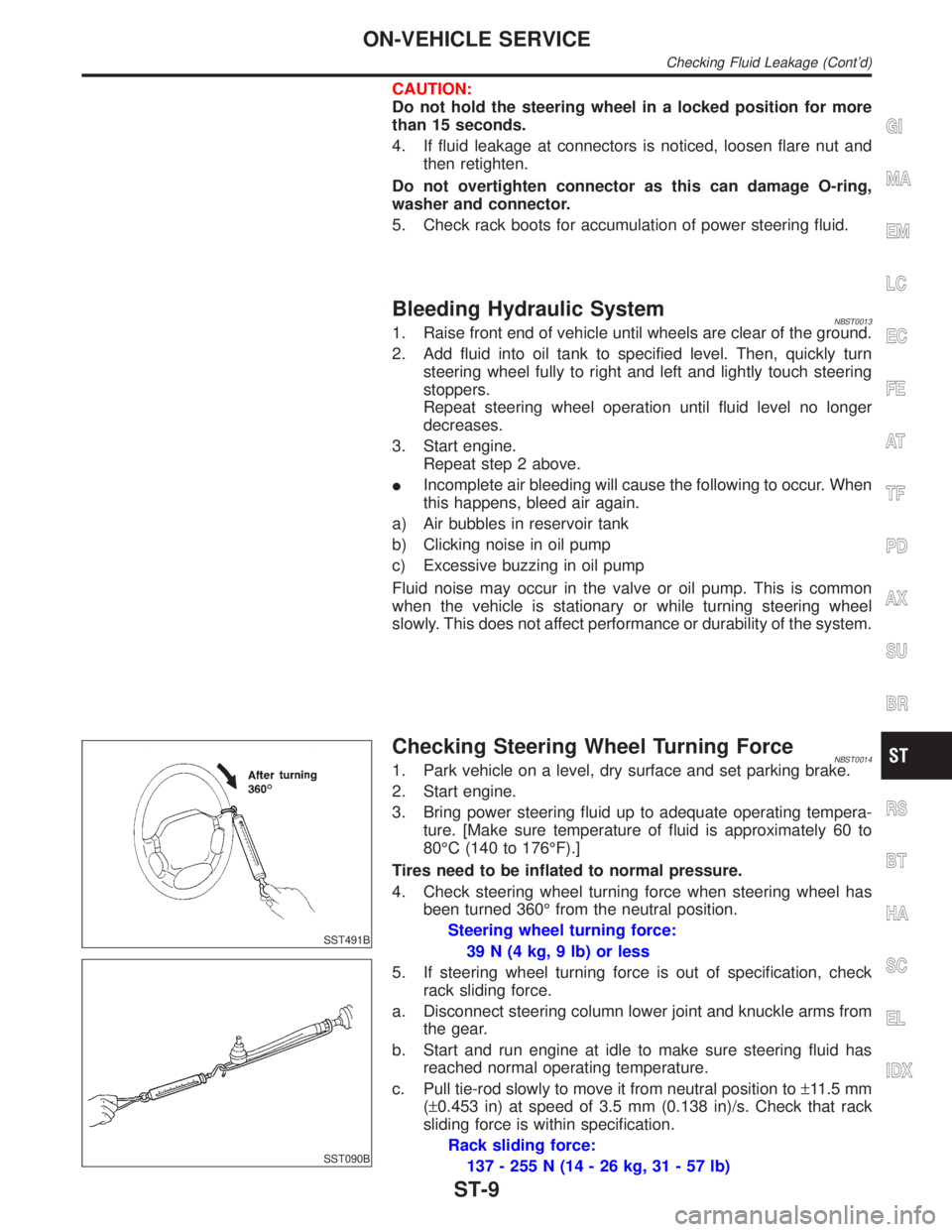

SST491B

SST090B

Checking Steering Wheel Turning ForceNBST00141. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Rack sliding force:

137 - 255 N (14 - 26 kg, 31 - 57 lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Checking Fluid Leakage (Cont'd)

ST-9

Page 2191 of 2395

6. If rack sliding force is not within specification, overhaul steer-

ing gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ªInspectionº, ªSTEERING WHEEL AND STEERING

COLUMNº, ST-14.

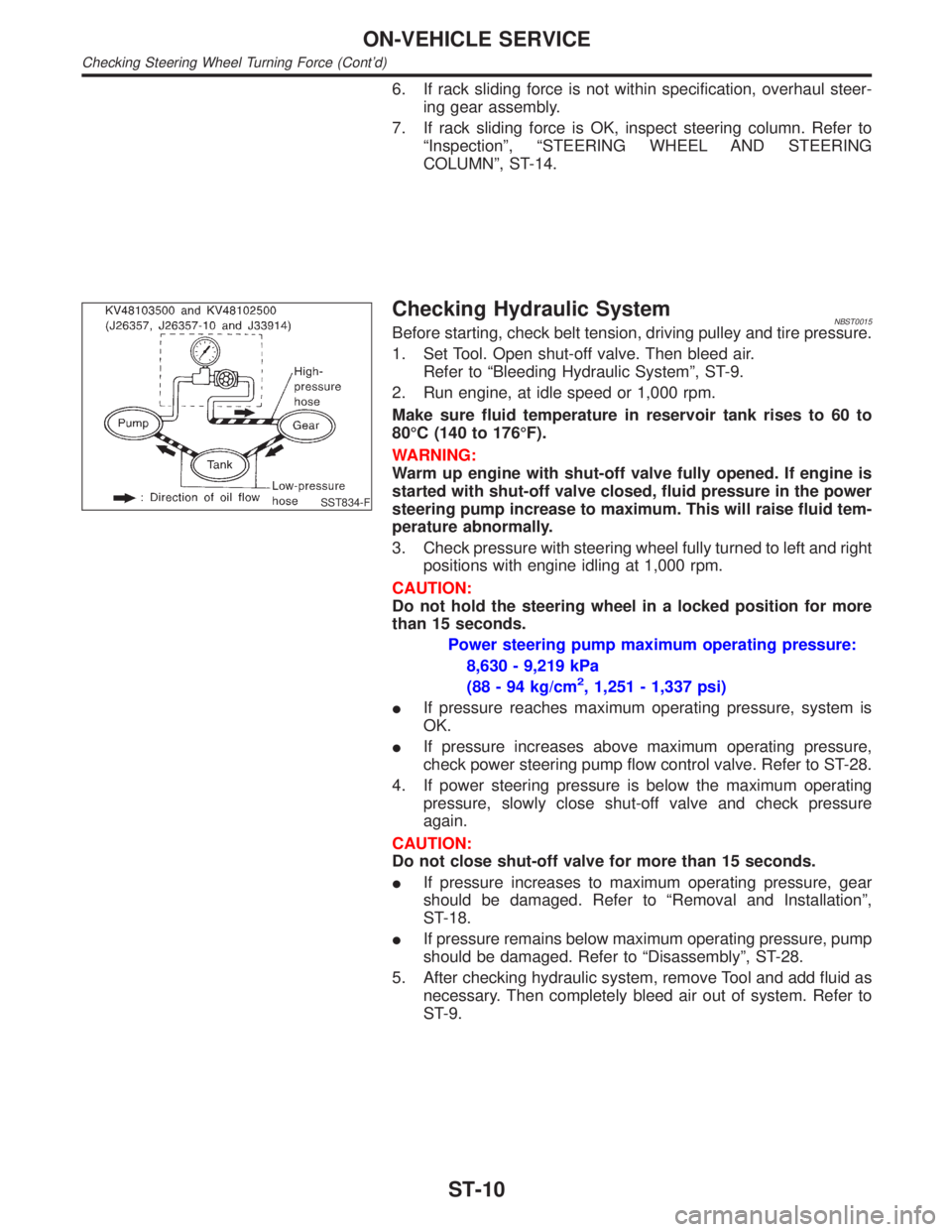

SST834-F

Checking Hydraulic SystemNBST0015Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air.

Refer to ªBleeding Hydraulic Systemº, ST-9.

2. Run engine, at idle speed or 1,000 rpm.

Make sure fluid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in the power

steering pump increase to maximum. This will raise fluid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,630 - 9,219 kPa

(88 - 94 kg/cm

2, 1,251 - 1,337 psi)

IIf pressure reaches maximum operating pressure, system is

OK.

IIf pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-28.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

IIf pressure increases to maximum operating pressure, gear

should be damaged. Refer to ªRemoval and Installationº,

ST-18.

IIf pressure remains below maximum operating pressure, pump

should be damaged. Refer to ªDisassemblyº, ST-28.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-9.

ON-VEHICLE SERVICE

Checking Steering Wheel Turning Force (Cont'd)

ST-10

Page 2193 of 2395

SRS266

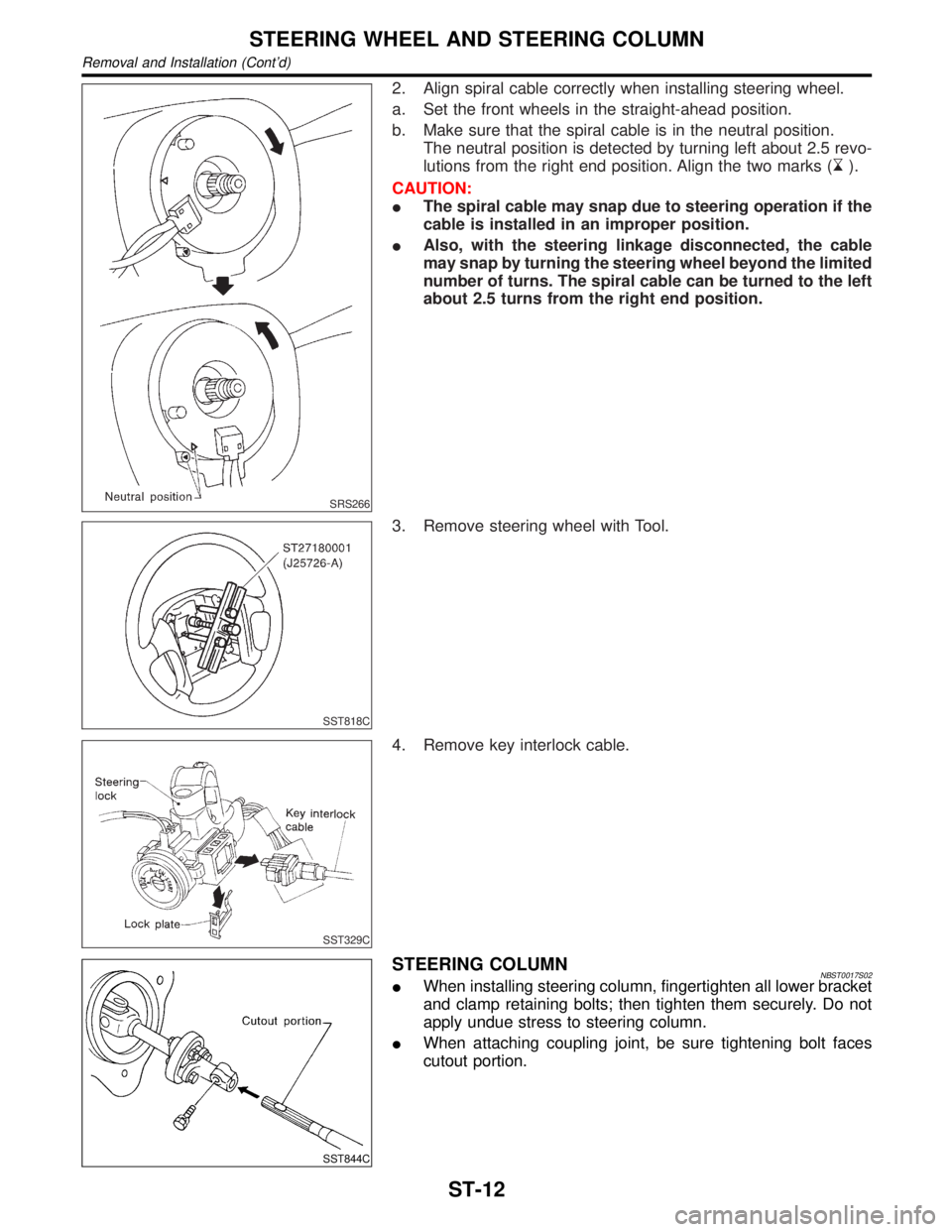

2. Align spiral cable correctly when installing steering wheel.

a. Set the front wheels in the straight-ahead position.

b. Make sure that the spiral cable is in the neutral position.

The neutral position is detected by turning left about 2.5 revo-

lutions from the right end position. Align the two marks (

).

CAUTION:

IThe spiral cable may snap due to steering operation if the

cable is installed in an improper position.

IAlso, with the steering linkage disconnected, the cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned to the left

about 2.5 turns from the right end position.

SST818C

3. Remove steering wheel with Tool.

SST329C

4. Remove key interlock cable.

SST844C

STEERING COLUMNNBST0017S02IWhen installing steering column, fingertighten all lower bracket

and clamp retaining bolts; then tighten them securely. Do not

apply undue stress to steering column.

IWhen attaching coupling joint, be sure tightening bolt faces

cutout portion.

STEERING WHEEL AND STEERING COLUMN

Removal and Installation (Cont'd)

ST-12

Page 2194 of 2395

Disassembly and AssemblyNBST0018

SST845C

1. Combination switch

2. Lock nut

3. Jacket tube assembly4. Tilt lever

5. Tilt spring

6. Steering column shaft assembly7. Band

8. Jacket tube bracket insulator

assembly

9. Hole cover

SST490C

IWhen disassembling and assembling, unlock steering lock

with key.

IInstall lock nut on steering column shaft and tighten the nut to

specification.

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SST742A

ISteering lock

a) Break self-shear type screws with a drill or other appropriate

tool.

b) Install new self-shear type screws and then cut off self-shear

type screw heads.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly

ST-13

Page 2198 of 2395

ComponentsNBST0026

SST618CB

1. Rear cover cap

2. Rear housing assembly

3. Pinion seal ring

4. Pinion assembly

5. O-ring

6. Shim

7. Pinion oil seal

8. Lock nut

9. Adjusting screw

10. Spring11. Retainer

12. Gear housing assembly

13. Rack oil seal

14. Rack assembly

15. Rack seal ring

16. O-ring

17. O-ring

18. Rack bushing

19. Rack oil seal

20. Snap ring21. End cover assembly

22. Boot clamp

23. Dust boot

24. Boot clamp

25. Lock plate

26. Tie-rod inner socket

27. Tie-rod

28. Tie-rod outer socket

29. Cotter pin

30. Cylinder tube

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Components

ST-17

Page 2205 of 2395

SST609C

14. Ensure that the rack is centered. Install rear cover cap so that

its protrusion is positioned as shown in figure.

Be careful not to damage worm ring and oil seal.

15. Install retainer, spring and adjusting screw temporarily.

SST135C

16. Install new lock plate.

IAttach lock plate 2 to side rod inner socket 1.

IApply locking sealant to inner socket threads 3.

Screw inner socket into rack 4 and tighten to specified torque.

IClinch two places of lock plate at rack's groove.

CAUTION:

To prevent scratching the boot, remove burrs from lock plate.

SST655C

17. Tighten outer socket lock nut.

Tie-rod length ªLº:

Refer to SDS, ST-33.

18. Measure rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-33.

SST967A

19. Before installing boot, coat the contact surfaces between boot

and tie-rod with grease.

SST619C

AdjustmentNBST0031Adjust pinion rotating torque as follows:

1. Set rack to the neutral position without fluid in the gear.

2. Coat the adjusting screw with locking sealant and screw it in.

3. Lightly tighten lock nut.

4. Tighten adjusting screw to a torque of 4.9 to 5.9 N´m (50 to 60

kg-cm, 43 to 52 in-lb).

5. Loosen adjusting screw, then retighten it to 0.2 N´m (2 kg-cm,

1.7 in-lb).

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-24

Page 2206 of 2395

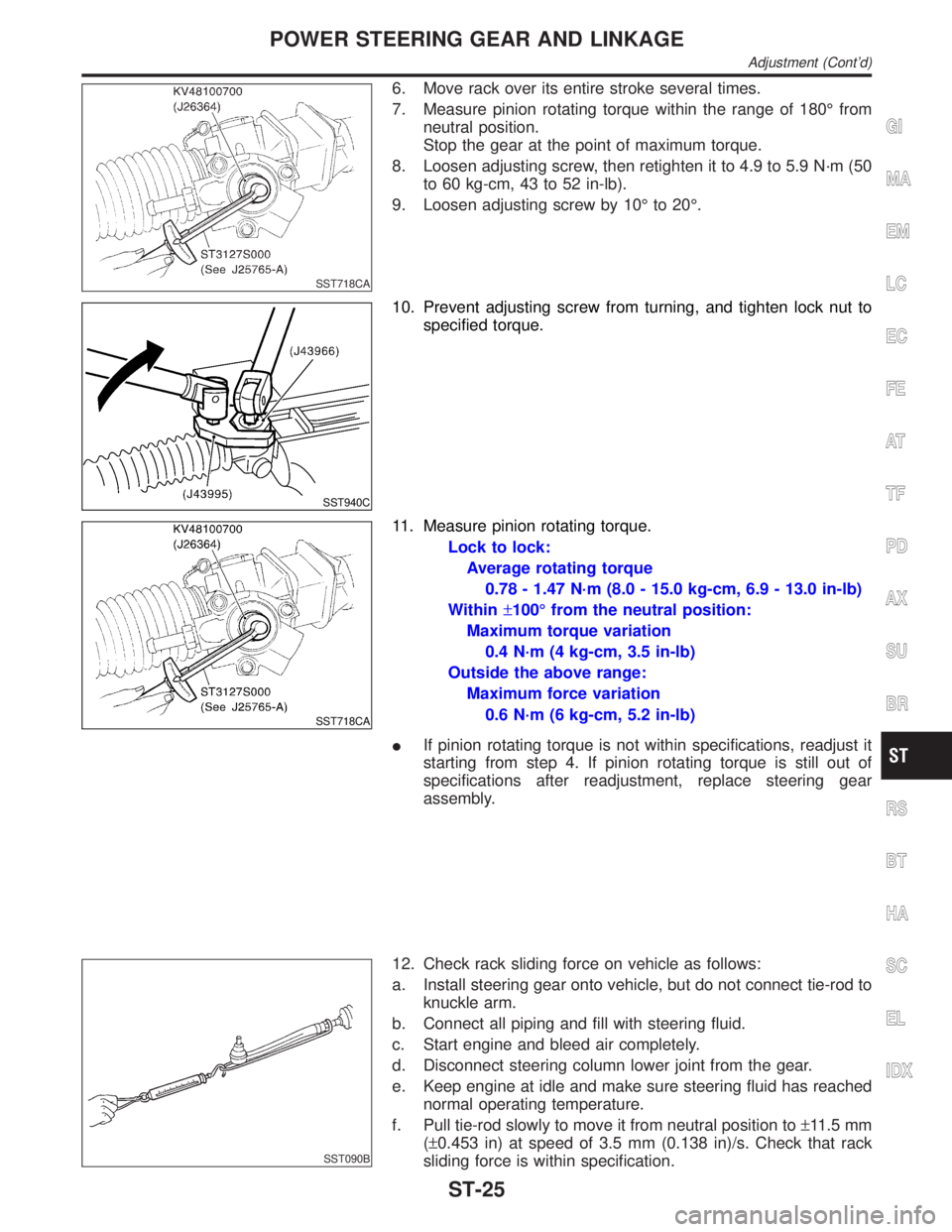

SST718CA

6. Move rack over its entire stroke several times.

7. Measure pinion rotating torque within the range of 180É from

neutral position.

Stop the gear at the point of maximum torque.

8. Loosen adjusting screw, then retighten it to 4.9 to 5.9 N´m (50

to 60 kg-cm, 43 to 52 in-lb).

9. Loosen adjusting screw by 10É to 20É.

SST940C

10. Prevent adjusting screw from turning, and tighten lock nut to

specified torque.

SST718CA

11. Measure pinion rotating torque.

Lock to lock:

Average rotating torque

0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position:

Maximum torque variation

0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range:

Maximum force variation

0.6 N´m (6 kg-cm, 5.2 in-lb)

IIf pinion rotating torque is not within specifications, readjust it

starting from step 4. If pinion rotating torque is still out of

specifications after readjustment, replace steering gear

assembly.

SST090B

12. Check rack sliding force on vehicle as follows:

a. Install steering gear onto vehicle, but do not connect tie-rod to

knuckle arm.

b. Connect all piping and fill with steering fluid.

c. Start engine and bleed air completely.

d. Disconnect steering column lower joint from the gear.

e. Keep engine at idle and make sure steering fluid has reached

normal operating temperature.

f. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-25

Page 2213 of 2395

General SpecificationsNBST0037

Applied modelAll

Steering modelPower steering

Steering gear typePR32K

Steering overall gear ratio 17.2

Turns of steering wheel

(Lock to lock)3.09

Steering column type Collapsible, tilt

Steering WheelNBST0038Unit: mm (in)

Steering wheel axial play0 (0)

Steering wheel play35 (1.38) or less

Movement of gear housing±2(±0.08) or less

Steering ColumnNBST0039Unit: mm (in)

Steering column length ªL1º 716.7 - 718.7 (28.22 - 28.30)

Steering column lower shaft length ªL

2º 178 - 180 (7.01 - 7.09)

Steering column upper joint length ªL

3º 430.7 - 432.7 (16.96 - 17.04)

SST739C

Steering Transfer GearNBST0041

Rotating torque0.25 - 0.69 N´m (2.5 - 7.0 kg-cm, 2.2 - 6.1 in-lb)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

ST-32

Page 2214 of 2395

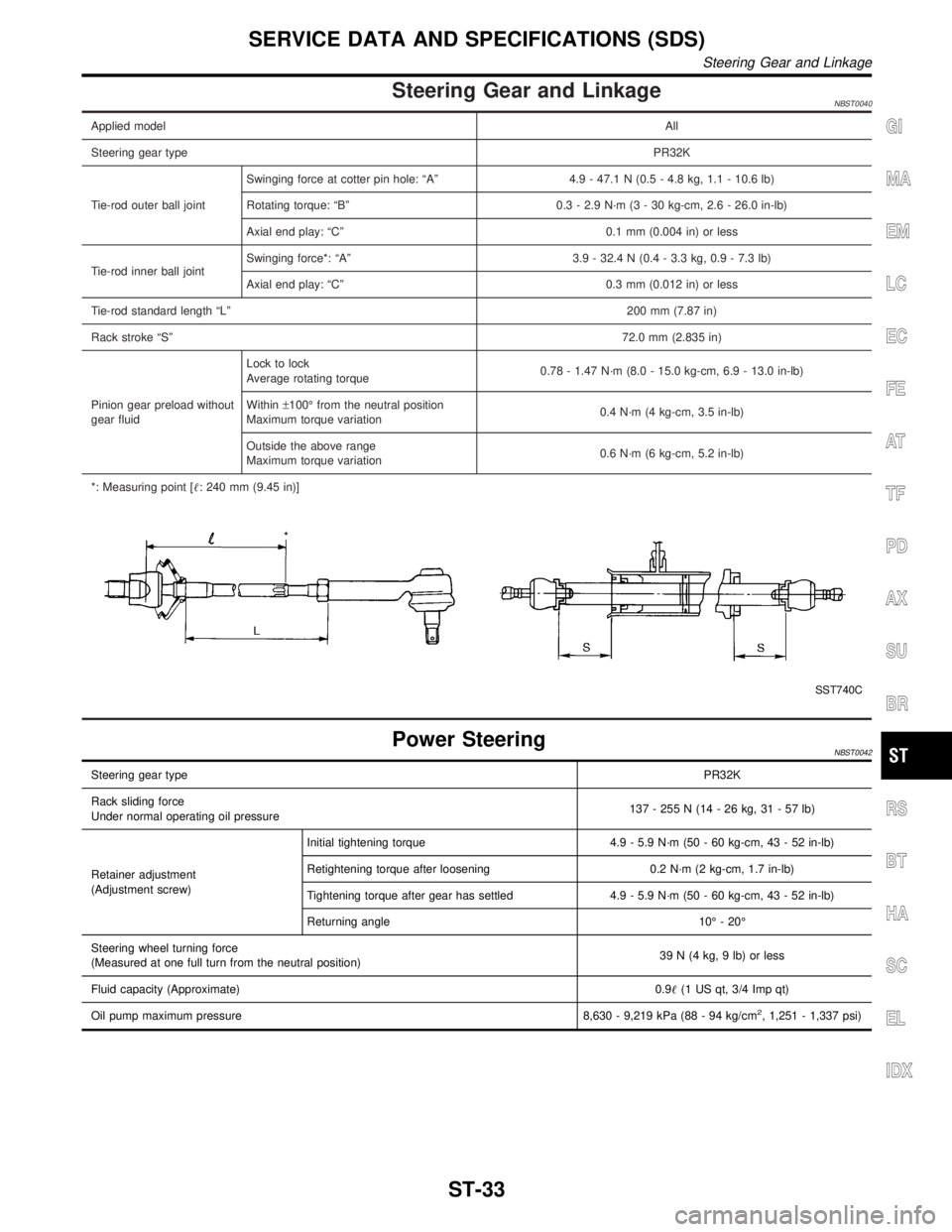

Steering Gear and LinkageNBST0040

Applied modelAll

Steering gear typePR32K

Tie-rod outer ball jointSwinging force at cotter pin hole: ªAº 4.9 - 47.1 N (0.5 - 4.8 kg, 1.1 - 10.6 lb)

Rotating torque: ªBº 0.3 - 2.9 N´m (3 - 30 kg-cm, 2.6 - 26.0 in-lb)

Axial end play: ªCº 0.1 mm (0.004 in) or less

Tie-rod inner ball jointSwinging force*: ªAº 3.9 - 32.4 N (0.4 - 3.3 kg, 0.9 - 7.3 lb)

Axial end play: ªCº 0.3 mm (0.012 in) or less

Tie-rod standard length ªLº200 mm (7.87 in)

Rack stroke ªSº72.0 mm (2.835 in)

Pinion gear preload without

gear fluidLock to lock

Average rotating torque0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position

Maximum torque variation0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range

Maximum torque variation0.6 N´m (6 kg-cm, 5.2 in-lb)

*: Measuring point [: 240 mm (9.45 in)]

SST740C

Power SteeringNBST0042

Steering gear typePR32K

Rack sliding force

Under normal operating oil pressure137 - 255 N (14 - 26 kg, 31 - 57 lb)

Retainer adjustment

(Adjustment screw)Initial tightening torque 4.9 - 5.9 N´m (50 - 60 kg-cm, 43 - 52 in-lb)

Retightening torque after loosening 0.2 N´m (2 kg-cm, 1.7 in-lb)

Tightening torque after gear has settled 4.9 - 5.9 N´m (50 - 60 kg-cm, 43 - 52 in-lb)

Returning angle 10É - 20É

Steering wheel turning force

(Measured at one full turn from the neutral position)39 N (4 kg, 9 lb) or less

Fluid capacity (Approximate)0.9(1 US qt, 3/4 Imp qt)

Oil pump maximum pressure 8,630 - 9,219 kPa (88 - 94 kg/cm

2, 1,251 - 1,337 psi)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear and Linkage

ST-33